How Butane-Derived Products Advance Chemical Vapor Infusion

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane-Derived CVI: Background and Objectives

Chemical Vapor Infusion (CVI) has emerged as a critical process in materials science and engineering, enabling the production of advanced composites with enhanced properties. The utilization of butane-derived products in CVI represents a significant advancement in this field, offering new possibilities for material synthesis and modification.

The evolution of CVI technology can be traced back to the mid-20th century, with initial applications in the aerospace industry for producing high-performance carbon-carbon composites. Over the decades, the technique has expanded to various sectors, including semiconductor manufacturing, energy storage, and biomedical engineering. The incorporation of butane-derived products into CVI processes marks a notable milestone in this technological progression.

Butane, a hydrocarbon with the formula C4H10, serves as a versatile precursor for numerous chemical compounds. When utilized in CVI, butane-derived products offer several advantages, including improved infiltration efficiency, enhanced control over deposition rates, and the ability to create unique material structures at the molecular level. These benefits stem from the chemical properties of butane and its derivatives, which can be tailored to suit specific CVI requirements.

The primary objective of employing butane-derived products in CVI is to overcome limitations associated with traditional precursors. These limitations often include insufficient infiltration depth, non-uniform deposition, and the need for high processing temperatures. By leveraging the unique characteristics of butane-derived compounds, researchers and engineers aim to develop more efficient and versatile CVI processes.

Key goals in this technological domain include optimizing the chemical composition of butane-derived precursors, enhancing the control over deposition kinetics, and expanding the range of materials that can be effectively processed using CVI techniques. Additionally, there is a focus on reducing energy consumption and minimizing environmental impact, aligning with broader sustainability objectives in materials processing.

The integration of butane-derived products into CVI also opens up new avenues for creating advanced functional materials. These materials may exhibit properties such as improved thermal stability, enhanced electrical conductivity, or superior mechanical strength. The potential applications span across multiple industries, from aerospace and automotive to electronics and energy storage.

As research in this field progresses, the overarching aim is to establish butane-derived CVI as a cornerstone technology for next-generation materials synthesis. This involves not only refining existing processes but also exploring novel applications and pushing the boundaries of what is achievable through chemical vapor infusion techniques.

The evolution of CVI technology can be traced back to the mid-20th century, with initial applications in the aerospace industry for producing high-performance carbon-carbon composites. Over the decades, the technique has expanded to various sectors, including semiconductor manufacturing, energy storage, and biomedical engineering. The incorporation of butane-derived products into CVI processes marks a notable milestone in this technological progression.

Butane, a hydrocarbon with the formula C4H10, serves as a versatile precursor for numerous chemical compounds. When utilized in CVI, butane-derived products offer several advantages, including improved infiltration efficiency, enhanced control over deposition rates, and the ability to create unique material structures at the molecular level. These benefits stem from the chemical properties of butane and its derivatives, which can be tailored to suit specific CVI requirements.

The primary objective of employing butane-derived products in CVI is to overcome limitations associated with traditional precursors. These limitations often include insufficient infiltration depth, non-uniform deposition, and the need for high processing temperatures. By leveraging the unique characteristics of butane-derived compounds, researchers and engineers aim to develop more efficient and versatile CVI processes.

Key goals in this technological domain include optimizing the chemical composition of butane-derived precursors, enhancing the control over deposition kinetics, and expanding the range of materials that can be effectively processed using CVI techniques. Additionally, there is a focus on reducing energy consumption and minimizing environmental impact, aligning with broader sustainability objectives in materials processing.

The integration of butane-derived products into CVI also opens up new avenues for creating advanced functional materials. These materials may exhibit properties such as improved thermal stability, enhanced electrical conductivity, or superior mechanical strength. The potential applications span across multiple industries, from aerospace and automotive to electronics and energy storage.

As research in this field progresses, the overarching aim is to establish butane-derived CVI as a cornerstone technology for next-generation materials synthesis. This involves not only refining existing processes but also exploring novel applications and pushing the boundaries of what is achievable through chemical vapor infusion techniques.

Market Analysis for Butane-Based CVI Products

The market for butane-derived products in Chemical Vapor Infusion (CVI) has shown significant growth potential in recent years. This expansion is driven by the increasing demand for high-performance materials in various industries, including aerospace, automotive, and electronics. Butane-based CVI products offer unique advantages in terms of cost-effectiveness and performance characteristics, making them attractive alternatives to traditional materials.

