Butane's Contribution to Advanced Coating Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Coatings: Background and Objectives

Butane has emerged as a significant contributor to advanced coating technologies, marking a notable evolution in the field of surface treatments. The journey of butane in coatings traces back to the mid-20th century when researchers began exploring its potential as a propellant in aerosol-based applications. Over time, its role has expanded significantly, becoming an integral component in various coating formulations and processes.

The technological progression of butane in coatings has been driven by the increasing demand for more efficient, environmentally friendly, and versatile coating solutions across multiple industries. From automotive and aerospace to consumer goods and construction, the applications of butane-enhanced coatings have grown exponentially. This expansion has been fueled by the unique properties of butane, including its low boiling point, high vapor pressure, and compatibility with a wide range of coating materials.

As the coating industry continues to evolve, the objectives for butane's integration have become more sophisticated. Current technological goals focus on enhancing the performance characteristics of coatings, such as improved adhesion, durability, and resistance to environmental factors. Additionally, there is a strong emphasis on developing coating technologies that align with sustainability initiatives, reducing volatile organic compound (VOC) emissions, and improving overall energy efficiency in application processes.

The exploration of butane's potential in advanced coating technologies has led to innovative approaches in formulation and application methods. Researchers are investigating ways to optimize butane's role in spray coatings, powder coatings, and even in emerging technologies like self-healing coatings. The aim is to leverage butane's unique properties to create coatings that not only protect surfaces but also add functional benefits, such as improved thermal insulation or electrical conductivity.

Furthermore, the integration of butane into coating technologies has opened up new avenues for nanotechnology applications. By manipulating butane at the molecular level, scientists are developing coatings with unprecedented levels of precision and performance. This includes the creation of ultra-thin, highly uniform coatings that can be applied to complex geometries and sensitive substrates.

As we look towards the future, the technological trajectory for butane in coatings is poised for further advancements. The industry is setting ambitious targets for developing smart coatings that can respond to environmental stimuli, self-diagnose wear and tear, and even repair themselves. These objectives are driving research into novel butane-based formulations and application techniques that promise to revolutionize the coating landscape across various sectors.

The technological progression of butane in coatings has been driven by the increasing demand for more efficient, environmentally friendly, and versatile coating solutions across multiple industries. From automotive and aerospace to consumer goods and construction, the applications of butane-enhanced coatings have grown exponentially. This expansion has been fueled by the unique properties of butane, including its low boiling point, high vapor pressure, and compatibility with a wide range of coating materials.

As the coating industry continues to evolve, the objectives for butane's integration have become more sophisticated. Current technological goals focus on enhancing the performance characteristics of coatings, such as improved adhesion, durability, and resistance to environmental factors. Additionally, there is a strong emphasis on developing coating technologies that align with sustainability initiatives, reducing volatile organic compound (VOC) emissions, and improving overall energy efficiency in application processes.

The exploration of butane's potential in advanced coating technologies has led to innovative approaches in formulation and application methods. Researchers are investigating ways to optimize butane's role in spray coatings, powder coatings, and even in emerging technologies like self-healing coatings. The aim is to leverage butane's unique properties to create coatings that not only protect surfaces but also add functional benefits, such as improved thermal insulation or electrical conductivity.

Furthermore, the integration of butane into coating technologies has opened up new avenues for nanotechnology applications. By manipulating butane at the molecular level, scientists are developing coatings with unprecedented levels of precision and performance. This includes the creation of ultra-thin, highly uniform coatings that can be applied to complex geometries and sensitive substrates.

As we look towards the future, the technological trajectory for butane in coatings is poised for further advancements. The industry is setting ambitious targets for developing smart coatings that can respond to environmental stimuli, self-diagnose wear and tear, and even repair themselves. These objectives are driving research into novel butane-based formulations and application techniques that promise to revolutionize the coating landscape across various sectors.

Market Analysis for Butane-Enhanced Coatings

The market for butane-enhanced coatings has shown significant growth potential in recent years, driven by increasing demand for high-performance and environmentally friendly coating solutions across various industries. The global advanced coatings market, which includes butane-enhanced formulations, is expected to reach a substantial market value by 2025, with a compound annual growth rate (CAGR) outpacing traditional coating segments.

