Butane’s Role in the Advancements of Cryogenic Preservation Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Cryogenics

Butane plays a crucial role in the advancement of cryogenic preservation technologies, serving as a key component in various cooling systems and processes. Its unique properties make it an ideal candidate for use in cryogenic applications, particularly in the preservation of biological materials and the development of efficient cooling systems.

The low boiling point of butane (-0.5°C) allows it to rapidly evaporate at room temperature, creating a powerful cooling effect. This characteristic is particularly valuable in flash-freezing techniques, where rapid temperature reduction is essential for preserving cellular structures. When used in conjunction with other cryogenic agents, butane can enhance the overall efficiency of preservation processes.

In cryogenic preservation systems, butane is often employed as a pre-cooling agent or as part of a cascade refrigeration system. Its ability to quickly lower temperatures helps minimize the formation of ice crystals, which can damage cellular structures during the freezing process. This property is especially beneficial in the preservation of delicate biological samples, such as stem cells, embryos, and tissue samples.

Butane's role extends beyond its direct cooling capabilities. It is also used as a propellant in cryogenic spray systems, allowing for precise and controlled application of cooling agents. This application is particularly useful in localized cryotherapy treatments and in the development of portable cryogenic devices for field research and medical applications.

The integration of butane into cryogenic preservation technologies has led to significant improvements in storage and transportation methods for temperature-sensitive materials. Its use in mixed refrigerants has enabled the development of more compact and energy-efficient cryogenic systems, which are essential for long-term storage and transportation of preserved specimens.

Furthermore, butane's compatibility with other cryogenic agents has facilitated the creation of novel preservation protocols. These protocols combine the rapid cooling effects of butane with the long-term stability provided by other cryoprotectants, resulting in improved preservation outcomes and extended storage capabilities.

As research in cryogenic preservation continues to advance, the role of butane is likely to evolve. Current investigations are exploring its potential in ultra-low temperature applications and its synergistic effects with emerging cryoprotectants. These developments promise to further enhance the efficacy and versatility of cryogenic preservation technologies across various scientific and medical fields.

The low boiling point of butane (-0.5°C) allows it to rapidly evaporate at room temperature, creating a powerful cooling effect. This characteristic is particularly valuable in flash-freezing techniques, where rapid temperature reduction is essential for preserving cellular structures. When used in conjunction with other cryogenic agents, butane can enhance the overall efficiency of preservation processes.

In cryogenic preservation systems, butane is often employed as a pre-cooling agent or as part of a cascade refrigeration system. Its ability to quickly lower temperatures helps minimize the formation of ice crystals, which can damage cellular structures during the freezing process. This property is especially beneficial in the preservation of delicate biological samples, such as stem cells, embryos, and tissue samples.

Butane's role extends beyond its direct cooling capabilities. It is also used as a propellant in cryogenic spray systems, allowing for precise and controlled application of cooling agents. This application is particularly useful in localized cryotherapy treatments and in the development of portable cryogenic devices for field research and medical applications.

The integration of butane into cryogenic preservation technologies has led to significant improvements in storage and transportation methods for temperature-sensitive materials. Its use in mixed refrigerants has enabled the development of more compact and energy-efficient cryogenic systems, which are essential for long-term storage and transportation of preserved specimens.

Furthermore, butane's compatibility with other cryogenic agents has facilitated the creation of novel preservation protocols. These protocols combine the rapid cooling effects of butane with the long-term stability provided by other cryoprotectants, resulting in improved preservation outcomes and extended storage capabilities.

As research in cryogenic preservation continues to advance, the role of butane is likely to evolve. Current investigations are exploring its potential in ultra-low temperature applications and its synergistic effects with emerging cryoprotectants. These developments promise to further enhance the efficacy and versatility of cryogenic preservation technologies across various scientific and medical fields.

Market for Cryogens

The market for cryogens, particularly in the context of cryogenic preservation technologies, has been experiencing significant growth and transformation in recent years. This expansion is driven by the increasing demand for advanced preservation techniques across various industries, including healthcare, biotechnology, and food processing.

In the healthcare sector, the market for cryogens has seen substantial growth due to the rising need for long-term storage of biological samples, stem cells, and organs for transplantation. The advancements in regenerative medicine and personalized healthcare have further fueled this demand, as cryogenic preservation allows for the storage of patient-specific tissues and cells for future use.

