The Utilization of Butane in Advanced Sterilization Techniques

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Sterilization Background and Objectives

Butane sterilization has emerged as a promising technique in the field of advanced sterilization methods. The utilization of butane for sterilization purposes has its roots in the broader context of gas sterilization, which has been a subject of research and development for several decades. Initially, ethylene oxide was the primary gas used for sterilization, but concerns over its toxicity and environmental impact led to the exploration of alternative gases.

The evolution of butane sterilization technology can be traced back to the early 2000s when researchers began investigating the potential of hydrocarbon gases for sterilization applications. Butane, being readily available and relatively safe to handle, quickly gained attention as a viable candidate. The initial studies focused on understanding the mechanism by which butane could effectively eliminate microorganisms and assessing its efficacy against various pathogens.

As research progressed, the objectives of butane sterilization technology became more refined. The primary goal has been to develop a sterilization method that is not only highly effective but also safe, cost-efficient, and environmentally friendly. Researchers have aimed to optimize the sterilization process by determining the ideal concentration of butane, exposure time, and temperature conditions required for complete microbial inactivation.

One of the key objectives in the development of butane sterilization has been to overcome the limitations of traditional sterilization methods. Conventional techniques such as autoclaving and chemical sterilization often have drawbacks, including high energy consumption, potential damage to sensitive materials, and long processing times. Butane sterilization aims to address these issues by offering a low-temperature, rapid, and gentle sterilization option.

Another significant goal in the advancement of butane sterilization technology has been to expand its applicability across various industries. While initially focused on medical device sterilization, researchers have been exploring its potential use in food processing, pharmaceutical manufacturing, and even space exploration. This broadening of scope has driven efforts to adapt the technology for different types of materials and environments.

The development of butane sterilization techniques has also been influenced by the growing emphasis on sustainability in industrial processes. As such, a key objective has been to design systems that minimize environmental impact, reduce energy consumption, and allow for the recycling or safe disposal of the sterilant gas. This aligns with global efforts to transition towards more eco-friendly manufacturing and healthcare practices.

In recent years, the focus has shifted towards enhancing the precision and control of butane sterilization processes. Researchers are working on developing advanced monitoring systems and predictive models to ensure consistent and reliable sterilization outcomes. This includes the integration of sensors and data analytics to provide real-time feedback and optimize process parameters dynamically.

The evolution of butane sterilization technology can be traced back to the early 2000s when researchers began investigating the potential of hydrocarbon gases for sterilization applications. Butane, being readily available and relatively safe to handle, quickly gained attention as a viable candidate. The initial studies focused on understanding the mechanism by which butane could effectively eliminate microorganisms and assessing its efficacy against various pathogens.

As research progressed, the objectives of butane sterilization technology became more refined. The primary goal has been to develop a sterilization method that is not only highly effective but also safe, cost-efficient, and environmentally friendly. Researchers have aimed to optimize the sterilization process by determining the ideal concentration of butane, exposure time, and temperature conditions required for complete microbial inactivation.

One of the key objectives in the development of butane sterilization has been to overcome the limitations of traditional sterilization methods. Conventional techniques such as autoclaving and chemical sterilization often have drawbacks, including high energy consumption, potential damage to sensitive materials, and long processing times. Butane sterilization aims to address these issues by offering a low-temperature, rapid, and gentle sterilization option.

Another significant goal in the advancement of butane sterilization technology has been to expand its applicability across various industries. While initially focused on medical device sterilization, researchers have been exploring its potential use in food processing, pharmaceutical manufacturing, and even space exploration. This broadening of scope has driven efforts to adapt the technology for different types of materials and environments.

The development of butane sterilization techniques has also been influenced by the growing emphasis on sustainability in industrial processes. As such, a key objective has been to design systems that minimize environmental impact, reduce energy consumption, and allow for the recycling or safe disposal of the sterilant gas. This aligns with global efforts to transition towards more eco-friendly manufacturing and healthcare practices.

In recent years, the focus has shifted towards enhancing the precision and control of butane sterilization processes. Researchers are working on developing advanced monitoring systems and predictive models to ensure consistent and reliable sterilization outcomes. This includes the integration of sensors and data analytics to provide real-time feedback and optimize process parameters dynamically.

