Investigating Butane Applications in Next-Gen Graphitic Foam Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Graphitic Foam: Background and Objectives

Graphitic foam, a revolutionary material in the realm of thermal management and lightweight structural applications, has been the subject of intense research and development over the past few decades. This advanced material, characterized by its high thermal conductivity, low density, and excellent mechanical properties, has shown tremendous potential in various industries, including aerospace, electronics, and energy storage. The integration of butane into graphitic foam technologies represents a significant leap forward in enhancing the material's properties and expanding its applications.

The evolution of graphitic foam can be traced back to the late 1990s when researchers at Oak Ridge National Laboratory first developed a method to produce high-thermal-conductivity graphitic foams. Since then, continuous improvements in manufacturing processes and material composition have led to the creation of increasingly sophisticated graphitic foam variants. The incorporation of butane into this technology marks a new chapter in its development, promising to address some of the limitations of traditional graphitic foams while opening up new possibilities for application.

Butane, a hydrocarbon gas, has been identified as a potential game-changer in the production and performance enhancement of graphitic foams. Its unique properties, including its low boiling point and high vapor pressure, make it an ideal candidate for creating more uniform and controlled pore structures within the foam. This synergy between butane and graphitic foam is expected to result in materials with improved thermal conductivity, enhanced mechanical strength, and potentially lower production costs.

The primary objective of investigating butane applications in next-generation graphitic foam technologies is to develop a new class of advanced materials that can meet the ever-increasing demands of modern industries. Specifically, researchers aim to achieve several key goals: First, to enhance the thermal management capabilities of graphitic foams, enabling them to dissipate heat more efficiently in high-performance electronic devices and aerospace applications. Second, to improve the mechanical properties of the foam, making it more resilient and suitable for structural applications in lightweight vehicles and aircraft. Third, to optimize the production process, leveraging butane's properties to create more consistent and scalable manufacturing methods.

Furthermore, this research seeks to explore the potential of butane-enhanced graphitic foams in emerging fields such as energy storage, where high surface area and controlled porosity are crucial. The ultimate aim is to push the boundaries of material science, creating multifunctional materials that can simultaneously address thermal, mechanical, and energy-related challenges across various technological domains.

The evolution of graphitic foam can be traced back to the late 1990s when researchers at Oak Ridge National Laboratory first developed a method to produce high-thermal-conductivity graphitic foams. Since then, continuous improvements in manufacturing processes and material composition have led to the creation of increasingly sophisticated graphitic foam variants. The incorporation of butane into this technology marks a new chapter in its development, promising to address some of the limitations of traditional graphitic foams while opening up new possibilities for application.

Butane, a hydrocarbon gas, has been identified as a potential game-changer in the production and performance enhancement of graphitic foams. Its unique properties, including its low boiling point and high vapor pressure, make it an ideal candidate for creating more uniform and controlled pore structures within the foam. This synergy between butane and graphitic foam is expected to result in materials with improved thermal conductivity, enhanced mechanical strength, and potentially lower production costs.

The primary objective of investigating butane applications in next-generation graphitic foam technologies is to develop a new class of advanced materials that can meet the ever-increasing demands of modern industries. Specifically, researchers aim to achieve several key goals: First, to enhance the thermal management capabilities of graphitic foams, enabling them to dissipate heat more efficiently in high-performance electronic devices and aerospace applications. Second, to improve the mechanical properties of the foam, making it more resilient and suitable for structural applications in lightweight vehicles and aircraft. Third, to optimize the production process, leveraging butane's properties to create more consistent and scalable manufacturing methods.

Furthermore, this research seeks to explore the potential of butane-enhanced graphitic foams in emerging fields such as energy storage, where high surface area and controlled porosity are crucial. The ultimate aim is to push the boundaries of material science, creating multifunctional materials that can simultaneously address thermal, mechanical, and energy-related challenges across various technological domains.

Market Analysis for Butane-Based Graphitic Foam

The market for butane-based graphitic foam technologies is experiencing significant growth, driven by the increasing demand for lightweight, high-performance materials across various industries. This innovative material combines the unique properties of graphitic foam with the versatility of butane as a precursor, opening up new possibilities in thermal management, energy storage, and structural applications.