The biotechnology industry has also contributed significantly to the expansion of the cryogen market. Research institutions and pharmaceutical companies rely heavily on cryogenic preservation for maintaining cell lines, genetic materials, and other biological specimens crucial for drug discovery and development processes.

Food processing and agriculture sectors have emerged as key players in the cryogen market, utilizing cryogenic technologies for flash freezing, transportation, and long-term storage of perishable goods. This application has led to improved food quality, extended shelf life, and reduced waste in the supply chain.

The global cryogen market has witnessed a shift towards more environmentally friendly and cost-effective solutions. This trend has led to increased research and development efforts focused on improving the efficiency of cryogenic systems and exploring alternative cryogens with lower environmental impact.

Geographically, North America and Europe have traditionally dominated the cryogen market due to their advanced healthcare and research infrastructure. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing investments in biotechnology and healthcare sectors in countries like China, Japan, and India.

The market landscape is characterized by a mix of established players and innovative start-ups. Major companies in the industrial gas sector have a significant presence in the cryogen market, while specialized cryogenic equipment manufacturers cater to specific industry needs. The competitive environment has led to continuous innovation in cryogenic technologies and applications.

Looking ahead, the cryogen market is poised for further growth, with projections indicating a steady increase in demand across various sectors. Factors such as technological advancements, increasing research activities, and the growing need for long-term biological preservation are expected to drive this growth in the coming years.

In the healthcare sector, the market for cryogens has seen substantial growth due to the rising need for long-term storage of biological samples, stem cells, and organs for transplantation. The advancements in regenerative medicine and personalized healthcare have further fueled this demand, as cryogenic preservation allows for the storage of patient-specific tissues and cells for future use.

The biotechnology industry has also contributed significantly to the expansion of the cryogen market. Research institutions and pharmaceutical companies rely heavily on cryogenic preservation for maintaining cell lines, genetic materials, and other biological specimens crucial for drug discovery and development processes.

Food processing and agriculture sectors have emerged as key players in the cryogen market, utilizing cryogenic technologies for flash freezing, transportation, and long-term storage of perishable goods. This application has led to improved food quality, extended shelf life, and reduced waste in the supply chain.

The global cryogen market has witnessed a shift towards more environmentally friendly and cost-effective solutions. This trend has led to increased research and development efforts focused on improving the efficiency of cryogenic systems and exploring alternative cryogens with lower environmental impact.

Geographically, North America and Europe have traditionally dominated the cryogen market due to their advanced healthcare and research infrastructure. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing investments in biotechnology and healthcare sectors in countries like China, Japan, and India.

The market landscape is characterized by a mix of established players and innovative start-ups. Major companies in the industrial gas sector have a significant presence in the cryogen market, while specialized cryogenic equipment manufacturers cater to specific industry needs. The competitive environment has led to continuous innovation in cryogenic technologies and applications.

Looking ahead, the cryogen market is poised for further growth, with projections indicating a steady increase in demand across various sectors. Factors such as technological advancements, increasing research activities, and the growing need for long-term biological preservation are expected to drive this growth in the coming years.

Butane Challenges

Despite the potential benefits of using butane in cryogenic preservation technologies, several significant challenges need to be addressed. One of the primary concerns is the flammability and explosive nature of butane. As a highly volatile hydrocarbon, butane poses substantial safety risks in laboratory and industrial settings. Strict safety protocols and specialized handling equipment are necessary to mitigate these risks, which can increase operational costs and complexity.

Another challenge lies in the precise control of butane's phase transitions during the cryopreservation process. The transition from liquid to gas state must be carefully managed to prevent rapid expansion and potential damage to biological samples. This requires advanced temperature and pressure control systems, adding to the technical complexity of cryopreservation equipment.

The purity of butane used in cryogenic applications is also a critical concern. Impurities can significantly affect the freezing and thawing processes, potentially compromising the integrity of preserved specimens. Ensuring a consistent supply of high-purity butane for large-scale cryopreservation operations can be challenging and costly.

Environmental concerns present another hurdle in the widespread adoption of butane-based cryogenic technologies. As a hydrocarbon, butane contributes to greenhouse gas emissions when released into the atmosphere. Developing closed-loop systems to minimize butane loss and implementing effective recycling methods are essential for sustainable long-term use.

Regulatory compliance is an additional challenge, particularly in medical and food preservation applications. Stringent regulations govern the use of hydrocarbons in these sectors, necessitating extensive testing and validation processes to ensure safety and efficacy. This can lead to prolonged development timelines and increased costs for bringing butane-based cryopreservation technologies to market.

