Biodegradable Plastics Redefine Agricultural Tools and Equipment

Biodegradable Plastics in Agriculture: Background and Objectives

Biodegradable plastics have emerged as a promising solution to address the growing environmental concerns associated with conventional plastic materials in agriculture. The agricultural sector has long relied on plastic products for various applications, including mulch films, greenhouse covers, irrigation systems, and packaging. However, the accumulation of non-biodegradable plastic waste in agricultural lands has led to soil degradation, water pollution, and harm to wildlife.

The development of biodegradable plastics for agricultural tools and equipment represents a significant technological advancement aimed at mitigating these environmental issues while maintaining the benefits of plastic materials in farming practices. These innovative materials are designed to break down naturally in the environment, typically through microbial action, into harmless substances such as water, carbon dioxide, and biomass.

The primary objective of research in this field is to create biodegradable plastics that can effectively replace conventional plastics in agricultural applications without compromising performance or increasing costs significantly. This involves developing materials that possess the necessary mechanical properties, durability, and functionality required for specific agricultural uses while ensuring complete biodegradation within a reasonable timeframe.

Key areas of focus in biodegradable plastics research for agriculture include the development of materials derived from renewable resources, such as plant-based polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). These bio-based plastics offer the additional advantage of reducing dependency on fossil fuels and lowering the carbon footprint of agricultural practices.

Another critical aspect of this research is the optimization of biodegradation rates to match the lifecycle of agricultural products and seasons. This ensures that the plastic materials maintain their integrity during use but degrade rapidly after their intended purpose is fulfilled, leaving no harmful residues in the soil.

The evolution of biodegradable plastics in agriculture is closely tied to advancements in polymer science, biotechnology, and materials engineering. Researchers are exploring various approaches, including the modification of natural polymers, the synthesis of novel biodegradable compounds, and the development of composite materials that combine biodegradable plastics with natural fibers or inorganic fillers to enhance performance characteristics.

As the agricultural sector faces increasing pressure to adopt sustainable practices, the development of biodegradable plastics for tools and equipment aligns with broader goals of environmental stewardship and circular economy principles. This technology has the potential to revolutionize agricultural practices by providing farmers with eco-friendly alternatives that maintain productivity while reducing environmental impact.

Market Analysis for Eco-friendly Agricultural Tools

The market for eco-friendly agricultural tools is experiencing significant growth, driven by increasing environmental awareness and the need for sustainable farming practices. This trend is particularly evident in the adoption of biodegradable plastics for agricultural equipment, which is reshaping the industry landscape.

The global market for biodegradable agricultural tools and equipment is projected to expand rapidly in the coming years. This growth is fueled by several factors, including stringent environmental regulations, rising consumer demand for organic produce, and the agricultural sector's push towards sustainability. Farmers are increasingly recognizing the long-term benefits of using biodegradable tools, such as reduced soil pollution and improved crop health.

In terms of product segments, biodegradable mulch films represent a substantial portion of the market. These films offer an environmentally friendly alternative to traditional plastic mulches, providing effective weed control and moisture retention while naturally decomposing after use. Other growing segments include biodegradable plant pots, seed trays, and packaging materials for agricultural products.

Geographically, Europe and North America currently lead the market for eco-friendly agricultural tools, owing to their advanced regulatory frameworks and high environmental consciousness. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing adoption of sustainable farming practices in countries like China and India.

The market is characterized by a mix of established players and innovative startups. Large agricultural equipment manufacturers are investing in research and development to incorporate biodegradable materials into their product lines. Meanwhile, specialized companies focusing solely on eco-friendly agricultural solutions are gaining traction, often partnering with research institutions to develop novel biodegradable materials.

Consumer demand is a significant driver in this market. There is a growing preference for organic and sustainably produced food, which in turn is pushing farmers to adopt more environmentally friendly practices, including the use of biodegradable tools and equipment. This shift in consumer behavior is expected to continue, further propelling market growth.