In the aerospace sector, butane-derived CVI products are gaining traction due to their ability to enhance the strength and heat resistance of composite materials used in aircraft components. The automotive industry is also adopting these products for lightweight yet durable parts, contributing to improved fuel efficiency and vehicle performance. The electronics sector utilizes butane-based CVI materials for advanced semiconductor manufacturing, where precise control of material properties is crucial.

The global market for butane-derived CVI products is expected to experience steady growth over the next five years. This growth is fueled by ongoing research and development efforts to improve the efficiency and versatility of CVI processes using butane-based precursors. Additionally, the increasing focus on sustainable manufacturing practices has led to the exploration of butane as a more environmentally friendly alternative to some traditional CVI precursors.

Key market players in the butane-derived CVI products sector include both established chemical companies and specialized materials manufacturers. These companies are investing in research and development to expand their product portfolios and improve the performance of butane-based CVI materials. Collaborations between industry and academic institutions are also driving innovation in this field, leading to the development of novel applications and improved production techniques.

Geographically, North America and Europe currently dominate the market for butane-derived CVI products, owing to their strong presence in aerospace and automotive industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization and increasing adoption of advanced materials in countries like China, Japan, and South Korea.

Challenges in the market include the need for specialized equipment and expertise to implement butane-based CVI processes effectively. Additionally, regulatory considerations regarding the use of butane and its derivatives in manufacturing processes may impact market growth in certain regions. Despite these challenges, the overall outlook for butane-derived CVI products remains positive, with opportunities for market expansion in emerging applications and regions.

In the aerospace sector, butane-derived CVI products are gaining traction due to their ability to enhance the strength and heat resistance of composite materials used in aircraft components. The automotive industry is also adopting these products for lightweight yet durable parts, contributing to improved fuel efficiency and vehicle performance. The electronics sector utilizes butane-based CVI materials for advanced semiconductor manufacturing, where precise control of material properties is crucial.

The global market for butane-derived CVI products is expected to experience steady growth over the next five years. This growth is fueled by ongoing research and development efforts to improve the efficiency and versatility of CVI processes using butane-based precursors. Additionally, the increasing focus on sustainable manufacturing practices has led to the exploration of butane as a more environmentally friendly alternative to some traditional CVI precursors.

Key market players in the butane-derived CVI products sector include both established chemical companies and specialized materials manufacturers. These companies are investing in research and development to expand their product portfolios and improve the performance of butane-based CVI materials. Collaborations between industry and academic institutions are also driving innovation in this field, leading to the development of novel applications and improved production techniques.

Geographically, North America and Europe currently dominate the market for butane-derived CVI products, owing to their strong presence in aerospace and automotive industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization and increasing adoption of advanced materials in countries like China, Japan, and South Korea.

Challenges in the market include the need for specialized equipment and expertise to implement butane-based CVI processes effectively. Additionally, regulatory considerations regarding the use of butane and its derivatives in manufacturing processes may impact market growth in certain regions. Despite these challenges, the overall outlook for butane-derived CVI products remains positive, with opportunities for market expansion in emerging applications and regions.

Current Challenges in Butane-Derived CVI Technology

Chemical Vapor Infusion (CVI) technology utilizing butane-derived products faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the control of deposition uniformity across complex substrate geometries. The infiltration of butane-derived precursors into intricate porous structures often results in non-uniform deposition, leading to variations in material properties and performance.

Another critical challenge lies in the optimization of process parameters. The delicate balance between temperature, pressure, and precursor concentration significantly impacts the quality and rate of deposition. Achieving the ideal combination of these parameters for different substrate materials and desired end-products remains a complex task, often requiring extensive experimentation and fine-tuning.

The scalability of butane-derived CVI processes presents a substantial hurdle for industrial applications. While the technology shows promise at laboratory scales, translating these results to large-scale production environments introduces new complexities in maintaining consistent quality and process control. This scaling issue is particularly pronounced when dealing with larger substrate sizes or increased production volumes.

Environmental and safety concerns also pose significant challenges. The use of butane-derived precursors often involves volatile organic compounds (VOCs) and potentially hazardous by-products. Ensuring proper containment, handling, and disposal of these materials while meeting stringent environmental regulations adds layers of complexity to the implementation of CVI technology.

