Gas Barrier Properties In Biodegradable Plastics

Biodegradable Plastics Gas Barrier Evolution

The evolution of gas barrier properties in biodegradable plastics has been a critical focus in the development of sustainable packaging materials. Initially, biodegradable plastics faced significant challenges in maintaining adequate gas barrier properties, limiting their application in food packaging and other sensitive product storage.

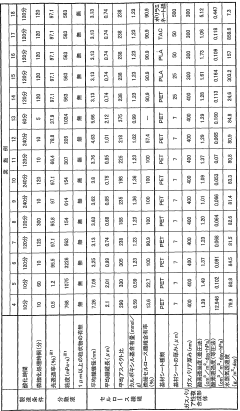

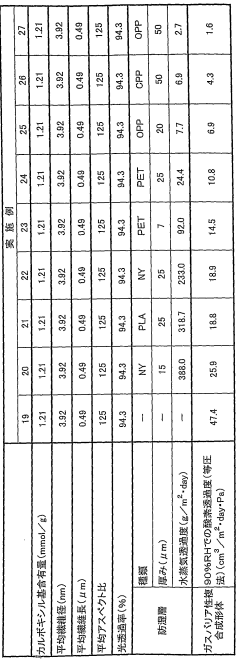

In the early stages, research primarily focused on improving the inherent barrier properties of biopolymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). These efforts involved optimizing processing conditions and exploring various blending techniques to enhance the crystallinity and reduce the free volume within the polymer matrix.

As the field progressed, researchers began to explore the incorporation of nanofillers to create nanocomposites with improved barrier properties. Clay nanoparticles, such as montmorillonite, were among the first materials investigated due to their high aspect ratio and ability to create tortuous paths for gas molecules. This approach led to significant improvements in oxygen and water vapor barrier properties.

The next major advancement came with the development of multilayer structures. By combining layers of different biodegradable polymers with complementary properties, researchers were able to create films with enhanced overall barrier performance. This strategy often involved alternating hydrophilic and hydrophobic layers to provide protection against both moisture and oxygen transmission.

Surface modification techniques emerged as another promising avenue for improving gas barrier properties. Plasma treatment and the application of thin coatings, such as silicon oxide or aluminum oxide, were explored to create an additional barrier layer on the surface of biodegradable films without compromising their biodegradability.

Recent years have seen a shift towards bio-based additives and fillers to maintain the overall sustainability of the materials. Cellulose nanocrystals, chitin nanofibers, and lignin-based compounds have shown promising results in enhancing gas barrier properties while preserving the biodegradable nature of the plastics.

The latest frontier in gas barrier evolution for biodegradable plastics involves the development of active and intelligent packaging systems. These incorporate oxygen scavengers, moisture regulators, and even responsive materials that can adapt to environmental conditions to maintain optimal barrier properties throughout the product's shelf life.

As research continues, the focus is increasingly on combining multiple strategies to achieve synergistic effects. This holistic approach aims to develop biodegradable plastics with gas barrier properties that can rival or even surpass those of conventional petroleum-based plastics, paving the way for their widespread adoption in high-performance packaging applications.

Market Demand Analysis

The market demand for biodegradable plastics with enhanced gas barrier properties has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic waste. This trend is particularly evident in the packaging industry, where there is a pressing need for sustainable alternatives to conventional petroleum-based plastics.

The food and beverage sector represents a significant portion of this market demand. Consumers are increasingly seeking eco-friendly packaging options that maintain the quality and shelf life of their products. Biodegradable plastics with improved gas barrier properties offer a solution to this challenge, as they can protect food items from oxygen and moisture while being environmentally friendly.

Another key driver of market demand is the pharmaceutical and healthcare industry. These sectors require packaging materials that can preserve the integrity of sensitive medical products and drugs. Biodegradable plastics with enhanced gas barrier properties provide an attractive option for this purpose, combining sustainability with high-performance characteristics.

The personal care and cosmetics industry is also contributing to the growing demand for these materials. As consumers become more environmentally conscious, there is an increasing preference for products packaged in sustainable materials that do not compromise on functionality.