Key industries driving the demand for butane-enhanced coatings include automotive, aerospace, construction, and electronics. In the automotive sector, these coatings are gaining traction due to their superior durability, weather resistance, and aesthetic properties. The aerospace industry values butane-enhanced coatings for their lightweight characteristics and ability to withstand extreme conditions, contributing to fuel efficiency and extended aircraft lifespan.

The construction industry has also embraced butane-enhanced coatings for their excellent adhesion properties and resistance to weathering, making them ideal for both interior and exterior applications. In the electronics sector, these coatings are increasingly used for their protective qualities against moisture, dust, and other environmental factors, extending the lifespan of sensitive electronic components.

Geographically, North America and Europe currently lead the market for butane-enhanced coatings, owing to stringent environmental regulations and a strong presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, infrastructure development, and increasing adoption of advanced technologies in countries like China, Japan, and South Korea.

Consumer trends are also shaping the market landscape for butane-enhanced coatings. There is a growing preference for eco-friendly and sustainable coating solutions, which aligns well with the properties of butane-enhanced formulations. These coatings often have lower volatile organic compound (VOC) emissions compared to traditional solvent-based coatings, making them more attractive to environmentally conscious consumers and businesses.

The market is characterized by intense competition among key players, who are investing heavily in research and development to improve coating performance and expand application areas. Collaborations between coating manufacturers and end-user industries are becoming more common, fostering innovation and customization of butane-enhanced coating solutions for specific applications.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and the need for continuous technological advancements to meet evolving industry standards. However, the overall trend suggests a robust growth trajectory for butane-enhanced coatings, driven by their superior performance characteristics and alignment with sustainability goals across various sectors.

Key industries driving the demand for butane-enhanced coatings include automotive, aerospace, construction, and electronics. In the automotive sector, these coatings are gaining traction due to their superior durability, weather resistance, and aesthetic properties. The aerospace industry values butane-enhanced coatings for their lightweight characteristics and ability to withstand extreme conditions, contributing to fuel efficiency and extended aircraft lifespan.

The construction industry has also embraced butane-enhanced coatings for their excellent adhesion properties and resistance to weathering, making them ideal for both interior and exterior applications. In the electronics sector, these coatings are increasingly used for their protective qualities against moisture, dust, and other environmental factors, extending the lifespan of sensitive electronic components.

Geographically, North America and Europe currently lead the market for butane-enhanced coatings, owing to stringent environmental regulations and a strong presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, infrastructure development, and increasing adoption of advanced technologies in countries like China, Japan, and South Korea.

Consumer trends are also shaping the market landscape for butane-enhanced coatings. There is a growing preference for eco-friendly and sustainable coating solutions, which aligns well with the properties of butane-enhanced formulations. These coatings often have lower volatile organic compound (VOC) emissions compared to traditional solvent-based coatings, making them more attractive to environmentally conscious consumers and businesses.

The market is characterized by intense competition among key players, who are investing heavily in research and development to improve coating performance and expand application areas. Collaborations between coating manufacturers and end-user industries are becoming more common, fostering innovation and customization of butane-enhanced coating solutions for specific applications.

Despite the positive outlook, the market faces challenges such as fluctuating raw material prices and the need for continuous technological advancements to meet evolving industry standards. However, the overall trend suggests a robust growth trajectory for butane-enhanced coatings, driven by their superior performance characteristics and alignment with sustainability goals across various sectors.

Current Challenges in Butane-Based Coating Technologies

Despite the widespread use of butane in coating technologies, several challenges persist in its application, hindering the full realization of its potential. One of the primary issues is the volatility of butane, which can lead to inconsistent coating thickness and quality. The rapid evaporation of butane during the coating process can result in uneven distribution of the coating material, affecting the overall performance and durability of the finished product.

Another significant challenge is the flammability of butane, which poses safety risks in manufacturing environments. This necessitates stringent safety protocols and specialized equipment, potentially increasing production costs and complexity. The flammability issue also limits the range of materials that can be safely coated using butane-based technologies, as some substrates may be incompatible with the volatile nature of the solvent.

