Butane's Role in the Chemical Vapor Deposition Process

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CVD Process Background and Objectives

Chemical Vapor Deposition (CVD) is a versatile and widely used technique in the semiconductor industry and materials science for depositing thin films of various materials. The process has evolved significantly since its inception in the 1960s, driven by the increasing demands of microelectronics and nanotechnology. The primary objective of CVD is to create high-quality, uniform thin films with precise control over composition and thickness.

In recent years, the role of butane in CVD processes has gained attention due to its potential as a carbon source for the growth of graphene and other carbon-based materials. Butane, a hydrocarbon with the chemical formula C4H10, offers several advantages in CVD applications, including its relatively low decomposition temperature and ability to produce high-quality carbon structures.

The evolution of CVD technology has been marked by continuous improvements in process control, precursor chemistry, and reactor design. Early CVD systems relied on simple thermal decomposition of precursors, while modern techniques incorporate plasma enhancement, laser assistance, and atomic layer deposition for greater precision and material quality.

As the semiconductor industry pushes towards smaller device dimensions and more complex architectures, the demands on CVD processes have intensified. The integration of butane into CVD systems aims to address challenges such as achieving uniform carbon deposition, minimizing defects, and enhancing growth rates. These advancements are crucial for the development of next-generation electronic devices and advanced materials.

The technical goals associated with butane's role in CVD processes include optimizing growth conditions for specific carbon structures, improving the scalability of the process for industrial applications, and developing novel precursor combinations to tailor material properties. Researchers are also exploring the potential of butane-based CVD for the synthesis of two-dimensional materials beyond graphene, such as transition metal dichalcogenides.

Understanding the fundamental mechanisms of butane decomposition and carbon film formation in CVD environments is essential for achieving these objectives. This involves investigating the gas-phase and surface reactions, the influence of substrate materials and temperatures, and the impact of various process parameters on film quality and growth kinetics.

As the field progresses, there is a growing emphasis on developing environmentally friendly and cost-effective CVD processes. Butane, being a readily available and relatively safe precursor, aligns well with these sustainability goals. However, optimizing its use to minimize waste and energy consumption remains an important area of research and development.

In recent years, the role of butane in CVD processes has gained attention due to its potential as a carbon source for the growth of graphene and other carbon-based materials. Butane, a hydrocarbon with the chemical formula C4H10, offers several advantages in CVD applications, including its relatively low decomposition temperature and ability to produce high-quality carbon structures.

The evolution of CVD technology has been marked by continuous improvements in process control, precursor chemistry, and reactor design. Early CVD systems relied on simple thermal decomposition of precursors, while modern techniques incorporate plasma enhancement, laser assistance, and atomic layer deposition for greater precision and material quality.

As the semiconductor industry pushes towards smaller device dimensions and more complex architectures, the demands on CVD processes have intensified. The integration of butane into CVD systems aims to address challenges such as achieving uniform carbon deposition, minimizing defects, and enhancing growth rates. These advancements are crucial for the development of next-generation electronic devices and advanced materials.

The technical goals associated with butane's role in CVD processes include optimizing growth conditions for specific carbon structures, improving the scalability of the process for industrial applications, and developing novel precursor combinations to tailor material properties. Researchers are also exploring the potential of butane-based CVD for the synthesis of two-dimensional materials beyond graphene, such as transition metal dichalcogenides.

Understanding the fundamental mechanisms of butane decomposition and carbon film formation in CVD environments is essential for achieving these objectives. This involves investigating the gas-phase and surface reactions, the influence of substrate materials and temperatures, and the impact of various process parameters on film quality and growth kinetics.

As the field progresses, there is a growing emphasis on developing environmentally friendly and cost-effective CVD processes. Butane, being a readily available and relatively safe precursor, aligns well with these sustainability goals. However, optimizing its use to minimize waste and energy consumption remains an important area of research and development.

Market Demand for CVD Applications

The Chemical Vapor Deposition (CVD) market has experienced significant growth in recent years, driven by increasing demand across various industries. The global CVD market size was valued at USD 23.17 billion in 2020 and is projected to reach USD 47.2 billion by 2028, growing at a CAGR of 8.4% from 2021 to 2028. This robust growth is primarily attributed to the expanding applications of CVD in semiconductor manufacturing, solar cells, and advanced materials production.