Market Analysis for Advanced Sterilization Solutions

The global market for advanced sterilization solutions is experiencing significant growth, driven by increasing awareness of infection control, stringent regulations in healthcare settings, and the need for more efficient and effective sterilization methods. The utilization of butane in advanced sterilization techniques represents a promising segment within this market, offering potential advantages over traditional sterilization methods.

The healthcare sector, particularly hospitals and surgical centers, remains the primary consumer of advanced sterilization solutions. With the rising incidence of healthcare-associated infections (HAIs) and the growing emphasis on patient safety, there is a strong demand for innovative sterilization technologies that can effectively eliminate a wide range of pathogens while being safe for use on sensitive medical equipment.

Butane-based sterilization techniques are gaining traction due to their ability to operate at lower temperatures compared to conventional steam sterilization methods. This characteristic makes them particularly suitable for heat-sensitive medical devices and materials, addressing a critical need in the market. The pharmaceutical and biotechnology industries are also showing increased interest in these advanced sterilization solutions for their manufacturing processes and research applications.

Geographically, North America and Europe currently dominate the market for advanced sterilization solutions, including butane-based technologies. However, rapid healthcare infrastructure development and increasing healthcare expenditure in emerging economies of Asia-Pacific and Latin America are expected to drive significant market growth in these regions over the coming years.

The market is characterized by intense competition among key players, with continuous investment in research and development to enhance sterilization efficacy, reduce cycle times, and improve overall operational efficiency. Collaborations between sterilization equipment manufacturers and medical device companies are becoming more common, aiming to develop tailored sterilization solutions for specific product lines.

Regulatory approvals play a crucial role in market dynamics, with stringent guidelines set by bodies such as the FDA and EMA influencing adoption rates and market penetration of new sterilization technologies. The increasing focus on environmental sustainability is also shaping market trends, with butane-based systems potentially offering advantages in terms of reduced energy consumption and environmental impact compared to some traditional methods.

As healthcare facilities seek to optimize their sterilization processes, there is a growing demand for integrated sterilization solutions that offer improved traceability, automation, and compatibility with various medical devices. This trend is driving the development of more sophisticated butane-based sterilization systems that incorporate advanced monitoring and control features.

The healthcare sector, particularly hospitals and surgical centers, remains the primary consumer of advanced sterilization solutions. With the rising incidence of healthcare-associated infections (HAIs) and the growing emphasis on patient safety, there is a strong demand for innovative sterilization technologies that can effectively eliminate a wide range of pathogens while being safe for use on sensitive medical equipment.

Butane-based sterilization techniques are gaining traction due to their ability to operate at lower temperatures compared to conventional steam sterilization methods. This characteristic makes them particularly suitable for heat-sensitive medical devices and materials, addressing a critical need in the market. The pharmaceutical and biotechnology industries are also showing increased interest in these advanced sterilization solutions for their manufacturing processes and research applications.

Geographically, North America and Europe currently dominate the market for advanced sterilization solutions, including butane-based technologies. However, rapid healthcare infrastructure development and increasing healthcare expenditure in emerging economies of Asia-Pacific and Latin America are expected to drive significant market growth in these regions over the coming years.

The market is characterized by intense competition among key players, with continuous investment in research and development to enhance sterilization efficacy, reduce cycle times, and improve overall operational efficiency. Collaborations between sterilization equipment manufacturers and medical device companies are becoming more common, aiming to develop tailored sterilization solutions for specific product lines.

Regulatory approvals play a crucial role in market dynamics, with stringent guidelines set by bodies such as the FDA and EMA influencing adoption rates and market penetration of new sterilization technologies. The increasing focus on environmental sustainability is also shaping market trends, with butane-based systems potentially offering advantages in terms of reduced energy consumption and environmental impact compared to some traditional methods.

As healthcare facilities seek to optimize their sterilization processes, there is a growing demand for integrated sterilization solutions that offer improved traceability, automation, and compatibility with various medical devices. This trend is driving the development of more sophisticated butane-based sterilization systems that incorporate advanced monitoring and control features.

Current Butane Sterilization Challenges

The utilization of butane in advanced sterilization techniques faces several significant challenges that hinder its widespread adoption and efficacy. One of the primary obstacles is the potential safety hazards associated with butane's flammability. As a highly combustible gas, butane requires stringent safety protocols and specialized equipment for handling and storage, which can increase operational costs and complexity.