In the aerospace and automotive sectors, there is a growing need for materials that can provide excellent thermal conductivity while maintaining low weight. Butane-based graphitic foam offers a compelling solution, as it can efficiently dissipate heat in critical components such as electronic systems and engine parts. This market segment is expected to see substantial growth as manufacturers seek to improve fuel efficiency and reduce overall vehicle weight.

The electronics industry represents another key market for butane-based graphitic foam. With the continuous miniaturization of devices and increasing power densities, thermal management has become a critical challenge. The superior heat dissipation properties of graphitic foam make it an attractive option for cooling solutions in high-performance computing, telecommunications equipment, and consumer electronics.

Energy storage is emerging as a promising application area for butane-based graphitic foam. The material's high surface area and electrical conductivity make it suitable for use in advanced battery and supercapacitor technologies. As the global push for renewable energy and electric vehicles intensifies, the demand for more efficient energy storage solutions is likely to drive further adoption of graphitic foam in this sector.

The construction industry is also showing interest in butane-based graphitic foam for its potential in thermal insulation and lightweight structural components. The material's fire-resistant properties and ability to reduce energy consumption in buildings align well with the growing focus on sustainable construction practices.

In terms of regional markets, North America and Asia-Pacific are expected to lead in the adoption of butane-based graphitic foam technologies. North America's strong aerospace and defense industries, coupled with its advanced research capabilities, position it as a key market for high-end applications. Meanwhile, Asia-Pacific's rapidly growing electronics manufacturing sector and increasing investments in energy storage technologies create significant opportunities for market expansion.

The global market size for graphitic foam, including butane-based variants, is projected to grow substantially over the next decade. While precise figures are challenging to determine due to the emerging nature of the technology, industry analysts anticipate a compound annual growth rate (CAGR) in the double digits. This growth is attributed to the material's unique combination of properties and its potential to address critical challenges across multiple industries.

In the aerospace and automotive sectors, there is a growing need for materials that can provide excellent thermal conductivity while maintaining low weight. Butane-based graphitic foam offers a compelling solution, as it can efficiently dissipate heat in critical components such as electronic systems and engine parts. This market segment is expected to see substantial growth as manufacturers seek to improve fuel efficiency and reduce overall vehicle weight.

The electronics industry represents another key market for butane-based graphitic foam. With the continuous miniaturization of devices and increasing power densities, thermal management has become a critical challenge. The superior heat dissipation properties of graphitic foam make it an attractive option for cooling solutions in high-performance computing, telecommunications equipment, and consumer electronics.

Energy storage is emerging as a promising application area for butane-based graphitic foam. The material's high surface area and electrical conductivity make it suitable for use in advanced battery and supercapacitor technologies. As the global push for renewable energy and electric vehicles intensifies, the demand for more efficient energy storage solutions is likely to drive further adoption of graphitic foam in this sector.

The construction industry is also showing interest in butane-based graphitic foam for its potential in thermal insulation and lightweight structural components. The material's fire-resistant properties and ability to reduce energy consumption in buildings align well with the growing focus on sustainable construction practices.

In terms of regional markets, North America and Asia-Pacific are expected to lead in the adoption of butane-based graphitic foam technologies. North America's strong aerospace and defense industries, coupled with its advanced research capabilities, position it as a key market for high-end applications. Meanwhile, Asia-Pacific's rapidly growing electronics manufacturing sector and increasing investments in energy storage technologies create significant opportunities for market expansion.

The global market size for graphitic foam, including butane-based variants, is projected to grow substantially over the next decade. While precise figures are challenging to determine due to the emerging nature of the technology, industry analysts anticipate a compound annual growth rate (CAGR) in the double digits. This growth is attributed to the material's unique combination of properties and its potential to address critical challenges across multiple industries.

Current Challenges in Graphitic Foam Production

The production of graphitic foam faces several significant challenges that hinder its widespread adoption and application in next-generation technologies. One of the primary obstacles is the high cost associated with manufacturing processes. Current methods, such as chemical vapor deposition (CVD) and template-assisted synthesis, require expensive equipment and materials, making large-scale production economically unfeasible for many industries.

