How Butane Transforms Water Filtration Efficiency in Industrial Systems

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Water Filtration Background and Objectives

Water filtration technology has undergone significant advancements over the years, with a constant focus on improving efficiency and effectiveness in industrial systems. The introduction of butane as a transformative agent in water filtration marks a new chapter in this field, promising enhanced performance and potential cost savings for industrial applications.

The evolution of water filtration techniques has been driven by the increasing demand for clean water in various industries, including manufacturing, pharmaceuticals, and food processing. Traditional filtration methods, while effective to a certain degree, have often struggled with issues such as membrane fouling, high energy consumption, and limited filtration rates. These challenges have spurred researchers and engineers to explore innovative approaches to water purification.

Butane, a hydrocarbon typically associated with fuel applications, has emerged as an unexpected ally in the quest for more efficient water filtration. Its unique properties, when applied to filtration systems, offer the potential to overcome many of the limitations faced by conventional methods. The integration of butane into water filtration processes represents a convergence of chemical engineering principles and environmental technology, opening up new possibilities for industrial water treatment.

The primary objective of incorporating butane into water filtration systems is to significantly enhance the efficiency of the filtration process. This includes improving the rate of water purification, reducing energy consumption, and extending the lifespan of filtration membranes. By leveraging the physical and chemical properties of butane, researchers aim to develop filtration systems that can handle larger volumes of water with greater speed and precision.

Another key goal is to address the persistent issue of membrane fouling, which has long been a bottleneck in industrial water filtration. Butane's potential to create a more dynamic filtration environment could lead to self-cleaning membrane systems, dramatically reducing maintenance requirements and operational downtime. This would not only improve the overall efficiency of water treatment facilities but also contribute to substantial cost savings in the long term.

Furthermore, the exploration of butane in water filtration aligns with the broader trend towards more sustainable industrial practices. By potentially reducing the energy footprint of water treatment processes and minimizing the use of harsh chemicals, butane-enhanced filtration systems could offer a more environmentally friendly approach to water purification. This aspect is particularly relevant in the context of increasing global emphasis on sustainable resource management and environmental protection.

As research in this area progresses, the ultimate aim is to develop scalable and adaptable butane-based filtration technologies that can be implemented across a wide range of industrial applications. This could revolutionize water treatment processes in sectors ranging from municipal water supplies to specialized industrial operations, potentially leading to more efficient use of water resources and improved water quality standards worldwide.

The evolution of water filtration techniques has been driven by the increasing demand for clean water in various industries, including manufacturing, pharmaceuticals, and food processing. Traditional filtration methods, while effective to a certain degree, have often struggled with issues such as membrane fouling, high energy consumption, and limited filtration rates. These challenges have spurred researchers and engineers to explore innovative approaches to water purification.

Butane, a hydrocarbon typically associated with fuel applications, has emerged as an unexpected ally in the quest for more efficient water filtration. Its unique properties, when applied to filtration systems, offer the potential to overcome many of the limitations faced by conventional methods. The integration of butane into water filtration processes represents a convergence of chemical engineering principles and environmental technology, opening up new possibilities for industrial water treatment.

The primary objective of incorporating butane into water filtration systems is to significantly enhance the efficiency of the filtration process. This includes improving the rate of water purification, reducing energy consumption, and extending the lifespan of filtration membranes. By leveraging the physical and chemical properties of butane, researchers aim to develop filtration systems that can handle larger volumes of water with greater speed and precision.

Another key goal is to address the persistent issue of membrane fouling, which has long been a bottleneck in industrial water filtration. Butane's potential to create a more dynamic filtration environment could lead to self-cleaning membrane systems, dramatically reducing maintenance requirements and operational downtime. This would not only improve the overall efficiency of water treatment facilities but also contribute to substantial cost savings in the long term.

Furthermore, the exploration of butane in water filtration aligns with the broader trend towards more sustainable industrial practices. By potentially reducing the energy footprint of water treatment processes and minimizing the use of harsh chemicals, butane-enhanced filtration systems could offer a more environmentally friendly approach to water purification. This aspect is particularly relevant in the context of increasing global emphasis on sustainable resource management and environmental protection.

As research in this area progresses, the ultimate aim is to develop scalable and adaptable butane-based filtration technologies that can be implemented across a wide range of industrial applications. This could revolutionize water treatment processes in sectors ranging from municipal water supplies to specialized industrial operations, potentially leading to more efficient use of water resources and improved water quality standards worldwide.