Another challenge lies in achieving consistent and uniform sterilization across various materials and surfaces. Butane's gaseous nature can lead to uneven distribution within sterilization chambers, potentially resulting in inadequate sterilization of certain areas or items. This issue is particularly pronounced when dealing with complex geometries or porous materials, where ensuring complete penetration of the sterilizing agent is crucial.

The environmental impact of butane sterilization is also a growing concern. While butane is generally considered less harmful than some traditional sterilization agents, it still contributes to greenhouse gas emissions. Regulatory bodies are increasingly scrutinizing the use of volatile organic compounds (VOCs) in industrial processes, which may lead to stricter controls on butane usage in sterilization applications.

Efficacy validation presents another significant challenge. Developing reliable and standardized methods to verify the complete elimination of microorganisms across diverse materials and conditions is essential for regulatory approval and widespread adoption. This process is complicated by the need to ensure that butane sterilization is effective against a broad spectrum of pathogens, including highly resistant spores.

The integration of butane sterilization into existing manufacturing and healthcare processes poses logistical and technical challenges. Many facilities are designed for traditional sterilization methods, and retrofitting them for butane-based systems can be costly and disruptive. Additionally, staff training and adaptation to new protocols are necessary to ensure safe and effective implementation.

Scalability is another hurdle in the advancement of butane sterilization techniques. While the method may be effective on a small scale, scaling up to industrial levels while maintaining efficiency and cost-effectiveness remains a significant challenge. This includes optimizing cycle times, minimizing butane consumption, and ensuring consistent results across large batches of diverse items.

Lastly, regulatory approval and acceptance in various industries present ongoing challenges. Different sectors, such as healthcare, food processing, and pharmaceuticals, have distinct regulatory requirements for sterilization processes. Obtaining necessary certifications and demonstrating equivalence or superiority to established methods is a time-consuming and resource-intensive process that can slow the adoption of butane sterilization technologies.

Another challenge lies in achieving consistent and uniform sterilization across various materials and surfaces. Butane's gaseous nature can lead to uneven distribution within sterilization chambers, potentially resulting in inadequate sterilization of certain areas or items. This issue is particularly pronounced when dealing with complex geometries or porous materials, where ensuring complete penetration of the sterilizing agent is crucial.

The environmental impact of butane sterilization is also a growing concern. While butane is generally considered less harmful than some traditional sterilization agents, it still contributes to greenhouse gas emissions. Regulatory bodies are increasingly scrutinizing the use of volatile organic compounds (VOCs) in industrial processes, which may lead to stricter controls on butane usage in sterilization applications.

Efficacy validation presents another significant challenge. Developing reliable and standardized methods to verify the complete elimination of microorganisms across diverse materials and conditions is essential for regulatory approval and widespread adoption. This process is complicated by the need to ensure that butane sterilization is effective against a broad spectrum of pathogens, including highly resistant spores.

The integration of butane sterilization into existing manufacturing and healthcare processes poses logistical and technical challenges. Many facilities are designed for traditional sterilization methods, and retrofitting them for butane-based systems can be costly and disruptive. Additionally, staff training and adaptation to new protocols are necessary to ensure safe and effective implementation.

Scalability is another hurdle in the advancement of butane sterilization techniques. While the method may be effective on a small scale, scaling up to industrial levels while maintaining efficiency and cost-effectiveness remains a significant challenge. This includes optimizing cycle times, minimizing butane consumption, and ensuring consistent results across large batches of diverse items.

Lastly, regulatory approval and acceptance in various industries present ongoing challenges. Different sectors, such as healthcare, food processing, and pharmaceuticals, have distinct regulatory requirements for sterilization processes. Obtaining necessary certifications and demonstrating equivalence or superiority to established methods is a time-consuming and resource-intensive process that can slow the adoption of butane sterilization technologies.

Existing Butane Sterilization Methods

01 Butane-based sterilization systems

Sterilization systems utilizing butane as a primary component for disinfecting various objects and surfaces. These systems may include specialized equipment for applying butane in controlled environments to achieve effective sterilization.- Butane sterilization methods: Various methods for sterilizing using butane gas have been developed. These methods may involve specific equipment, pressure conditions, or combinations with other substances to achieve effective sterilization. The processes are designed to eliminate microorganisms and ensure sterility in different applications.

- Butane-based sterilization devices: Specialized devices have been invented for sterilization using butane. These may include portable sterilizers, industrial-scale equipment, or integrated systems in other machinery. The devices are engineered to safely and effectively utilize butane for sterilization purposes in various settings.

