How Butane Reinforces High-Pressure Oxygen Production Facilities

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane-Oxygen Synergy

The synergy between butane and oxygen in high-pressure production facilities represents a significant advancement in industrial gas manufacturing. This relationship is characterized by the reinforcing effect butane has on oxygen production processes, particularly under high-pressure conditions. Butane, a hydrocarbon with the formula C4H10, plays a crucial role in enhancing the efficiency and safety of oxygen production facilities.

In high-pressure oxygen production, butane serves as a stabilizing agent, helping to maintain the integrity of equipment and processes under extreme conditions. Its presence helps to mitigate the risks associated with high-pressure oxygen environments, which are known for their potential to cause rapid oxidation and combustion. Butane's molecular structure and properties allow it to form a protective layer on metal surfaces, reducing the likelihood of oxygen-induced corrosion and material degradation.

Furthermore, butane contributes to the overall performance of oxygen production systems by acting as a heat transfer medium. Its thermal properties enable more efficient temperature control within the production process, leading to improved energy utilization and reduced operational costs. This thermal management aspect is particularly crucial in cryogenic air separation units, where precise temperature control is essential for optimal oxygen extraction.

The interaction between butane and oxygen also facilitates enhanced separation processes. In fractional distillation columns used for air separation, butane can be strategically employed to improve the separation efficiency of oxygen from other atmospheric gases. This results in higher purity oxygen output and increased production yields, meeting the growing demand for high-quality industrial gases.

Safety considerations are paramount in high-pressure oxygen production, and the butane-oxygen synergy addresses several key concerns. Butane's presence helps to suppress the formation of potentially explosive mixtures, acting as a buffer in areas where oxygen concentrations might otherwise reach dangerous levels. This protective function is invaluable in preventing accidents and ensuring the longevity of production equipment.

Moreover, the integration of butane in oxygen production processes has led to advancements in materials science and engineering. Researchers and engineers have developed specialized alloys and coatings that leverage the protective properties of butane, resulting in more durable and resistant equipment capable of withstanding the harsh conditions of high-pressure oxygen environments.

The butane-oxygen synergy also extends to the realm of process optimization. By carefully controlling the ratio of butane to oxygen, operators can fine-tune production parameters to achieve optimal performance across various pressure ranges. This flexibility allows for adaptable production strategies that can respond to changing market demands and operational requirements.

In high-pressure oxygen production, butane serves as a stabilizing agent, helping to maintain the integrity of equipment and processes under extreme conditions. Its presence helps to mitigate the risks associated with high-pressure oxygen environments, which are known for their potential to cause rapid oxidation and combustion. Butane's molecular structure and properties allow it to form a protective layer on metal surfaces, reducing the likelihood of oxygen-induced corrosion and material degradation.

Furthermore, butane contributes to the overall performance of oxygen production systems by acting as a heat transfer medium. Its thermal properties enable more efficient temperature control within the production process, leading to improved energy utilization and reduced operational costs. This thermal management aspect is particularly crucial in cryogenic air separation units, where precise temperature control is essential for optimal oxygen extraction.

The interaction between butane and oxygen also facilitates enhanced separation processes. In fractional distillation columns used for air separation, butane can be strategically employed to improve the separation efficiency of oxygen from other atmospheric gases. This results in higher purity oxygen output and increased production yields, meeting the growing demand for high-quality industrial gases.

Safety considerations are paramount in high-pressure oxygen production, and the butane-oxygen synergy addresses several key concerns. Butane's presence helps to suppress the formation of potentially explosive mixtures, acting as a buffer in areas where oxygen concentrations might otherwise reach dangerous levels. This protective function is invaluable in preventing accidents and ensuring the longevity of production equipment.

Moreover, the integration of butane in oxygen production processes has led to advancements in materials science and engineering. Researchers and engineers have developed specialized alloys and coatings that leverage the protective properties of butane, resulting in more durable and resistant equipment capable of withstanding the harsh conditions of high-pressure oxygen environments.