Furthermore, the energy efficiency of the CVI process using butane-derived products remains a concern. The high temperatures and long processing times typically required for effective infiltration and deposition contribute to substantial energy consumption. This not only impacts the economic viability of the process but also raises questions about its sustainability in an increasingly environmentally conscious industrial landscape.

The development of suitable in-situ monitoring and control systems represents another technological challenge. Real-time analysis of the deposition process and the ability to make dynamic adjustments are crucial for ensuring consistent product quality. However, the harsh environments within CVI reactors and the complexity of the deposition mechanisms make the implementation of such systems technically demanding.

Lastly, the limited understanding of the fundamental reaction mechanisms and kinetics of butane-derived precursors in various CVI conditions hampers the development of predictive models. This knowledge gap makes it difficult to optimize processes efficiently and predict outcomes accurately, necessitating a heavy reliance on empirical approaches and trial-and-error methodologies.

Another critical challenge lies in the optimization of process parameters. The delicate balance between temperature, pressure, and precursor concentration significantly impacts the quality and rate of deposition. Achieving the ideal combination of these parameters for different substrate materials and desired end-products remains a complex task, often requiring extensive experimentation and fine-tuning.

The scalability of butane-derived CVI processes presents a substantial hurdle for industrial applications. While the technology shows promise at laboratory scales, translating these results to large-scale production environments introduces new complexities in maintaining consistent quality and process control. This scaling issue is particularly pronounced when dealing with larger substrate sizes or increased production volumes.

Environmental and safety concerns also pose significant challenges. The use of butane-derived precursors often involves volatile organic compounds (VOCs) and potentially hazardous by-products. Ensuring proper containment, handling, and disposal of these materials while meeting stringent environmental regulations adds layers of complexity to the implementation of CVI technology.

Furthermore, the energy efficiency of the CVI process using butane-derived products remains a concern. The high temperatures and long processing times typically required for effective infiltration and deposition contribute to substantial energy consumption. This not only impacts the economic viability of the process but also raises questions about its sustainability in an increasingly environmentally conscious industrial landscape.

The development of suitable in-situ monitoring and control systems represents another technological challenge. Real-time analysis of the deposition process and the ability to make dynamic adjustments are crucial for ensuring consistent product quality. However, the harsh environments within CVI reactors and the complexity of the deposition mechanisms make the implementation of such systems technically demanding.

Lastly, the limited understanding of the fundamental reaction mechanisms and kinetics of butane-derived precursors in various CVI conditions hampers the development of predictive models. This knowledge gap makes it difficult to optimize processes efficiently and predict outcomes accurately, necessitating a heavy reliance on empirical approaches and trial-and-error methodologies.

Existing Butane-Based CVI Solutions

01 Chemical vapor infusion techniques for butane-derived products

This category focuses on methods and systems for infusing butane-derived products using chemical vapor techniques. These processes involve the controlled introduction of chemical vapors into the target material, allowing for precise modification of the product's properties. The techniques may include specialized equipment for vapor generation, distribution, and control, ensuring uniform infusion throughout the material.- Chemical vapor infusion techniques for butane-derived products: This category focuses on methods and systems for chemical vapor infusion of butane-derived products. The techniques involve the use of specialized equipment and processes to infuse various substances with butane-derived vapors, potentially enhancing their properties or creating new compounds.

- Purification and processing of butane-derived products: This point covers techniques for purifying and processing butane-derived products. It includes methods for removing impurities, separating different components, and refining the products to meet specific quality standards or requirements for various applications.

- Applications of butane-derived products in consumer goods: This category explores the use of butane-derived products in various consumer goods. It includes applications in personal care products, household items, and other consumer-oriented products that utilize butane derivatives or infusion techniques.

- Industrial applications of butane-derived chemical vapor infusion: This point focuses on the industrial applications of chemical vapor infusion techniques using butane-derived products. It covers processes and systems used in manufacturing, material treatment, and other industrial sectors that leverage butane-derived vapor infusion.

- Safety and environmental considerations in butane-derived product processing: This category addresses safety measures and environmental considerations related to the processing and use of butane-derived products. It includes techniques for minimizing environmental impact, ensuring worker safety, and complying with regulations in the handling and application of these products.