In the semiconductor industry, CVD plays a crucial role in fabricating integrated circuits and microelectronic devices. As the demand for smaller, faster, and more efficient electronic devices continues to rise, the need for advanced CVD processes, including those utilizing butane, is expected to grow substantially. The semiconductor market, a key driver for CVD applications, is forecasted to reach USD 726 billion by 2027, indicating a strong potential for CVD technology adoption.

The solar energy sector represents another significant market for CVD applications. The global solar energy market is projected to grow from USD 184.03 billion in 2021 to USD 293.18 billion in 2028, with a CAGR of 6.9%. CVD processes are essential in the production of thin-film solar cells, where butane can be used as a precursor gas. As countries worldwide push for renewable energy adoption, the demand for CVD in solar cell manufacturing is expected to surge.

Advanced materials production, including carbon nanotubes, graphene, and other nanomaterials, relies heavily on CVD processes. The global nanomaterials market is anticipated to reach USD 14.8 billion by 2025, growing at a CAGR of 13.1%. Butane's role in CVD for these applications is becoming increasingly important, as it offers advantages in terms of cost-effectiveness and process control.

The automotive industry is emerging as a promising market for CVD applications, particularly in the production of lightweight materials and coatings. With the global automotive lightweight materials market expected to reach USD 99.3 billion by 2025, the demand for CVD processes, including those involving butane, is likely to increase significantly in this sector.

Geographically, Asia Pacific dominates the CVD market, accounting for over 40% of the global market share. This is primarily due to the strong presence of semiconductor and electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow, with growing applications in aerospace, medical devices, and advanced materials research driving the demand for CVD technologies.

In conclusion, the market demand for CVD applications, including those utilizing butane, shows strong growth potential across multiple industries. The semiconductor, solar energy, advanced materials, and automotive sectors are expected to be the primary drivers of this growth, with Asia Pacific leading the global market expansion.

In the semiconductor industry, CVD plays a crucial role in fabricating integrated circuits and microelectronic devices. As the demand for smaller, faster, and more efficient electronic devices continues to rise, the need for advanced CVD processes, including those utilizing butane, is expected to grow substantially. The semiconductor market, a key driver for CVD applications, is forecasted to reach USD 726 billion by 2027, indicating a strong potential for CVD technology adoption.

The solar energy sector represents another significant market for CVD applications. The global solar energy market is projected to grow from USD 184.03 billion in 2021 to USD 293.18 billion in 2028, with a CAGR of 6.9%. CVD processes are essential in the production of thin-film solar cells, where butane can be used as a precursor gas. As countries worldwide push for renewable energy adoption, the demand for CVD in solar cell manufacturing is expected to surge.

Advanced materials production, including carbon nanotubes, graphene, and other nanomaterials, relies heavily on CVD processes. The global nanomaterials market is anticipated to reach USD 14.8 billion by 2025, growing at a CAGR of 13.1%. Butane's role in CVD for these applications is becoming increasingly important, as it offers advantages in terms of cost-effectiveness and process control.

The automotive industry is emerging as a promising market for CVD applications, particularly in the production of lightweight materials and coatings. With the global automotive lightweight materials market expected to reach USD 99.3 billion by 2025, the demand for CVD processes, including those involving butane, is likely to increase significantly in this sector.

Geographically, Asia Pacific dominates the CVD market, accounting for over 40% of the global market share. This is primarily due to the strong presence of semiconductor and electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow, with growing applications in aerospace, medical devices, and advanced materials research driving the demand for CVD technologies.

In conclusion, the market demand for CVD applications, including those utilizing butane, shows strong growth potential across multiple industries. The semiconductor, solar energy, advanced materials, and automotive sectors are expected to be the primary drivers of this growth, with Asia Pacific leading the global market expansion.

Butane in CVD: Current State and Challenges

Chemical Vapor Deposition (CVD) is a widely used technique in the semiconductor industry for depositing thin films of various materials. Butane, a hydrocarbon gas, plays a significant role in this process. Currently, the use of butane in CVD is well-established, but it also faces several challenges that researchers and industry professionals are working to overcome.