Geographically, Europe and North America are currently leading the market demand for biodegradable plastics with improved gas barrier properties. This is largely due to stringent environmental regulations and high consumer awareness in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in demand, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness.

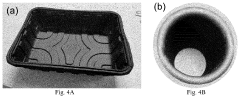

The agricultural sector is another area where demand for these materials is on the rise. Biodegradable mulch films with enhanced gas barrier properties are gaining popularity as they offer improved crop yields while reducing plastic waste in fields.

Despite the growing demand, challenges remain in terms of cost and performance. Biodegradable plastics with enhanced gas barrier properties are often more expensive than their conventional counterparts, which can limit their adoption in price-sensitive markets. Additionally, there is ongoing research to further improve the gas barrier properties of these materials to match or exceed those of traditional plastics.

In conclusion, the market demand for biodegradable plastics with enhanced gas barrier properties is robust and expected to continue growing. This demand is driven by a combination of environmental concerns, regulatory pressures, and consumer preferences across various industries. As research progresses and production scales up, it is likely that these materials will play an increasingly important role in the global plastics market.

Current Challenges

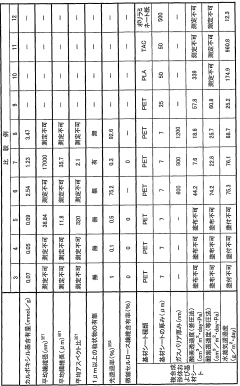

The development of biodegradable plastics with enhanced gas barrier properties faces several significant challenges. One of the primary obstacles is the inherent trade-off between biodegradability and barrier performance. As biodegradable materials are designed to break down in natural environments, they often possess a more open molecular structure, which can lead to increased permeability to gases such as oxygen and water vapor.

Another major challenge lies in maintaining the gas barrier properties of biodegradable plastics throughout their intended shelf life. Unlike conventional plastics, biodegradable materials may begin to degrade prematurely when exposed to certain environmental conditions, potentially compromising their barrier effectiveness over time. This necessitates the development of stabilization techniques that can preserve the material's integrity without hindering its ultimate biodegradability.

The cost-effectiveness of producing high-performance biodegradable plastics with superior gas barrier properties remains a significant hurdle. Current manufacturing processes for such materials often involve complex formulations and specialized production techniques, resulting in higher production costs compared to traditional petroleum-based plastics. This cost disparity can limit widespread adoption, particularly in price-sensitive markets.

Achieving consistent and reproducible gas barrier properties in biodegradable plastics is another technical challenge. The natural variability of bio-based raw materials can lead to inconsistencies in the final product's performance. This variability makes it difficult to meet the stringent quality standards required for certain applications, such as food packaging or medical devices.

The limited availability of suitable bio-based additives and compatibilizers that can enhance gas barrier properties without compromising biodegradability is also a significant constraint. Many conventional barrier-enhancing additives are not compatible with biodegradable matrices or may interfere with the material's ability to decompose in natural environments.

Regulatory challenges and the lack of standardized testing methods for assessing both biodegradability and gas barrier properties simultaneously pose additional obstacles. The absence of unified global standards makes it difficult for manufacturers to validate their products' performance claims and comply with diverse regional regulations.

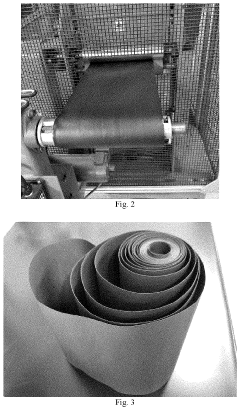

Lastly, the challenge of scaling up laboratory-developed solutions to industrial production levels remains a critical issue. Many promising technologies for improving gas barrier properties in biodegradable plastics have been demonstrated at small scales, but translating these innovations into commercially viable, large-scale production processes presents significant engineering and economic challenges.

