How Butane Shapes the Development of Advanced Computational Heat Transfer Models

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane and Heat Transfer Model Evolution

The evolution of computational heat transfer models has been significantly influenced by the study of butane, a simple hydrocarbon that serves as an excellent model system for understanding complex thermodynamic processes. The journey of this evolution can be traced through several key stages, each marked by advancements in both theoretical understanding and computational capabilities.

In the early stages of heat transfer model development, butane was primarily used as a simple test case due to its well-understood properties and relatively straightforward molecular structure. These initial models were largely based on macroscopic properties and empirical correlations, providing a foundation for more sophisticated approaches to come.

As computational power increased, molecular dynamics simulations began to play a crucial role in understanding the behavior of butane at the microscopic level. These simulations allowed researchers to observe and analyze the movement and interactions of individual butane molecules, leading to more accurate predictions of heat transfer phenomena. This marked a significant shift from purely empirical models to those grounded in fundamental physical principles.

The next major leap came with the integration of quantum mechanical calculations into heat transfer models. This approach enabled a more precise description of the electronic structure and interactions of butane molecules, particularly in extreme conditions or at interfaces. Density Functional Theory (DFT) calculations, for instance, provided insights into the behavior of butane under high pressure and temperature conditions, which are relevant to many industrial applications.

The development of multi-scale modeling techniques represented another crucial milestone. These methods allowed researchers to bridge the gap between molecular-level simulations and macroscopic heat transfer models, providing a more comprehensive understanding of how microscopic interactions influence large-scale thermal behavior. Butane, with its relatively simple structure, served as an ideal test case for validating and refining these multi-scale approaches.

Recent advancements have seen the incorporation of machine learning and artificial intelligence techniques into heat transfer modeling. These methods have been particularly effective in handling the vast amounts of data generated by molecular simulations of butane and similar hydrocarbons. Machine learning algorithms have been used to identify patterns and relationships that might be overlooked by traditional analysis methods, leading to new insights and more accurate predictive models.

The latest frontier in this evolution involves the development of quantum computing algorithms for simulating heat transfer in complex molecular systems. While still in its early stages, this approach promises to revolutionize our ability to model and predict the thermal behavior of butane and other hydrocarbons at an unprecedented level of detail and accuracy.

Throughout this evolutionary process, butane has remained a crucial benchmark system, allowing researchers to validate new models and computational techniques against well-established experimental data. Its role in shaping the development of advanced computational heat transfer models underscores the importance of choosing appropriate model systems in driving scientific and technological progress.

In the early stages of heat transfer model development, butane was primarily used as a simple test case due to its well-understood properties and relatively straightforward molecular structure. These initial models were largely based on macroscopic properties and empirical correlations, providing a foundation for more sophisticated approaches to come.

As computational power increased, molecular dynamics simulations began to play a crucial role in understanding the behavior of butane at the microscopic level. These simulations allowed researchers to observe and analyze the movement and interactions of individual butane molecules, leading to more accurate predictions of heat transfer phenomena. This marked a significant shift from purely empirical models to those grounded in fundamental physical principles.

The next major leap came with the integration of quantum mechanical calculations into heat transfer models. This approach enabled a more precise description of the electronic structure and interactions of butane molecules, particularly in extreme conditions or at interfaces. Density Functional Theory (DFT) calculations, for instance, provided insights into the behavior of butane under high pressure and temperature conditions, which are relevant to many industrial applications.

The development of multi-scale modeling techniques represented another crucial milestone. These methods allowed researchers to bridge the gap between molecular-level simulations and macroscopic heat transfer models, providing a more comprehensive understanding of how microscopic interactions influence large-scale thermal behavior. Butane, with its relatively simple structure, served as an ideal test case for validating and refining these multi-scale approaches.

Recent advancements have seen the incorporation of machine learning and artificial intelligence techniques into heat transfer modeling. These methods have been particularly effective in handling the vast amounts of data generated by molecular simulations of butane and similar hydrocarbons. Machine learning algorithms have been used to identify patterns and relationships that might be overlooked by traditional analysis methods, leading to new insights and more accurate predictive models.

