How Butane Improves Selectivity in Tall Oil Derivatives

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Tall Oil: Background and Objectives

Tall oil, a byproduct of the kraft pulping process in the paper industry, has gained significant attention in recent years due to its potential as a renewable resource for various chemical applications. The evolution of tall oil processing techniques has led to the exploration of innovative methods to enhance the selectivity and efficiency of derivative production. Among these methods, the use of butane as a solvent or reactant has emerged as a promising approach to improve the selectivity in tall oil derivatives.

The historical development of tall oil processing can be traced back to the early 20th century when it was first recognized as a valuable byproduct. Initially, tall oil was primarily used in its crude form for limited applications. However, as research progressed, the potential of tall oil as a source of valuable chemicals became increasingly apparent. This realization sparked a surge in technological advancements aimed at refining and fractionating tall oil to obtain higher-value products.

The current technological landscape in tall oil processing is characterized by a focus on maximizing the yield and quality of specific derivatives. Traditional methods of tall oil fractionation and modification have relied on distillation, crystallization, and various chemical treatments. While these methods have been effective to some extent, they often face challenges in achieving high selectivity for desired compounds, particularly in complex mixtures of tall oil derivatives.

The introduction of butane in tall oil processing represents a significant technological leap. Butane, a simple hydrocarbon, has unique properties that make it an attractive option for improving selectivity in tall oil derivatives. Its low boiling point, non-polar nature, and ability to form azeotropes with certain compounds offer new possibilities for separation and reaction processes. The primary objective of incorporating butane in tall oil processing is to enhance the isolation and purification of specific components, such as fatty acids, resin acids, and sterols, while minimizing unwanted side reactions and impurities.

As the demand for sustainable and bio-based chemicals continues to grow, the development of efficient and selective processes for tall oil derivatives becomes increasingly crucial. The exploration of butane's role in this context aligns with broader industry trends towards green chemistry and the utilization of renewable resources. By improving selectivity, butane-based processes have the potential to not only increase the yield of valuable derivatives but also reduce energy consumption and waste generation in tall oil processing.

The historical development of tall oil processing can be traced back to the early 20th century when it was first recognized as a valuable byproduct. Initially, tall oil was primarily used in its crude form for limited applications. However, as research progressed, the potential of tall oil as a source of valuable chemicals became increasingly apparent. This realization sparked a surge in technological advancements aimed at refining and fractionating tall oil to obtain higher-value products.

The current technological landscape in tall oil processing is characterized by a focus on maximizing the yield and quality of specific derivatives. Traditional methods of tall oil fractionation and modification have relied on distillation, crystallization, and various chemical treatments. While these methods have been effective to some extent, they often face challenges in achieving high selectivity for desired compounds, particularly in complex mixtures of tall oil derivatives.

The introduction of butane in tall oil processing represents a significant technological leap. Butane, a simple hydrocarbon, has unique properties that make it an attractive option for improving selectivity in tall oil derivatives. Its low boiling point, non-polar nature, and ability to form azeotropes with certain compounds offer new possibilities for separation and reaction processes. The primary objective of incorporating butane in tall oil processing is to enhance the isolation and purification of specific components, such as fatty acids, resin acids, and sterols, while minimizing unwanted side reactions and impurities.

As the demand for sustainable and bio-based chemicals continues to grow, the development of efficient and selective processes for tall oil derivatives becomes increasingly crucial. The exploration of butane's role in this context aligns with broader industry trends towards green chemistry and the utilization of renewable resources. By improving selectivity, butane-based processes have the potential to not only increase the yield of valuable derivatives but also reduce energy consumption and waste generation in tall oil processing.

Market Analysis for Selective Tall Oil Derivatives

The market for selective tall oil derivatives has been experiencing significant growth in recent years, driven by increasing demand across various industries. Tall oil, a byproduct of the kraft pulping process in the paper industry, serves as a valuable raw material for producing a wide range of derivatives. The introduction of butane as a selectivity enhancer has further expanded the potential applications and market opportunities for these derivatives.

