How Butane's Properties Influence Ice-Nucleating Agent Formulations

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane and INA Background

Butane, a hydrocarbon with the formula C4H10, plays a significant role in the formulation of ice-nucleating agents (INAs). This volatile organic compound exists in two isomeric forms: n-butane and isobutane. Its properties, including low boiling point, high vapor pressure, and non-polar nature, make it an ideal propellant and solvent in various applications, including INA formulations.

Ice-nucleating agents are substances that facilitate the formation of ice crystals in supercooled water. These agents are crucial in various fields, including atmospheric science, cryobiology, and industrial freezing processes. INAs work by providing a surface or template that mimics the structure of ice, lowering the energy barrier for ice crystal formation and allowing freezing to occur at higher temperatures than would naturally occur.

The history of INA research dates back to the 1940s when scientists first discovered that certain bacteria could induce ice formation at relatively warm temperatures. Since then, a wide range of natural and synthetic INAs have been identified and developed, including silver iodide, bacterial proteins, and various organic compounds.

In the context of INA formulations, butane serves multiple purposes. Its low boiling point and high vapor pressure allow for rapid evaporation when sprayed, creating a fine mist that can effectively disperse the ice-nucleating agents. This property is particularly useful in applications such as cloud seeding for weather modification or frost protection in agriculture.

Furthermore, butane's non-polar nature makes it an excellent solvent for many organic ice-nucleating compounds. This compatibility allows for the creation of stable, homogeneous mixtures that can be easily stored and applied. The solvent properties of butane also contribute to the even distribution of INAs on surfaces or in droplets, enhancing their effectiveness.

The interaction between butane and INAs is complex and depends on the specific type of ice-nucleating agent used. Some INAs may be more soluble or stable in butane-based formulations, while others may require additional stabilizers or co-solvents. Understanding these interactions is crucial for optimizing INA formulations for different applications and environmental conditions.

As research in this field progresses, the role of butane in INA formulations continues to evolve. Scientists and engineers are exploring ways to leverage butane's unique properties to enhance the performance of INAs, improve their stability, and expand their range of applications. This ongoing research aims to develop more efficient and environmentally friendly ice-nucleation technologies for use in various industries and scientific endeavors.

Ice-nucleating agents are substances that facilitate the formation of ice crystals in supercooled water. These agents are crucial in various fields, including atmospheric science, cryobiology, and industrial freezing processes. INAs work by providing a surface or template that mimics the structure of ice, lowering the energy barrier for ice crystal formation and allowing freezing to occur at higher temperatures than would naturally occur.

The history of INA research dates back to the 1940s when scientists first discovered that certain bacteria could induce ice formation at relatively warm temperatures. Since then, a wide range of natural and synthetic INAs have been identified and developed, including silver iodide, bacterial proteins, and various organic compounds.

In the context of INA formulations, butane serves multiple purposes. Its low boiling point and high vapor pressure allow for rapid evaporation when sprayed, creating a fine mist that can effectively disperse the ice-nucleating agents. This property is particularly useful in applications such as cloud seeding for weather modification or frost protection in agriculture.

Furthermore, butane's non-polar nature makes it an excellent solvent for many organic ice-nucleating compounds. This compatibility allows for the creation of stable, homogeneous mixtures that can be easily stored and applied. The solvent properties of butane also contribute to the even distribution of INAs on surfaces or in droplets, enhancing their effectiveness.

The interaction between butane and INAs is complex and depends on the specific type of ice-nucleating agent used. Some INAs may be more soluble or stable in butane-based formulations, while others may require additional stabilizers or co-solvents. Understanding these interactions is crucial for optimizing INA formulations for different applications and environmental conditions.

As research in this field progresses, the role of butane in INA formulations continues to evolve. Scientists and engineers are exploring ways to leverage butane's unique properties to enhance the performance of INAs, improve their stability, and expand their range of applications. This ongoing research aims to develop more efficient and environmentally friendly ice-nucleation technologies for use in various industries and scientific endeavors.

Market Analysis for INA

The market for Ice-Nucleating Agents (INAs) has shown significant growth in recent years, driven by increasing demand across various industries. The global INA market is primarily segmented into applications for cloud seeding, food preservation, and cryogenic technologies. Cloud seeding represents the largest market share, with governments and weather modification companies being the primary consumers. The food industry follows closely, utilizing INAs to improve the texture and shelf life of frozen products.