The latest frontier in this evolution involves the development of quantum computing algorithms for simulating heat transfer in complex molecular systems. While still in its early stages, this approach promises to revolutionize our ability to model and predict the thermal behavior of butane and other hydrocarbons at an unprecedented level of detail and accuracy.

Throughout this evolutionary process, butane has remained a crucial benchmark system, allowing researchers to validate new models and computational techniques against well-established experimental data. Its role in shaping the development of advanced computational heat transfer models underscores the importance of choosing appropriate model systems in driving scientific and technological progress.

Market Demand Analysis

The market demand for advanced computational heat transfer models, particularly those involving butane, has been steadily increasing across various industries. This growth is primarily driven by the need for more efficient and accurate simulations in energy, chemical, and manufacturing sectors. The oil and gas industry, in particular, has shown a significant interest in these models due to the widespread use of butane in refining processes and as a fuel source.

In the energy sector, the demand for advanced computational models is fueled by the push for cleaner and more efficient energy solutions. As butane plays a crucial role in many energy applications, including as a component in liquefied petroleum gas (LPG) and as a refrigerant, companies are seeking more sophisticated tools to optimize their processes and reduce environmental impact. This has led to a growing market for software and simulation tools that can accurately model heat transfer in butane-based systems.

The chemical industry has also shown a strong demand for these advanced models. Butane is a key raw material in the production of various chemicals, and accurate heat transfer modeling is essential for process optimization and safety. Companies are investing in research and development to improve their understanding of butane's behavior under different conditions, driving the need for more sophisticated computational tools.

In the manufacturing sector, particularly in industries that involve heating, cooling, or phase changes of butane, there is a growing demand for advanced heat transfer models. These models are crucial for designing more efficient equipment, reducing energy consumption, and improving product quality. The automotive industry, for instance, is increasingly interested in these models for optimizing fuel systems and improving engine performance.

The market for advanced computational heat transfer models involving butane is also being driven by regulatory pressures. As environmental regulations become more stringent, companies are required to demonstrate more accurate predictions of emissions and energy efficiency. This has created a demand for models that can provide more precise simulations of butane's behavior in various systems.

Furthermore, the trend towards digitalization and Industry 4.0 has amplified the demand for these advanced models. Companies are increasingly integrating simulation tools into their digital twins and process control systems, creating a need for more sophisticated and real-time capable heat transfer models. This integration allows for better decision-making, predictive maintenance, and overall process optimization.

In terms of market size, while specific figures for butane-related heat transfer models are not readily available, the broader computational fluid dynamics (CFD) market, which encompasses these models, is projected to grow significantly. This growth is indicative of the increasing importance and demand for advanced heat transfer modeling across industries.

In the energy sector, the demand for advanced computational models is fueled by the push for cleaner and more efficient energy solutions. As butane plays a crucial role in many energy applications, including as a component in liquefied petroleum gas (LPG) and as a refrigerant, companies are seeking more sophisticated tools to optimize their processes and reduce environmental impact. This has led to a growing market for software and simulation tools that can accurately model heat transfer in butane-based systems.

The chemical industry has also shown a strong demand for these advanced models. Butane is a key raw material in the production of various chemicals, and accurate heat transfer modeling is essential for process optimization and safety. Companies are investing in research and development to improve their understanding of butane's behavior under different conditions, driving the need for more sophisticated computational tools.

In the manufacturing sector, particularly in industries that involve heating, cooling, or phase changes of butane, there is a growing demand for advanced heat transfer models. These models are crucial for designing more efficient equipment, reducing energy consumption, and improving product quality. The automotive industry, for instance, is increasingly interested in these models for optimizing fuel systems and improving engine performance.