The butane-oxygen synergy also extends to the realm of process optimization. By carefully controlling the ratio of butane to oxygen, operators can fine-tune production parameters to achieve optimal performance across various pressure ranges. This flexibility allows for adaptable production strategies that can respond to changing market demands and operational requirements.

Market Demand Analysis

The market demand for high-pressure oxygen production facilities reinforced with butane is driven by several key factors in the industrial gas sector. The global industrial gas market, which includes oxygen as a major component, has been experiencing steady growth due to increasing applications in various industries such as healthcare, metallurgy, and chemical manufacturing. The use of butane as a reinforcing agent in high-pressure oxygen production facilities addresses critical safety concerns and operational efficiency requirements.

In the healthcare sector, the demand for medical-grade oxygen has surged, particularly in light of recent global health crises. Hospitals and medical facilities require a reliable and safe supply of high-purity oxygen, creating a sustained market for advanced production facilities. The integration of butane reinforcement in these facilities enhances their safety profile, making them more attractive to healthcare providers who prioritize risk mitigation in their oxygen supply chains.

The metallurgical industry, another significant consumer of high-pressure oxygen, has been expanding, especially in developing economies. Steel production, which heavily relies on oxygen for processes like basic oxygen steelmaking, continues to drive demand for efficient and safe oxygen production facilities. The use of butane-reinforced systems in this sector offers improved operational stability and potentially longer equipment lifespan, factors that are highly valued in the cost-sensitive steel industry.

Chemical manufacturing represents another substantial market for high-pressure oxygen. The production of various chemicals, including ethylene oxide, propylene oxide, and synthetic gas, requires large volumes of oxygen. As the chemical industry grows and diversifies, the demand for advanced oxygen production facilities increases. Butane reinforcement in these facilities addresses the industry's stringent safety standards and the need for uninterrupted oxygen supply.

The environmental sector also contributes to the market demand for high-pressure oxygen production facilities. Wastewater treatment plants use oxygen in their processes, and as environmental regulations become more stringent worldwide, the demand for efficient oxygen production and delivery systems grows. Butane-reinforced facilities offer enhanced reliability, which is crucial for maintaining continuous environmental compliance.

From a geographical perspective, emerging markets in Asia-Pacific and Latin America are expected to be significant drivers of demand for advanced oxygen production facilities. These regions are experiencing rapid industrialization and urbanization, leading to increased oxygen consumption across various sectors. The safety enhancements provided by butane reinforcement align well with the growing focus on industrial safety in these developing markets.

In conclusion, the market demand for high-pressure oxygen production facilities reinforced with butane is robust and multifaceted. It is supported by growth in healthcare, metallurgy, chemical manufacturing, and environmental sectors, as well as by the expanding industrial base in emerging economies. The emphasis on safety, efficiency, and reliability in oxygen production aligns perfectly with the benefits offered by butane reinforcement, positioning this technology favorably in the industrial gas market.

In the healthcare sector, the demand for medical-grade oxygen has surged, particularly in light of recent global health crises. Hospitals and medical facilities require a reliable and safe supply of high-purity oxygen, creating a sustained market for advanced production facilities. The integration of butane reinforcement in these facilities enhances their safety profile, making them more attractive to healthcare providers who prioritize risk mitigation in their oxygen supply chains.

The metallurgical industry, another significant consumer of high-pressure oxygen, has been expanding, especially in developing economies. Steel production, which heavily relies on oxygen for processes like basic oxygen steelmaking, continues to drive demand for efficient and safe oxygen production facilities. The use of butane-reinforced systems in this sector offers improved operational stability and potentially longer equipment lifespan, factors that are highly valued in the cost-sensitive steel industry.