The primary advantage of using butane in CVD is its ability to serve as a carbon source for the deposition of carbon-based materials, such as diamond-like carbon (DLC) films. Butane's relatively low decomposition temperature and high carbon content make it an attractive precursor for these applications. Additionally, its gaseous state at room temperature facilitates easy handling and precise control of gas flow rates during the deposition process.

However, the current state of butane usage in CVD is not without its challenges. One of the main issues is the incomplete decomposition of butane during the process, which can lead to the incorporation of unwanted hydrogen into the deposited films. This can affect the film's properties and overall quality. Researchers are actively working on developing more efficient catalysts and optimizing process parameters to enhance butane decomposition and minimize hydrogen incorporation.

Another challenge is the potential for carbon contamination in non-carbon-based film depositions. When butane is used as a carrier gas or diluent in CVD processes for other materials, there is a risk of unintended carbon incorporation, which can alter the film's composition and properties. This necessitates careful process control and the development of strategies to mitigate carbon contamination.

The environmental impact of butane usage in CVD is also a growing concern. As a hydrocarbon, butane contributes to greenhouse gas emissions when used in industrial processes. The semiconductor industry is under increasing pressure to reduce its carbon footprint, prompting research into more environmentally friendly alternatives or methods to capture and recycle butane emissions.

Safety considerations present another challenge in the use of butane for CVD. As a flammable gas, butane requires stringent safety protocols and specialized handling equipment. This can increase the complexity and cost of CVD systems, particularly in large-scale industrial applications.

Despite these challenges, ongoing research and development efforts are focused on improving the efficiency and sustainability of butane usage in CVD. Advanced reactor designs, novel catalysts, and innovative process control strategies are being explored to address the current limitations and expand the applications of butane in CVD processes.

The primary advantage of using butane in CVD is its ability to serve as a carbon source for the deposition of carbon-based materials, such as diamond-like carbon (DLC) films. Butane's relatively low decomposition temperature and high carbon content make it an attractive precursor for these applications. Additionally, its gaseous state at room temperature facilitates easy handling and precise control of gas flow rates during the deposition process.

However, the current state of butane usage in CVD is not without its challenges. One of the main issues is the incomplete decomposition of butane during the process, which can lead to the incorporation of unwanted hydrogen into the deposited films. This can affect the film's properties and overall quality. Researchers are actively working on developing more efficient catalysts and optimizing process parameters to enhance butane decomposition and minimize hydrogen incorporation.

Another challenge is the potential for carbon contamination in non-carbon-based film depositions. When butane is used as a carrier gas or diluent in CVD processes for other materials, there is a risk of unintended carbon incorporation, which can alter the film's composition and properties. This necessitates careful process control and the development of strategies to mitigate carbon contamination.

The environmental impact of butane usage in CVD is also a growing concern. As a hydrocarbon, butane contributes to greenhouse gas emissions when used in industrial processes. The semiconductor industry is under increasing pressure to reduce its carbon footprint, prompting research into more environmentally friendly alternatives or methods to capture and recycle butane emissions.

Safety considerations present another challenge in the use of butane for CVD. As a flammable gas, butane requires stringent safety protocols and specialized handling equipment. This can increase the complexity and cost of CVD systems, particularly in large-scale industrial applications.

Despite these challenges, ongoing research and development efforts are focused on improving the efficiency and sustainability of butane usage in CVD. Advanced reactor designs, novel catalysts, and innovative process control strategies are being explored to address the current limitations and expand the applications of butane in CVD processes.

Existing Butane-based CVD Solutions

01 Butane gas lighters and refill devices

Various designs for butane gas lighters and refill devices have been developed. These include improvements in safety features, refilling mechanisms, and overall functionality. Some designs focus on portable lighters, while others are intended for more specialized applications.- Butane gas lighters and refill devices: Various designs for butane gas lighters and refill devices, including improvements in safety, efficiency, and ease of use. These innovations cover portable lighters, refillable lighters, and refill mechanisms for butane-based devices.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes aim to improve the quality and purity of butane for various industrial applications.