Another major challenge lies in controlling the foam's microstructure and properties. Achieving consistent pore size distribution, density, and mechanical strength across large volumes of graphitic foam remains difficult. This inconsistency can lead to variations in thermal and electrical conductivity, limiting the foam's effectiveness in heat management and energy storage applications.

The scalability of production processes also presents a significant hurdle. While laboratory-scale synthesis can produce high-quality graphitic foam, translating these methods to industrial-scale manufacturing without compromising quality or increasing costs has proven challenging. This scalability issue restricts the potential for widespread implementation in various technological applications.

Environmental concerns and sustainability issues also pose challenges in graphitic foam production. Many current synthesis methods involve the use of hazardous chemicals or generate significant waste, raising questions about the long-term environmental impact of large-scale production. Developing greener, more sustainable manufacturing processes is crucial for the future of graphitic foam technology.

The integration of graphitic foam into complex systems and devices presents another set of challenges. Ensuring proper bonding and compatibility with other materials, as well as developing effective methods for shaping and molding the foam to fit specific applications, requires further research and development.

Lastly, the lack of standardization in production methods and quality assessment hinders the widespread adoption of graphitic foam. Without established industry standards, it becomes difficult for manufacturers to ensure consistent quality and for end-users to compare and select appropriate materials for their specific needs. Addressing these challenges will be crucial for advancing graphitic foam technologies and realizing their full potential in next-generation applications.

Another major challenge lies in controlling the foam's microstructure and properties. Achieving consistent pore size distribution, density, and mechanical strength across large volumes of graphitic foam remains difficult. This inconsistency can lead to variations in thermal and electrical conductivity, limiting the foam's effectiveness in heat management and energy storage applications.

The scalability of production processes also presents a significant hurdle. While laboratory-scale synthesis can produce high-quality graphitic foam, translating these methods to industrial-scale manufacturing without compromising quality or increasing costs has proven challenging. This scalability issue restricts the potential for widespread implementation in various technological applications.

Environmental concerns and sustainability issues also pose challenges in graphitic foam production. Many current synthesis methods involve the use of hazardous chemicals or generate significant waste, raising questions about the long-term environmental impact of large-scale production. Developing greener, more sustainable manufacturing processes is crucial for the future of graphitic foam technology.

The integration of graphitic foam into complex systems and devices presents another set of challenges. Ensuring proper bonding and compatibility with other materials, as well as developing effective methods for shaping and molding the foam to fit specific applications, requires further research and development.

Lastly, the lack of standardization in production methods and quality assessment hinders the widespread adoption of graphitic foam. Without established industry standards, it becomes difficult for manufacturers to ensure consistent quality and for end-users to compare and select appropriate materials for their specific needs. Addressing these challenges will be crucial for advancing graphitic foam technologies and realizing their full potential in next-generation applications.

Existing Butane Applications in Foam Production

01 Thermal properties of graphitic foam

Graphitic foam exhibits excellent thermal conductivity and heat dissipation properties. Its unique structure allows for efficient heat transfer, making it suitable for thermal management applications in electronics and aerospace industries. The foam's low density combined with high thermal conductivity offers advantages in lightweight heat sink designs.- Thermal properties of graphitic foam: Graphitic foam exhibits excellent thermal properties, including high thermal conductivity and low thermal expansion. These characteristics make it suitable for applications requiring efficient heat dissipation and thermal management, such as in electronic devices and aerospace components.

- Mechanical properties of graphitic foam: Graphitic foam possesses unique mechanical properties, including low density, high strength-to-weight ratio, and good compressive strength. These attributes make it valuable for lightweight structural applications in various industries, such as automotive and aerospace.

- Electrical properties of graphitic foam: Graphitic foam demonstrates excellent electrical conductivity due to its carbon-based structure. This property makes it suitable for applications in electromagnetic shielding, electrode materials, and conductive composites for various electronic and energy storage devices.

