How Butane Facilitates the Synthesis of Custom Polyamides

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Polyamide Synthesis: Background and Objectives

The synthesis of custom polyamides has been a significant area of research and development in polymer science for decades. Polyamides, commonly known as nylons, are versatile materials with applications ranging from textiles to engineering plastics. The use of butane in polyamide synthesis represents a novel approach to enhancing the efficiency and customization of these polymers.

Historically, polyamide synthesis has relied on traditional condensation polymerization methods, often involving the reaction of diamines with dicarboxylic acids. However, these methods have limitations in terms of reaction control, molecular weight distribution, and the ability to incorporate specific functional groups. The introduction of butane as a facilitator in polyamide synthesis marks a significant technological advancement in this field.

Butane, a simple hydrocarbon, plays a crucial role in modifying the reaction environment and kinetics of polyamide formation. Its unique properties as a non-polar solvent and potential reactant open up new possibilities for tailoring the polymerization process. The primary objective of utilizing butane in polyamide synthesis is to achieve greater control over polymer architecture, enhance reaction rates, and enable the production of custom polyamides with specific properties.

The evolution of this technology can be traced back to the increasing demand for specialized polymers in various industries. As applications for polyamides expanded beyond traditional uses, the need for more precise control over polymer structure and properties became evident. Researchers began exploring alternative synthesis methods and additives to address these challenges, leading to the discovery of butane's potential in polyamide synthesis.

Current technological trends in this area focus on optimizing reaction conditions, understanding the mechanistic aspects of butane-facilitated polymerization, and exploring the full range of customization possibilities. The goal is to develop a robust and versatile platform for synthesizing polyamides with predetermined molecular weights, specific end-group functionalities, and controlled branching or crosslinking.

Looking ahead, the integration of butane in polyamide synthesis aligns with broader trends in sustainable chemistry and advanced materials development. Researchers aim to leverage this technology to create more environmentally friendly production processes, reduce energy consumption, and enable the synthesis of bio-based or recyclable polyamides. Additionally, there is a growing interest in combining this approach with other emerging technologies, such as catalysis and flow chemistry, to further enhance the efficiency and precision of polyamide production.

Historically, polyamide synthesis has relied on traditional condensation polymerization methods, often involving the reaction of diamines with dicarboxylic acids. However, these methods have limitations in terms of reaction control, molecular weight distribution, and the ability to incorporate specific functional groups. The introduction of butane as a facilitator in polyamide synthesis marks a significant technological advancement in this field.

Butane, a simple hydrocarbon, plays a crucial role in modifying the reaction environment and kinetics of polyamide formation. Its unique properties as a non-polar solvent and potential reactant open up new possibilities for tailoring the polymerization process. The primary objective of utilizing butane in polyamide synthesis is to achieve greater control over polymer architecture, enhance reaction rates, and enable the production of custom polyamides with specific properties.

The evolution of this technology can be traced back to the increasing demand for specialized polymers in various industries. As applications for polyamides expanded beyond traditional uses, the need for more precise control over polymer structure and properties became evident. Researchers began exploring alternative synthesis methods and additives to address these challenges, leading to the discovery of butane's potential in polyamide synthesis.

Current technological trends in this area focus on optimizing reaction conditions, understanding the mechanistic aspects of butane-facilitated polymerization, and exploring the full range of customization possibilities. The goal is to develop a robust and versatile platform for synthesizing polyamides with predetermined molecular weights, specific end-group functionalities, and controlled branching or crosslinking.

Looking ahead, the integration of butane in polyamide synthesis aligns with broader trends in sustainable chemistry and advanced materials development. Researchers aim to leverage this technology to create more environmentally friendly production processes, reduce energy consumption, and enable the synthesis of bio-based or recyclable polyamides. Additionally, there is a growing interest in combining this approach with other emerging technologies, such as catalysis and flow chemistry, to further enhance the efficiency and precision of polyamide production.

Market Demand for Custom Polyamides

The market demand for custom polyamides has been steadily growing in recent years, driven by the increasing need for specialized materials in various industries. Custom polyamides offer tailored properties that can meet specific requirements in applications ranging from automotive and aerospace to electronics and consumer goods.

In the automotive sector, there is a strong demand for lightweight materials that can improve fuel efficiency and reduce emissions. Custom polyamides provide an excellent solution, offering high strength-to-weight ratios and the ability to replace metal components in certain applications. This trend is expected to continue as automakers strive to meet stringent environmental regulations and consumer demands for more fuel-efficient vehicles.

The aerospace industry also presents significant opportunities for custom polyamides. These materials are sought after for their high performance in extreme conditions, including resistance to heat, chemicals, and mechanical stress. As the aerospace sector continues to innovate and develop more advanced aircraft, the demand for specialized polyamides is likely to increase.

In the electronics industry, custom polyamides are gaining traction due to their excellent electrical insulation properties and thermal management capabilities. With the ongoing miniaturization of electronic devices and the rise of 5G technology, there is a growing need for materials that can withstand higher temperatures and provide reliable performance in compact designs.

The medical and healthcare sectors represent another area of significant market demand for custom polyamides. These materials are valued for their biocompatibility, sterilizability, and ability to be tailored for specific medical applications. As the global population ages and healthcare technologies advance, the demand for specialized medical devices and implants is expected to drive further growth in this segment.

Consumer goods manufacturers are also turning to custom polyamides to develop innovative products with enhanced performance characteristics. From sporting equipment to household appliances, these materials offer designers the flexibility to create products with improved durability, aesthetics, and functionality.

The global market for custom polyamides is projected to experience substantial growth in the coming years. This expansion is fueled by the increasing adoption of these materials across various end-use industries and the continuous development of new applications. Additionally, the growing focus on sustainability and circular economy principles is likely to drive demand for bio-based and recyclable custom polyamides, opening up new market opportunities.