02 Purification and refinement of butane-derived products

This point covers processes for purifying and refining butane-derived products to enhance their quality and performance. These methods may involve various separation techniques, filtration processes, or chemical treatments to remove impurities and unwanted byproducts. The refined products can then be used in a wide range of applications, including as precursors for further chemical synthesis or as end products themselves.Expand Specific Solutions03 Butane-derived product applications in electronic devices

This category explores the use of butane-derived products in electronic devices and systems. These applications may include the use of butane-derived materials in semiconductor manufacturing, as components in electronic circuits, or as part of cooling systems for electronic devices. The unique properties of these products can contribute to improved performance, efficiency, or durability of electronic components.Expand Specific Solutions04 Environmental and safety considerations for butane-derived products

This point addresses the environmental impact and safety aspects of using butane-derived products and their chemical vapor infusion processes. It includes methods for reducing emissions, improving energy efficiency, and ensuring safe handling and storage of these materials. Additionally, it covers regulatory compliance and best practices for minimizing potential hazards associated with butane-derived products and their processing.Expand Specific Solutions05 Innovative applications of butane-derived products in various industries

This category highlights novel and diverse applications of butane-derived products across different industries. These may include their use in pharmaceuticals, cosmetics, automotive, aerospace, or energy sectors. The unique properties of butane-derived materials, combined with advanced processing techniques like chemical vapor infusion, enable the development of innovative products and solutions for a wide range of industrial challenges.Expand Specific Solutions

Key Players in Butane-Derived CVI Industry

The chemical vapor infusion (CVI) market for butane-derived products is in a growth phase, driven by increasing demand in various industries. The market size is expanding, with major players like China Petroleum & Chemical Corp., Saudi Basic Industries Corp., and BASF Corp. leading the way. These companies are investing heavily in research and development to advance CVI technology. The technical maturity of butane-derived CVI processes is moderate, with ongoing innovations from key players such as SABIC Global Technologies BV and ExxonMobil Technology & Engineering Co. As the technology evolves, we can expect to see improved efficiency, cost-effectiveness, and broader applications across different sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced chemical vapor infusion (CVI) techniques using butane-derived products. Their process involves the controlled decomposition of butane to produce carbon-rich precursors for CVI. These precursors are then infused into porous substrates under precise temperature and pressure conditions. The company has optimized the process to achieve uniform carbon deposition throughout the substrate, resulting in enhanced mechanical and thermal properties[1]. Sinopec's method allows for the production of high-performance carbon-carbon composites with applications in aerospace and high-temperature industrial settings[3].

Strengths: Extensive experience in petrochemical processes, large-scale production capabilities, and access to butane feedstock. Weaknesses: Potential environmental concerns related to butane processing and carbon emissions.

BASF Corp.

Technical Solution: BASF Corp. has innovated in the field of butane-derived products for chemical vapor infusion by developing a novel catalytic process. Their approach utilizes a proprietary catalyst system to convert butane into reactive intermediates suitable for CVI applications. The process operates at lower temperatures compared to traditional methods, reducing energy consumption and improving overall efficiency[2]. BASF's technology enables the production of specialized carbon coatings with tailored properties, such as enhanced corrosion resistance and thermal stability. The company has successfully applied this technology in the manufacturing of high-performance materials for the automotive and electronics industries[4].

Strengths: Strong R&D capabilities, diverse product portfolio, and global market presence. Weaknesses: Dependence on volatile petrochemical markets and potential regulatory challenges.

Innovative Approaches in Butane-Derived CVI

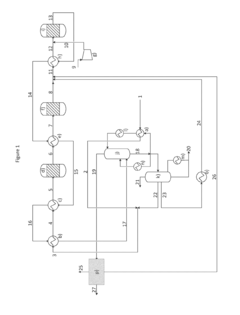

Integrated method for producing butadiene from butanol

PatentActiveUS20180258008A1

Innovation

- A thermally-integrated method involving the dehydration of n-butanol to butene, followed by oxidizing dehydrogenation using an alumina catalyst, where the dehydrogenation reaction supplies thermal energy for preheating and vaporizing the feedstock, allowing for high conversion and selectivity of n-butenes while minimizing isobutene impurities and reducing water vapor consumption.