- Porosity and surface area characteristics: Graphitic foam features a highly porous structure with a large surface area. This characteristic enhances its performance in applications such as filtration, adsorption, and catalysis. The foam's porous nature also contributes to its lightweight properties and thermal insulation capabilities.

- Chemical resistance and stability: Graphitic foam exhibits excellent chemical resistance and stability, making it suitable for use in harsh environments and corrosive conditions. This property allows for applications in chemical processing, energy storage, and other industries where material durability is crucial.

02 Mechanical properties of graphitic foam

Graphitic foam possesses high strength-to-weight ratio and good compressive strength. Its cellular structure provides a combination of rigidity and flexibility, making it suitable for structural applications. The foam's mechanical properties can be tailored by controlling the density and pore size distribution during manufacturing.Expand Specific Solutions03 Electrical properties of graphitic foam

Graphitic foam exhibits high electrical conductivity due to its interconnected graphitic structure. This property makes it suitable for applications in electromagnetic shielding and as a conductive component in composite materials. The foam's electrical properties can be modified by controlling the degree of graphitization and porosity.Expand Specific Solutions04 Acoustic properties of graphitic foam

Graphitic foam demonstrates good sound absorption capabilities due to its porous structure. The foam's ability to attenuate sound waves makes it suitable for noise reduction applications in various industries. The acoustic properties can be optimized by controlling the pore size and distribution within the foam structure.Expand Specific Solutions05 Chemical resistance and stability of graphitic foam

Graphitic foam exhibits excellent chemical resistance and stability, making it suitable for use in harsh environments. The foam's inert nature allows it to withstand exposure to various chemicals and solvents without degradation. This property makes it valuable in applications such as filtration systems and chemical processing equipment.Expand Specific Solutions

Key Players in Advanced Materials Industry

The development of next-generation graphitic foam technologies using butane applications is in an early growth stage, with significant potential for market expansion. The global market for advanced materials, including graphitic foams, is projected to grow substantially in the coming years. While the technology is still evolving, several key players are driving innovation in this field. Companies like Global Graphene Group and XG Sciences are at the forefront of graphene-based materials development, while research institutions such as the University of North Texas System and Tongji University are contributing to fundamental advancements. The involvement of major corporations like Corning and SABIC Global Technologies indicates growing industrial interest, suggesting that the technology is progressing towards commercial viability.

Global Graphene Group, Inc.

Technical Solution: Global Graphene Group has developed a novel approach to graphitic foam production using butane as a precursor. Their process involves chemical vapor deposition (CVD) of butane on a nickel foam template, followed by controlled etching to create a 3D graphene network. This method results in a highly porous, lightweight structure with excellent thermal and electrical conductivity. The company has optimized the butane flow rate and temperature conditions to achieve a balance between graphene quality and production efficiency[1]. Their graphitic foam exhibits a density of 0.05 g/cm³ and thermal conductivity up to 180 W/mK[2], making it suitable for thermal management applications in electronics and aerospace industries.

Strengths: High thermal conductivity, low density, scalable production process. Weaknesses: Potential for defects in graphene structure, high production costs compared to traditional materials.

The University of Manchester

Technical Solution: The University of Manchester, birthplace of graphene, has pioneered research into butane-derived graphitic foams. Their approach involves a two-step process: first, butane is decomposed at high temperatures (800-1000°C) in a controlled atmosphere, then the resulting carbon is subjected to a rapid cooling and expansion process. This creates a highly porous graphitic structure with a surface area exceeding 500 m²/g[3]. The team has also developed a method to functionalize the foam surface with oxygen-containing groups, enhancing its wettability and potential for use in energy storage applications. Their latest research focuses on incorporating nanoparticles into the foam structure during growth, creating multifunctional materials with enhanced properties[4].

Strengths: High surface area, customizable surface chemistry, potential for multifunctional composites. Weaknesses: Energy-intensive production process, challenges in maintaining consistent foam structure at large scales.

