Biodegradable Plastics Reinvent Sports Gear Production Methods

Biodegradable Plastics in Sports Gear: Background and Objectives

Biodegradable plastics have emerged as a promising solution to address the environmental concerns associated with traditional plastic materials in sports gear production. The evolution of this technology can be traced back to the early 1990s when researchers began exploring alternatives to conventional petroleum-based plastics. Over the past three decades, significant advancements have been made in developing biodegradable polymers that offer comparable performance characteristics to their non-biodegradable counterparts.

The primary objective of incorporating biodegradable plastics into sports gear production is to reduce the environmental impact of these products throughout their lifecycle. This includes minimizing waste generation, reducing carbon footprint, and mitigating the long-term effects of plastic pollution on ecosystems. Additionally, the integration of biodegradable materials aims to meet the growing consumer demand for sustainable and eco-friendly sporting goods.

The technological trajectory in this field has been marked by continuous improvements in material properties, processing techniques, and scalability. Early biodegradable plastics faced challenges related to durability, cost-effectiveness, and limited application scope. However, recent innovations have led to the development of more robust and versatile biodegradable polymers, such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based blends.

A key trend in the evolution of biodegradable plastics for sports gear is the focus on enhancing material performance to meet the rigorous demands of athletic equipment. This includes improving tensile strength, impact resistance, and flexibility while maintaining biodegradability. Researchers are also exploring novel composite materials that combine biodegradable polymers with natural fibers to create high-performance, sustainable alternatives to traditional sports gear materials.

The anticipated technological goals in this domain include developing biodegradable plastics that can fully replace conventional materials in a wide range of sports gear applications without compromising on performance or durability. This encompasses creating materials suitable for high-impact sports equipment, moisture-resistant outdoor gear, and lightweight, breathable fabrics for athletic apparel. Additionally, there is a push towards optimizing the end-of-life management of these materials, ensuring they can be effectively composted or recycled within existing waste management systems.

As the field progresses, interdisciplinary collaboration between material scientists, sports equipment designers, and environmental experts is becoming increasingly crucial. This collaborative approach aims to address the complex challenges of balancing performance requirements with environmental sustainability, ultimately driving innovation in sports gear production methods.

Market Demand for Eco-Friendly Sports Equipment

The demand for eco-friendly sports equipment has been steadily rising in recent years, driven by increasing environmental awareness among consumers and a growing emphasis on sustainability in the sports industry. This trend is particularly evident in the market for biodegradable plastics in sports gear production, which is experiencing significant growth and attracting attention from both manufacturers and consumers.

Consumer preferences are shifting towards more sustainable products, with many athletes and sports enthusiasts actively seeking out environmentally friendly alternatives to traditional sports equipment. This shift is not only driven by personal values but also by a broader societal push towards reducing plastic waste and carbon footprints. As a result, sports brands and manufacturers are under pressure to innovate and develop more sustainable production methods and materials.

The market for eco-friendly sports equipment encompasses a wide range of products, including apparel, footwear, and various types of gear for different sports. Biodegradable plastics are particularly relevant in the production of items such as water bottles, protective gear, and certain components of sports equipment. The potential for these materials to replace conventional plastics in sports gear production represents a significant market opportunity.

Several factors are contributing to the growth of this market. Firstly, there is an increasing awareness of the environmental impact of traditional plastics, particularly in terms of waste accumulation and marine pollution. Secondly, advancements in biodegradable plastic technology have improved the performance and durability of these materials, making them more viable for use in sports equipment. Lastly, regulatory pressures and corporate sustainability initiatives are pushing companies to adopt more environmentally friendly practices and materials.

The market demand for eco-friendly sports equipment is not limited to a specific demographic or region. It spans across various age groups, from young athletes to older sports enthusiasts, and is observed in both developed and developing markets. However, the adoption rate and willingness to pay premium prices for sustainable products may vary across different segments and regions.