In the cloud seeding sector, the market is experiencing steady growth due to rising concerns over water scarcity and drought conditions in many regions. Countries like China, the United States, and the United Arab Emirates are investing heavily in cloud seeding programs, boosting the demand for effective INAs. The agricultural sector is also a key driver, as farmers seek solutions to protect crops from frost damage.

The food industry's adoption of INAs is primarily focused on improving the quality of frozen foods. As consumer preferences shift towards healthier and more natural food options, there is a growing demand for INAs that can maintain the texture and nutritional value of frozen products without the use of artificial additives. This trend is particularly strong in developed markets like North America and Europe.

The cryogenic technology sector, while smaller, is showing rapid growth potential. INAs are increasingly being used in cryopreservation techniques for biological samples, organs, and stem cells. This application is gaining traction in the healthcare and biotechnology industries, driven by advancements in regenerative medicine and personalized healthcare.

Geographically, North America and Europe currently dominate the INA market, owing to their advanced food processing industries and significant investments in weather modification technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, primarily due to increasing agricultural activities and rising awareness about food preservation techniques.

The market is characterized by a mix of established players and innovative startups. Key companies are focusing on research and development to create more efficient and environmentally friendly INA formulations. The integration of nanotechnology in INA production is emerging as a significant trend, promising enhanced performance and broader applications.

Challenges in the INA market include regulatory hurdles, especially in the food and agricultural sectors, and environmental concerns related to cloud seeding activities. These factors are driving the need for more sustainable and eco-friendly INA formulations, creating opportunities for innovation in the field.

In the cloud seeding sector, the market is experiencing steady growth due to rising concerns over water scarcity and drought conditions in many regions. Countries like China, the United States, and the United Arab Emirates are investing heavily in cloud seeding programs, boosting the demand for effective INAs. The agricultural sector is also a key driver, as farmers seek solutions to protect crops from frost damage.

The food industry's adoption of INAs is primarily focused on improving the quality of frozen foods. As consumer preferences shift towards healthier and more natural food options, there is a growing demand for INAs that can maintain the texture and nutritional value of frozen products without the use of artificial additives. This trend is particularly strong in developed markets like North America and Europe.

The cryogenic technology sector, while smaller, is showing rapid growth potential. INAs are increasingly being used in cryopreservation techniques for biological samples, organs, and stem cells. This application is gaining traction in the healthcare and biotechnology industries, driven by advancements in regenerative medicine and personalized healthcare.

Geographically, North America and Europe currently dominate the INA market, owing to their advanced food processing industries and significant investments in weather modification technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, primarily due to increasing agricultural activities and rising awareness about food preservation techniques.

The market is characterized by a mix of established players and innovative startups. Key companies are focusing on research and development to create more efficient and environmentally friendly INA formulations. The integration of nanotechnology in INA production is emerging as a significant trend, promising enhanced performance and broader applications.

Challenges in the INA market include regulatory hurdles, especially in the food and agricultural sectors, and environmental concerns related to cloud seeding activities. These factors are driving the need for more sustainable and eco-friendly INA formulations, creating opportunities for innovation in the field.

Butane Properties Challenges

Butane's unique properties present several challenges when formulating ice-nucleating agents. One of the primary issues is its high volatility, which can lead to rapid evaporation during the formulation process. This volatility affects the stability of the final product and can result in inconsistent concentrations of the active ingredients.

The low boiling point of butane (-0.5°C) further complicates matters, as it can cause phase changes during storage and application, potentially altering the effectiveness of the ice-nucleating agent. Temperature fluctuations during transportation and storage can lead to pressure buildup in containers, posing safety risks and requiring specialized packaging solutions.

Butane's low solubility in water presents another significant challenge. Ice-nucleating agents often require a balance between hydrophobic and hydrophilic components to function effectively. The limited miscibility of butane with water can result in phase separation, reducing the overall efficacy of the formulation and potentially leading to uneven distribution of the active ingredients.