The integration of butane into existing cryopreservation infrastructure poses logistical challenges. Many facilities are designed for traditional cryogens like liquid nitrogen, and retrofitting them for butane use may require significant modifications. This includes upgrading storage tanks, transfer systems, and safety equipment, which can be both time-consuming and expensive.

Lastly, there is a need for comprehensive research on the long-term effects of butane exposure on various biological materials. While initial studies show promise, more extensive investigations are required to fully understand the impact of butane-based cryopreservation on cellular structures, genetic material, and overall viability of preserved specimens across different species and tissue types.

Another challenge lies in the precise control of butane's phase transitions during the cryopreservation process. The transition from liquid to gas state must be carefully managed to prevent rapid expansion and potential damage to biological samples. This requires advanced temperature and pressure control systems, adding to the technical complexity of cryopreservation equipment.

The purity of butane used in cryogenic applications is also a critical concern. Impurities can significantly affect the freezing and thawing processes, potentially compromising the integrity of preserved specimens. Ensuring a consistent supply of high-purity butane for large-scale cryopreservation operations can be challenging and costly.

Environmental concerns present another hurdle in the widespread adoption of butane-based cryogenic technologies. As a hydrocarbon, butane contributes to greenhouse gas emissions when released into the atmosphere. Developing closed-loop systems to minimize butane loss and implementing effective recycling methods are essential for sustainable long-term use.

Regulatory compliance is an additional challenge, particularly in medical and food preservation applications. Stringent regulations govern the use of hydrocarbons in these sectors, necessitating extensive testing and validation processes to ensure safety and efficacy. This can lead to prolonged development timelines and increased costs for bringing butane-based cryopreservation technologies to market.

The integration of butane into existing cryopreservation infrastructure poses logistical challenges. Many facilities are designed for traditional cryogens like liquid nitrogen, and retrofitting them for butane use may require significant modifications. This includes upgrading storage tanks, transfer systems, and safety equipment, which can be both time-consuming and expensive.

Lastly, there is a need for comprehensive research on the long-term effects of butane exposure on various biological materials. While initial studies show promise, more extensive investigations are required to fully understand the impact of butane-based cryopreservation on cellular structures, genetic material, and overall viability of preserved specimens across different species and tissue types.

Butane Solutions

01 Butane storage and preservation methods

Various methods and devices are used for storing and preserving butane. These include specialized containers, tanks, and systems designed to maintain the quality and safety of butane during storage and transportation. Such methods often involve pressure control, temperature regulation, and safety features to prevent leaks or contamination.- Butane storage and preservation methods: Various methods and devices are used for storing and preserving butane. These include specialized containers, tanks, and storage systems designed to maintain the quality and safety of butane during storage and transportation. The methods focus on preventing leakage, contamination, and degradation of the butane.

- Butane purification techniques: Purification techniques are employed to remove impurities and maintain the quality of butane. These methods may include filtration, distillation, or chemical treatments to ensure the butane meets specific purity standards for various applications, such as fuel or industrial use.

- Butane handling and dispensing systems: Specialized systems and equipment are developed for safe handling and dispensing of butane. These include filling stations, transfer systems, and dispensing nozzles designed to minimize leakage and ensure accurate measurement during the transfer of butane from storage to end-use applications.

- Butane stabilization and additive incorporation: Methods for stabilizing butane and incorporating additives to enhance its properties or extend its shelf life. This may include the addition of antioxidants, stabilizers, or other chemicals to improve the butane's performance or longevity in various applications.

- Butane safety and monitoring systems: Development of safety features and monitoring systems for butane storage and use. These include leak detection systems, pressure relief valves, and other safety devices designed to prevent accidents and ensure the safe handling and storage of butane in various settings.