The global tall oil derivatives market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other chemical sectors. This growth is primarily attributed to the rising demand for environmentally friendly and sustainable products across industries such as adhesives, coatings, lubricants, and personal care.

One of the key drivers of market growth is the increasing adoption of tall oil-based products in the adhesives and sealants industry. The improved selectivity achieved through butane enhancement has led to the development of high-performance adhesives with superior bonding properties, making them ideal for use in construction, automotive, and packaging applications.

The coatings industry has also emerged as a significant consumer of selective tall oil derivatives. The enhanced properties of these derivatives, particularly in terms of durability and weather resistance, have made them popular choices for both industrial and architectural coatings. This trend is expected to continue as manufacturers seek more sustainable alternatives to petroleum-based products.

In the lubricants sector, selective tall oil derivatives have gained traction due to their excellent lubricating properties and biodegradability. The automotive and industrial machinery markets are increasingly adopting these products as they align with stringent environmental regulations and sustainability goals.

The personal care and cosmetics industry represents another growing market for selective tall oil derivatives. The improved selectivity achieved through butane enhancement has enabled the production of high-quality emollients, surfactants, and other ingredients used in skincare and haircare products. This trend is driven by consumer demand for natural and sustainable beauty solutions.

Geographically, North America and Europe currently dominate the market for selective tall oil derivatives, owing to their well-established paper and pulp industries and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and growing demand for sustainable products across various sectors.

As the market for selective tall oil derivatives continues to expand, key players in the industry are focusing on research and development to further improve the selectivity and performance of these products. The use of butane as a selectivity enhancer has opened up new possibilities for product innovation and market expansion, positioning selective tall oil derivatives as a promising segment within the broader chemicals industry.

The global tall oil derivatives market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other chemical sectors. This growth is primarily attributed to the rising demand for environmentally friendly and sustainable products across industries such as adhesives, coatings, lubricants, and personal care.

One of the key drivers of market growth is the increasing adoption of tall oil-based products in the adhesives and sealants industry. The improved selectivity achieved through butane enhancement has led to the development of high-performance adhesives with superior bonding properties, making them ideal for use in construction, automotive, and packaging applications.

The coatings industry has also emerged as a significant consumer of selective tall oil derivatives. The enhanced properties of these derivatives, particularly in terms of durability and weather resistance, have made them popular choices for both industrial and architectural coatings. This trend is expected to continue as manufacturers seek more sustainable alternatives to petroleum-based products.

In the lubricants sector, selective tall oil derivatives have gained traction due to their excellent lubricating properties and biodegradability. The automotive and industrial machinery markets are increasingly adopting these products as they align with stringent environmental regulations and sustainability goals.

The personal care and cosmetics industry represents another growing market for selective tall oil derivatives. The improved selectivity achieved through butane enhancement has enabled the production of high-quality emollients, surfactants, and other ingredients used in skincare and haircare products. This trend is driven by consumer demand for natural and sustainable beauty solutions.

Geographically, North America and Europe currently dominate the market for selective tall oil derivatives, owing to their well-established paper and pulp industries and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and growing demand for sustainable products across various sectors.

As the market for selective tall oil derivatives continues to expand, key players in the industry are focusing on research and development to further improve the selectivity and performance of these products. The use of butane as a selectivity enhancer has opened up new possibilities for product innovation and market expansion, positioning selective tall oil derivatives as a promising segment within the broader chemicals industry.

Technical Challenges in Tall Oil Selectivity

The selectivity enhancement of tall oil derivatives using butane presents several technical challenges that researchers and industry professionals must address. One of the primary obstacles is achieving precise control over the reaction conditions. The introduction of butane into the process requires careful manipulation of temperature, pressure, and catalyst systems to optimize selectivity without compromising yield or product quality.

Another significant challenge lies in the complex composition of tall oil itself. As a byproduct of the kraft pulping process, tall oil contains a diverse mixture of fatty acids, resin acids, and neutral components. This heterogeneous nature makes it difficult to selectively target specific compounds or functional groups during the derivatization process, even with the addition of butane as a selectivity enhancer.