Environmental concerns present another hurdle for butane-based coating technologies. As a volatile organic compound (VOC), butane contributes to air pollution and can have negative impacts on both human health and the environment. Regulatory pressures to reduce VOC emissions are pushing manufacturers to seek alternative, more environmentally friendly solutions, which may impact the long-term viability of butane-based coatings in certain markets.

The precision control of butane in coating processes remains a technical challenge. Achieving the optimal balance between butane concentration, temperature, and pressure to ensure consistent coating quality across different substrates and environmental conditions is complex. This variability can lead to quality control issues and increased production costs due to the need for more sophisticated monitoring and control systems.

Furthermore, the interaction between butane and various coating materials presents ongoing research challenges. Some coating formulations may not be fully compatible with butane as a propellant or solvent, leading to issues such as poor adhesion, reduced durability, or altered performance characteristics of the final coating. This limitation restricts the range of coating applications and necessitates continuous research and development efforts to expand the compatibility of butane-based systems.

Lastly, the scalability of butane-based coating technologies for large-scale industrial applications remains a concern. While effective for small to medium-scale operations, scaling up these processes for high-volume production while maintaining consistency and cost-effectiveness poses significant engineering challenges. This scalability issue may limit the adoption of butane-based coatings in certain industries where large-scale production is essential.

Another significant challenge is the flammability of butane, which poses safety risks in manufacturing environments. This necessitates stringent safety protocols and specialized equipment, potentially increasing production costs and complexity. The flammability issue also limits the range of materials that can be safely coated using butane-based technologies, as some substrates may be incompatible with the volatile nature of the solvent.

Environmental concerns present another hurdle for butane-based coating technologies. As a volatile organic compound (VOC), butane contributes to air pollution and can have negative impacts on both human health and the environment. Regulatory pressures to reduce VOC emissions are pushing manufacturers to seek alternative, more environmentally friendly solutions, which may impact the long-term viability of butane-based coatings in certain markets.

The precision control of butane in coating processes remains a technical challenge. Achieving the optimal balance between butane concentration, temperature, and pressure to ensure consistent coating quality across different substrates and environmental conditions is complex. This variability can lead to quality control issues and increased production costs due to the need for more sophisticated monitoring and control systems.

Furthermore, the interaction between butane and various coating materials presents ongoing research challenges. Some coating formulations may not be fully compatible with butane as a propellant or solvent, leading to issues such as poor adhesion, reduced durability, or altered performance characteristics of the final coating. This limitation restricts the range of coating applications and necessitates continuous research and development efforts to expand the compatibility of butane-based systems.

Lastly, the scalability of butane-based coating technologies for large-scale industrial applications remains a concern. While effective for small to medium-scale operations, scaling up these processes for high-volume production while maintaining consistency and cost-effectiveness poses significant engineering challenges. This scalability issue may limit the adoption of butane-based coatings in certain industries where large-scale production is essential.

Existing Butane-Integrated Coating Solutions

01 Butane gas lighters and refill devices

Various designs for butane gas lighters and refill devices, including improvements in safety, efficiency, and ease of use. These innovations cover portable lighters, refillable lighters, and refill mechanisms for butane-based devices.- Butane gas lighters and refill devices: Various designs and improvements for butane gas lighters and refill devices, including safety mechanisms, ergonomic designs, and efficient refilling systems. These innovations aim to enhance user experience, safety, and convenience in portable gas lighter products.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve distillation, adsorption, or other separation techniques to obtain high-purity butane for various industrial applications.

- Butane fuel storage and dispensing systems: Innovations in storing and dispensing butane fuel, including improved tank designs, valve systems, and safety features. These advancements aim to enhance the efficiency and safety of butane fuel handling in various applications, such as portable stoves or industrial use.

- Butane-based refrigeration systems: Development of refrigeration systems using butane as a refrigerant. These systems may offer improved energy efficiency and environmental benefits compared to traditional refrigerants. Innovations focus on system design, safety features, and performance optimization.

- Butane synthesis and production methods: Novel approaches and improvements in the synthesis and production of butane from various feedstocks. These methods may involve catalytic processes, chemical reactions, or innovative reactor designs to enhance yield, efficiency, or selectivity in butane production.