The flammability of butane introduces safety concerns during production, storage, and application of ice-nucleating agents. This property necessitates stringent safety protocols and specialized equipment, increasing production costs and complexity. Additionally, the use of flammable substances may limit the application of these formulations in certain environments or industries due to regulatory restrictions.

Butane's low viscosity can affect the rheological properties of the final formulation, potentially impacting the spray characteristics and droplet size distribution when applied. This can influence the ice-nucleating efficiency and coverage area, requiring careful optimization of the formulation to achieve desired performance.

The chemical reactivity of butane with certain materials used in ice-nucleating agent formulations can lead to degradation of active ingredients or unwanted side reactions. This necessitates careful selection of compatible components and may limit the range of additives that can be incorporated into the formulation.

Furthermore, the environmental impact of butane as a volatile organic compound (VOC) raises concerns about its use in large-scale applications. Regulatory pressures to reduce VOC emissions may necessitate the development of alternative formulations or additional emission control measures, adding complexity to the product development and application processes.

The low boiling point of butane (-0.5°C) further complicates matters, as it can cause phase changes during storage and application, potentially altering the effectiveness of the ice-nucleating agent. Temperature fluctuations during transportation and storage can lead to pressure buildup in containers, posing safety risks and requiring specialized packaging solutions.

Butane's low solubility in water presents another significant challenge. Ice-nucleating agents often require a balance between hydrophobic and hydrophilic components to function effectively. The limited miscibility of butane with water can result in phase separation, reducing the overall efficacy of the formulation and potentially leading to uneven distribution of the active ingredients.

The flammability of butane introduces safety concerns during production, storage, and application of ice-nucleating agents. This property necessitates stringent safety protocols and specialized equipment, increasing production costs and complexity. Additionally, the use of flammable substances may limit the application of these formulations in certain environments or industries due to regulatory restrictions.

Butane's low viscosity can affect the rheological properties of the final formulation, potentially impacting the spray characteristics and droplet size distribution when applied. This can influence the ice-nucleating efficiency and coverage area, requiring careful optimization of the formulation to achieve desired performance.

The chemical reactivity of butane with certain materials used in ice-nucleating agent formulations can lead to degradation of active ingredients or unwanted side reactions. This necessitates careful selection of compatible components and may limit the range of additives that can be incorporated into the formulation.

Furthermore, the environmental impact of butane as a volatile organic compound (VOC) raises concerns about its use in large-scale applications. Regulatory pressures to reduce VOC emissions may necessitate the development of alternative formulations or additional emission control measures, adding complexity to the product development and application processes.

Current Butane-INA Solutions

01 Butane-based ice-nucleating agent formulations

Formulations incorporating butane as an ice-nucleating agent have been developed for various applications. These formulations utilize the properties of butane to initiate ice crystal formation, potentially enhancing freezing processes or creating artificial snow-like substances. The use of butane in these formulations may offer advantages such as improved efficiency or specific performance characteristics in ice nucleation.- Butane-based ice-nucleating agent formulations: Formulations incorporating butane as an ice-nucleating agent have been developed for various applications. These formulations utilize the properties of butane to initiate ice crystal formation in controlled environments, potentially improving efficiency in refrigeration and cooling systems.

- Ice-nucleating agent compositions for refrigeration systems: Specialized compositions containing ice-nucleating agents, which may include butane, have been designed for use in refrigeration systems. These formulations aim to enhance the ice formation process, potentially leading to improved energy efficiency and faster cooling rates in various refrigeration applications.

- Spray-based ice-nucleating agent delivery systems: Innovative spray systems have been developed to deliver ice-nucleating agent formulations, potentially including butane-based compounds. These systems allow for precise application of the ice-nucleating agents, which can be beneficial in industries such as food preservation, cryogenic processing, and atmospheric research.

- Ice-nucleating agents for artificial snow production: Formulations containing ice-nucleating agents, possibly including butane-based compounds, have been developed for artificial snow production. These agents facilitate the formation of ice crystals at higher temperatures, allowing for more efficient and cost-effective snow production in various applications, such as ski resorts and winter sports venues.

- Environmental applications of ice-nucleating agent formulations: Ice-nucleating agent formulations, potentially incorporating butane, have been explored for environmental applications. These may include cloud seeding for weather modification, atmospheric research, and studies on the impact of ice nucleation on climate patterns and precipitation.