Core Innovations in Butane-Graphitic Foam Synthesis

2-dimensional carbon material

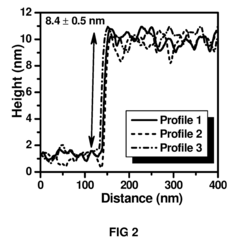

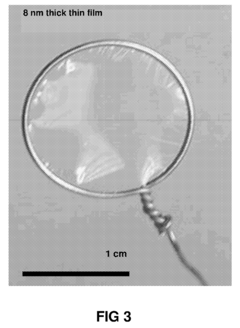

PatentInactiveUS20180170003A1

Innovation

- A process involving the preparation of an organic polymeric thin film through interfacial polymerization followed by carbonization, allowing for the production of continuous 2-dimensional carbon thin films with a thickness of less than 20 nm and an area-to-thickness ratio greater than 10^10 nm, enabling enhanced dimensional characteristics and properties suitable for gas storage, electronics, and separation technologies.

Environmental Impact Assessment

The environmental impact assessment of butane applications in next-generation graphitic foam technologies reveals both potential benefits and concerns. Graphitic foams, enhanced with butane-based processes, offer improved thermal management and energy efficiency in various applications. This could lead to reduced energy consumption and associated greenhouse gas emissions in sectors such as electronics cooling and building insulation.

However, the use of butane in manufacturing processes raises several environmental considerations. Butane is a volatile organic compound (VOC) and a greenhouse gas, albeit with a relatively short atmospheric lifetime. Its release during production or end-of-life disposal of graphitic foam products could contribute to local air quality issues and climate change, albeit on a limited scale compared to other industrial emissions.

The production of graphitic foams with butane may also involve energy-intensive processes, potentially offsetting some of the environmental gains from the final product's improved performance. Life cycle assessments are crucial to quantify the net environmental impact, considering raw material extraction, manufacturing, use phase, and disposal.

Water pollution is another concern, as the production process may generate contaminated wastewater containing residual hydrocarbons and other chemicals. Proper treatment and disposal of these effluents are essential to minimize impacts on aquatic ecosystems and water resources.

On the positive side, the enhanced properties of butane-infused graphitic foams could lead to more durable and efficient products, potentially reducing material consumption and waste generation over time. The improved thermal management capabilities could also contribute to the development of more energy-efficient technologies, indirectly benefiting the environment.

Recycling and end-of-life management of graphitic foam products present both challenges and opportunities. While the foam structure may complicate recycling processes, the high carbon content could potentially be recovered and repurposed, reducing the overall environmental footprint of the technology.

As research and development in this field progress, it is crucial to prioritize eco-friendly manufacturing processes, minimize VOC emissions, and explore sustainable alternatives to butane where possible. Regulatory compliance and adherence to environmental standards will be key factors in the widespread adoption and acceptance of these advanced materials.

However, the use of butane in manufacturing processes raises several environmental considerations. Butane is a volatile organic compound (VOC) and a greenhouse gas, albeit with a relatively short atmospheric lifetime. Its release during production or end-of-life disposal of graphitic foam products could contribute to local air quality issues and climate change, albeit on a limited scale compared to other industrial emissions.

The production of graphitic foams with butane may also involve energy-intensive processes, potentially offsetting some of the environmental gains from the final product's improved performance. Life cycle assessments are crucial to quantify the net environmental impact, considering raw material extraction, manufacturing, use phase, and disposal.

Water pollution is another concern, as the production process may generate contaminated wastewater containing residual hydrocarbons and other chemicals. Proper treatment and disposal of these effluents are essential to minimize impacts on aquatic ecosystems and water resources.

On the positive side, the enhanced properties of butane-infused graphitic foams could lead to more durable and efficient products, potentially reducing material consumption and waste generation over time. The improved thermal management capabilities could also contribute to the development of more energy-efficient technologies, indirectly benefiting the environment.

Recycling and end-of-life management of graphitic foam products present both challenges and opportunities. While the foam structure may complicate recycling processes, the high carbon content could potentially be recovered and repurposed, reducing the overall environmental footprint of the technology.