However, the market faces challenges, primarily related to the higher cost of biodegradable materials compared to traditional plastics. This cost differential can be a barrier to adoption, especially for small-scale farmers. Additionally, there are concerns about the performance and durability of some biodegradable tools compared to their conventional counterparts.

Despite these challenges, the overall outlook for the eco-friendly agricultural tools market remains positive. Technological advancements in material science are expected to improve the performance and reduce the cost of biodegradable plastics, making them more competitive with traditional options. As sustainability becomes increasingly central to agricultural practices, the demand for biodegradable tools and equipment is likely to see sustained growth in the coming years.

Current State and Challenges in Biodegradable Plastics

The current state of biodegradable plastics in agricultural tools and equipment is characterized by significant progress, yet it faces several challenges. Recent advancements have led to the development of various biodegradable materials suitable for agricultural applications, including polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based plastics. These materials offer promising alternatives to conventional petroleum-based plastics, addressing environmental concerns and aligning with sustainable farming practices.

In the agricultural sector, biodegradable plastics are being increasingly utilized in mulch films, seedling containers, and temporary protective covers. These applications demonstrate the potential for reducing plastic waste accumulation in fields and minimizing the environmental impact of agricultural activities. However, the widespread adoption of biodegradable plastics in more durable agricultural tools and equipment remains limited.

One of the primary challenges is the balance between biodegradability and durability. Agricultural tools often require robust materials that can withstand harsh environmental conditions and prolonged use. Current biodegradable plastics struggle to match the mechanical strength and longevity of traditional plastics, limiting their application in heavy-duty equipment or long-lasting tools.

Cost remains a significant barrier to the widespread adoption of biodegradable plastics in agriculture. The production processes for these materials are often more expensive than those for conventional plastics, resulting in higher prices for end products. This cost differential makes it difficult for farmers and agricultural businesses to justify the switch to biodegradable alternatives, especially in regions with tight profit margins.

Another challenge lies in the variability of biodegradation rates under different environmental conditions. The decomposition of biodegradable plastics can be influenced by factors such as temperature, moisture, and microbial activity. This variability makes it challenging to predict and control the lifespan of biodegradable agricultural tools and equipment, potentially leading to premature degradation or unexpected failures in the field.

The lack of standardized testing and certification processes for biodegradable plastics in agricultural applications further complicates their adoption. Without clear guidelines and regulations, it becomes difficult for manufacturers to make reliable claims about biodegradability and for consumers to make informed choices.

Research efforts are ongoing to address these challenges. Scientists are exploring new material formulations and composite structures to enhance the mechanical properties of biodegradable plastics while maintaining their environmental benefits. Additionally, work is being done to develop more cost-effective production methods and to improve the consistency of biodegradation processes across various environmental conditions.

In conclusion, while biodegradable plastics show great promise in redefining agricultural tools and equipment, significant challenges remain. Overcoming these hurdles will require continued research, innovation, and collaboration between material scientists, agricultural experts, and policymakers to create sustainable, effective, and economically viable solutions for the agricultural industry.

Existing Biodegradable Solutions for Agricultural Tools

01 Composition of biodegradable plastics

Biodegradable plastics are composed of materials that can break down naturally in the environment. These plastics often incorporate natural polymers, such as starch or cellulose, or synthetic biodegradable polymers. The composition may also include additives to enhance biodegradability or improve material properties.- Composition of biodegradable plastics: Biodegradable plastics are developed using various compositions of materials that can break down naturally in the environment. These compositions often include natural polymers, synthetic biodegradable polymers, or blends of both. The materials are designed to degrade under specific environmental conditions, such as exposure to moisture, heat, or microorganisms.

- Manufacturing processes for biodegradable plastics: Different manufacturing processes are employed to produce biodegradable plastics, including extrusion, injection molding, and film blowing. These processes are optimized to ensure the final product maintains its biodegradable properties while meeting performance requirements. Innovations in manufacturing techniques aim to improve the scalability and cost-effectiveness of biodegradable plastic production.