- Butane purification for sterilization: Techniques for purifying butane to make it suitable for sterilization applications have been developed. These methods may involve removing impurities, adjusting the composition, or enhancing specific properties of butane to improve its sterilization efficacy and safety.

- Combination of butane with other sterilizing agents: Research has been conducted on combining butane with other sterilizing agents or substances to enhance sterilization effectiveness. These combinations may provide synergistic effects, broader spectrum of action, or improved penetration for sterilization purposes.

- Safety measures in butane sterilization: Given the flammable nature of butane, safety measures and protocols have been developed for its use in sterilization. These may include specialized containment systems, monitoring devices, or operational procedures to ensure safe handling and application of butane in sterilization processes.

02 Butane purification for sterilization purposes

Methods and apparatus for purifying butane to enhance its sterilization properties. This may involve removing impurities or adjusting the composition of butane to optimize its effectiveness as a sterilizing agent.Expand Specific Solutions03 Butane sterilization in medical applications

Specific applications of butane sterilization in medical settings, including sterilization of medical devices, surgical instruments, and healthcare facilities. This may involve specialized protocols and equipment designed for medical-grade sterilization.Expand Specific Solutions04 Butane sterilization in food processing

Use of butane for sterilization in food processing and packaging industries. This may include methods for sterilizing food containers, processing equipment, and packaging materials to ensure food safety and extend shelf life.Expand Specific Solutions05 Safety measures in butane sterilization

Safety protocols and equipment designed to mitigate risks associated with using butane for sterilization. This may include ventilation systems, fire prevention measures, and personal protective equipment for operators handling butane in sterilization processes.Expand Specific Solutions

Key Players in Butane Sterilization Industry

The utilization of butane in advanced sterilization techniques is an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research and development activities. While the market size is still relatively small, it is expected to expand rapidly due to the growing demand for efficient and safe sterilization methods across various industries. Technologically, the field is progressing, with companies like ExxonMobil Chemical Patents, SABIC Global Technologies, and China Petroleum & Chemical Corp. leading the way in developing innovative applications. Academic institutions such as China Agricultural University and Nanjing Tech University are also contributing to the advancement of this technology, indicating a collaborative approach between industry and academia in driving progress.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a butane-based sterilization process that utilizes supercritical fluid technology. Their method involves creating a supercritical mixture of carbon dioxide and butane (5-15% butane) at pressures above 73 bar and temperatures between 31-50°C[10]. This supercritical fluid is then used as a carrier for a small amount of peracetic acid (0.1-0.5%) or hydrogen peroxide (0.5-2%). The supercritical state allows for excellent penetration into complex geometries and porous materials. The sterilization cycle typically lasts 30-60 minutes, followed by a rapid depressurization phase that aids in the removal of residual sterilants[11]. Dow's system includes precise pressure and temperature control mechanisms to maintain optimal supercritical conditions throughout the process.

Strengths: Excellent penetration, short cycle times, low residuals, compatibility with heat-sensitive materials. Weaknesses: High equipment costs, complexity of the system, potential regulatory hurdles for novel technology.

Ethicon, Inc.

Technical Solution: Ethicon has developed an advanced sterilization technique utilizing butane as a key component. Their method involves creating a sterilizing gas mixture containing 1-5% butane, 30-50% ethylene oxide, and the remainder being an inert carrier gas[1]. This mixture is applied in a pressurized chamber at temperatures between 40-60°C for 1-4 hours[2]. The addition of butane enhances the penetration of ethylene oxide into hard-to-reach areas of medical devices, improving sterilization efficacy. Ethicon's process also incorporates a post-sterilization aeration phase to remove residual gases, ensuring product safety[3].

Strengths: Enhanced penetration of sterilant, improved efficacy for complex medical devices, reduced sterilization time. Weaknesses: Potential flammability concerns, need for specialized equipment, regulatory challenges due to use of multiple gases.