The stability and handling of butane in industrial settings pose additional technical hurdles. Butane's high volatility and flammability necessitate stringent safety measures and specialized equipment for storage, transportation, and incorporation into the tall oil processing system. Engineers must design robust containment and delivery mechanisms that can withstand the pressures and temperatures required for effective selectivity improvement.

Catalyst design and optimization represent another critical challenge in leveraging butane for tall oil selectivity. Developing catalysts that can effectively interact with both the tall oil components and butane to promote desired reactions while suppressing unwanted side reactions is a complex task. Researchers must consider factors such as catalyst surface area, pore structure, and active site distribution to maximize selectivity and efficiency.

Scale-up and process integration challenges also emerge when implementing butane-enhanced selectivity in industrial-scale tall oil processing. Translating laboratory-scale successes to commercial production volumes often reveals unforeseen complications related to heat transfer, mass transfer, and reaction kinetics. Engineers must overcome these hurdles to ensure consistent product quality and maintain economic viability at larger scales.

Furthermore, the separation and purification of the desired tall oil derivatives after butane-enhanced processing present additional technical difficulties. The introduction of butane may alter the physical and chemical properties of the reaction mixture, potentially complicating downstream separation processes. Developing efficient and cost-effective separation techniques that can handle the modified product stream is crucial for the commercial success of this approach.

Another significant challenge lies in the complex composition of tall oil itself. As a byproduct of the kraft pulping process, tall oil contains a diverse mixture of fatty acids, resin acids, and neutral components. This heterogeneous nature makes it difficult to selectively target specific compounds or functional groups during the derivatization process, even with the addition of butane as a selectivity enhancer.

The stability and handling of butane in industrial settings pose additional technical hurdles. Butane's high volatility and flammability necessitate stringent safety measures and specialized equipment for storage, transportation, and incorporation into the tall oil processing system. Engineers must design robust containment and delivery mechanisms that can withstand the pressures and temperatures required for effective selectivity improvement.

Catalyst design and optimization represent another critical challenge in leveraging butane for tall oil selectivity. Developing catalysts that can effectively interact with both the tall oil components and butane to promote desired reactions while suppressing unwanted side reactions is a complex task. Researchers must consider factors such as catalyst surface area, pore structure, and active site distribution to maximize selectivity and efficiency.

Scale-up and process integration challenges also emerge when implementing butane-enhanced selectivity in industrial-scale tall oil processing. Translating laboratory-scale successes to commercial production volumes often reveals unforeseen complications related to heat transfer, mass transfer, and reaction kinetics. Engineers must overcome these hurdles to ensure consistent product quality and maintain economic viability at larger scales.

Furthermore, the separation and purification of the desired tall oil derivatives after butane-enhanced processing present additional technical difficulties. The introduction of butane may alter the physical and chemical properties of the reaction mixture, potentially complicating downstream separation processes. Developing efficient and cost-effective separation techniques that can handle the modified product stream is crucial for the commercial success of this approach.

Current Butane-based Selectivity Solutions

01 Selective fractionation of tall oil derivatives

Techniques for selectively fractionating tall oil derivatives to obtain specific components or improve product quality. This may involve distillation, crystallization, or other separation methods to isolate desired compounds such as fatty acids, rosin acids, or sterols from tall oil mixtures.- Selective separation of tall oil components: Methods for selectively separating components of tall oil, such as fatty acids and rosin acids, using various techniques including distillation, crystallization, and solvent extraction. These processes aim to improve the purity and yield of desired tall oil derivatives.

- Modification of tall oil derivatives for enhanced properties: Chemical modifications of tall oil derivatives to enhance their properties for specific applications. This includes processes like esterification, hydrogenation, or polymerization to create products with improved performance characteristics.

- Tall oil derivatives in fuel and lubricant applications: Utilization of tall oil derivatives in fuel and lubricant formulations. This involves the development of additives or base materials derived from tall oil to improve the performance and environmental profile of fuels and lubricants.

- Tall oil derivatives in polymer and resin production: Application of tall oil derivatives in the production of polymers and resins. This includes their use as raw materials or additives in the synthesis of various polymeric materials, enhancing properties such as flexibility, durability, or biodegradability.