Existing Barrier Solutions

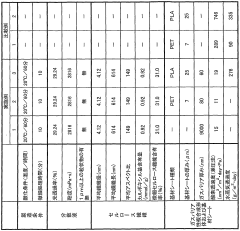

01 Biodegradable polymers with improved gas barrier properties

Development of biodegradable polymers with enhanced gas barrier properties through various techniques such as blending, coating, or modification of polymer structures. These materials aim to provide environmentally friendly packaging solutions while maintaining the necessary barrier properties against gases like oxygen and water vapor.- Biodegradable polymers with improved gas barrier properties: Development of biodegradable polymers with enhanced gas barrier properties through various methods such as blending, coating, or modification of existing biodegradable materials. These improvements aim to extend the shelf life of packaged products while maintaining environmental sustainability.

- Nanocomposite materials for gas barrier enhancement: Incorporation of nanoparticles or nanomaterials into biodegradable plastics to create nanocomposites with superior gas barrier properties. This approach can significantly reduce gas permeability while maintaining the biodegradability of the plastic material.

- Multi-layer structures for improved gas barrier: Design and fabrication of multi-layer structures using biodegradable materials to achieve enhanced gas barrier properties. These structures may combine different biodegradable polymers or incorporate specialized barrier layers to minimize gas transmission.

- Surface modification techniques for gas barrier improvement: Application of various surface modification techniques to biodegradable plastics to enhance their gas barrier properties. These methods may include plasma treatment, chemical grafting, or coating with barrier materials to create a more effective gas barrier on the surface of the biodegradable plastic.

- Biodegradable additives for gas barrier enhancement: Development and use of biodegradable additives that can be incorporated into biodegradable plastics to improve their gas barrier properties. These additives may include natural or synthetic compounds that are compatible with the base polymer and contribute to reducing gas permeability while maintaining biodegradability.

02 Multilayer structures for gas barrier enhancement

Creation of multilayer structures using biodegradable materials to improve gas barrier properties. These structures often combine different biodegradable polymers or incorporate inorganic materials to achieve better barrier performance while maintaining biodegradability.Expand Specific Solutions03 Nanocomposites for improved gas barrier in biodegradable plastics

Incorporation of nanoparticles or nanomaterials into biodegradable polymer matrices to enhance gas barrier properties. These nanocomposites can significantly improve the barrier performance of biodegradable plastics while maintaining their biodegradability.Expand Specific Solutions04 Surface treatments and coatings for biodegradable plastics

Application of surface treatments or coatings to biodegradable plastic substrates to improve their gas barrier properties. These treatments can include plasma treatment, chemical modification, or application of thin barrier layers while preserving the overall biodegradability of the material.Expand Specific Solutions05 Biodegradable plastics with active gas scavenging properties

Development of biodegradable plastics with active gas scavenging properties to improve overall gas barrier performance. These materials incorporate compounds that actively absorb or react with gases like oxygen, enhancing the barrier properties of the biodegradable plastic.Expand Specific Solutions

Key Industry Players

The research on gas barrier properties in biodegradable plastics is in a growth phase, with increasing market demand driven by environmental concerns. The global biodegradable plastics market is expanding rapidly, expected to reach significant value in the coming years. Technologically, the field is advancing but still maturing. Companies like Mitsui Chemicals, LG Chem, and Sumitomo Chemical are leading in innovation, developing high-performance biodegradable materials with enhanced gas barrier properties. Academic institutions such as the University of Tokyo and University of Guelph are contributing fundamental research. Collaborations between industry players like Toppan Holdings and Dai Nippon Printing, and research organizations are accelerating progress in this competitive landscape.

Sumitomo Chemical Co., Ltd.

LG Chem Ltd.

Innovative Barrier Tech

- A biodegradable gas barrier material composed of cellulose fibers with an average diameter of 200 nm or less, treated with TEMPO to introduce carboxyl groups, forming a dense layer with high gas barrier properties through oxidation and refinement processes, which can be applied as a coating or molded into articles.