The market for advanced computational heat transfer models involving butane is also being driven by regulatory pressures. As environmental regulations become more stringent, companies are required to demonstrate more accurate predictions of emissions and energy efficiency. This has created a demand for models that can provide more precise simulations of butane's behavior in various systems.

Furthermore, the trend towards digitalization and Industry 4.0 has amplified the demand for these advanced models. Companies are increasingly integrating simulation tools into their digital twins and process control systems, creating a need for more sophisticated and real-time capable heat transfer models. This integration allows for better decision-making, predictive maintenance, and overall process optimization.

In terms of market size, while specific figures for butane-related heat transfer models are not readily available, the broader computational fluid dynamics (CFD) market, which encompasses these models, is projected to grow significantly. This growth is indicative of the increasing importance and demand for advanced heat transfer modeling across industries.

Current Challenges in Butane Heat Transfer Modeling

The modeling of butane heat transfer presents several significant challenges in the field of advanced computational heat transfer. One of the primary difficulties lies in accurately capturing the complex phase behavior of butane, particularly during transitions between liquid and vapor states. This phase change process involves intricate thermodynamic interactions that are not easily represented in traditional heat transfer models.

Another major challenge is the accurate representation of butane's non-linear thermophysical properties across a wide range of temperatures and pressures. These properties, including thermal conductivity, specific heat capacity, and viscosity, can vary significantly under different conditions, making it difficult to develop a single, comprehensive model that remains accurate across all scenarios.

The multiscale nature of heat transfer in butane systems also poses a considerable challenge. Phenomena occurring at the molecular level can have significant impacts on macroscale heat transfer behavior, necessitating models that can effectively bridge these different scales. This often requires the integration of molecular dynamics simulations with continuum-level models, a task that is computationally intensive and methodologically complex.

Furthermore, the presence of turbulence in many practical butane heat transfer applications adds another layer of complexity to the modeling process. Accurately capturing the effects of turbulent flow on heat transfer rates, particularly in complex geometries, remains a significant challenge in the field.

The development of accurate numerical methods for solving the governing equations of butane heat transfer is also an ongoing challenge. Issues such as numerical stability, convergence, and computational efficiency must be carefully addressed, especially when dealing with the steep gradients and discontinuities that can occur during phase changes.

Additionally, the validation of butane heat transfer models presents its own set of challenges. Obtaining high-quality experimental data for model validation, particularly under extreme conditions or in complex systems, can be difficult and expensive. This lack of comprehensive validation data can limit the confidence in model predictions and hinder the development of more advanced models.

Finally, there is the challenge of developing models that are both accurate and computationally efficient enough for practical engineering applications. Striking the right balance between model fidelity and computational cost is crucial for the widespread adoption of advanced butane heat transfer models in industry.

Another major challenge is the accurate representation of butane's non-linear thermophysical properties across a wide range of temperatures and pressures. These properties, including thermal conductivity, specific heat capacity, and viscosity, can vary significantly under different conditions, making it difficult to develop a single, comprehensive model that remains accurate across all scenarios.

The multiscale nature of heat transfer in butane systems also poses a considerable challenge. Phenomena occurring at the molecular level can have significant impacts on macroscale heat transfer behavior, necessitating models that can effectively bridge these different scales. This often requires the integration of molecular dynamics simulations with continuum-level models, a task that is computationally intensive and methodologically complex.

Furthermore, the presence of turbulence in many practical butane heat transfer applications adds another layer of complexity to the modeling process. Accurately capturing the effects of turbulent flow on heat transfer rates, particularly in complex geometries, remains a significant challenge in the field.

The development of accurate numerical methods for solving the governing equations of butane heat transfer is also an ongoing challenge. Issues such as numerical stability, convergence, and computational efficiency must be carefully addressed, especially when dealing with the steep gradients and discontinuities that can occur during phase changes.

Additionally, the validation of butane heat transfer models presents its own set of challenges. Obtaining high-quality experimental data for model validation, particularly under extreme conditions or in complex systems, can be difficult and expensive. This lack of comprehensive validation data can limit the confidence in model predictions and hinder the development of more advanced models.