- Applications of biodegradable plastics: Biodegradable plastics find applications in various industries, including packaging, agriculture, and consumer goods. They are used to create products such as food packaging, disposable cutlery, agricultural films, and personal care items. The development of biodegradable plastics for specific applications focuses on meeting performance requirements while ensuring environmental compatibility.

- Additives and modifiers for biodegradable plastics: Various additives and modifiers are incorporated into biodegradable plastics to enhance their properties and performance. These may include plasticizers, compatibilizers, fillers, and stabilizers. The additives are carefully selected to maintain the biodegradability of the final product while improving characteristics such as strength, flexibility, and durability.

- Biodegradation mechanisms and testing methods: Research focuses on understanding the mechanisms of biodegradation for different types of biodegradable plastics. This includes studying the role of microorganisms, environmental conditions, and chemical processes in the breakdown of these materials. Standardized testing methods are developed to assess the biodegradability and environmental impact of biodegradable plastics under various conditions.

02 Manufacturing processes for biodegradable plastics

Various manufacturing processes are employed to produce biodegradable plastics, including extrusion, injection molding, and film blowing. These processes may require specific modifications to accommodate the unique properties of biodegradable materials. Some methods focus on blending biodegradable polymers with conventional plastics to improve overall biodegradability.Expand Specific Solutions03 Applications of biodegradable plastics

Biodegradable plastics find applications in various industries, including packaging, agriculture, and consumer goods. They are used to produce items such as food packaging, disposable cutlery, agricultural films, and compostable bags. The growing demand for environmentally friendly alternatives to traditional plastics drives the development of new applications.Expand Specific Solutions04 Biodegradation mechanisms and testing

Understanding the mechanisms of biodegradation is crucial for developing effective biodegradable plastics. This includes studying the role of microorganisms, environmental conditions, and material properties in the breakdown process. Standardized testing methods are employed to assess the biodegradability and compostability of plastic materials under various conditions.Expand Specific Solutions05 Enhancing biodegradability and material properties

Research focuses on improving the biodegradability of plastics while maintaining or enhancing their mechanical and functional properties. This may involve developing new polymer blends, incorporating biodegradation-promoting additives, or modifying the molecular structure of existing polymers. Balancing biodegradability with durability and performance is a key challenge in this field.Expand Specific Solutions

Key Players in Biodegradable Agricultural Equipment

The research on biodegradable plastics for agricultural tools and equipment is in a growth phase, with increasing market size due to environmental concerns and sustainability initiatives. The global biodegradable plastics market is expected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like BASF SE, Kaneka Corp., and Stratasys, Inc. leading innovation. These firms, along with others such as BIOTEC Biologische Naturverpackungen GmbH & Co. KG and Danimer IPCo LLC, are developing more efficient and cost-effective biodegradable materials. Academic institutions like Zhejiang Sci-Tech University and Beijing Forestry University are also contributing to technological advancements, indicating a collaborative ecosystem between industry and academia in this sector.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Kingfa Sci. & Tech. Co., Ltd.

Innovative Biodegradable Plastics for Agriculture

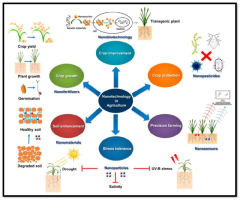

- Development and utilization of biodegradable organic nanomaterials derived from natural sources, engineered to possess insecticidal, fungicidal, and antimicrobial properties, for targeted delivery of nutrients and protection against pests and diseases, enhancing soil health and sustainability.

- A method to convert agricultural wastes into biodegradable products through a combination of organic processes and chemical treatments, utilizing fibrous and non-fibrous waste materials, involving steps like powdering, crushing, mixing, and moulding with edible binders, to create durable, eco-friendly materials comparable to traditional plastics.

Environmental Impact Assessment

The adoption of biodegradable plastics in agricultural tools and equipment presents a significant opportunity to reduce the environmental impact of traditional farming practices. This shift towards more sustainable materials has the potential to address several key environmental concerns associated with conventional plastic use in agriculture.