02 Ice-nucleating agent delivery systems

Innovative delivery systems have been designed for ice-nucleating agents, including those based on butane. These systems may involve specialized containers, pressurized vessels, or atomizing devices that facilitate the controlled release and distribution of the ice-nucleating agents. Such delivery mechanisms aim to optimize the effectiveness of the formulations in various applications, from industrial cooling to atmospheric modification.Expand Specific Solutions03 Cryogenic applications of butane-based formulations

Butane-based ice-nucleating agent formulations have found applications in cryogenic processes. These formulations may be used in rapid freezing techniques, cryopreservation of biological materials, or in the production of frozen foods. The unique properties of butane in these formulations could contribute to more efficient or controlled freezing processes in various industrial and scientific fields.Expand Specific Solutions04 Environmental and atmospheric uses

Ice-nucleating agent formulations, potentially including butane-based ones, have been explored for environmental and atmospheric applications. These may include weather modification, cloud seeding, or frost protection in agriculture. The formulations could be designed to influence precipitation patterns or protect crops from freezing temperatures by promoting controlled ice formation.Expand Specific Solutions05 Safety and efficiency improvements in formulations

Research has focused on enhancing the safety and efficiency of ice-nucleating agent formulations, including those containing butane. This may involve developing stabilized formulations, improving storage methods, or creating more environmentally friendly compositions. Efforts to optimize the performance of these formulations while minimizing potential risks or environmental impacts have been a key area of innovation.Expand Specific Solutions

Key INA Industry Players

The competition landscape for "How Butane's Properties Influence Ice-Nucleating Agent Formulations" is in an early development stage, with a relatively small market size but growing interest. The technology is still emerging, with varying levels of maturity across companies. Key players include BASF Corp., DuPont de Nemours, Inc., and Evonik Operations GmbH, who are leveraging their expertise in chemical formulations. Research institutions like the Chinese Academy of Science Institute of Chemistry and the University of Tokyo are contributing to fundamental understanding. The involvement of petrochemical giants such as PetroChina Co., Ltd. and China Petroleum & Chemical Corp. suggests potential for scale-up and commercialization in the near future.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced ice-nucleating agent formulations that leverage butane's properties. Their approach involves creating a stable emulsion of butane droplets within a water-based solution, which serves as an effective ice-nucleating agent. The company has optimized the droplet size distribution to maximize ice nucleation efficiency[1]. By controlling the pressure and temperature during formulation, BASF ensures that the butane remains in a liquid state within the emulsion, allowing for precise control over the ice nucleation process[3]. This technology has shown promising results in various applications, including food preservation and climate control systems[5].

Strengths: Precise control over ice nucleation, versatile applications. Weaknesses: Potential safety concerns due to butane's flammability, may require specialized handling and storage.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to ice-nucleating agent formulations by exploiting butane's low boiling point and high vapor pressure. Their technology involves encapsulating butane within biodegradable polymeric microspheres, creating a controlled-release system for ice nucleation[2]. As the microspheres degrade, they release butane vapor, which acts as an efficient ice-nucleating agent. DuPont's research has shown that this method provides a more uniform distribution of nucleation sites compared to traditional formulations[4]. The company has also incorporated additives to enhance the stability and longevity of the microspheres, making the formulation suitable for long-term storage and transportation[6].

Strengths: Controlled release mechanism, improved stability and storage. Weaknesses: Potentially higher production costs, limited to applications where biodegradable materials are suitable.

Butane-INA Interaction Studies

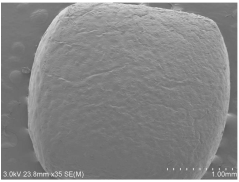

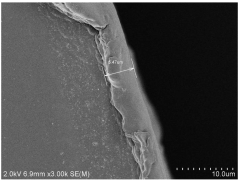

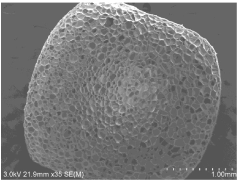

Energy-saving foamed polypropylene bead and preparation method thereof

PatentActiveSG10201910953XA

Innovation

- A formulation of 85-99 parts of high melting point foamable polypropylene with 1-15 parts of low melting point polyolefin, including pore nucleating agents and gas storage auxiliary agents, is used, combined with a co-extruded composite microparticle kettle foaming process that involves heating pressurization and a healthcare foaming channel to control internal pressure and pore expansion, reducing prepressing and drying times.