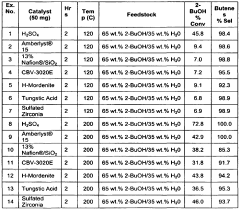

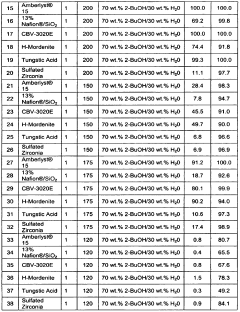

Process for making butenes from aqueous 2-butanol

PatentWO2008066581A1

Innovation

- A process involving contacting a reactant comprising 2-butanol and at least 5% water with an acid catalyst at temperatures between 50°C to 450°C and pressures from 0.1 MPa to 20.7 MPa to produce butenes, allowing for the direct use of aqueous streams from fermentation broth without prior water removal, and recovering the butenes for further conversion into fuel additives.

Environmental Impact of Butane-Derived CVI Processes

The environmental impact of butane-derived Chemical Vapor Infusion (CVI) processes is a critical consideration in the advancement of this technology. These processes, while offering significant benefits in material synthesis and modification, also present potential environmental challenges that must be carefully addressed.

One of the primary environmental concerns associated with butane-derived CVI processes is the emission of volatile organic compounds (VOCs). Butane and its derivatives are known to contribute to the formation of ground-level ozone and smog when released into the atmosphere. These emissions can have detrimental effects on air quality, particularly in urban and industrial areas where CVI processes are commonly employed.

Furthermore, the production and use of butane-derived precursors in CVI processes often involve energy-intensive steps, contributing to increased carbon dioxide emissions and overall carbon footprint. The extraction, refinement, and transportation of butane and its derivatives also pose potential environmental risks, including soil and water contamination in the event of spills or leaks.

However, it is important to note that advancements in CVI technology have led to improved process efficiency and reduced environmental impact. Closed-loop systems and advanced filtration technologies have been developed to minimize VOC emissions and recover unused precursors, significantly reducing waste and environmental pollution.

The use of butane-derived CVI processes can also have indirect positive environmental impacts. For instance, the ability to create high-performance materials with enhanced properties through CVI can lead to the development of more durable and lightweight products. This, in turn, can result in reduced material consumption and improved energy efficiency in various applications, such as aerospace and automotive industries.

Water consumption is another environmental aspect to consider in butane-derived CVI processes. While these processes generally require less water compared to traditional manufacturing methods, the treatment and disposal of wastewater containing trace amounts of organic compounds must be carefully managed to prevent water pollution.

As environmental regulations become increasingly stringent, the chemical industry is investing in research and development to further mitigate the environmental impact of butane-derived CVI processes. This includes exploring alternative precursors with lower environmental footprints, developing more efficient reactor designs, and implementing advanced process control systems to optimize resource utilization and minimize waste generation.

In conclusion, while butane-derived CVI processes present certain environmental challenges, ongoing technological advancements and improved process management are continuously reducing their environmental impact. Balancing the benefits of these processes with their potential environmental consequences remains a key focus for researchers and industry practitioners alike.

One of the primary environmental concerns associated with butane-derived CVI processes is the emission of volatile organic compounds (VOCs). Butane and its derivatives are known to contribute to the formation of ground-level ozone and smog when released into the atmosphere. These emissions can have detrimental effects on air quality, particularly in urban and industrial areas where CVI processes are commonly employed.

Furthermore, the production and use of butane-derived precursors in CVI processes often involve energy-intensive steps, contributing to increased carbon dioxide emissions and overall carbon footprint. The extraction, refinement, and transportation of butane and its derivatives also pose potential environmental risks, including soil and water contamination in the event of spills or leaks.

However, it is important to note that advancements in CVI technology have led to improved process efficiency and reduced environmental impact. Closed-loop systems and advanced filtration technologies have been developed to minimize VOC emissions and recover unused precursors, significantly reducing waste and environmental pollution.

The use of butane-derived CVI processes can also have indirect positive environmental impacts. For instance, the ability to create high-performance materials with enhanced properties through CVI can lead to the development of more durable and lightweight products. This, in turn, can result in reduced material consumption and improved energy efficiency in various applications, such as aerospace and automotive industries.

Water consumption is another environmental aspect to consider in butane-derived CVI processes. While these processes generally require less water compared to traditional manufacturing methods, the treatment and disposal of wastewater containing trace amounts of organic compounds must be carefully managed to prevent water pollution.