02 Butane purification techniques

Purification techniques are employed to remove impurities from butane, ensuring its quality for various applications. These methods may include distillation, adsorption, or chemical treatments to separate butane from other hydrocarbons or contaminants. Purification is crucial for maintaining the effectiveness and safety of butane in different industrial and consumer uses.Expand Specific Solutions03 Butane dispensing and refilling systems

Specialized systems are developed for dispensing and refilling butane in various applications. These systems often include safety features, precise measurement mechanisms, and efficient transfer methods to ensure accurate and safe handling of butane during refilling processes. Such systems are commonly used in portable devices, industrial equipment, and fuel stations.Expand Specific Solutions04 Butane stabilization and additive incorporation

Techniques for stabilizing butane and incorporating additives are used to enhance its properties or extend its shelf life. This may involve the addition of chemical stabilizers, antioxidants, or other compounds that improve the butane's performance, safety, or longevity. Such methods are particularly important in applications where butane quality must be maintained over extended periods.Expand Specific Solutions05 Butane safety and leak prevention

Safety measures and leak prevention techniques are crucial in butane preservation. These include the development of specialized valves, seals, and containment systems designed to prevent accidental release or leakage of butane. Advanced monitoring systems and safety protocols are also implemented to ensure the safe handling, storage, and use of butane in various settings.Expand Specific Solutions

Cryogenic Industry

The cryogenic preservation technology market is in a growth phase, driven by advancements in butane's role and increasing applications across various industries. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is progressing rapidly, with companies like Praxair Technology, Inc. and Linde GmbH leading innovations in cryogenic equipment and processes. China Petroleum & Chemical Corp. and BASF Corp. are contributing to the development of specialized chemicals for cryogenic applications. Emerging players such as Criotec Impianti SpA and Alcor Life Extension Foundation are pushing boundaries in niche areas, indicating a diversifying and maturing market landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant advancements in cryogenic preservation technologies using butane. Their approach involves utilizing butane as a cryogenic fluid in a novel cascade refrigeration system. This system achieves ultra-low temperatures by employing a multi-stage cooling process, where butane is used in the initial stages due to its favorable thermodynamic properties[1]. The company has developed proprietary heat exchangers that maximize the efficiency of butane in the cryogenic cycle, allowing for rapid cooling and stable temperature maintenance[3]. Additionally, Sinopec has integrated smart control systems that optimize butane flow and pressure, ensuring precise temperature regulation in cryogenic preservation applications[5].

Strengths: Efficient use of butane in multi-stage cooling, proprietary heat exchanger technology, and smart control systems for precise temperature regulation. Weaknesses: Potential safety concerns due to butane's flammability, and the need for specialized handling and storage infrastructure.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed an innovative cryogenic preservation system that leverages butane's unique properties. Their approach involves using butane as a component in a mixed refrigerant system, which allows for more efficient cooling compared to traditional single-component systems[2]. The company has engineered specialized compressors and expansion valves that can handle butane's specific pressure and temperature requirements in cryogenic applications[4]. Praxair's system also incorporates advanced insulation techniques that minimize heat transfer, thereby reducing butane consumption and improving overall energy efficiency[6]. Furthermore, they have implemented a closed-loop recycling process for butane, enhancing the sustainability of their cryogenic preservation technology[8].

Strengths: Efficient mixed refrigerant system, specialized equipment for butane handling, advanced insulation techniques, and sustainable butane recycling. Weaknesses: Complexity of the mixed refrigerant system may require more maintenance and expertise to operate.

Butane Innovations

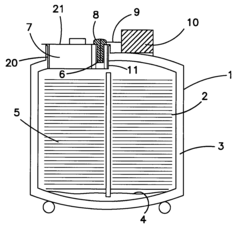

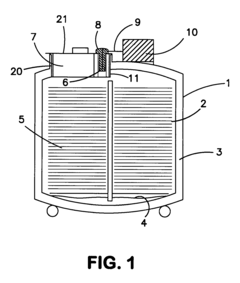

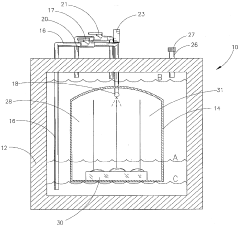

Cryogenic biological preservation unit

PatentInactiveUS7290396B2

Innovation

- A cryogenic biological preservation unit incorporating an insulated vessel with a pool of liquid cryogen and a cryocooler featuring a cold finger or cold head that provides refrigeration to the vessel interior, reducing the need for external cryogen replenishment by condensing cryogen vapor and maintaining sample integrity across the storage space.