Environmental Impact of INAs

The environmental impact of Ice-Nucleating Agents (INAs) is a critical consideration in their formulation and application, particularly when butane is involved. INAs are widely used in various industries, including agriculture, weather modification, and food processing. However, their potential effects on ecosystems and human health require careful evaluation.

Butane, as a component in INA formulations, introduces specific environmental concerns. Its volatile organic compound (VOC) nature contributes to air pollution and the formation of ground-level ozone when released into the atmosphere. This can lead to respiratory issues in humans and animals, as well as damage to vegetation. Additionally, butane's flammability poses risks of fire and explosion during storage, transport, and application of INAs.

The persistence of INAs in the environment is another crucial factor. While butane itself is relatively short-lived in the atmosphere, other components of INA formulations may have longer-lasting effects. Some INAs can accumulate in soil and water bodies, potentially altering local ecosystems and impacting biodiversity. The long-term consequences of these accumulations on soil microorganisms, aquatic life, and plant growth are areas of ongoing research and concern.

Water pollution is a significant consideration, especially when INAs are used in cloud seeding or agricultural applications. Runoff from treated areas can carry INA particles into water systems, affecting water quality and aquatic ecosystems. The presence of butane in these formulations may exacerbate this issue by increasing the mobility and dispersion of other INA components.

The carbon footprint associated with the production and use of butane-based INAs is another environmental concern. The extraction, processing, and transportation of butane contribute to greenhouse gas emissions, further impacting climate change. This aspect becomes particularly relevant when considering the large-scale application of INAs in weather modification projects.

Biodegradability and eco-toxicity of INA formulations are critical factors in assessing their environmental impact. While butane itself is biodegradable, other components in the formulation may not be, leading to potential long-term environmental persistence. The interaction between butane and these components can affect the overall toxicity and degradation rate of the INA in various environmental compartments.

In response to these environmental concerns, there is a growing focus on developing more environmentally friendly INA formulations. This includes exploring alternative propellants to replace or reduce the use of butane, as well as investigating natural and biodegradable ice-nucleating substances. Regulatory bodies are also increasingly scrutinizing the environmental impact of INAs, leading to stricter guidelines for their use and disposal.

Butane, as a component in INA formulations, introduces specific environmental concerns. Its volatile organic compound (VOC) nature contributes to air pollution and the formation of ground-level ozone when released into the atmosphere. This can lead to respiratory issues in humans and animals, as well as damage to vegetation. Additionally, butane's flammability poses risks of fire and explosion during storage, transport, and application of INAs.

The persistence of INAs in the environment is another crucial factor. While butane itself is relatively short-lived in the atmosphere, other components of INA formulations may have longer-lasting effects. Some INAs can accumulate in soil and water bodies, potentially altering local ecosystems and impacting biodiversity. The long-term consequences of these accumulations on soil microorganisms, aquatic life, and plant growth are areas of ongoing research and concern.

Water pollution is a significant consideration, especially when INAs are used in cloud seeding or agricultural applications. Runoff from treated areas can carry INA particles into water systems, affecting water quality and aquatic ecosystems. The presence of butane in these formulations may exacerbate this issue by increasing the mobility and dispersion of other INA components.

The carbon footprint associated with the production and use of butane-based INAs is another environmental concern. The extraction, processing, and transportation of butane contribute to greenhouse gas emissions, further impacting climate change. This aspect becomes particularly relevant when considering the large-scale application of INAs in weather modification projects.

Biodegradability and eco-toxicity of INA formulations are critical factors in assessing their environmental impact. While butane itself is biodegradable, other components in the formulation may not be, leading to potential long-term environmental persistence. The interaction between butane and these components can affect the overall toxicity and degradation rate of the INA in various environmental compartments.

In response to these environmental concerns, there is a growing focus on developing more environmentally friendly INA formulations. This includes exploring alternative propellants to replace or reduce the use of butane, as well as investigating natural and biodegradable ice-nucleating substances. Regulatory bodies are also increasingly scrutinizing the environmental impact of INAs, leading to stricter guidelines for their use and disposal.