Chemical manufacturing represents another substantial market for high-pressure oxygen. The production of various chemicals, including ethylene oxide, propylene oxide, and synthetic gas, requires large volumes of oxygen. As the chemical industry grows and diversifies, the demand for advanced oxygen production facilities increases. Butane reinforcement in these facilities addresses the industry's stringent safety standards and the need for uninterrupted oxygen supply.

The environmental sector also contributes to the market demand for high-pressure oxygen production facilities. Wastewater treatment plants use oxygen in their processes, and as environmental regulations become more stringent worldwide, the demand for efficient oxygen production and delivery systems grows. Butane-reinforced facilities offer enhanced reliability, which is crucial for maintaining continuous environmental compliance.

From a geographical perspective, emerging markets in Asia-Pacific and Latin America are expected to be significant drivers of demand for advanced oxygen production facilities. These regions are experiencing rapid industrialization and urbanization, leading to increased oxygen consumption across various sectors. The safety enhancements provided by butane reinforcement align well with the growing focus on industrial safety in these developing markets.

In conclusion, the market demand for high-pressure oxygen production facilities reinforced with butane is robust and multifaceted. It is supported by growth in healthcare, metallurgy, chemical manufacturing, and environmental sectors, as well as by the expanding industrial base in emerging economies. The emphasis on safety, efficiency, and reliability in oxygen production aligns perfectly with the benefits offered by butane reinforcement, positioning this technology favorably in the industrial gas market.

Technical Challenges

The reinforcement of high-pressure oxygen production facilities with butane presents several technical challenges that require careful consideration and innovative solutions. One of the primary obstacles is the inherent volatility of butane when combined with high-pressure oxygen environments. This combination creates a potentially explosive atmosphere, necessitating advanced safety measures and robust containment systems.

Material compatibility poses another significant challenge. The presence of butane in high-pressure oxygen systems can lead to accelerated degradation of certain materials commonly used in these facilities. Engineers must carefully select and test materials that can withstand both the corrosive effects of high-pressure oxygen and the chemical interactions with butane over extended periods.

The design of sealing systems becomes increasingly complex when incorporating butane into high-pressure oxygen production. Traditional sealing methods may not be sufficient to prevent leaks or permeation of butane, which could compromise the purity of the oxygen produced or create safety hazards. Developing and implementing advanced sealing technologies that can maintain integrity under these demanding conditions is crucial.

Temperature control presents another technical hurdle. The introduction of butane into the system can affect the thermal properties of the production process. Maintaining optimal temperatures for efficient oxygen production while managing the potential cooling effects or heat generation from butane interactions requires sophisticated thermal management systems.

Monitoring and control systems face increased complexity in butane-reinforced facilities. Real-time detection of butane levels, oxygen purity, and potential leaks becomes critical for safe operation. Developing sensors and analytical tools capable of accurately measuring and distinguishing between oxygen and butane in high-pressure environments is a significant technical challenge.

The purification process for oxygen production must be adapted to account for the presence of butane. Conventional purification methods may not be sufficient to remove trace amounts of butane from the final oxygen product, potentially affecting its quality and suitability for certain applications. Developing new or modified purification techniques that can effectively separate butane from oxygen under high-pressure conditions is essential.

Lastly, the scale-up of butane-reinforced high-pressure oxygen production facilities from laboratory or pilot scale to industrial scale presents its own set of challenges. Ensuring that the benefits observed in smaller-scale operations translate effectively to large-scale production while maintaining safety and efficiency requires extensive engineering and process optimization efforts.

Material compatibility poses another significant challenge. The presence of butane in high-pressure oxygen systems can lead to accelerated degradation of certain materials commonly used in these facilities. Engineers must carefully select and test materials that can withstand both the corrosive effects of high-pressure oxygen and the chemical interactions with butane over extended periods.

The design of sealing systems becomes increasingly complex when incorporating butane into high-pressure oxygen production. Traditional sealing methods may not be sufficient to prevent leaks or permeation of butane, which could compromise the purity of the oxygen produced or create safety hazards. Developing and implementing advanced sealing technologies that can maintain integrity under these demanding conditions is crucial.