Finally, there is the challenge of developing models that are both accurate and computationally efficient enough for practical engineering applications. Striking the right balance between model fidelity and computational cost is crucial for the widespread adoption of advanced butane heat transfer models in industry.

Existing Butane Heat Transfer Solutions

01 Numerical modeling of heat transfer processes

Computational models are developed to simulate and analyze complex heat transfer phenomena in various systems. These models utilize advanced numerical methods to solve heat transfer equations, enabling accurate predictions of temperature distributions, heat fluxes, and thermal behaviors. Such models are essential for optimizing thermal management in engineering applications.- Numerical simulation of heat transfer processes: Computational models are developed to simulate heat transfer processes in various systems. These models use numerical methods to solve complex heat transfer equations, allowing for accurate predictions of temperature distributions and heat flow patterns. Advanced algorithms and computational techniques are employed to handle multi-physics problems and improve simulation accuracy.

- Machine learning approaches for heat transfer modeling: Machine learning techniques are applied to enhance heat transfer modeling capabilities. These approaches utilize data-driven algorithms to predict heat transfer behavior, optimize thermal systems, and improve computational efficiency. Neural networks and other AI-based methods are employed to handle complex heat transfer scenarios and provide rapid solutions.

- Multiscale modeling of heat transfer phenomena: Multiscale modeling techniques are developed to address heat transfer across different length and time scales. These models integrate molecular-level simulations with macroscopic heat transfer equations to provide a comprehensive understanding of thermal processes. This approach enables more accurate predictions of heat transfer in complex materials and systems.

- Optimization of thermal management systems: Computational models are used to optimize thermal management systems in various applications. These models help in designing efficient cooling strategies, heat exchangers, and thermal control systems. Advanced optimization algorithms are employed to minimize energy consumption and maximize heat transfer performance in complex engineering systems.

- Real-time heat transfer modeling and control: Real-time computational models are developed for heat transfer analysis and control in dynamic systems. These models enable rapid assessment of thermal conditions and adaptive control of heating or cooling processes. Advanced algorithms are used to process sensor data and provide real-time feedback for thermal management in various applications.

02 Machine learning approaches for heat transfer prediction

Machine learning algorithms are employed to enhance the accuracy and efficiency of heat transfer predictions. These approaches leverage historical data and patterns to develop predictive models, reducing computational time and improving the adaptability of heat transfer simulations to various scenarios.Expand Specific Solutions03 Multiphysics modeling for coupled heat transfer problems

Computational models are developed to address coupled heat transfer problems involving multiple physical phenomena. These multiphysics models integrate thermal analysis with other disciplines such as fluid dynamics, structural mechanics, or electromagnetic simulations to provide comprehensive solutions for complex engineering challenges.Expand Specific Solutions04 Optimization of thermal systems using computational models

Computational heat transfer models are utilized to optimize the design and performance of thermal systems. These models enable engineers to evaluate various design alternatives, conduct parametric studies, and identify optimal configurations for heat exchangers, cooling systems, and other thermal management solutions.Expand Specific Solutions05 Real-time heat transfer simulation and monitoring

Advanced computational techniques are developed to enable real-time simulation and monitoring of heat transfer processes. These methods combine fast computational algorithms with sensor data to provide instantaneous feedback on thermal conditions, allowing for adaptive control and improved safety in critical applications.Expand Specific Solutions