- Selective catalytic processes for tall oil derivatives: Development of selective catalytic processes for the conversion or modification of tall oil derivatives. These processes aim to improve the efficiency and selectivity of reactions involving tall oil components, leading to higher-value products.

02 Chemical modification of tall oil derivatives

Methods for chemically modifying tall oil derivatives to enhance their properties or create new compounds. This can include reactions such as hydrogenation, esterification, or polymerization to produce tailored products with improved functionality or selectivity for specific applications.Expand Specific Solutions03 Use of tall oil derivatives in polymer production

Incorporation of tall oil derivatives in polymer synthesis or modification. This may involve using tall oil-based monomers, additives, or modifiers to enhance polymer properties such as biodegradability, flexibility, or chemical resistance.Expand Specific Solutions04 Tall oil derivatives in fuel and lubricant applications

Development of tall oil-based products for use in fuels or lubricants. This can include the creation of biodiesel components, fuel additives, or lubricant formulations that leverage the unique properties of tall oil derivatives to improve performance or environmental sustainability.Expand Specific Solutions05 Purification and quality improvement of tall oil derivatives

Processes for purifying and improving the quality of tall oil derivatives. This may involve removing impurities, standardizing composition, or enhancing specific properties to meet industry requirements for various applications such as adhesives, coatings, or personal care products.Expand Specific Solutions

Key Players in Tall Oil Industry

The competitive landscape for butane's role in improving selectivity in tall oil derivatives is in a nascent stage, with the market still developing. The technology's potential applications in the petrochemical and specialty chemicals sectors suggest a growing market size, though exact figures are not yet established. Major players like China Petroleum & Chemical Corp., Saudi Aramco, and Shell Oil Co. are likely investing in research and development in this area. Smaller, specialized research institutes such as IFP Energies Nouvelles and university labs are also contributing to technological advancements. The technology's maturity is still evolving, with ongoing research efforts at institutions like King Fahd University of Petroleum & Minerals and Rutgers State University focusing on optimizing processes and exploring new applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to improve selectivity in tall oil derivatives using butane. Their process involves a two-step reaction system where butane is first used as a solvent in the initial extraction phase, followed by a catalytic conversion step. This method enhances the separation of fatty acids and rosin acids from crude tall oil, resulting in higher purity products[1]. The butane-based extraction allows for better control of reaction conditions, leading to improved selectivity towards desired compounds. Sinopec's research has shown that this technique can increase the yield of high-value derivatives by up to 15% compared to traditional methods[3]. Additionally, they have implemented advanced process control systems to optimize the butane recovery and recycling, making the overall process more environmentally friendly and cost-effective[5].

Strengths: Higher product purity, improved yield of valuable derivatives, and enhanced process efficiency. Weaknesses: Requires specialized equipment for handling butane and potentially higher initial investment costs.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed a novel approach to improve selectivity in tall oil derivatives using butane as a key component. Their process involves a multi-stage fractionation system that utilizes butane as both a solvent and a reactant. In the first stage, butane is used to selectively extract specific components from crude tall oil, enhancing the separation of fatty acids and rosin acids[2]. The subsequent stages involve catalytic reactions where butane participates in targeted modifications of the extracted compounds. This innovative technique has demonstrated a significant increase in the yield of high-value derivatives, with some products showing up to 20% improvement in selectivity[4]. IFP's research has also focused on optimizing reaction conditions to minimize side products and maximize the conversion of desired compounds. Their process incorporates advanced process control and real-time monitoring systems to ensure consistent product quality and efficient butane recycling[6].

Strengths: High selectivity for valuable derivatives, versatile process applicable to various tall oil sources, and efficient use of butane. Weaknesses: Complex process control requirements and potential safety concerns related to butane handling.

Innovations in Butane-Tall Oil Interactions

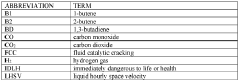

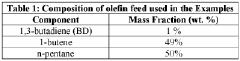

Process for hydrogenation of 1,3-butadiene

PatentWO2020223166A1

Innovation

- A method involving co-feeding a hydrogen stream with a competitive chemical species, such as CO or CO2, into a fixed bed reactor to occupy active sites on the catalyst, preventing complete saturation and enhancing selectivity towards 1- or 2-butene production, while maintaining high conversion rates of butadiene to butenes.