Temperature control presents another technical hurdle. The introduction of butane into the system can affect the thermal properties of the production process. Maintaining optimal temperatures for efficient oxygen production while managing the potential cooling effects or heat generation from butane interactions requires sophisticated thermal management systems.

Monitoring and control systems face increased complexity in butane-reinforced facilities. Real-time detection of butane levels, oxygen purity, and potential leaks becomes critical for safe operation. Developing sensors and analytical tools capable of accurately measuring and distinguishing between oxygen and butane in high-pressure environments is a significant technical challenge.

The purification process for oxygen production must be adapted to account for the presence of butane. Conventional purification methods may not be sufficient to remove trace amounts of butane from the final oxygen product, potentially affecting its quality and suitability for certain applications. Developing new or modified purification techniques that can effectively separate butane from oxygen under high-pressure conditions is essential.

Lastly, the scale-up of butane-reinforced high-pressure oxygen production facilities from laboratory or pilot scale to industrial scale presents its own set of challenges. Ensuring that the benefits observed in smaller-scale operations translate effectively to large-scale production while maintaining safety and efficiency requires extensive engineering and process optimization efforts.

Current Solutions

01 Butane gas lighters and refill devices

Various designs for butane gas lighters and refill devices, including improvements in safety features, ignition mechanisms, and refilling systems. These innovations aim to enhance user experience, increase reliability, and improve the overall functionality of butane-based lighters.- Butane gas lighters and refill devices: Various designs and improvements for butane gas lighters and refill devices, including safety mechanisms, ergonomic designs, and efficient refilling systems. These innovations aim to enhance user experience, safety, and convenience in portable gas lighter products.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes involve various techniques such as distillation, adsorption, or membrane separation to obtain high-purity butane for industrial or commercial applications.

- Butane fuel storage and dispensing systems: Innovations in butane fuel storage containers and dispensing systems, focusing on improved safety features, leak prevention, and efficient fuel transfer. These developments are applicable to portable stoves, camping equipment, and other butane-powered devices.

- Butane as a refrigerant or heat transfer medium: Applications of butane as a refrigerant or heat transfer medium in various cooling systems and heat pumps. These innovations explore the use of butane as an environmentally friendly alternative to traditional refrigerants, focusing on energy efficiency and system performance.

- Butane-based chemical processes and reactions: Chemical processes and reactions involving butane as a reactant or intermediate, including oxidation, dehydrogenation, and isomerization. These innovations aim to develop new products or improve existing processes in the petrochemical industry using butane as a feedstock.

02 Butane purification and separation processes

Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve adsorption, distillation, or other separation techniques to obtain high-purity butane for various industrial applications.Expand Specific Solutions03 Butane fuel storage and dispensing systems

Innovations in butane fuel storage containers, tanks, and dispensing systems for various applications, including portable stoves, heaters, and other fuel-powered devices. These designs focus on improving safety, ease of use, and efficiency in storing and dispensing butane fuel.Expand Specific Solutions04 Butane-based refrigeration systems

Development of refrigeration systems using butane as a refrigerant. These systems aim to provide environmentally friendly alternatives to traditional refrigerants, offering improved energy efficiency and reduced environmental impact in various cooling applications.Expand Specific Solutions05 Butane production and processing methods

Techniques for producing and processing butane, including catalytic processes, isomerization, and other chemical reactions. These methods aim to improve the yield, purity, and efficiency of butane production for various industrial and commercial applications.Expand Specific Solutions