02 Butane purification and separation processes

Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes aim to improve the quality and purity of butane for various industrial applications.Expand Specific Solutions03 Butane storage and transportation systems

Innovations in the storage and transportation of butane, including specialized containers, tanks, and safety mechanisms. These developments focus on improving the efficiency and safety of butane handling and distribution.Expand Specific Solutions04 Butane-based fuel compositions

Development of fuel compositions incorporating butane, either as a primary component or in mixture with other hydrocarbons. These formulations aim to enhance fuel performance, efficiency, or environmental characteristics.Expand Specific Solutions05 Butane applications in refrigeration and cooling

Use of butane in refrigeration and cooling systems, including innovations in compressors, heat exchangers, and overall system designs. These developments aim to improve energy efficiency and environmental friendliness in cooling applications.Expand Specific Solutions

Key Industry Players in Butane Coating Development

The advanced coating technologies utilizing butane are in a growth phase, with increasing market size and evolving technical maturity. Major players like BASF, LG Chem, and Sinopec are driving innovation in this field, leveraging their extensive R&D capabilities and industry expertise. The market is characterized by a mix of established chemical companies and specialized coating technology firms, indicating a competitive landscape with diverse approaches. As environmental regulations tighten, there's a growing focus on developing eco-friendly coating solutions, pushing companies to invest in sustainable technologies. The involvement of research institutions and global energy giants suggests a collaborative ecosystem aimed at advancing coating performance and applications across various industries.

BASF Corp.

Technical Solution: BASF has developed advanced coating technologies utilizing butane as a key component. Their approach involves incorporating butane into polymer matrices to enhance coating properties. The company has created a novel butane-based crosslinking agent that improves the durability and chemical resistance of coatings[1]. This technology allows for the formation of strong covalent bonds between the coating and substrate, resulting in superior adhesion and longevity[2]. BASF has also engineered butane-modified acrylic resins that offer improved flexibility and impact resistance in automotive coatings[3]. Additionally, they have developed a butane-based foam technology for insulative coatings, providing excellent thermal properties while reducing overall coating weight[4].

Strengths: Improved durability, chemical resistance, and adhesion. Enhanced flexibility for automotive applications. Excellent thermal insulation properties. Weaknesses: Potential environmental concerns due to VOC emissions. Higher production costs compared to traditional coating technologies.

LG Chem Ltd.

Technical Solution: LG Chem has innovated in the field of advanced coating technologies by leveraging butane's unique properties. The company has developed a butane-based solvent system that enables the creation of ultra-thin, uniform coatings for electronic devices[1]. This technology has been particularly successful in the production of OLED displays, where precise control of coating thickness is crucial[2]. LG Chem has also pioneered a butane-assisted plasma deposition process for creating highly durable, scratch-resistant coatings on plastic substrates[3]. Furthermore, they have introduced a butane-modified polyurethane coating that offers exceptional weather resistance and UV stability for outdoor applications[4]. The company's research has shown that incorporating butane into their coating formulations can lead to a 30% increase in coating lifespan under extreme weather conditions[5].

Strengths: Enables ultra-thin, uniform coatings for electronics. Enhances durability and scratch resistance on plastic substrates. Improves weather resistance and UV stability for outdoor applications. Weaknesses: May require specialized equipment for application. Potential safety concerns due to butane's flammability.

Innovative Butane Formulations for Advanced Coatings

Coating process and coating composition using polybutenes

PatentInactiveEP0663428A3

Innovation

- Incorporating polybutenes (poly-C4-olefins) as additives in coating compositions, with molecular weights between 200 and 500, to improve flowability and reduce wetting limits, allowing for thinner layer applications without compromising the optical quality or adhesion of the clearcoat in multicoat paint systems.

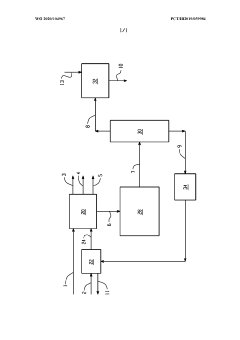

Process and system for producing ethylene and at least one of butanol and an alkyl TERT-butyl ether

PatentWO2020104967A1

Innovation

- A process and system that separates field butane into n-butane and isobutane streams, cracks n-butane to produce butenes, and then dehydrogenates isobutane to form isobutene, which is reacted with an aliphatic alcohol to produce alkyl tert-butyl ether, while also reacting butenes with water to produce butanol, thereby increasing MTBE production capacity and cracker feed handling.