Despite the growing demand, challenges remain in the widespread adoption of biodegradable plastics in sports gear production. These include concerns about the performance and durability of eco-friendly materials compared to traditional plastics, as well as the higher costs associated with their production and implementation. Overcoming these challenges will be crucial for meeting the market demand and realizing the full potential of biodegradable plastics in the sports equipment industry.

Current State and Challenges in Biodegradable Plastics

The current state of biodegradable plastics in sports gear production is marked by significant progress, yet faces numerous challenges. Recent advancements have led to the development of various biodegradable materials, including polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based plastics. These materials have shown promise in replacing traditional petroleum-based plastics in certain sports equipment applications.

However, the widespread adoption of biodegradable plastics in sports gear production is hindered by several factors. One major challenge is the limited mechanical properties of many biodegradable materials compared to conventional plastics. This includes lower tensile strength, reduced impact resistance, and decreased durability, which are crucial for sports equipment performance and longevity.

Another significant obstacle is the higher production costs associated with biodegradable plastics. The manufacturing processes for these materials are often more complex and energy-intensive, leading to increased expenses that can be difficult to justify in the competitive sports gear market.

The degradation rate and consistency of biodegradable plastics pose additional challenges. While these materials are designed to break down in specific environmental conditions, controlling the degradation process to ensure product longevity during use, while still allowing for eventual biodegradation, remains a complex issue.

Furthermore, the sports industry faces difficulties in establishing a comprehensive recycling and composting infrastructure for biodegradable plastics. Many existing recycling facilities are not equipped to handle these materials, potentially leading to contamination of conventional plastic recycling streams.

There are also concerns regarding the environmental impact of biodegradable plastics. While they offer potential benefits in reducing plastic pollution, questions remain about their overall lifecycle assessment, including the resources required for production and the byproducts of degradation.

Regulatory challenges further complicate the landscape. The lack of standardized definitions and testing methods for biodegradability in different environments creates uncertainty for manufacturers and consumers alike.

Despite these challenges, ongoing research and development efforts are focused on addressing these issues. Scientists and engineers are working to enhance the mechanical properties of biodegradable plastics, optimize production processes to reduce costs, and develop more controlled degradation mechanisms.

Collaborations between material scientists, sports equipment manufacturers, and environmental experts are driving innovation in this field. These partnerships aim to create biodegradable plastics that not only meet the performance requirements of sports gear but also offer genuine environmental benefits throughout their lifecycle.

Existing Biodegradable Solutions for Sports Gear Production

01 Polymer-based biodegradable plastics production

This method involves the synthesis of biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), through various polymerization techniques. These polymers can be derived from renewable resources and are designed to break down naturally in the environment.- Polymer-based biodegradable plastics production: This method involves the synthesis of biodegradable polymers from renewable resources or petrochemical-based monomers. The process often includes polymerization techniques such as condensation or ring-opening polymerization to create materials that can degrade naturally in the environment.

- Starch-based biodegradable plastics production: This approach utilizes starch, a naturally occurring polymer, as the primary raw material. The process typically involves modifying starch through various chemical or physical treatments to improve its properties and compatibility with other materials, resulting in biodegradable plastic alternatives.

- Microbial fermentation for biodegradable plastics: This method employs microorganisms to produce biodegradable polymers through fermentation processes. Bacteria or other microbes are cultivated under specific conditions to synthesize polymers such as polyhydroxyalkanoates (PHAs), which can be extracted and processed into biodegradable plastics.

- Blending and composite formation for biodegradable plastics: This technique involves combining different biodegradable materials or incorporating natural fibers into polymer matrices. The process aims to enhance the properties of biodegradable plastics, such as mechanical strength or degradation rate, by creating synergistic blends or composites.

- Chemical modification of existing polymers for biodegradability: This method focuses on modifying conventional, non-biodegradable polymers to make them biodegradable. Techniques may include grafting biodegradable segments onto existing polymer chains or introducing functional groups that promote degradation under specific environmental conditions.