Innovative Butane Sterilization Technologies

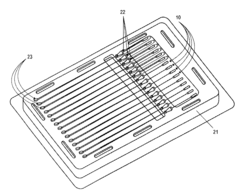

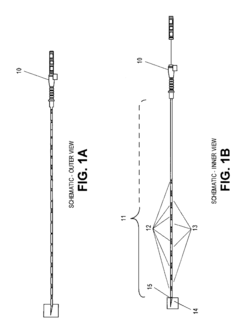

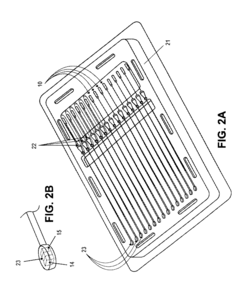

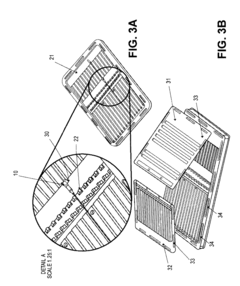

Delivery system and prescription method for interstitial radiation therapy using enhanced parametric release sterilization techniques

PatentInactiveUS7540998B2

Innovation

- A delivery system and method for interstitial radiation therapy using enhanced parametric release sterilization techniques, where ethylene oxide (EtO) sterilization is optimized through controlled physical parameters, eliminating the need for bio-indicators by ensuring consistent sterilization based on documented process parameters, reducing sterilization time, and maintaining seed spacing and positioning.

Method of sterilizing plant pollen

PatentWO1989008401A1

Innovation

- A method involving the use of specific sterilizing agents, such as alkyl and phenyl derivatives, in combination with diluents and emulsifiers, applied during the fifth and sixth stages of organogenesis, to achieve effective sterilization and maintain high seed setting rates while ensuring male plant fertility.

Safety and Regulatory Considerations

The utilization of butane in advanced sterilization techniques presents significant safety and regulatory considerations that must be carefully addressed. Butane, being a highly flammable hydrocarbon, requires stringent safety protocols to mitigate risks associated with its use in sterilization processes. Proper ventilation systems and explosion-proof equipment are essential to prevent the accumulation of butane vapors and minimize the potential for fire or explosion hazards.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established specific guidelines for the handling and use of flammable gases like butane in industrial settings. These regulations typically mandate the implementation of comprehensive safety management systems, including regular equipment inspections, employee training programs, and emergency response procedures.

In the context of sterilization applications, the use of butane must comply with relevant industry standards and regulations governing medical device sterilization. Organizations such as the International Organization for Standardization (ISO) and the Association for the Advancement of Medical Instrumentation (AAMI) provide guidelines for sterilization processes, including those involving flammable gases. Adherence to these standards is crucial for ensuring the safety and efficacy of sterilized products.

Environmental considerations also play a significant role in the regulatory landscape surrounding butane-based sterilization techniques. Emissions control measures may be required to minimize the release of volatile organic compounds (VOCs) into the atmosphere, in compliance with local and national environmental regulations. Additionally, proper disposal protocols for any waste products generated during the sterilization process must be established and followed.

The transportation and storage of butane for sterilization purposes are subject to strict regulations due to its classification as a hazardous material. Compliance with the United Nations Recommendations on the Transport of Dangerous Goods and similar national regulations is essential for the safe movement of butane between facilities.

As advanced sterilization techniques involving butane continue to evolve, ongoing regulatory assessment and adaptation will be necessary. Manufacturers and users of such sterilization systems must stay informed about changes in safety standards and regulatory requirements to ensure continued compliance and safe operation. This may involve regular audits, documentation of safety procedures, and engagement with regulatory bodies to address any emerging concerns or requirements specific to butane-based sterilization methods.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established specific guidelines for the handling and use of flammable gases like butane in industrial settings. These regulations typically mandate the implementation of comprehensive safety management systems, including regular equipment inspections, employee training programs, and emergency response procedures.

In the context of sterilization applications, the use of butane must comply with relevant industry standards and regulations governing medical device sterilization. Organizations such as the International Organization for Standardization (ISO) and the Association for the Advancement of Medical Instrumentation (AAMI) provide guidelines for sterilization processes, including those involving flammable gases. Adherence to these standards is crucial for ensuring the safety and efficacy of sterilized products.

Environmental considerations also play a significant role in the regulatory landscape surrounding butane-based sterilization techniques. Emissions control measures may be required to minimize the release of volatile organic compounds (VOCs) into the atmosphere, in compliance with local and national environmental regulations. Additionally, proper disposal protocols for any waste products generated during the sterilization process must be established and followed.

The transportation and storage of butane for sterilization purposes are subject to strict regulations due to its classification as a hazardous material. Compliance with the United Nations Recommendations on the Transport of Dangerous Goods and similar national regulations is essential for the safe movement of butane between facilities.