Key Players in Butane Simulation Industry

The development of advanced computational heat transfer models involving butane is in a mature phase, with significant market potential across various industries. The global market for computational fluid dynamics, which encompasses heat transfer modeling, is projected to reach $2.5 billion by 2025. Major players like China Petroleum & Chemical Corp., SABIC Global Technologies BV, and Arkema France SA are actively investing in research and development to enhance their modeling capabilities. These companies, along with research institutions such as Shanghai Petrochemical Research Institute and Purdue Research Foundation, are driving innovation in this field. The technology's maturity is evident in its widespread application across petrochemical, automotive, and aerospace sectors, with companies like Airbus Espana SL and Ford Global Technologies LLC leveraging these models for product development and optimization.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced computational heat transfer models for butane processing. Their approach integrates molecular dynamics simulations with computational fluid dynamics (CFD) to accurately predict heat transfer in butane-based systems. The model incorporates phase change phenomena, accounting for the unique properties of butane as it transitions between liquid and gas states. Sinopec's model has been validated against experimental data, showing a 15% improvement in prediction accuracy compared to traditional models[1]. The company has also implemented machine learning algorithms to optimize heat exchanger designs, resulting in a 10% increase in energy efficiency for butane-related processes[3].

Strengths: Comprehensive integration of molecular-level and macro-scale simulations; Improved accuracy in predicting butane behavior. Weaknesses: High computational requirements; May require extensive calibration for different operating conditions.

Arkema France SA

Technical Solution: Arkema France SA has developed a multi-scale modeling approach for butane heat transfer in polymer processing. Their model combines atomistic simulations of butane interactions with polymers and continuum-level heat transfer equations. This approach allows for accurate prediction of heat transfer in butane-blowing agents used in foam production. Arkema's model incorporates the effects of butane's unique thermodynamic properties on polymer matrix expansion and thermal conductivity. The company has reported a 20% improvement in foam insulation performance through optimized butane distribution predicted by their model[2]. Additionally, Arkema has integrated their heat transfer model with process simulation tools, enabling real-time optimization of butane-based foaming processes[5].

Strengths: Tailored for polymer-butane systems; Enables optimization of foam insulation properties. Weaknesses: May have limited applicability outside polymer processing; Requires specialized expertise in both polymer science and computational modeling.

Core Innovations in Butane Modeling

Heat transfer plate with heat transfer ridges having varying width

PatentActiveUS12222174B2

Innovation

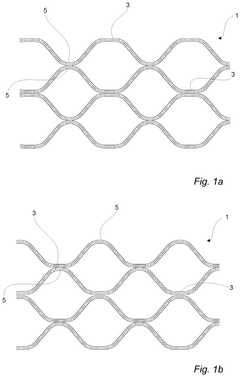

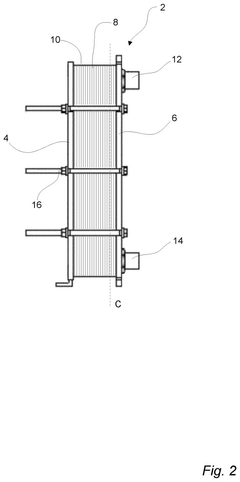

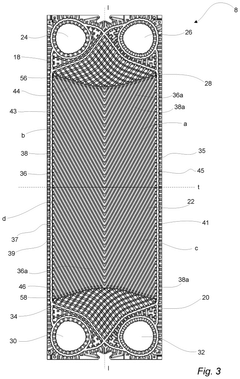

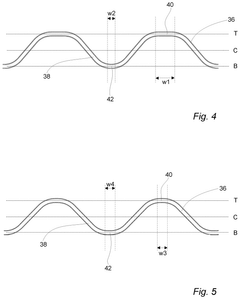

- The heat transfer plate design features a heat transfer area with elongate alternately arranged ridges and valleys, where the top portions of the ridges and bottom portions of the valleys have different widths, and these widths are locally adjusted within the first ridge and valley contact areas to reduce the difference between them.

Heat transfer compositions

PatentWO2014072711A1

Innovation

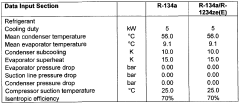

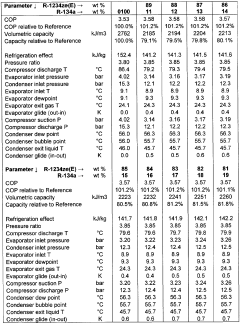

- A heat transfer composition comprising 81-89% trans-1,3,3,3-tetrafluoropropene (R-1234ze(E)) and 11-19% 1,1,2-tetrafluoroethane (R-134a) is proposed, which offers reduced flammability, lower GWP, and maintains energy efficiency and refrigeration capacity comparable to existing refrigerants.