- Development of biodegradable composites incorporating biocarbon and hybrid fillers such as starch, talc, and graphite, which are processed using one-step extrusion to create high oxygen and water barrier materials, eliminating the need for pre- or post-treatment of fillers and reducing costs.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and adoption of biodegradable plastics with enhanced gas barrier properties. These regulations are designed to address the growing concerns over plastic pollution and its impact on ecosystems, particularly in marine environments.

In recent years, many countries and regions have implemented stringent policies to reduce single-use plastics and promote more sustainable alternatives. The European Union, for instance, has introduced the Single-Use Plastics Directive, which aims to ban certain single-use plastic items and encourage the use of biodegradable materials. This directive has significantly influenced research and development efforts in the field of biodegradable plastics with improved gas barrier properties.

Similarly, countries like China, India, and several African nations have enacted regulations to phase out conventional plastic bags and promote biodegradable alternatives. These policies have created a strong market demand for biodegradable plastics that can match the performance of traditional petroleum-based plastics, particularly in terms of gas barrier properties.

The regulatory landscape also includes standards and certifications for biodegradable plastics. Organizations such as ASTM International and the European Committee for Standardization (CEN) have developed specific standards for testing and verifying the biodegradability and compostability of plastics. These standards often include requirements for gas permeability, as packaging materials must maintain their barrier properties to ensure product quality and safety.

Environmental regulations have also influenced funding and research priorities in the field of biodegradable plastics. Many government agencies and research institutions now allocate significant resources to developing sustainable materials with enhanced properties, including gas barrier characteristics. This has led to increased collaboration between academia and industry, fostering innovation in this area.

Furthermore, extended producer responsibility (EPR) programs implemented in various countries have incentivized manufacturers to invest in more sustainable packaging solutions. These programs often require producers to take responsibility for the entire lifecycle of their products, including disposal and recycling. As a result, there is a growing interest in biodegradable plastics that can offer both environmental benefits and the necessary functional properties, such as gas barrier performance.

The regulatory framework surrounding biodegradable plastics continues to evolve, with ongoing discussions about the need for more comprehensive and harmonized global standards. As research on gas barrier properties in biodegradable plastics progresses, it is likely that future regulations will incorporate more specific requirements for these materials, further driving innovation and market adoption.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of biodegradable plastics with enhanced gas barrier properties. This comprehensive approach considers the entire lifecycle of these materials, from raw material extraction to disposal or recycling.

The production phase of biodegradable plastics with improved gas barrier properties often involves more complex processes compared to conventional plastics. These may include the synthesis of specialized monomers, the incorporation of nanoparticles, or the application of surface treatments. LCA studies have shown that these additional steps can lead to increased energy consumption and greenhouse gas emissions during manufacturing.

However, the use phase of these materials often demonstrates significant environmental benefits. The enhanced gas barrier properties contribute to extended shelf life for packaged products, particularly in food packaging applications. This reduction in food waste can offset the initial environmental costs of production, as food waste is a major contributor to greenhouse gas emissions and resource depletion.

End-of-life considerations for biodegradable plastics with gas barrier properties present both challenges and opportunities. While these materials are designed to degrade under specific conditions, the presence of additives or treatments for gas barrier enhancement may affect their biodegradability. LCA studies have indicated that industrial composting facilities are often necessary to achieve complete biodegradation, which may not be available in all regions.

The recycling potential of these materials is another important aspect of their lifecycle. Some gas barrier treatments may complicate traditional recycling processes, necessitating the development of specialized recycling technologies. However, advancements in chemical recycling methods show promise for recovering both the base polymer and the barrier additives, potentially creating a more circular economy for these materials.

When comparing biodegradable plastics with enhanced gas barrier properties to conventional alternatives, LCA results often show a complex trade-off. While they may have higher environmental impacts in production, their benefits in use and end-of-life stages can lead to a net positive environmental outcome, particularly when considering factors such as reduced food waste and potential for biodegradation or recycling.

It is important to note that the results of LCA studies can vary significantly depending on the specific materials, production methods, and end-of-life scenarios considered. Ongoing research is focused on optimizing the entire lifecycle of these materials, aiming to minimize environmental impacts while maximizing performance and functionality.