Industrial Demand for Enhanced Water Filtration

The industrial sector's demand for enhanced water filtration has been steadily increasing due to several factors driving the need for more efficient and effective water treatment solutions. As global industrialization continues to expand, the volume of water used in various industrial processes has grown significantly, leading to a greater emphasis on water conservation and reuse strategies.

One of the primary drivers for improved water filtration in industrial systems is the stringent environmental regulations imposed by governments worldwide. These regulations require industries to meet specific water quality standards for both intake and discharge, necessitating advanced filtration technologies to remove contaminants and pollutants effectively.

The rising costs associated with water consumption and wastewater treatment have also contributed to the increased demand for enhanced filtration systems. Industries are seeking ways to optimize their water usage and reduce operational expenses by implementing more efficient filtration methods that can extend the life of process water and minimize the need for fresh water intake.

Furthermore, the growing awareness of water scarcity and the importance of sustainable water management practices have prompted industries to invest in advanced filtration technologies. This shift towards sustainability has led to a greater focus on water recycling and reuse within industrial processes, requiring highly effective filtration systems to ensure water quality meets the necessary standards for various applications.

The semiconductor and electronics manufacturing sectors, in particular, have shown a significant demand for ultra-pure water, driving the need for advanced filtration technologies capable of removing even the smallest impurities. Similarly, the pharmaceutical and food and beverage industries require high-quality water for their production processes, further fueling the demand for sophisticated filtration solutions.

The oil and gas industry, known for its water-intensive operations, has also been a major contributor to the demand for enhanced water filtration. As exploration and production activities expand into more challenging environments, the need for efficient water treatment and reuse technologies has become increasingly critical.

In response to these demands, the water filtration industry has been developing innovative technologies and materials to improve filtration efficiency and effectiveness. This includes the exploration of novel filtration media, advanced membrane technologies, and smart filtration systems that can adapt to changing water quality conditions.

One of the primary drivers for improved water filtration in industrial systems is the stringent environmental regulations imposed by governments worldwide. These regulations require industries to meet specific water quality standards for both intake and discharge, necessitating advanced filtration technologies to remove contaminants and pollutants effectively.

The rising costs associated with water consumption and wastewater treatment have also contributed to the increased demand for enhanced filtration systems. Industries are seeking ways to optimize their water usage and reduce operational expenses by implementing more efficient filtration methods that can extend the life of process water and minimize the need for fresh water intake.

Furthermore, the growing awareness of water scarcity and the importance of sustainable water management practices have prompted industries to invest in advanced filtration technologies. This shift towards sustainability has led to a greater focus on water recycling and reuse within industrial processes, requiring highly effective filtration systems to ensure water quality meets the necessary standards for various applications.

The semiconductor and electronics manufacturing sectors, in particular, have shown a significant demand for ultra-pure water, driving the need for advanced filtration technologies capable of removing even the smallest impurities. Similarly, the pharmaceutical and food and beverage industries require high-quality water for their production processes, further fueling the demand for sophisticated filtration solutions.

The oil and gas industry, known for its water-intensive operations, has also been a major contributor to the demand for enhanced water filtration. As exploration and production activities expand into more challenging environments, the need for efficient water treatment and reuse technologies has become increasingly critical.

In response to these demands, the water filtration industry has been developing innovative technologies and materials to improve filtration efficiency and effectiveness. This includes the exploration of novel filtration media, advanced membrane technologies, and smart filtration systems that can adapt to changing water quality conditions.

Current Challenges in Butane-Based Filtration

Despite the promising potential of butane-based water filtration systems in industrial applications, several significant challenges currently hinder their widespread adoption and optimal performance. These challenges span technical, operational, and regulatory domains, requiring innovative solutions and further research to overcome.

One of the primary technical challenges is the optimization of butane-water interaction within the filtration system. While butane's hydrophobic nature enhances its ability to separate contaminants from water, achieving consistent and efficient contact between butane and water molecules across various flow rates and pressure conditions remains problematic. This inconsistency can lead to reduced filtration efficiency and unpredictable performance in industrial-scale systems.

The stability and control of butane within the filtration system pose another significant challenge. Butane's high volatility at room temperature necessitates sophisticated containment and pressure regulation mechanisms. Fluctuations in temperature and pressure can cause butane to transition between liquid and gaseous states, potentially disrupting the filtration process and compromising system integrity. Developing robust control systems that maintain optimal butane conditions across diverse operational environments is crucial for reliable performance.