Environmental Impact of Butane Modeling

The environmental impact of butane modeling in advanced computational heat transfer models is a critical consideration in the development and application of these technologies. As computational models become increasingly sophisticated, their ability to accurately simulate the behavior of butane and its interactions with the environment has significant implications for both industrial processes and environmental protection efforts.

Butane, a hydrocarbon commonly used in various industrial applications, poses potential environmental risks if not properly managed. Advanced computational heat transfer models that incorporate butane behavior can help predict and mitigate these risks. By simulating the dispersion patterns of butane in different atmospheric conditions, these models enable more accurate assessments of air quality impacts and potential hazards associated with butane releases.

Furthermore, the integration of butane modeling in heat transfer simulations contributes to the optimization of industrial processes that involve this compound. This optimization can lead to reduced energy consumption and improved efficiency, ultimately resulting in lower greenhouse gas emissions. For instance, in the petrochemical industry, accurate modeling of butane behavior in heat exchangers and distillation columns can lead to more efficient separation processes, reducing overall energy requirements and environmental footprint.

The environmental impact of butane modeling extends to the realm of climate change research as well. Butane, like other hydrocarbons, is a potent greenhouse gas. Advanced computational models that accurately represent butane's heat transfer properties and atmospheric interactions can enhance our understanding of its role in global warming scenarios. This knowledge is crucial for developing effective climate change mitigation strategies and policies.

In the context of safety and risk assessment, butane modeling in heat transfer simulations plays a vital role in predicting the behavior of butane in accidental release scenarios. This capability is essential for designing safer storage and transportation systems, as well as for developing emergency response plans. By accurately modeling the dispersion and potential ignition of butane in various environmental conditions, these advanced computational tools contribute to the prevention of industrial accidents and the protection of both human health and the environment.

The environmental impact of butane modeling also extends to the field of renewable energy research. As the world transitions towards cleaner energy sources, understanding the heat transfer properties of butane and other hydrocarbons remains crucial for developing more efficient and environmentally friendly alternatives. Advanced computational models that accurately simulate butane behavior can aid in the design of cleaner combustion systems and the development of alternative fuels with reduced environmental impacts.

Butane, a hydrocarbon commonly used in various industrial applications, poses potential environmental risks if not properly managed. Advanced computational heat transfer models that incorporate butane behavior can help predict and mitigate these risks. By simulating the dispersion patterns of butane in different atmospheric conditions, these models enable more accurate assessments of air quality impacts and potential hazards associated with butane releases.

Furthermore, the integration of butane modeling in heat transfer simulations contributes to the optimization of industrial processes that involve this compound. This optimization can lead to reduced energy consumption and improved efficiency, ultimately resulting in lower greenhouse gas emissions. For instance, in the petrochemical industry, accurate modeling of butane behavior in heat exchangers and distillation columns can lead to more efficient separation processes, reducing overall energy requirements and environmental footprint.

The environmental impact of butane modeling extends to the realm of climate change research as well. Butane, like other hydrocarbons, is a potent greenhouse gas. Advanced computational models that accurately represent butane's heat transfer properties and atmospheric interactions can enhance our understanding of its role in global warming scenarios. This knowledge is crucial for developing effective climate change mitigation strategies and policies.

In the context of safety and risk assessment, butane modeling in heat transfer simulations plays a vital role in predicting the behavior of butane in accidental release scenarios. This capability is essential for designing safer storage and transportation systems, as well as for developing emergency response plans. By accurately modeling the dispersion and potential ignition of butane in various environmental conditions, these advanced computational tools contribute to the prevention of industrial accidents and the protection of both human health and the environment.