- Butane storage and transportation systems: Innovations in the storage and transportation of butane, including specialized containers, tanks, and safety mechanisms. These developments focus on improving the efficiency and safety of butane handling and distribution.

- Butane-based fuel systems and applications: Various applications and systems utilizing butane as a fuel source, including portable stoves, heating devices, and automotive fuel systems. These innovations aim to improve the efficiency and performance of butane-powered devices.

- Butane synthesis and production methods: Novel methods and processes for synthesizing and producing butane, including chemical reactions, catalytic processes, and industrial-scale production techniques. These innovations aim to improve the efficiency and yield of butane production.

02 Butane purification and separation processes

Methods for purifying and separating butane from other hydrocarbons have been invented. These processes aim to improve the quality of butane for various industrial applications, including the removal of impurities and the separation of different isomers of butane.Expand Specific Solutions03 Butane storage and transportation systems

Innovations in butane storage and transportation systems have been developed to improve safety and efficiency. These include specialized containers, valves, and filling systems designed to handle the unique properties of butane gas.Expand Specific Solutions04 Butane-based fuel compositions

Various fuel compositions incorporating butane have been formulated for specific applications. These compositions may include additives or blends with other hydrocarbons to enhance performance or meet particular requirements in different industries.Expand Specific Solutions05 Butane detection and safety systems

Safety systems and detection methods for butane gas have been invented to prevent accidents and improve handling. These include sensors, alarms, and automatic shut-off mechanisms designed to detect leaks or unsafe conditions in environments where butane is used or stored.Expand Specific Solutions

Key Players in CVD Industry

The competitive landscape for butane's role in the Chemical Vapor Deposition (CVD) process is characterized by a mature market with established players and ongoing technological advancements. The market is dominated by major chemical and petrochemical companies such as BASF, DuPont, and China Petroleum & Chemical Corp., who leverage their extensive R&D capabilities and global presence. The technology's maturity is evident in its widespread adoption across semiconductor, electronics, and materials industries. However, continuous innovation is driven by the need for higher purity precursors and more efficient deposition processes. Companies like UOP LLC and Linde GmbH are at the forefront of developing specialized CVD equipment and gases, while research institutions like IFP Energies Nouvelles contribute to advancing the technology's fundamental understanding and applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced butane-based Chemical Vapor Deposition (CVD) process for producing high-quality graphene films. Their method utilizes a controlled flow of butane gas as a carbon source in a low-pressure CVD reactor. The process involves precise temperature control and catalyst optimization to achieve uniform graphene growth[1]. Sinopec's technique allows for the synthesis of large-area, single-layer graphene with improved electrical and mechanical properties[3]. The company has also implemented in-situ doping techniques during the CVD process to enhance the graphene's conductivity and tailor its properties for specific applications[5].

Strengths: Large-scale production capability, high-quality graphene synthesis, and customizable properties. Weaknesses: Potentially high energy consumption and the need for specialized equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a novel butane-assisted CVD process for the deposition of high-k dielectric materials in semiconductor manufacturing. Their approach uses butane as a reducing agent to control the oxidation state of metal precursors during the deposition process. This results in improved film quality and reduced impurity incorporation[2]. DuPont's method allows for precise thickness control down to the atomic level, enabling the production of ultra-thin dielectric layers crucial for advanced logic and memory devices[4]. The company has also developed a proprietary catalyst system that enhances the decomposition of butane, leading to more efficient precursor utilization and reduced process temperatures[6].

Strengths: Precise control over film properties, compatibility with existing semiconductor manufacturing processes. Weaknesses: Potential safety concerns due to the use of flammable butane gas.