As research and development in this field progress, it is crucial to prioritize eco-friendly manufacturing processes, minimize VOC emissions, and explore sustainable alternatives to butane where possible. Regulatory compliance and adherence to environmental standards will be key factors in the widespread adoption and acceptance of these advanced materials.

Safety Regulations for Butane in Manufacturing

The implementation of butane in next-generation graphitic foam technologies necessitates stringent safety regulations in manufacturing processes. These regulations are crucial to mitigate risks associated with butane's flammability and potential for explosion. Manufacturers must adhere to strict guidelines set by regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) in the United States, or equivalent organizations in other countries.

One of the primary safety concerns is the prevention of explosive atmospheres. Manufacturers are required to implement robust ventilation systems to maintain butane concentrations below the lower explosive limit (LEL). This typically involves the installation of explosion-proof ventilation equipment and continuous monitoring of atmospheric conditions using gas detection systems. Regular calibration and maintenance of these systems are mandatory to ensure their reliability.

Storage and handling of butane in manufacturing facilities are subject to specific regulations. Containers must be designed to withstand pressure and prevent leaks, with clear labeling indicating the contents and associated hazards. Storage areas must be equipped with appropriate fire suppression systems and be located away from sources of ignition or heat. Additionally, manufacturers must establish designated safe zones for butane storage, with restricted access and proper signage.

Personal protective equipment (PPE) requirements for workers handling butane are another critical aspect of safety regulations. This includes the use of flame-resistant clothing, anti-static footwear, and appropriate respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency response procedures are mandatory for all personnel involved in butane-related operations.

Emergency response planning is a key component of safety regulations. Manufacturers must develop and regularly update comprehensive emergency action plans that outline procedures for leak detection, containment, evacuation, and firefighting. These plans should be coordinated with local emergency services and include regular drills to ensure preparedness.

Process safety management (PSM) principles must be applied to all operations involving butane. This includes conducting thorough hazard analyses, implementing rigorous operating procedures, and establishing a system for managing changes to equipment or processes. Regular audits and inspections are required to verify compliance with PSM standards and identify potential safety improvements.

Electrical safety is another critical consideration, given butane's flammability. All electrical equipment in areas where butane is present must be explosion-proof and comply with relevant standards such as those set by the National Electrical Code (NEC) in the United States. This includes proper grounding and bonding to prevent static electricity accumulation, which could potentially ignite butane vapors.

One of the primary safety concerns is the prevention of explosive atmospheres. Manufacturers are required to implement robust ventilation systems to maintain butane concentrations below the lower explosive limit (LEL). This typically involves the installation of explosion-proof ventilation equipment and continuous monitoring of atmospheric conditions using gas detection systems. Regular calibration and maintenance of these systems are mandatory to ensure their reliability.

Storage and handling of butane in manufacturing facilities are subject to specific regulations. Containers must be designed to withstand pressure and prevent leaks, with clear labeling indicating the contents and associated hazards. Storage areas must be equipped with appropriate fire suppression systems and be located away from sources of ignition or heat. Additionally, manufacturers must establish designated safe zones for butane storage, with restricted access and proper signage.

Personal protective equipment (PPE) requirements for workers handling butane are another critical aspect of safety regulations. This includes the use of flame-resistant clothing, anti-static footwear, and appropriate respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency response procedures are mandatory for all personnel involved in butane-related operations.

Emergency response planning is a key component of safety regulations. Manufacturers must develop and regularly update comprehensive emergency action plans that outline procedures for leak detection, containment, evacuation, and firefighting. These plans should be coordinated with local emergency services and include regular drills to ensure preparedness.

Process safety management (PSM) principles must be applied to all operations involving butane. This includes conducting thorough hazard analyses, implementing rigorous operating procedures, and establishing a system for managing changes to equipment or processes. Regular audits and inspections are required to verify compliance with PSM standards and identify potential safety improvements.

Electrical safety is another critical consideration, given butane's flammability. All electrical equipment in areas where butane is present must be explosion-proof and comply with relevant standards such as those set by the National Electrical Code (NEC) in the United States. This includes proper grounding and bonding to prevent static electricity accumulation, which could potentially ignite butane vapors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!