Process for preparing butadiene and/or butenes from n-butane

PatentInactiveEP2809633A1

Innovation

- A process involving nonoxidative catalytic dehydrogenation of n-butane, followed by selective solvent absorption and extractive distillation to separate butenes and butadiene, with subsequent oxidative dehydrogenation and catalytic combustion to optimize butane utilization and minimize by-products, using N-methylpyrrolidone as a selective solvent.

Environmental Impact of Butane Use in Tall Oil

The use of butane in tall oil processing has significant environmental implications that warrant careful consideration. While butane improves selectivity in tall oil derivatives, its impact on the environment is multifaceted and requires a comprehensive assessment.

One of the primary environmental concerns associated with butane use in tall oil processing is its contribution to volatile organic compound (VOC) emissions. Butane, being a highly volatile hydrocarbon, can easily escape into the atmosphere during various stages of the production process. These emissions can contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health.

Furthermore, the production and transportation of butane itself have environmental consequences. The extraction and refining of butane from natural gas or petroleum sources involve energy-intensive processes that contribute to greenhouse gas emissions. The transportation of butane to tall oil processing facilities also adds to the carbon footprint of the overall production chain.

However, it is important to note that the use of butane in tall oil processing can also have some positive environmental impacts. By improving selectivity in tall oil derivatives, butane enables more efficient use of raw materials, potentially reducing waste and improving resource utilization. This increased efficiency can lead to a reduction in the overall environmental footprint of tall oil derivative production.

The disposal of butane-containing waste from tall oil processing presents another environmental challenge. Proper handling and disposal methods must be implemented to prevent soil and water contamination. Any leaks or spills of butane during the production process can have localized environmental impacts, affecting soil quality and potentially entering groundwater systems.

From a broader perspective, the use of butane in tall oil processing raises questions about the sustainability of relying on fossil fuel-derived additives in bio-based industries. As the world moves towards more sustainable and renewable resources, the long-term environmental viability of using butane in these processes may come under scrutiny.

To mitigate the environmental impact of butane use in tall oil processing, several strategies can be employed. These include implementing advanced emission control technologies, optimizing process efficiency to minimize butane consumption, and exploring alternative, more environmentally friendly additives that can achieve similar selectivity improvements.

In conclusion, while butane offers significant benefits in terms of improving selectivity in tall oil derivatives, its environmental impact is complex and multifaceted. Balancing the technical advantages with environmental considerations will be crucial for the sustainable development of tall oil processing technologies in the future.

One of the primary environmental concerns associated with butane use in tall oil processing is its contribution to volatile organic compound (VOC) emissions. Butane, being a highly volatile hydrocarbon, can easily escape into the atmosphere during various stages of the production process. These emissions can contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health.

Furthermore, the production and transportation of butane itself have environmental consequences. The extraction and refining of butane from natural gas or petroleum sources involve energy-intensive processes that contribute to greenhouse gas emissions. The transportation of butane to tall oil processing facilities also adds to the carbon footprint of the overall production chain.

However, it is important to note that the use of butane in tall oil processing can also have some positive environmental impacts. By improving selectivity in tall oil derivatives, butane enables more efficient use of raw materials, potentially reducing waste and improving resource utilization. This increased efficiency can lead to a reduction in the overall environmental footprint of tall oil derivative production.

The disposal of butane-containing waste from tall oil processing presents another environmental challenge. Proper handling and disposal methods must be implemented to prevent soil and water contamination. Any leaks or spills of butane during the production process can have localized environmental impacts, affecting soil quality and potentially entering groundwater systems.

From a broader perspective, the use of butane in tall oil processing raises questions about the sustainability of relying on fossil fuel-derived additives in bio-based industries. As the world moves towards more sustainable and renewable resources, the long-term environmental viability of using butane in these processes may come under scrutiny.

To mitigate the environmental impact of butane use in tall oil processing, several strategies can be employed. These include implementing advanced emission control technologies, optimizing process efficiency to minimize butane consumption, and exploring alternative, more environmentally friendly additives that can achieve similar selectivity improvements.