Scalability presents a formidable obstacle in the implementation of butane-based filtration technologies. While laboratory-scale experiments have demonstrated promising results, translating these successes to industrial-scale operations introduces complexities in system design, flow dynamics, and maintenance requirements. Engineers must overcome challenges related to uniform butane distribution, efficient contaminant removal, and system modularity to meet the diverse needs of industrial applications.

Safety concerns associated with butane's flammability and potential for gas leaks pose significant operational and regulatory challenges. Implementing comprehensive safety protocols, leak detection systems, and explosion-proof designs is essential but adds complexity and cost to system development and operation. Addressing these safety issues is critical for regulatory compliance and widespread industrial acceptance of butane-based filtration technologies.

The environmental impact of butane usage in water filtration systems remains a point of concern. While butane itself is not considered a significant pollutant, its production and potential release into the atmosphere contribute to greenhouse gas emissions. Developing closed-loop systems that minimize butane loss and exploring more environmentally friendly alternatives are ongoing challenges in the field.

Lastly, the integration of butane-based filtration systems with existing industrial water treatment infrastructure presents logistical and technical hurdles. Retrofitting current systems or designing new facilities to accommodate butane-based technologies requires significant investment and expertise. Overcoming resistance to change and demonstrating clear cost-benefit advantages over conventional filtration methods are essential for industry-wide adoption.

One of the primary technical challenges is the optimization of butane-water interaction within the filtration system. While butane's hydrophobic nature enhances its ability to separate contaminants from water, achieving consistent and efficient contact between butane and water molecules across various flow rates and pressure conditions remains problematic. This inconsistency can lead to reduced filtration efficiency and unpredictable performance in industrial-scale systems.

The stability and control of butane within the filtration system pose another significant challenge. Butane's high volatility at room temperature necessitates sophisticated containment and pressure regulation mechanisms. Fluctuations in temperature and pressure can cause butane to transition between liquid and gaseous states, potentially disrupting the filtration process and compromising system integrity. Developing robust control systems that maintain optimal butane conditions across diverse operational environments is crucial for reliable performance.

Scalability presents a formidable obstacle in the implementation of butane-based filtration technologies. While laboratory-scale experiments have demonstrated promising results, translating these successes to industrial-scale operations introduces complexities in system design, flow dynamics, and maintenance requirements. Engineers must overcome challenges related to uniform butane distribution, efficient contaminant removal, and system modularity to meet the diverse needs of industrial applications.

Safety concerns associated with butane's flammability and potential for gas leaks pose significant operational and regulatory challenges. Implementing comprehensive safety protocols, leak detection systems, and explosion-proof designs is essential but adds complexity and cost to system development and operation. Addressing these safety issues is critical for regulatory compliance and widespread industrial acceptance of butane-based filtration technologies.

The environmental impact of butane usage in water filtration systems remains a point of concern. While butane itself is not considered a significant pollutant, its production and potential release into the atmosphere contribute to greenhouse gas emissions. Developing closed-loop systems that minimize butane loss and exploring more environmentally friendly alternatives are ongoing challenges in the field.

Lastly, the integration of butane-based filtration systems with existing industrial water treatment infrastructure presents logistical and technical hurdles. Retrofitting current systems or designing new facilities to accommodate butane-based technologies requires significant investment and expertise. Overcoming resistance to change and demonstrating clear cost-benefit advantages over conventional filtration methods are essential for industry-wide adoption.

Existing Butane Filtration Solutions

01 Filtration systems for butane gas

Various filtration systems have been developed to improve the efficiency of butane gas purification. These systems may include multiple stages of filtration, utilizing different materials and techniques to remove impurities and contaminants from the butane gas stream. The design of these systems aims to enhance the overall filtration efficiency while maintaining optimal flow rates.- Filtration systems for butane gas: Various filtration systems are designed specifically for butane gas to improve its purity and efficiency. These systems may include multiple stages of filtration, utilizing different materials and techniques to remove impurities and contaminants from the gas stream. The filtration process can enhance the quality of butane for various applications, including fuel and industrial uses.