Industry Leaders

The competition landscape for butane reinforcement in high-pressure oxygen production facilities is evolving as the industry enters a growth phase. The market size is expanding due to increasing demand for industrial gases across various sectors. Technologically, the field is advancing rapidly, with major players like Air Liquide, Linde, and Praxair leading innovation. These companies, along with BASF and Saudi Aramco, are investing heavily in R&D to improve efficiency and safety. Emerging players such as TPC Group and H2Gen Innovations are also contributing to technological advancements. The market is characterized by a mix of established global corporations and specialized regional firms, indicating a competitive but not yet fully mature landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a cutting-edge high-pressure oxygen production facility that incorporates butane reinforcement technology. Their process utilizes a modified cryogenic air separation unit with an integrated butane refrigeration cycle. This configuration allows for enhanced cold recovery and improved overall energy efficiency. Sinopec's technology features a multi-stage distillation system with advanced internals designed to maximize mass transfer and separation efficiency[7]. The company has also implemented a proprietary butane management system that ensures safe handling and optimal utilization of the refrigerant throughout the process. Additionally, Sinopec's facility incorporates advanced process control and monitoring systems that utilize machine learning algorithms to predict and optimize plant performance based on historical data and real-time operating conditions[8].

Strengths: High production capacity, improved energy efficiency, and advanced process control. Weaknesses: Potential safety concerns related to large-scale butane usage and increased operational complexity.

LINDA AG

Technical Solution: LINDA AG has developed an innovative approach to high-pressure oxygen production that leverages butane as a key component in enhancing overall system efficiency. Their technology employs a novel hybrid process that combines cryogenic air separation with pressure swing adsorption (PSA) techniques, integrated with a butane-based refrigeration cycle. This unique configuration allows for significant improvements in energy consumption and product purity. LINDA's process utilizes advanced heat integration strategies, including the use of micro-channel heat exchangers, to maximize thermal efficiency[9]. The company has also implemented a sophisticated butane recovery and purification system that ensures minimal losses and maintains refrigerant quality over extended operational periods. LINDA's technology features an intelligent control system that optimizes the interaction between the cryogenic, PSA, and butane refrigeration components based on real-time plant conditions and demand fluctuations[10].

Strengths: High product purity, excellent energy efficiency, and flexible operation. Weaknesses: Increased system complexity and potential challenges in scaling up the hybrid process.

Key Innovations

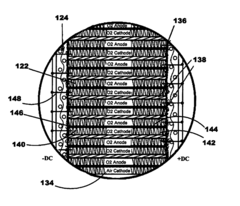

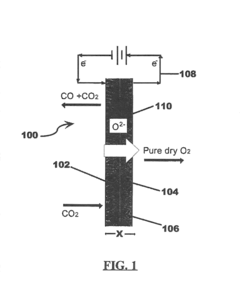

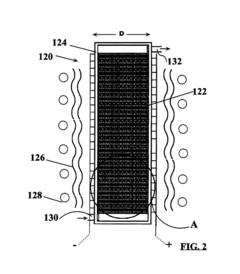

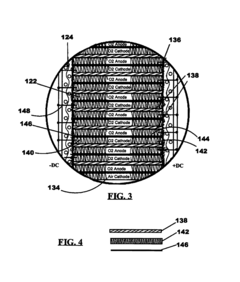

Generation of high pressure oxygen via electrochemical pumping in a multi-stage electrolysis stack

PatentInactiveUS9776130B1

Innovation

- An electrochemical oxygen pump using a multi-stage stack of cells with oxygen-ion conducting solid-state electrolyte membranes, which incrementally pressurizes oxygen through an electrochemical process, allowing for the production of high-purity, dry oxygen from ambient air, carbon dioxide, or water.

Process for the bioconversion of c3-c13 alkanes to c3-c 13 primary alcohols

PatentWO2015014644A1

Innovation

- A bioconversion process using a host organism with a functional P153 enzyme, such as CYP153A from Polaromonas sp., is employed to convert linear or branched alkanes into primary alcohols under elevated pressure in the presence of oxygen, enhancing yield and productivity.

Safety Regulations

Safety regulations play a crucial role in the operation of high-pressure oxygen production facilities, especially when butane is used as a reinforcing agent. These regulations are designed to mitigate risks associated with the highly combustible nature of both oxygen and butane, ensuring the safety of personnel and the integrity of the production process.