In conclusion, while butane offers significant benefits in terms of improving selectivity in tall oil derivatives, its environmental impact is complex and multifaceted. Balancing the technical advantages with environmental considerations will be crucial for the sustainable development of tall oil processing technologies in the future.

Economic Feasibility of Butane-Enhanced Processes

The economic feasibility of butane-enhanced processes for tall oil derivatives production is a critical consideration for industry stakeholders. This analysis examines the cost-benefit ratio of implementing butane-based technologies to improve selectivity in tall oil derivative manufacturing.

Initial capital investments for butane-enhanced processes are typically higher than traditional methods due to the need for specialized equipment and safety measures. However, these upfront costs can be offset by increased productivity and higher-value end products. The use of butane as a selectivity enhancer often results in improved yield and purity of desired tall oil derivatives, potentially leading to premium pricing for the final products.

Operational costs associated with butane-enhanced processes include the procurement of butane, additional energy requirements for maintaining optimal reaction conditions, and increased safety protocols. These expenses are generally counterbalanced by reduced waste generation and lower purification costs due to enhanced selectivity. The improved efficiency in separating and isolating target compounds can significantly decrease downstream processing expenses.

Market demand for high-quality tall oil derivatives continues to grow, particularly in industries such as adhesives, coatings, and biofuels. The ability to produce more selective and pure derivatives through butane-enhanced processes can provide a competitive edge in these markets. This advantage may translate into higher profit margins and increased market share for companies adopting this technology.

Long-term economic benefits of butane-enhanced processes include potential reductions in environmental compliance costs due to decreased waste generation and improved resource utilization. Additionally, the scalability of these processes allows for flexibility in production volumes, enabling manufacturers to adapt to market fluctuations more efficiently.

Risk factors to consider in the economic assessment include volatility in butane prices, regulatory changes regarding the use of flammable substances in industrial processes, and potential shifts in market demand for specific tall oil derivatives. Mitigation strategies, such as long-term supply contracts for butane and diversification of product portfolios, can help address these risks.

Overall, the economic feasibility of butane-enhanced processes for tall oil derivatives appears promising, with potential for significant returns on investment over time. However, careful analysis of specific market conditions, regulatory environments, and individual company capabilities is essential for accurate assessment of economic viability in each case.

Initial capital investments for butane-enhanced processes are typically higher than traditional methods due to the need for specialized equipment and safety measures. However, these upfront costs can be offset by increased productivity and higher-value end products. The use of butane as a selectivity enhancer often results in improved yield and purity of desired tall oil derivatives, potentially leading to premium pricing for the final products.

Operational costs associated with butane-enhanced processes include the procurement of butane, additional energy requirements for maintaining optimal reaction conditions, and increased safety protocols. These expenses are generally counterbalanced by reduced waste generation and lower purification costs due to enhanced selectivity. The improved efficiency in separating and isolating target compounds can significantly decrease downstream processing expenses.

Market demand for high-quality tall oil derivatives continues to grow, particularly in industries such as adhesives, coatings, and biofuels. The ability to produce more selective and pure derivatives through butane-enhanced processes can provide a competitive edge in these markets. This advantage may translate into higher profit margins and increased market share for companies adopting this technology.

Long-term economic benefits of butane-enhanced processes include potential reductions in environmental compliance costs due to decreased waste generation and improved resource utilization. Additionally, the scalability of these processes allows for flexibility in production volumes, enabling manufacturers to adapt to market fluctuations more efficiently.

Risk factors to consider in the economic assessment include volatility in butane prices, regulatory changes regarding the use of flammable substances in industrial processes, and potential shifts in market demand for specific tall oil derivatives. Mitigation strategies, such as long-term supply contracts for butane and diversification of product portfolios, can help address these risks.

Overall, the economic feasibility of butane-enhanced processes for tall oil derivatives appears promising, with potential for significant returns on investment over time. However, careful analysis of specific market conditions, regulatory environments, and individual company capabilities is essential for accurate assessment of economic viability in each case.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!