- Measurement and testing of butane filtration efficiency: Methods and apparatus for measuring and testing the efficiency of butane filtration systems have been developed. These techniques may involve specialized equipment to analyze the composition of the gas before and after filtration, as well as monitoring pressure drops and flow rates. Such measurements help in optimizing filtration processes and ensuring the quality of filtered butane.

- Innovative filter materials for butane purification: Research has led to the development of novel filter materials specifically designed for butane purification. These materials may include advanced adsorbents, molecular sieves, or composite structures that can effectively remove a wide range of impurities from butane gas. The use of these innovative materials can significantly improve filtration efficiency and extend the lifespan of filtration systems.

- Integration of butane filtration in processing equipment: Butane filtration systems are being integrated into various processing equipment and appliances. This integration aims to improve the overall efficiency of butane-based processes by ensuring a constant supply of high-purity gas. Examples include built-in filters in butane stoves, lighters, and industrial processing equipment, which can enhance performance and safety.

- Environmental and safety considerations in butane filtration: Advancements in butane filtration technology are focusing on environmental and safety aspects. This includes the development of eco-friendly filter materials, methods for safe disposal of used filters, and systems that reduce the release of volatile organic compounds during the filtration process. These improvements aim to make butane filtration more sustainable and safer for both industrial and consumer applications.

02 Adsorption-based filtration methods

Adsorption-based filtration methods are employed to remove impurities from butane gas. These methods typically use adsorbent materials such as activated carbon, zeolites, or molecular sieves to capture contaminants. The efficiency of adsorption-based filtration can be improved by optimizing factors such as adsorbent selection, contact time, and regeneration processes.Expand Specific Solutions03 Membrane filtration technology

Membrane filtration technology is utilized for butane gas purification. This approach involves the use of selective membranes that allow the passage of butane molecules while blocking larger impurities. The efficiency of membrane filtration can be enhanced by developing advanced membrane materials, optimizing operating conditions, and implementing multi-stage membrane systems.Expand Specific Solutions04 Cryogenic filtration techniques

Cryogenic filtration techniques are employed to separate impurities from butane gas by exploiting differences in boiling points. These methods involve cooling the gas mixture to very low temperatures, causing impurities to condense or freeze out. The efficiency of cryogenic filtration can be improved by optimizing cooling rates, residence times, and heat exchange processes.Expand Specific Solutions05 Monitoring and control systems for filtration efficiency

Advanced monitoring and control systems are implemented to optimize butane filtration efficiency. These systems may include sensors, real-time analysis tools, and automated control mechanisms to continuously monitor filtration performance and adjust operating parameters. By implementing such systems, the overall efficiency of butane filtration processes can be significantly improved.Expand Specific Solutions

Key Players in Industrial Water Treatment

The water filtration efficiency enhancement using butane in industrial systems is an emerging field, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for more efficient water treatment solutions in various industries. The technology's maturity is still evolving, with key players like DuPont de Nemours, Inc., SABIC, and Evonik Operations GmbH leading research and development efforts. These companies are leveraging their expertise in chemical engineering and materials science to explore butane's potential in water filtration. While the technology shows promise, it is not yet widely adopted, indicating significant room for growth and innovation in this sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative butane-based water filtration system for industrial applications. The system utilizes a proprietary membrane technology that incorporates butane as a key component in the filtration process. This approach leverages butane's unique properties to enhance water purification efficiency. The technology involves a multi-stage filtration process where butane is used to create a hydrophobic barrier within the membrane structure, allowing for more effective removal of contaminants[1]. The system also incorporates a novel regeneration process that uses butane to clean and restore the membrane's filtration capacity, significantly extending its operational lifespan[3]. Sinopec's research has shown that this butane-enhanced filtration system can achieve up to 30% higher throughput compared to conventional methods, while maintaining superior water quality standards[5].

Strengths: Higher filtration efficiency, extended membrane lifespan, and reduced operational costs. Weaknesses: Potential safety concerns related to butane handling and the need for specialized equipment for butane integration in the filtration process.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a groundbreaking butane-assisted water filtration technology for industrial systems. Their approach involves the use of butane as a pre-treatment agent in the filtration process. The technology employs a patented butane injection system that introduces controlled amounts of butane into the water stream prior to filtration[2]. This pre-treatment step alters the surface tension and molecular structure of contaminants, making them more susceptible to removal by subsequent filtration stages. DuPont's research has demonstrated that this butane pre-treatment can enhance the removal efficiency of various pollutants, including organic compounds and suspended solids, by up to 40%[4]. The system also incorporates a butane recovery unit, ensuring minimal environmental impact and cost-effectiveness[6]. Additionally, DuPont has developed specialized membrane materials that are optimized for use with butane-treated water, further improving the overall filtration performance.