As environmental regulations become increasingly stringent, the chemical industry is investing in research and development to further mitigate the environmental impact of butane-derived CVI processes. This includes exploring alternative precursors with lower environmental footprints, developing more efficient reactor designs, and implementing advanced process control systems to optimize resource utilization and minimize waste generation.

In conclusion, while butane-derived CVI processes present certain environmental challenges, ongoing technological advancements and improved process management are continuously reducing their environmental impact. Balancing the benefits of these processes with their potential environmental consequences remains a key focus for researchers and industry practitioners alike.

Safety Regulations for Butane-Based CVI Applications

The safety regulations for butane-based Chemical Vapor Infusion (CVI) applications are critical to ensure the protection of workers, facilities, and the environment. These regulations are primarily governed by occupational safety and health administrations, environmental protection agencies, and industry-specific standards organizations.

One of the key aspects of safety regulations is the proper handling and storage of butane. Strict guidelines are in place for the transportation, storage, and use of butane in CVI processes. These include requirements for specialized containment systems, pressure relief mechanisms, and ventilation systems to prevent the accumulation of flammable vapors.

Personal protective equipment (PPE) is another crucial component of safety regulations. Workers involved in butane-based CVI applications must wear appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Regular training on the proper use of PPE and emergency procedures is mandated to ensure worker safety.

Facility design and engineering controls play a significant role in safety compliance. CVI facilities must be equipped with advanced fire detection and suppression systems, emergency shutdown mechanisms, and proper electrical classifications to minimize the risk of ignition sources. Adequate ventilation and exhaust systems are essential to maintain safe atmospheric conditions and prevent the buildup of potentially explosive mixtures.

Monitoring and detection systems are required to continuously assess the presence of butane vapors in the work environment. These systems must be calibrated regularly and integrated with alarm systems to alert personnel of potential hazards. Evacuation plans and emergency response procedures must be clearly defined and regularly practiced.

Waste management and disposal regulations are also crucial for butane-based CVI applications. Proper handling and disposal of butane-contaminated materials and byproducts are necessary to prevent environmental contamination and comply with environmental protection standards.

Regular inspections and audits are mandated to ensure ongoing compliance with safety regulations. These assessments evaluate the integrity of equipment, effectiveness of safety systems, and adherence to established protocols. Documentation and record-keeping requirements are stringent, with detailed logs of safety checks, maintenance activities, and incident reports being maintained.

Lastly, regulations often require the implementation of a comprehensive safety management system that integrates all aspects of safety, from risk assessment and hazard identification to continuous improvement processes. This system-wide approach ensures that safety remains a top priority throughout all stages of butane-based CVI operations.

One of the key aspects of safety regulations is the proper handling and storage of butane. Strict guidelines are in place for the transportation, storage, and use of butane in CVI processes. These include requirements for specialized containment systems, pressure relief mechanisms, and ventilation systems to prevent the accumulation of flammable vapors.

Personal protective equipment (PPE) is another crucial component of safety regulations. Workers involved in butane-based CVI applications must wear appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Regular training on the proper use of PPE and emergency procedures is mandated to ensure worker safety.

Facility design and engineering controls play a significant role in safety compliance. CVI facilities must be equipped with advanced fire detection and suppression systems, emergency shutdown mechanisms, and proper electrical classifications to minimize the risk of ignition sources. Adequate ventilation and exhaust systems are essential to maintain safe atmospheric conditions and prevent the buildup of potentially explosive mixtures.

Monitoring and detection systems are required to continuously assess the presence of butane vapors in the work environment. These systems must be calibrated regularly and integrated with alarm systems to alert personnel of potential hazards. Evacuation plans and emergency response procedures must be clearly defined and regularly practiced.

Waste management and disposal regulations are also crucial for butane-based CVI applications. Proper handling and disposal of butane-contaminated materials and byproducts are necessary to prevent environmental contamination and comply with environmental protection standards.

Regular inspections and audits are mandated to ensure ongoing compliance with safety regulations. These assessments evaluate the integrity of equipment, effectiveness of safety systems, and adherence to established protocols. Documentation and record-keeping requirements are stringent, with detailed logs of safety checks, maintenance activities, and incident reports being maintained.

Lastly, regulations often require the implementation of a comprehensive safety management system that integrates all aspects of safety, from risk assessment and hazard identification to continuous improvement processes. This system-wide approach ensures that safety remains a top priority throughout all stages of butane-based CVI operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!