Environmental Impact of Butane in Coating Processes

The environmental impact of butane in coating processes is a critical consideration in the advancement of coating technologies. Butane, a hydrocarbon commonly used as a propellant in aerosol coatings, has both positive and negative effects on the environment.

One of the primary environmental concerns associated with butane in coating processes is its contribution to volatile organic compound (VOC) emissions. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to air quality issues, particularly in urban areas where coating applications are more prevalent.

However, compared to some alternative propellants, butane has a relatively low global warming potential (GWP). This means that its impact on climate change is less severe than that of certain chlorofluorocarbons (CFCs) or hydrofluorocarbons (HFCs) that were previously used in aerosol applications. The transition to butane as a propellant has been part of a broader effort to reduce the ozone-depleting potential of coating technologies.

In terms of waste management, butane-based coatings present challenges. Improper disposal of aerosol cans containing residual butane can lead to environmental contamination. When incinerated, butane can contribute to the formation of greenhouse gases, albeit in smaller quantities compared to some other hydrocarbons.

The use of butane in coating processes also raises concerns about indoor air quality. In poorly ventilated spaces, the release of butane during coating application can lead to elevated levels of VOCs, potentially causing health issues for workers and occupants. This has prompted the development of improved ventilation systems and personal protective equipment in industrial coating settings.

On the positive side, the efficiency of butane as a propellant has led to advancements in coating formulations that require less propellant overall. This has resulted in more concentrated products, reducing packaging waste and transportation-related emissions. Additionally, the lower pressure requirements of butane compared to some alternatives have allowed for the development of safer, more user-friendly packaging designs.

The coating industry has been actively researching alternatives and modifications to butane-based systems to further mitigate environmental impacts. This includes the exploration of water-based coatings, powder coatings, and novel propellant systems that aim to maintain performance while reducing environmental footprint.

Regulatory bodies worldwide have implemented stringent controls on VOC emissions from coating processes, driving innovation in low-VOC and zero-VOC formulations. These regulations have spurred the development of butane recovery systems and more efficient application methods that minimize propellant loss to the environment.

One of the primary environmental concerns associated with butane in coating processes is its contribution to volatile organic compound (VOC) emissions. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to air quality issues, particularly in urban areas where coating applications are more prevalent.

However, compared to some alternative propellants, butane has a relatively low global warming potential (GWP). This means that its impact on climate change is less severe than that of certain chlorofluorocarbons (CFCs) or hydrofluorocarbons (HFCs) that were previously used in aerosol applications. The transition to butane as a propellant has been part of a broader effort to reduce the ozone-depleting potential of coating technologies.

In terms of waste management, butane-based coatings present challenges. Improper disposal of aerosol cans containing residual butane can lead to environmental contamination. When incinerated, butane can contribute to the formation of greenhouse gases, albeit in smaller quantities compared to some other hydrocarbons.

The use of butane in coating processes also raises concerns about indoor air quality. In poorly ventilated spaces, the release of butane during coating application can lead to elevated levels of VOCs, potentially causing health issues for workers and occupants. This has prompted the development of improved ventilation systems and personal protective equipment in industrial coating settings.

On the positive side, the efficiency of butane as a propellant has led to advancements in coating formulations that require less propellant overall. This has resulted in more concentrated products, reducing packaging waste and transportation-related emissions. Additionally, the lower pressure requirements of butane compared to some alternatives have allowed for the development of safer, more user-friendly packaging designs.

The coating industry has been actively researching alternatives and modifications to butane-based systems to further mitigate environmental impacts. This includes the exploration of water-based coatings, powder coatings, and novel propellant systems that aim to maintain performance while reducing environmental footprint.

Regulatory bodies worldwide have implemented stringent controls on VOC emissions from coating processes, driving innovation in low-VOC and zero-VOC formulations. These regulations have spurred the development of butane recovery systems and more efficient application methods that minimize propellant loss to the environment.