Core Innovations in Butane CVD Technology

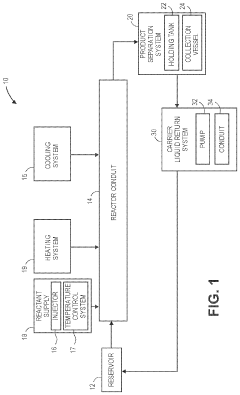

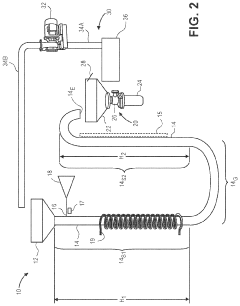

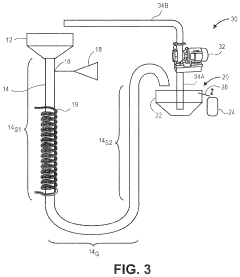

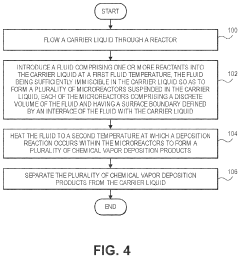

System and process for chemical vapor deposition

PatentActiveUS11371135B2

Innovation

- A microreactor system for CVD that involves flowing a carrier liquid through a reactor, where reactants are introduced to form microreactors suspended in the liquid, allowing for controlled temperature and pressure conditions to achieve uniform chemical vapor deposition products, including hollow spherical shells and carbon nanotubes.

Method for operating a chemical deposition chamber

PatentActiveUS8105648B2

Innovation

- A pre-tuning step is performed on a digital liquid flow controller after the chamber-cleaning step, involving cycles of turning it on and off to stabilize the flow rate of the precursor fluid, ensuring a stable and uniform flow for the chemical vapor deposition process.

Environmental Impact of Butane in CVD

The use of butane in Chemical Vapor Deposition (CVD) processes has significant environmental implications that warrant careful consideration. As a volatile organic compound (VOC), butane can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. In CVD applications, there is a risk of butane emissions during the deposition process, particularly if proper containment and exhaust systems are not in place.

The environmental impact of butane in CVD extends beyond air quality concerns. The production and transportation of butane for industrial use involve energy-intensive processes that contribute to greenhouse gas emissions. Additionally, the potential for accidental releases during storage and handling poses risks to local ecosystems and human health.

However, it is important to note that the environmental footprint of butane in CVD can be mitigated through proper management and technological advancements. Many modern CVD systems incorporate efficient gas handling and recycling mechanisms that minimize butane waste and emissions. The implementation of closed-loop systems and advanced scrubbing technologies can significantly reduce the release of butane and its byproducts into the environment.

From a lifecycle perspective, the environmental impact of butane in CVD must be weighed against the benefits of the resulting products. Many materials produced through CVD processes, such as thin films for solar cells or advanced coatings for energy-efficient windows, contribute to sustainable technologies that may offset the environmental costs associated with their production.

Regulatory frameworks play a crucial role in managing the environmental impact of butane in CVD. Stringent emission standards and workplace safety regulations in many countries have led to the development of cleaner CVD processes and improved handling practices. Companies engaged in CVD manufacturing are increasingly adopting environmental management systems to ensure compliance and minimize their ecological footprint.

Looking ahead, research into alternative precursor materials and process optimizations may further reduce the reliance on butane in CVD applications. The development of low-temperature CVD techniques and the exploration of bio-based precursors represent promising avenues for enhancing the environmental sustainability of CVD processes. As the industry continues to evolve, balancing technological advancement with environmental stewardship remains a key challenge in the responsible use of butane in CVD.

The environmental impact of butane in CVD extends beyond air quality concerns. The production and transportation of butane for industrial use involve energy-intensive processes that contribute to greenhouse gas emissions. Additionally, the potential for accidental releases during storage and handling poses risks to local ecosystems and human health.

However, it is important to note that the environmental footprint of butane in CVD can be mitigated through proper management and technological advancements. Many modern CVD systems incorporate efficient gas handling and recycling mechanisms that minimize butane waste and emissions. The implementation of closed-loop systems and advanced scrubbing technologies can significantly reduce the release of butane and its byproducts into the environment.

From a lifecycle perspective, the environmental impact of butane in CVD must be weighed against the benefits of the resulting products. Many materials produced through CVD processes, such as thin films for solar cells or advanced coatings for energy-efficient windows, contribute to sustainable technologies that may offset the environmental costs associated with their production.

Regulatory frameworks play a crucial role in managing the environmental impact of butane in CVD. Stringent emission standards and workplace safety regulations in many countries have led to the development of cleaner CVD processes and improved handling practices. Companies engaged in CVD manufacturing are increasingly adopting environmental management systems to ensure compliance and minimize their ecological footprint.