The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive guidelines for handling compressed gases, including oxygen and butane. These regulations mandate the use of proper storage containers, handling procedures, and safety equipment. For instance, OSHA requires that oxygen and butane be stored separately, with a minimum distance of 20 feet between them, or separated by a fire-resistant barrier.

In the European Union, the ATEX Directive (2014/34/EU) governs equipment and protective systems intended for use in potentially explosive atmospheres. This directive is particularly relevant for facilities using butane in oxygen production, as it sets standards for equipment design, manufacturing, and testing to prevent ignition sources in hazardous areas.

The National Fire Protection Association (NFPA) provides specific guidelines for oxygen-enriched atmospheres in its NFPA 53 standard. This standard outlines requirements for the design, construction, and operation of systems involving oxygen concentrations above 23.5%, which is common in high-pressure oxygen production facilities.

Safety regulations also emphasize the importance of proper training for personnel working in these facilities. Operators must be well-versed in the properties of both oxygen and butane, emergency procedures, and the correct use of personal protective equipment (PPE). Regular safety drills and refresher courses are typically mandated to ensure ongoing compliance and preparedness.

Maintenance and inspection protocols form another critical aspect of safety regulations. Regular checks of equipment integrity, leak detection systems, and pressure relief valves are essential to prevent accidents. These inspections must be documented and conducted by qualified personnel, with any deficiencies addressed promptly.

Environmental regulations also intersect with safety considerations in high-pressure oxygen production facilities. Emissions control and waste management practices must comply with local and national environmental protection standards, ensuring that the use of butane does not lead to harmful releases into the atmosphere or surrounding ecosystems.

As technology advances, safety regulations continue to evolve. The integration of digital monitoring systems and automated safety controls is becoming increasingly common, with some jurisdictions beginning to incorporate these technologies into their regulatory frameworks. This trend towards "smart" safety systems is likely to shape future regulations in the industry.

The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive guidelines for handling compressed gases, including oxygen and butane. These regulations mandate the use of proper storage containers, handling procedures, and safety equipment. For instance, OSHA requires that oxygen and butane be stored separately, with a minimum distance of 20 feet between them, or separated by a fire-resistant barrier.

In the European Union, the ATEX Directive (2014/34/EU) governs equipment and protective systems intended for use in potentially explosive atmospheres. This directive is particularly relevant for facilities using butane in oxygen production, as it sets standards for equipment design, manufacturing, and testing to prevent ignition sources in hazardous areas.

The National Fire Protection Association (NFPA) provides specific guidelines for oxygen-enriched atmospheres in its NFPA 53 standard. This standard outlines requirements for the design, construction, and operation of systems involving oxygen concentrations above 23.5%, which is common in high-pressure oxygen production facilities.

Safety regulations also emphasize the importance of proper training for personnel working in these facilities. Operators must be well-versed in the properties of both oxygen and butane, emergency procedures, and the correct use of personal protective equipment (PPE). Regular safety drills and refresher courses are typically mandated to ensure ongoing compliance and preparedness.

Maintenance and inspection protocols form another critical aspect of safety regulations. Regular checks of equipment integrity, leak detection systems, and pressure relief valves are essential to prevent accidents. These inspections must be documented and conducted by qualified personnel, with any deficiencies addressed promptly.

Environmental regulations also intersect with safety considerations in high-pressure oxygen production facilities. Emissions control and waste management practices must comply with local and national environmental protection standards, ensuring that the use of butane does not lead to harmful releases into the atmosphere or surrounding ecosystems.

As technology advances, safety regulations continue to evolve. The integration of digital monitoring systems and automated safety controls is becoming increasingly common, with some jurisdictions beginning to incorporate these technologies into their regulatory frameworks. This trend towards "smart" safety systems is likely to shape future regulations in the industry.