Strengths: Significantly improved contaminant removal efficiency, versatility in treating various pollutants, and environmentally friendly butane recovery system. Weaknesses: Initial implementation costs may be higher due to specialized equipment requirements, and potential regulatory challenges related to butane use in water treatment processes.

Core Innovations in Butane-Water Interaction

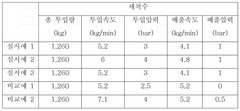

Method for preparing 1,3-butadiene

PatentWO2019168276A1

Innovation

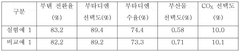

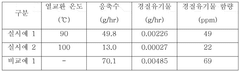

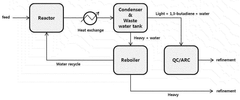

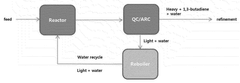

- A method involving heat exchange and condensation of products from the oxidative dehydrogenation of butene to separate and recycle wastewater free of light components, preventing their reaction with oxygen and maintaining butene conversion rates, thereby enhancing the yield and selectivity of 1,3-butadiene production.

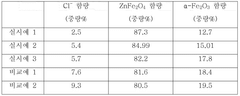

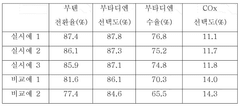

Method for producing catalyst for oxidative dehydrogenation reaction, catalyst for oxidative dehydrogenation reaction, and method for producing butadiene using same

PatentWO2021137532A1

Innovation

- A method involving the production of a zinc-ferrite catalyst using a filter press with controlled washing water discharge rate and pressure to minimize wastewater and enhance catalyst performance, allowing for improved selectivity and yield of 1,3-butadiene through oxidative dehydrogenation reaction.

Environmental Impact Assessment

The integration of butane in water filtration systems for industrial applications presents both potential benefits and environmental concerns that require careful assessment. The use of butane as a filtration aid can significantly enhance the efficiency of water treatment processes, potentially reducing energy consumption and chemical usage. This improved efficiency may lead to a decrease in the overall environmental footprint of industrial water treatment facilities.

However, the introduction of butane into water systems also raises important environmental considerations. Butane is a hydrocarbon and a volatile organic compound (VOC), which can contribute to air pollution if not properly managed. The release of butane into the atmosphere during the filtration process or through accidental leaks could potentially contribute to the formation of ground-level ozone and smog, particularly in urban or industrialized areas.

Water quality is another critical factor to consider. While butane-enhanced filtration may improve the removal of certain contaminants, it is essential to ensure that the process does not introduce new pollutants or alter the chemical composition of the treated water in ways that could harm aquatic ecosystems or human health. Comprehensive water quality monitoring and testing protocols must be implemented to assess the long-term effects of butane-enhanced filtration on effluent characteristics.

The disposal of filter media and waste products from butane-enhanced filtration systems also requires careful consideration. These materials may contain residual hydrocarbons or other compounds that could pose environmental risks if not properly handled and disposed of. Developing appropriate waste management strategies and exploring recycling options for used filter media will be crucial in minimizing the environmental impact of this technology.

Energy consumption is another aspect that warrants attention in the environmental impact assessment. While butane-enhanced filtration may lead to improved efficiency and potentially reduced energy use in the filtration process itself, the production and transportation of butane for this application should also be factored into the overall energy balance and carbon footprint calculations.

Lastly, the potential for accidental releases or spills of butane during storage, handling, or system operation must be carefully evaluated. Implementing robust safety measures, containment systems, and emergency response protocols will be essential to mitigate the risk of environmental contamination and ensure the protection of surrounding ecosystems and communities.

However, the introduction of butane into water systems also raises important environmental considerations. Butane is a hydrocarbon and a volatile organic compound (VOC), which can contribute to air pollution if not properly managed. The release of butane into the atmosphere during the filtration process or through accidental leaks could potentially contribute to the formation of ground-level ozone and smog, particularly in urban or industrialized areas.

Water quality is another critical factor to consider. While butane-enhanced filtration may improve the removal of certain contaminants, it is essential to ensure that the process does not introduce new pollutants or alter the chemical composition of the treated water in ways that could harm aquatic ecosystems or human health. Comprehensive water quality monitoring and testing protocols must be implemented to assess the long-term effects of butane-enhanced filtration on effluent characteristics.