Looking ahead, research into alternative precursor materials and process optimizations may further reduce the reliance on butane in CVD applications. The development of low-temperature CVD techniques and the exploration of bio-based precursors represent promising avenues for enhancing the environmental sustainability of CVD processes. As the industry continues to evolve, balancing technological advancement with environmental stewardship remains a key challenge in the responsible use of butane in CVD.

Safety Regulations for Butane in CVD

The use of butane in Chemical Vapor Deposition (CVD) processes necessitates strict adherence to safety regulations due to its flammable and potentially explosive nature. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established comprehensive guidelines for the handling and storage of butane in industrial settings, including CVD applications.

One of the primary safety concerns is the prevention of gas leaks. CVD systems utilizing butane must be equipped with robust leak detection systems, typically employing infrared or catalytic sensors capable of detecting butane concentrations well below the lower explosive limit (LEL). These systems should be regularly calibrated and maintained to ensure optimal performance. Additionally, proper ventilation is crucial in CVD facilities to prevent the accumulation of butane vapors. OSHA mandates a minimum of six air changes per hour in areas where flammable gases are used.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Operators working with butane in CVD processes must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves rated for handling flammable gases. Emergency response plans must be in place, with clearly marked evacuation routes and easily accessible fire suppression equipment.

Storage regulations for butane cylinders used in CVD are equally stringent. Cylinders must be stored in well-ventilated areas, away from sources of heat or ignition, and secured to prevent tipping. The NFPA 55 standard provides detailed guidelines on the storage and handling of compressed gases, including specific requirements for flammable gases like butane.

Training is a fundamental component of safety regulations. All personnel involved in CVD processes using butane must undergo comprehensive safety training, covering topics such as proper handling procedures, emergency response protocols, and the use of safety equipment. This training should be documented and refreshed periodically to ensure ongoing compliance and safety awareness.

Waste management and disposal of butane-containing byproducts from CVD processes are also subject to strict regulations. The Environmental Protection Agency (EPA) provides guidelines for the proper disposal of hazardous waste, which may include unreacted butane or its derivatives. CVD facilities must implement proper waste segregation and disposal procedures to comply with these regulations.

Regular safety audits and inspections are mandated to ensure ongoing compliance with safety regulations. These audits should assess the integrity of CVD equipment, the effectiveness of safety systems, and adherence to established safety protocols. Any deficiencies identified during these audits must be promptly addressed to maintain a safe working environment.

One of the primary safety concerns is the prevention of gas leaks. CVD systems utilizing butane must be equipped with robust leak detection systems, typically employing infrared or catalytic sensors capable of detecting butane concentrations well below the lower explosive limit (LEL). These systems should be regularly calibrated and maintained to ensure optimal performance. Additionally, proper ventilation is crucial in CVD facilities to prevent the accumulation of butane vapors. OSHA mandates a minimum of six air changes per hour in areas where flammable gases are used.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Operators working with butane in CVD processes must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves rated for handling flammable gases. Emergency response plans must be in place, with clearly marked evacuation routes and easily accessible fire suppression equipment.

Storage regulations for butane cylinders used in CVD are equally stringent. Cylinders must be stored in well-ventilated areas, away from sources of heat or ignition, and secured to prevent tipping. The NFPA 55 standard provides detailed guidelines on the storage and handling of compressed gases, including specific requirements for flammable gases like butane.

Training is a fundamental component of safety regulations. All personnel involved in CVD processes using butane must undergo comprehensive safety training, covering topics such as proper handling procedures, emergency response protocols, and the use of safety equipment. This training should be documented and refreshed periodically to ensure ongoing compliance and safety awareness.

Waste management and disposal of butane-containing byproducts from CVD processes are also subject to strict regulations. The Environmental Protection Agency (EPA) provides guidelines for the proper disposal of hazardous waste, which may include unreacted butane or its derivatives. CVD facilities must implement proper waste segregation and disposal procedures to comply with these regulations.

Regular safety audits and inspections are mandated to ensure ongoing compliance with safety regulations. These audits should assess the integrity of CVD equipment, the effectiveness of safety systems, and adherence to established safety protocols. Any deficiencies identified during these audits must be promptly addressed to maintain a safe working environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!