Firstly, the use of biodegradable plastics can substantially reduce plastic pollution in agricultural settings. Traditional plastic tools and equipment often contribute to microplastic contamination in soil and water systems. Biodegradable alternatives, designed to break down naturally over time, can mitigate this issue by decomposing into harmless organic compounds. This decomposition process not only reduces plastic accumulation in the environment but also helps maintain soil health and ecosystem balance.

Furthermore, the production of biodegradable plastics often has a lower carbon footprint compared to conventional plastics. Many biodegradable materials are derived from renewable resources, such as plant-based feedstocks, which can be replenished more quickly than fossil fuel-based resources used in traditional plastic production. This shift can lead to reduced greenhouse gas emissions and a decrease in overall energy consumption throughout the product lifecycle.

The implementation of biodegradable plastics in agricultural tools and equipment can also contribute to improved waste management practices. As these materials break down naturally, they reduce the burden on landfills and waste processing facilities. This is particularly beneficial in rural areas where waste management infrastructure may be limited, helping to prevent the accumulation of plastic waste in agricultural landscapes.

Additionally, the use of biodegradable plastics can enhance soil quality over time. As these materials decompose, they can potentially add organic matter to the soil, improving its structure and nutrient content. This process can contribute to increased soil fertility and better water retention capabilities, which are crucial factors in sustainable agriculture.

However, it is important to note that the environmental impact of biodegradable plastics is not uniformly positive. The rate of biodegradation can vary significantly depending on environmental conditions, and in some cases, these materials may not break down as quickly or completely as desired. There are also concerns about the potential release of microplastics during the degradation process, which requires further research and monitoring.

In conclusion, while the adoption of biodegradable plastics in agricultural tools and equipment offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and optimize their impact. This includes considering factors such as production methods, use patterns, and end-of-life management to ensure that the transition to biodegradable materials truly results in a net positive environmental outcome.

Regulatory Framework for Biodegradable Agricultural Products

The regulatory framework for biodegradable agricultural products is a critical aspect of the transition towards more sustainable farming practices. As biodegradable plastics increasingly redefine agricultural tools and equipment, governments and international organizations are developing comprehensive guidelines to ensure their safe and effective use.

At the forefront of these regulations is the establishment of clear standards for biodegradability and compostability. The European Union, through its EN 13432 standard, has set benchmarks for the biodegradation of packaging materials, which are being adapted for agricultural applications. Similarly, the ASTM D6400 standard in the United States provides specifications for compostable plastics.

Certification systems play a crucial role in the regulatory landscape. Organizations such as TÜV Austria and the Biodegradable Products Institute (BPI) offer certification programs that verify the biodegradability claims of agricultural products. These certifications provide farmers and consumers with assurance about the environmental performance of biodegradable tools and equipment.

Environmental impact assessments are becoming mandatory for new biodegradable agricultural products. Regulators are requiring manufacturers to demonstrate that their products do not introduce harmful substances into the soil or water systems during the degradation process. This includes evaluating the potential effects on soil microorganisms and crop health.

Labeling requirements are another key component of the regulatory framework. Many jurisdictions now mandate clear and standardized labeling for biodegradable agricultural products, including information on proper disposal methods and expected degradation timeframes. This helps prevent misuse and ensures that farmers can make informed decisions about product selection and end-of-life management.

Waste management regulations are being updated to accommodate the increasing use of biodegradable agricultural plastics. Some countries are implementing separate collection and processing systems for these materials to optimize their environmental benefits and prevent contamination of conventional recycling streams.

Incentive programs and subsidies are being introduced by various governments to encourage the adoption of biodegradable agricultural products. These may include tax breaks for manufacturers, grants for farmers transitioning to biodegradable tools, or preferential treatment in public procurement processes for sustainable agricultural equipment.

Research and development guidelines are also emerging as part of the regulatory framework. Governments are allocating funds and establishing research priorities to accelerate the development of more effective and environmentally friendly biodegradable materials for agricultural applications. This includes collaborations between academic institutions, industry partners, and regulatory bodies to ensure that innovation aligns with environmental and safety standards.