The disposal of filter media and waste products from butane-enhanced filtration systems also requires careful consideration. These materials may contain residual hydrocarbons or other compounds that could pose environmental risks if not properly handled and disposed of. Developing appropriate waste management strategies and exploring recycling options for used filter media will be crucial in minimizing the environmental impact of this technology.

Energy consumption is another aspect that warrants attention in the environmental impact assessment. While butane-enhanced filtration may lead to improved efficiency and potentially reduced energy use in the filtration process itself, the production and transportation of butane for this application should also be factored into the overall energy balance and carbon footprint calculations.

Lastly, the potential for accidental releases or spills of butane during storage, handling, or system operation must be carefully evaluated. Implementing robust safety measures, containment systems, and emergency response protocols will be essential to mitigate the risk of environmental contamination and ensure the protection of surrounding ecosystems and communities.

Regulatory Framework for Industrial Water Treatment

The regulatory framework for industrial water treatment plays a crucial role in ensuring the safe and efficient use of water filtration systems, including those incorporating butane-based technologies. In the United States, the Environmental Protection Agency (EPA) is the primary federal agency responsible for setting and enforcing water quality standards. The Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA) form the foundation of these regulations, establishing guidelines for the discharge of pollutants and the quality of drinking water.

For industrial water treatment systems utilizing butane, compliance with the National Pollutant Discharge Elimination System (NPDES) permit program is essential. This program regulates point sources that discharge pollutants into waters of the United States. Industries must obtain permits that specify the allowable levels of pollutants in their wastewater discharges, including any potential byproducts from butane-based filtration processes.

The Occupational Safety and Health Administration (OSHA) also plays a significant role in regulating the use of butane in industrial settings. OSHA's Process Safety Management (PSM) standard applies to the handling of flammable gases like butane, requiring employers to implement comprehensive safety programs to prevent accidents and protect workers.

At the state level, regulations may vary, with some states imposing stricter standards than federal requirements. For example, California's Water Resources Control Board enforces more stringent water quality standards through its Porter-Cologne Water Quality Control Act. Industries operating in multiple states must navigate these varying regulatory landscapes to ensure compliance across their operations.

Internationally, the regulatory framework for industrial water treatment is diverse. The European Union's Water Framework Directive (WFD) sets overarching guidelines for water management and quality across member states. In contrast, developing countries may have less stringent regulations, although many are working to strengthen their environmental protection laws.

As the use of butane in water filtration systems evolves, regulatory bodies are likely to adapt their frameworks to address new challenges and opportunities. This may include updating existing regulations or developing new standards specifically tailored to butane-based technologies. Industries implementing these innovative filtration methods must stay informed about regulatory changes and proactively engage with regulatory agencies to ensure compliance and contribute to the development of appropriate standards.

For industrial water treatment systems utilizing butane, compliance with the National Pollutant Discharge Elimination System (NPDES) permit program is essential. This program regulates point sources that discharge pollutants into waters of the United States. Industries must obtain permits that specify the allowable levels of pollutants in their wastewater discharges, including any potential byproducts from butane-based filtration processes.

The Occupational Safety and Health Administration (OSHA) also plays a significant role in regulating the use of butane in industrial settings. OSHA's Process Safety Management (PSM) standard applies to the handling of flammable gases like butane, requiring employers to implement comprehensive safety programs to prevent accidents and protect workers.

At the state level, regulations may vary, with some states imposing stricter standards than federal requirements. For example, California's Water Resources Control Board enforces more stringent water quality standards through its Porter-Cologne Water Quality Control Act. Industries operating in multiple states must navigate these varying regulatory landscapes to ensure compliance across their operations.

Internationally, the regulatory framework for industrial water treatment is diverse. The European Union's Water Framework Directive (WFD) sets overarching guidelines for water management and quality across member states. In contrast, developing countries may have less stringent regulations, although many are working to strengthen their environmental protection laws.

As the use of butane in water filtration systems evolves, regulatory bodies are likely to adapt their frameworks to address new challenges and opportunities. This may include updating existing regulations or developing new standards specifically tailored to butane-based technologies. Industries implementing these innovative filtration methods must stay informed about regulatory changes and proactively engage with regulatory agencies to ensure compliance and contribute to the development of appropriate standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!