The environmental impact of butane modeling also extends to the field of renewable energy research. As the world transitions towards cleaner energy sources, understanding the heat transfer properties of butane and other hydrocarbons remains crucial for developing more efficient and environmentally friendly alternatives. Advanced computational models that accurately simulate butane behavior can aid in the design of cleaner combustion systems and the development of alternative fuels with reduced environmental impacts.

Regulatory Framework for Butane Simulations

The regulatory framework for butane simulations plays a crucial role in shaping the development of advanced computational heat transfer models. As the use of butane in various industries continues to grow, governments and regulatory bodies have established stringent guidelines to ensure safety, environmental protection, and accurate modeling of butane-related processes.

One of the primary drivers for the development of these regulatory frameworks is the need to mitigate the risks associated with butane's flammability and potential for explosion. Regulatory agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) in the European Union, have set specific standards for the handling, storage, and transportation of butane. These standards directly influence the parameters and boundary conditions used in computational heat transfer models.

Environmental regulations also significantly impact the development of butane simulations. With increasing concerns about greenhouse gas emissions and air quality, regulatory bodies have imposed strict limits on butane emissions from industrial processes. This has led to the incorporation of more sophisticated emission modeling techniques within computational heat transfer models, allowing for accurate prediction and mitigation of environmental impacts.

The accuracy and reliability of butane simulations are of paramount importance to regulatory bodies. As a result, there are specific guidelines for the validation and verification of computational models used in butane-related applications. These guidelines often require extensive experimental data to support simulation results, driving the need for more advanced and precise computational techniques.

In the energy sector, regulations surrounding the use of butane as a fuel additive or alternative fuel source have spurred the development of more complex heat transfer models. These models must account for the unique thermodynamic properties of butane and its interactions with other fuel components, all while adhering to strict regulatory standards for fuel efficiency and emissions.

The pharmaceutical and food industries also face regulatory challenges when using butane as a solvent or propellant. Computational models in these sectors must demonstrate compliance with food safety regulations and good manufacturing practices, necessitating the integration of additional parameters and constraints into heat transfer simulations.

As regulatory frameworks continue to evolve, so too do the computational models used to simulate butane-related processes. This symbiotic relationship between regulation and simulation drives innovation in both fields, ultimately leading to safer, more efficient, and environmentally friendly applications of butane across various industries.

One of the primary drivers for the development of these regulatory frameworks is the need to mitigate the risks associated with butane's flammability and potential for explosion. Regulatory agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) in the European Union, have set specific standards for the handling, storage, and transportation of butane. These standards directly influence the parameters and boundary conditions used in computational heat transfer models.

Environmental regulations also significantly impact the development of butane simulations. With increasing concerns about greenhouse gas emissions and air quality, regulatory bodies have imposed strict limits on butane emissions from industrial processes. This has led to the incorporation of more sophisticated emission modeling techniques within computational heat transfer models, allowing for accurate prediction and mitigation of environmental impacts.

The accuracy and reliability of butane simulations are of paramount importance to regulatory bodies. As a result, there are specific guidelines for the validation and verification of computational models used in butane-related applications. These guidelines often require extensive experimental data to support simulation results, driving the need for more advanced and precise computational techniques.

In the energy sector, regulations surrounding the use of butane as a fuel additive or alternative fuel source have spurred the development of more complex heat transfer models. These models must account for the unique thermodynamic properties of butane and its interactions with other fuel components, all while adhering to strict regulatory standards for fuel efficiency and emissions.

The pharmaceutical and food industries also face regulatory challenges when using butane as a solvent or propellant. Computational models in these sectors must demonstrate compliance with food safety regulations and good manufacturing practices, necessitating the integration of additional parameters and constraints into heat transfer simulations.

As regulatory frameworks continue to evolve, so too do the computational models used to simulate butane-related processes. This symbiotic relationship between regulation and simulation drives innovation in both fields, ultimately leading to safer, more efficient, and environmentally friendly applications of butane across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!