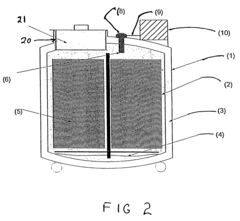

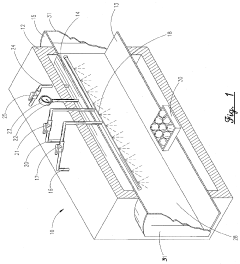

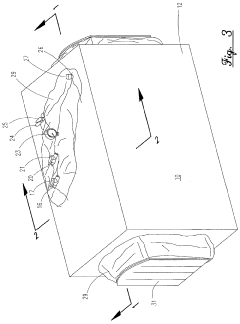

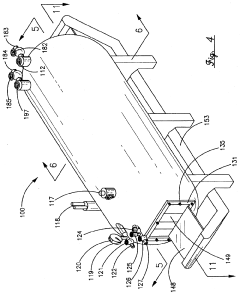

Apparatus and methods for cryogenic treatment of materials

PatentInactiveUS5520004A

Innovation

- The development of an apparatus and method utilizing the latent heat of vaporization of cryogenic or low-temperature fluids for directional freezing, minimizing immersion in liquid coolants, and employing vapor or liquid sprays to achieve rapid and uniform temperature reduction without fracturing, using liquid nitrogen or carbon dioxide as coolants.

Safety Regulations

The integration of butane in cryogenic preservation technologies necessitates stringent safety regulations due to its flammable nature. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA), have established comprehensive guidelines for the handling, storage, and use of butane in cryogenic applications.

These regulations mandate specific safety measures, including proper ventilation systems, explosion-proof electrical equipment, and regular leak detection protocols. Facilities utilizing butane-based cryogenic systems must implement rigorous risk assessment procedures and maintain detailed safety documentation. Employee training programs are required to ensure proper handling techniques and emergency response protocols are understood and followed.

Storage regulations for butane in cryogenic preservation facilities are particularly stringent. Tanks and containers must meet specific design criteria to withstand extreme temperatures and pressures. Regular inspections and maintenance schedules are mandated to ensure the integrity of storage systems and prevent potential leaks or failures.

Transportation of butane for cryogenic applications is subject to strict regulations outlined by the Department of Transportation (DOT). These include specific requirements for container design, labeling, and documentation. Vehicles transporting butane must adhere to designated routes and carry appropriate safety equipment.

Personal protective equipment (PPE) requirements for workers handling butane in cryogenic environments are clearly defined. This includes specialized cold-resistant gloves, face shields, and protective clothing to prevent exposure to both the cryogenic temperatures and potential butane leaks.

Emergency response plans are a critical component of safety regulations. Facilities must have detailed procedures in place for various scenarios, including fires, leaks, and accidental exposures. Regular drills and simulations are required to ensure staff readiness in emergency situations.

Environmental regulations also play a significant role, with strict guidelines on emissions control and waste management. Facilities must implement systems to minimize butane release into the atmosphere and properly dispose of any contaminated materials.

Compliance with these regulations is monitored through regular inspections and audits by regulatory agencies. Non-compliance can result in severe penalties, including fines and operational shutdowns. As cryogenic preservation technologies continue to advance, safety regulations are continuously reviewed and updated to address new challenges and ensure the highest standards of safety in the industry.

These regulations mandate specific safety measures, including proper ventilation systems, explosion-proof electrical equipment, and regular leak detection protocols. Facilities utilizing butane-based cryogenic systems must implement rigorous risk assessment procedures and maintain detailed safety documentation. Employee training programs are required to ensure proper handling techniques and emergency response protocols are understood and followed.

Storage regulations for butane in cryogenic preservation facilities are particularly stringent. Tanks and containers must meet specific design criteria to withstand extreme temperatures and pressures. Regular inspections and maintenance schedules are mandated to ensure the integrity of storage systems and prevent potential leaks or failures.

Transportation of butane for cryogenic applications is subject to strict regulations outlined by the Department of Transportation (DOT). These include specific requirements for container design, labeling, and documentation. Vehicles transporting butane must adhere to designated routes and carry appropriate safety equipment.

Personal protective equipment (PPE) requirements for workers handling butane in cryogenic environments are clearly defined. This includes specialized cold-resistant gloves, face shields, and protective clothing to prevent exposure to both the cryogenic temperatures and potential butane leaks.

Emergency response plans are a critical component of safety regulations. Facilities must have detailed procedures in place for various scenarios, including fires, leaks, and accidental exposures. Regular drills and simulations are required to ensure staff readiness in emergency situations.

Environmental regulations also play a significant role, with strict guidelines on emissions control and waste management. Facilities must implement systems to minimize butane release into the atmosphere and properly dispose of any contaminated materials.