02 Starch-based biodegradable plastics production

This approach utilizes starch, a naturally occurring polymer, as the base material for biodegradable plastics. The process often involves modifying starch through chemical or physical means to improve its properties and compatibility with other materials, resulting in a biodegradable plastic alternative.Expand Specific Solutions03 Cellulose-based biodegradable plastics production

This method focuses on using cellulose, a abundant natural polymer, as the primary component in biodegradable plastic production. The process may involve chemical modification of cellulose or blending it with other biodegradable materials to create plastics with desired properties.Expand Specific Solutions04 Composite biodegradable plastics production

This approach involves combining different biodegradable materials, such as natural fibers, biopolymers, and additives, to create composite biodegradable plastics. The resulting materials often have improved mechanical properties and biodegradability compared to single-component biodegradable plastics.Expand Specific Solutions05 Microbial-based biodegradable plastics production

This method utilizes microorganisms to produce biodegradable plastics, such as polyhydroxyalkanoates (PHA). The process involves cultivating specific bacteria or other microorganisms under controlled conditions, allowing them to accumulate biodegradable polymers within their cells, which are then extracted and processed into plastic materials.Expand Specific Solutions

Key Players in Biodegradable Plastics and Sports Equipment

The biodegradable plastics market for sports gear production is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing but still evolving, with varying levels of maturity across different applications. Companies like BASF SE, NIKE, Inc., and Kaneka Corp. are at the forefront, investing heavily in R&D to develop innovative, high-performance biodegradable materials. Academic institutions such as Zhejiang University and the Swiss Federal Institute of Technology are contributing cutting-edge research, while specialized firms like Bioretec Ltd. and BIOTEC Biologische Naturverpackungen GmbH & Co. KG are focusing on niche applications. The competitive landscape is diverse, with collaborations between industry leaders and research institutions driving progress in this challenging yet promising field.

Stratasys, Inc.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Core Innovations in Biodegradable Plastic Technologies

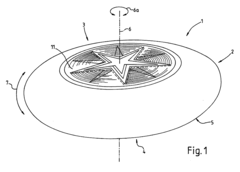

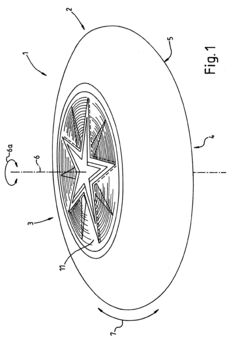

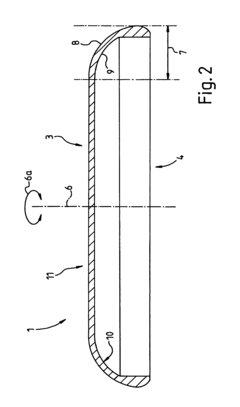

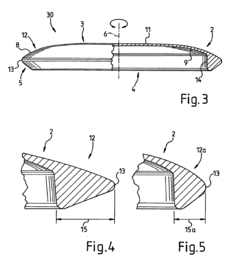

- A sport flying disc with a biodegradable synthetic plastic material, featuring a three-dimensional body shape with a mass distribution that enhances stability and aerodynamics, and a reduced diameter, designed to promote gliding, reduce impact risk, and be easily recyclable.

- A method is developed to manufacture corn fiber fabric by extracting fibers from corn husk, mixing them with polyethylene or rayon, and performing a heat treatment process to enhance strength and thermal properties, resulting in a fabric with improved absorbency and elasticity.

Environmental Impact Assessment of Biodegradable Sports Gear

The environmental impact assessment of biodegradable sports gear is a crucial aspect of evaluating the sustainability and ecological footprint of innovative production methods using biodegradable plastics. This assessment encompasses various factors, including raw material sourcing, manufacturing processes, product use, and end-of-life disposal.

One of the primary environmental benefits of biodegradable sports gear is the reduction of plastic waste accumulation in landfills and natural ecosystems. Traditional sports equipment often contains non-biodegradable plastics that persist in the environment for hundreds of years. In contrast, biodegradable alternatives can decompose within months to a few years, depending on the specific materials and environmental conditions.