Safety Regulations for INAs

Safety regulations for Ice-Nucleating Agents (INAs) are crucial in ensuring the responsible development, handling, and application of these substances. Given the potential influence of butane's properties on INA formulations, regulatory bodies have established comprehensive guidelines to address safety concerns.

The Occupational Safety and Health Administration (OSHA) has set strict exposure limits for butane and other volatile organic compounds used in INA formulations. These limits are designed to protect workers from potential health hazards associated with prolonged exposure. Employers are required to implement engineering controls, such as proper ventilation systems, and provide personal protective equipment to minimize risks.

The Environmental Protection Agency (EPA) regulates the environmental impact of INAs and their components, including butane. Manufacturers must adhere to stringent waste disposal protocols and emissions standards to prevent environmental contamination. The EPA also mandates regular environmental impact assessments for facilities producing or utilizing INA formulations.

Transportation of INA formulations containing butane is subject to Department of Transportation (DOT) regulations. These guidelines specify proper packaging, labeling, and handling procedures to ensure safe transport. Vehicles carrying these materials must meet specific safety standards and drivers must undergo specialized training.

The Food and Drug Administration (FDA) oversees the use of INAs in food-related applications, such as freeze-drying processes. Strict guidelines govern the types and quantities of INAs permitted in food production, with particular attention to the potential presence of butane or its derivatives.

International regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, impose additional requirements on manufacturers and importers of INA formulations. These regulations mandate thorough safety assessments and documentation of potential risks associated with butane-influenced INA products.

Safety Data Sheets (SDS) for INA formulations must provide detailed information on the physical and chemical properties of butane and other components, as well as specific handling and storage recommendations. Regular updates to these documents are required to reflect the latest safety information and regulatory changes.

Research institutions and laboratories working with INA formulations must adhere to strict safety protocols, including proper storage of butane-containing materials, use of fume hoods, and implementation of emergency response procedures. Institutional review boards often oversee research involving potentially hazardous materials to ensure compliance with safety regulations.

As the understanding of butane's influence on INA formulations evolves, regulatory bodies continue to update and refine safety regulations. This ongoing process involves collaboration between industry experts, researchers, and policymakers to address emerging safety concerns and incorporate new scientific findings into regulatory frameworks.

The Occupational Safety and Health Administration (OSHA) has set strict exposure limits for butane and other volatile organic compounds used in INA formulations. These limits are designed to protect workers from potential health hazards associated with prolonged exposure. Employers are required to implement engineering controls, such as proper ventilation systems, and provide personal protective equipment to minimize risks.

The Environmental Protection Agency (EPA) regulates the environmental impact of INAs and their components, including butane. Manufacturers must adhere to stringent waste disposal protocols and emissions standards to prevent environmental contamination. The EPA also mandates regular environmental impact assessments for facilities producing or utilizing INA formulations.

Transportation of INA formulations containing butane is subject to Department of Transportation (DOT) regulations. These guidelines specify proper packaging, labeling, and handling procedures to ensure safe transport. Vehicles carrying these materials must meet specific safety standards and drivers must undergo specialized training.

The Food and Drug Administration (FDA) oversees the use of INAs in food-related applications, such as freeze-drying processes. Strict guidelines govern the types and quantities of INAs permitted in food production, with particular attention to the potential presence of butane or its derivatives.

International regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, impose additional requirements on manufacturers and importers of INA formulations. These regulations mandate thorough safety assessments and documentation of potential risks associated with butane-influenced INA products.

Safety Data Sheets (SDS) for INA formulations must provide detailed information on the physical and chemical properties of butane and other components, as well as specific handling and storage recommendations. Regular updates to these documents are required to reflect the latest safety information and regulatory changes.

Research institutions and laboratories working with INA formulations must adhere to strict safety protocols, including proper storage of butane-containing materials, use of fume hoods, and implementation of emergency response procedures. Institutional review boards often oversee research involving potentially hazardous materials to ensure compliance with safety regulations.

As the understanding of butane's influence on INA formulations evolves, regulatory bodies continue to update and refine safety regulations. This ongoing process involves collaboration between industry experts, researchers, and policymakers to address emerging safety concerns and incorporate new scientific findings into regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!