Compliance with these regulations is monitored through regular inspections and audits by regulatory agencies. Non-compliance can result in severe penalties, including fines and operational shutdowns. As cryogenic preservation technologies continue to advance, safety regulations are continuously reviewed and updated to address new challenges and ensure the highest standards of safety in the industry.

Environmental Impact

The environmental impact of butane's role in cryogenic preservation technologies is a critical aspect that requires careful consideration. As the use of butane in these advanced technologies increases, it is essential to assess both the positive and negative effects on the environment.

Butane, as a hydrocarbon, is a fossil fuel derivative and its production and use contribute to greenhouse gas emissions. However, when compared to other cryogenic agents, butane offers some environmental advantages. Its lower global warming potential (GWP) and ozone depletion potential (ODP) make it a more environmentally friendly option than traditional chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs) used in cryogenic applications.

The energy efficiency of butane-based cryogenic systems is another factor that influences its environmental impact. These systems often require less energy to achieve and maintain ultra-low temperatures compared to conventional methods, potentially reducing overall energy consumption and associated carbon emissions in cryogenic preservation processes.

However, the release of butane into the atmosphere, whether through leaks or during the disposal of cryogenic equipment, can contribute to air pollution and smog formation. This necessitates stringent safety measures and proper handling protocols to minimize unintended emissions and their subsequent environmental consequences.

The lifecycle assessment of butane in cryogenic preservation technologies reveals both benefits and challenges. While its production does have an environmental footprint, the extended preservation capabilities it enables can lead to reduced waste in various industries, particularly in food preservation and biomedical applications. This indirect positive impact on resource conservation and waste reduction should be factored into the overall environmental evaluation.

As cryogenic preservation technologies advance, there is a growing focus on developing closed-loop systems that minimize butane loss and maximize recycling. These innovations aim to further reduce the environmental impact by ensuring that the butane used in cryogenic processes is contained and reused, rather than released into the environment.

The regulatory landscape surrounding the use of butane in cryogenic applications is evolving, with increasing emphasis on environmental protection. Compliance with emissions standards and implementation of best practices for handling and disposal are becoming integral to the adoption of butane-based cryogenic technologies across various industries.

In conclusion, while butane's role in advancing cryogenic preservation technologies offers significant benefits, its environmental impact remains a complex issue. Ongoing research and development efforts are focused on optimizing its use to maximize efficiency and minimize negative environmental effects, ensuring a more sustainable future for cryogenic preservation technologies.

Butane, as a hydrocarbon, is a fossil fuel derivative and its production and use contribute to greenhouse gas emissions. However, when compared to other cryogenic agents, butane offers some environmental advantages. Its lower global warming potential (GWP) and ozone depletion potential (ODP) make it a more environmentally friendly option than traditional chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs) used in cryogenic applications.

The energy efficiency of butane-based cryogenic systems is another factor that influences its environmental impact. These systems often require less energy to achieve and maintain ultra-low temperatures compared to conventional methods, potentially reducing overall energy consumption and associated carbon emissions in cryogenic preservation processes.

However, the release of butane into the atmosphere, whether through leaks or during the disposal of cryogenic equipment, can contribute to air pollution and smog formation. This necessitates stringent safety measures and proper handling protocols to minimize unintended emissions and their subsequent environmental consequences.

The lifecycle assessment of butane in cryogenic preservation technologies reveals both benefits and challenges. While its production does have an environmental footprint, the extended preservation capabilities it enables can lead to reduced waste in various industries, particularly in food preservation and biomedical applications. This indirect positive impact on resource conservation and waste reduction should be factored into the overall environmental evaluation.

As cryogenic preservation technologies advance, there is a growing focus on developing closed-loop systems that minimize butane loss and maximize recycling. These innovations aim to further reduce the environmental impact by ensuring that the butane used in cryogenic processes is contained and reused, rather than released into the environment.

The regulatory landscape surrounding the use of butane in cryogenic applications is evolving, with increasing emphasis on environmental protection. Compliance with emissions standards and implementation of best practices for handling and disposal are becoming integral to the adoption of butane-based cryogenic technologies across various industries.

In conclusion, while butane's role in advancing cryogenic preservation technologies offers significant benefits, its environmental impact remains a complex issue. Ongoing research and development efforts are focused on optimizing its use to maximize efficiency and minimize negative environmental effects, ensuring a more sustainable future for cryogenic preservation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!