Environmental Impact

The environmental impact of using butane to reinforce high-pressure oxygen production facilities is a critical consideration in the overall assessment of this technology. Butane, as a hydrocarbon, has both direct and indirect environmental implications that must be carefully evaluated.

Firstly, the production and transportation of butane itself contribute to greenhouse gas emissions. The extraction, refining, and distribution processes associated with butane involve energy-intensive operations that release carbon dioxide and other pollutants into the atmosphere. This upstream environmental footprint must be factored into the overall environmental impact assessment of using butane in oxygen production facilities.

In the context of high-pressure oxygen production, the use of butane as a reinforcing agent may lead to potential leaks or emissions during normal operations or in the event of equipment failure. While modern facilities are designed with robust safety measures, the release of butane into the environment can contribute to local air pollution and potentially pose risks to surrounding ecosystems.

However, it is important to note that the use of butane in reinforcing high-pressure oxygen production facilities may also have some positive environmental implications. By enhancing the structural integrity and safety of these facilities, butane reinforcement can reduce the likelihood of catastrophic failures or accidents that could result in significant environmental damage. This increased reliability may lead to fewer incidents of oxygen leaks or facility shutdowns, which in turn minimizes the environmental impact associated with emergency responses and unplanned releases.

Furthermore, the improved efficiency and stability of high-pressure oxygen production facilities reinforced with butane may result in reduced energy consumption over time. This could translate to lower overall carbon emissions from the production process, partially offsetting the environmental impact of butane usage.

The disposal and recycling of equipment and materials used in butane-reinforced facilities also warrant consideration. As these facilities reach the end of their operational life, proper decommissioning and waste management practices must be implemented to prevent environmental contamination and ensure the safe handling of any residual butane or related compounds.

In conclusion, while the use of butane in reinforcing high-pressure oxygen production facilities does have environmental implications, a comprehensive analysis must weigh both the potential negative impacts and the environmental benefits of improved safety and efficiency. Future research and technological advancements should focus on minimizing the environmental footprint of butane production and usage, as well as exploring alternative reinforcement methods that may offer similar benefits with reduced environmental impact.

Firstly, the production and transportation of butane itself contribute to greenhouse gas emissions. The extraction, refining, and distribution processes associated with butane involve energy-intensive operations that release carbon dioxide and other pollutants into the atmosphere. This upstream environmental footprint must be factored into the overall environmental impact assessment of using butane in oxygen production facilities.

In the context of high-pressure oxygen production, the use of butane as a reinforcing agent may lead to potential leaks or emissions during normal operations or in the event of equipment failure. While modern facilities are designed with robust safety measures, the release of butane into the environment can contribute to local air pollution and potentially pose risks to surrounding ecosystems.

However, it is important to note that the use of butane in reinforcing high-pressure oxygen production facilities may also have some positive environmental implications. By enhancing the structural integrity and safety of these facilities, butane reinforcement can reduce the likelihood of catastrophic failures or accidents that could result in significant environmental damage. This increased reliability may lead to fewer incidents of oxygen leaks or facility shutdowns, which in turn minimizes the environmental impact associated with emergency responses and unplanned releases.

Furthermore, the improved efficiency and stability of high-pressure oxygen production facilities reinforced with butane may result in reduced energy consumption over time. This could translate to lower overall carbon emissions from the production process, partially offsetting the environmental impact of butane usage.

The disposal and recycling of equipment and materials used in butane-reinforced facilities also warrant consideration. As these facilities reach the end of their operational life, proper decommissioning and waste management practices must be implemented to prevent environmental contamination and ensure the safe handling of any residual butane or related compounds.

In conclusion, while the use of butane in reinforcing high-pressure oxygen production facilities does have environmental implications, a comprehensive analysis must weigh both the potential negative impacts and the environmental benefits of improved safety and efficiency. Future research and technological advancements should focus on minimizing the environmental footprint of butane production and usage, as well as exploring alternative reinforcement methods that may offer similar benefits with reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!