Safety Regulations for Butane Use in Coating Industry

The use of butane in advanced coating technologies has necessitated the implementation of stringent safety regulations within the coating industry. These regulations are designed to protect workers, the environment, and the general public from potential hazards associated with butane's flammability and volatility.

Occupational safety standards form the cornerstone of these regulations. Workers handling butane-based coatings are required to undergo comprehensive safety training, covering proper handling procedures, emergency protocols, and the use of personal protective equipment (PPE). Mandatory PPE typically includes flame-resistant clothing, safety goggles, and respiratory protection to guard against both fire hazards and inhalation of volatile organic compounds (VOCs).

Ventilation requirements are another critical aspect of safety regulations. Coating facilities must maintain adequate air circulation to prevent the accumulation of butane vapors, which can create explosive atmospheres. This often involves the installation of sophisticated ventilation systems with continuous air quality monitoring to ensure that butane concentrations remain below the lower explosive limit (LEL).

Storage and handling regulations for butane and butane-based coatings are particularly stringent. These materials must be stored in specially designed, explosion-proof containers and kept in well-ventilated areas away from sources of ignition. Transportation of butane and related products is subject to strict guidelines, including proper labeling, secure packaging, and adherence to specific routing requirements for hazardous materials.

Fire safety measures are paramount in facilities using butane-based coatings. Regulations mandate the installation of advanced fire detection and suppression systems, as well as the establishment of clear evacuation procedures. Regular fire drills and equipment inspections are typically required to ensure preparedness in case of emergencies.

Environmental regulations also play a significant role in governing the use of butane in coating technologies. Emissions control measures are often mandated to minimize the release of VOCs into the atmosphere. This may include the use of capture and recovery systems for butane vapors, as well as the implementation of low-VOC or VOC-free coating alternatives where possible.

Waste management regulations address the proper disposal of butane-containing materials and byproducts. Coating facilities must adhere to specific protocols for handling, storing, and disposing of hazardous waste to prevent environmental contamination and reduce fire risks associated with improperly discarded materials.

Compliance with these safety regulations is typically enforced through regular inspections by regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States. Companies are required to maintain detailed records of their safety practices, incident reports, and employee training to demonstrate ongoing compliance with industry standards.

Occupational safety standards form the cornerstone of these regulations. Workers handling butane-based coatings are required to undergo comprehensive safety training, covering proper handling procedures, emergency protocols, and the use of personal protective equipment (PPE). Mandatory PPE typically includes flame-resistant clothing, safety goggles, and respiratory protection to guard against both fire hazards and inhalation of volatile organic compounds (VOCs).

Ventilation requirements are another critical aspect of safety regulations. Coating facilities must maintain adequate air circulation to prevent the accumulation of butane vapors, which can create explosive atmospheres. This often involves the installation of sophisticated ventilation systems with continuous air quality monitoring to ensure that butane concentrations remain below the lower explosive limit (LEL).

Storage and handling regulations for butane and butane-based coatings are particularly stringent. These materials must be stored in specially designed, explosion-proof containers and kept in well-ventilated areas away from sources of ignition. Transportation of butane and related products is subject to strict guidelines, including proper labeling, secure packaging, and adherence to specific routing requirements for hazardous materials.

Fire safety measures are paramount in facilities using butane-based coatings. Regulations mandate the installation of advanced fire detection and suppression systems, as well as the establishment of clear evacuation procedures. Regular fire drills and equipment inspections are typically required to ensure preparedness in case of emergencies.

Environmental regulations also play a significant role in governing the use of butane in coating technologies. Emissions control measures are often mandated to minimize the release of VOCs into the atmosphere. This may include the use of capture and recovery systems for butane vapors, as well as the implementation of low-VOC or VOC-free coating alternatives where possible.

Waste management regulations address the proper disposal of butane-containing materials and byproducts. Coating facilities must adhere to specific protocols for handling, storing, and disposing of hazardous waste to prevent environmental contamination and reduce fire risks associated with improperly discarded materials.

Compliance with these safety regulations is typically enforced through regular inspections by regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States. Companies are required to maintain detailed records of their safety practices, incident reports, and employee training to demonstrate ongoing compliance with industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!