As advanced sterilization techniques involving butane continue to evolve, ongoing regulatory assessment and adaptation will be necessary. Manufacturers and users of such sterilization systems must stay informed about changes in safety standards and regulatory requirements to ensure continued compliance and safe operation. This may involve regular audits, documentation of safety procedures, and engagement with regulatory bodies to address any emerging concerns or requirements specific to butane-based sterilization methods.

Environmental Impact Assessment

The utilization of butane in advanced sterilization techniques presents both potential benefits and environmental concerns that require careful assessment. Butane, as a hydrocarbon gas, has properties that make it effective for sterilization purposes, but its use also raises questions about environmental impact.

One of the primary environmental considerations is the potential for butane to contribute to air pollution. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a key component of smog. This can have negative effects on air quality, particularly in urban areas where sterilization facilities may be located. Additionally, butane is a volatile organic compound (VOC), which can contribute to the formation of secondary organic aerosols, further impacting air quality.

The global warming potential of butane is another important factor to consider. While not as potent as some other greenhouse gases, butane does have a warming effect when released into the atmosphere. However, its relatively short atmospheric lifetime means that its long-term impact is less severe compared to more persistent greenhouse gases.

In terms of water pollution, the risk is generally low when butane is used properly in sterilization processes. However, improper handling or disposal of butane-containing materials could potentially lead to contamination of water sources. This risk necessitates proper protocols for storage, use, and disposal of butane and related materials in sterilization facilities.

The production and transportation of butane for sterilization purposes also have environmental implications. The extraction and refining processes for butane can have localized environmental impacts, including potential soil and water contamination at production sites. Transportation of butane to sterilization facilities may contribute to carbon emissions, depending on the methods and distances involved.

On the positive side, butane-based sterilization techniques may offer environmental advantages over some alternative methods. For instance, compared to ethylene oxide, which is commonly used in sterilization but is highly toxic and potentially carcinogenic, butane may present a lower risk to human health and the environment when properly managed.

The energy efficiency of butane-based sterilization processes is another factor to consider in environmental impact assessment. If these processes prove to be more energy-efficient than alternative methods, they could potentially lead to reduced overall energy consumption and associated environmental benefits.

In conclusion, while butane offers potential advantages in advanced sterilization techniques, its environmental impact must be carefully managed. This includes implementing stringent emission controls, ensuring proper handling and disposal practices, and continuously monitoring and mitigating potential environmental risks associated with its use in sterilization processes.

One of the primary environmental considerations is the potential for butane to contribute to air pollution. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a key component of smog. This can have negative effects on air quality, particularly in urban areas where sterilization facilities may be located. Additionally, butane is a volatile organic compound (VOC), which can contribute to the formation of secondary organic aerosols, further impacting air quality.

The global warming potential of butane is another important factor to consider. While not as potent as some other greenhouse gases, butane does have a warming effect when released into the atmosphere. However, its relatively short atmospheric lifetime means that its long-term impact is less severe compared to more persistent greenhouse gases.

In terms of water pollution, the risk is generally low when butane is used properly in sterilization processes. However, improper handling or disposal of butane-containing materials could potentially lead to contamination of water sources. This risk necessitates proper protocols for storage, use, and disposal of butane and related materials in sterilization facilities.

The production and transportation of butane for sterilization purposes also have environmental implications. The extraction and refining processes for butane can have localized environmental impacts, including potential soil and water contamination at production sites. Transportation of butane to sterilization facilities may contribute to carbon emissions, depending on the methods and distances involved.

On the positive side, butane-based sterilization techniques may offer environmental advantages over some alternative methods. For instance, compared to ethylene oxide, which is commonly used in sterilization but is highly toxic and potentially carcinogenic, butane may present a lower risk to human health and the environment when properly managed.

The energy efficiency of butane-based sterilization processes is another factor to consider in environmental impact assessment. If these processes prove to be more energy-efficient than alternative methods, they could potentially lead to reduced overall energy consumption and associated environmental benefits.

In conclusion, while butane offers potential advantages in advanced sterilization techniques, its environmental impact must be carefully managed. This includes implementing stringent emission controls, ensuring proper handling and disposal practices, and continuously monitoring and mitigating potential environmental risks associated with its use in sterilization processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!