The production of biodegradable plastics for sports gear typically involves renewable resources such as corn starch, sugarcane, or cellulose. This shift away from petroleum-based plastics contributes to a decrease in fossil fuel consumption and associated greenhouse gas emissions. However, it is essential to consider the potential environmental impacts of increased agricultural production to meet the demand for these bio-based raw materials.

Water consumption and land use are significant factors to evaluate in the production of biodegradable sports gear. While traditional plastic production is water-intensive, some biodegradable alternatives may require even more water during the manufacturing process. Additionally, the cultivation of crops for bio-based plastics could lead to land-use changes and potential competition with food production.

The manufacturing processes for biodegradable sports gear often involve lower energy consumption compared to traditional plastic production. This reduction in energy use can lead to decreased carbon emissions throughout the product lifecycle. However, the specific energy savings depend on the type of biodegradable plastic and the manufacturing techniques employed.

During the use phase, biodegradable sports gear may have a shorter lifespan compared to traditional equipment, potentially leading to increased production and replacement rates. This aspect needs to be carefully balanced against the environmental benefits of biodegradability to ensure a net positive impact.

End-of-life considerations are particularly important for biodegradable sports gear. While these products are designed to break down naturally, the rate and completeness of biodegradation can vary significantly depending on disposal conditions. Proper waste management infrastructure and consumer education are crucial to maximize the environmental benefits of biodegradable materials.

The overall environmental impact of biodegradable sports gear must be assessed through comprehensive life cycle analyses. These studies should compare the entire product lifecycle, from raw material extraction to disposal, against traditional plastic alternatives. Such assessments will provide valuable insights into the true ecological benefits and potential trade-offs associated with biodegradable sports equipment production methods.

Regulatory Framework for Biodegradable Materials in Sports

The regulatory framework for biodegradable materials in sports is a complex and evolving landscape that plays a crucial role in shaping the future of sustainable sports gear production. As the demand for environmentally friendly products continues to grow, governments and regulatory bodies worldwide are developing and implementing standards to ensure the safety, efficacy, and environmental impact of biodegradable materials used in sports equipment.

One of the primary regulatory bodies overseeing biodegradable materials is the International Organization for Standardization (ISO). The ISO 17088 standard specifically addresses the specifications for compostable plastics, providing guidelines for manufacturers and consumers alike. This standard ensures that materials labeled as biodegradable meet specific criteria for decomposition, ecotoxicity, and heavy metal content.

In the European Union, the EN 13432 standard governs the requirements for packaging recoverable through composting and biodegradation. While not specifically tailored to sports equipment, this standard has been influential in shaping regulations for biodegradable materials across various industries, including sports gear production.

The United States has its own set of regulations, with the Federal Trade Commission (FTC) playing a key role in overseeing environmental marketing claims. The FTC's Green Guides provide guidelines for businesses making environmental claims, including those related to biodegradability. These guidelines help prevent greenwashing and ensure that consumers receive accurate information about the environmental attributes of sports products.

Specific to the sports industry, organizations like the Sustainable Apparel Coalition (SAC) have developed tools such as the Higg Index, which measures sustainability performance across the entire supply chain. While not a regulatory body, the SAC's standards have been widely adopted and influence regulatory decisions in the sports apparel and equipment sector.

As research on biodegradable plastics advances, regulatory frameworks are expected to evolve. Emerging areas of focus include the development of standardized testing methods for biodegradation in various environments, such as marine ecosystems, which are particularly relevant for water sports equipment. Additionally, regulations are likely to address the full lifecycle of biodegradable sports gear, including production methods, use phase, and end-of-life management.

The challenge for regulators lies in balancing the need for innovation in sustainable materials with ensuring product safety and performance. As such, future regulatory frameworks may incorporate more flexible approaches that can adapt to rapidly evolving technologies while maintaining rigorous standards for environmental protection and consumer safety.