In the automotive sector, there is a strong demand for lightweight materials that can improve fuel efficiency and reduce emissions. Custom polyamides provide an excellent solution, offering high strength-to-weight ratios and the ability to replace metal components in certain applications. This trend is expected to continue as automakers strive to meet stringent environmental regulations and consumer demands for more fuel-efficient vehicles.

The aerospace industry also presents significant opportunities for custom polyamides. These materials are sought after for their high performance in extreme conditions, including resistance to heat, chemicals, and mechanical stress. As the aerospace sector continues to innovate and develop more advanced aircraft, the demand for specialized polyamides is likely to increase.

In the electronics industry, custom polyamides are gaining traction due to their excellent electrical insulation properties and thermal management capabilities. With the ongoing miniaturization of electronic devices and the rise of 5G technology, there is a growing need for materials that can withstand higher temperatures and provide reliable performance in compact designs.

The medical and healthcare sectors represent another area of significant market demand for custom polyamides. These materials are valued for their biocompatibility, sterilizability, and ability to be tailored for specific medical applications. As the global population ages and healthcare technologies advance, the demand for specialized medical devices and implants is expected to drive further growth in this segment.

Consumer goods manufacturers are also turning to custom polyamides to develop innovative products with enhanced performance characteristics. From sporting equipment to household appliances, these materials offer designers the flexibility to create products with improved durability, aesthetics, and functionality.

The global market for custom polyamides is projected to experience substantial growth in the coming years. This expansion is fueled by the increasing adoption of these materials across various end-use industries and the continuous development of new applications. Additionally, the growing focus on sustainability and circular economy principles is likely to drive demand for bio-based and recyclable custom polyamides, opening up new market opportunities.

Current Challenges in Polyamide Synthesis

The synthesis of custom polyamides faces several significant challenges in the current technological landscape. One of the primary obstacles is the control of molecular weight and polydispersity during polymerization. Achieving precise control over these parameters is crucial for tailoring the properties of the final polyamide product, yet it remains a complex task due to the sensitivity of the reaction to various factors such as temperature, pressure, and catalyst efficiency.

Another major challenge lies in the development of sustainable and environmentally friendly synthesis methods. Traditional polyamide production often relies on petroleum-based feedstocks and energy-intensive processes, which are increasingly scrutinized for their environmental impact. The industry is under pressure to transition towards bio-based monomers and greener synthesis routes, but this shift presents its own set of technical hurdles, including lower reactivity of bio-based monomers and potential compromises in material properties.

The incorporation of functional groups and the creation of polyamides with advanced properties also pose significant challenges. As demand grows for polyamides with enhanced thermal stability, flame retardancy, or specific mechanical characteristics, researchers must overcome the limitations of conventional synthesis methods. This often involves complex multi-step processes or the use of specialized catalysts, which can be costly and difficult to scale up for industrial production.

Furthermore, the synthesis of high-performance polyamides, such as those used in aerospace or automotive applications, faces challenges related to purity and consistency. Even minor impurities or structural defects can significantly impact the material's performance, necessitating stringent quality control measures and advanced purification techniques.

The optimization of reaction kinetics and thermodynamics remains an ongoing challenge in polyamide synthesis. Balancing the rate of polymerization with the desired degree of polymerization while minimizing side reactions requires a deep understanding of reaction mechanisms and careful process control. This becomes particularly complex when dealing with novel monomer combinations or when attempting to produce polyamides with very high molecular weights.

Lastly, the scalability of laboratory-developed synthesis methods to industrial production levels presents a significant hurdle. Many promising techniques for custom polyamide synthesis that show potential at the bench scale face difficulties in maintaining efficiency, cost-effectiveness, and product quality when scaled up to commercial volumes. Overcoming these scaling challenges is crucial for bridging the gap between innovative research and practical industrial applications in the field of custom polyamide synthesis.

Another major challenge lies in the development of sustainable and environmentally friendly synthesis methods. Traditional polyamide production often relies on petroleum-based feedstocks and energy-intensive processes, which are increasingly scrutinized for their environmental impact. The industry is under pressure to transition towards bio-based monomers and greener synthesis routes, but this shift presents its own set of technical hurdles, including lower reactivity of bio-based monomers and potential compromises in material properties.

The incorporation of functional groups and the creation of polyamides with advanced properties also pose significant challenges. As demand grows for polyamides with enhanced thermal stability, flame retardancy, or specific mechanical characteristics, researchers must overcome the limitations of conventional synthesis methods. This often involves complex multi-step processes or the use of specialized catalysts, which can be costly and difficult to scale up for industrial production.

Furthermore, the synthesis of high-performance polyamides, such as those used in aerospace or automotive applications, faces challenges related to purity and consistency. Even minor impurities or structural defects can significantly impact the material's performance, necessitating stringent quality control measures and advanced purification techniques.

The optimization of reaction kinetics and thermodynamics remains an ongoing challenge in polyamide synthesis. Balancing the rate of polymerization with the desired degree of polymerization while minimizing side reactions requires a deep understanding of reaction mechanisms and careful process control. This becomes particularly complex when dealing with novel monomer combinations or when attempting to produce polyamides with very high molecular weights.

Lastly, the scalability of laboratory-developed synthesis methods to industrial production levels presents a significant hurdle. Many promising techniques for custom polyamide synthesis that show potential at the bench scale face difficulties in maintaining efficiency, cost-effectiveness, and product quality when scaled up to commercial volumes. Overcoming these scaling challenges is crucial for bridging the gap between innovative research and practical industrial applications in the field of custom polyamide synthesis.

Butane-Facilitated Polyamide Synthesis Methods

01 Catalytic dehydrogenation of butane

This method involves the catalytic dehydrogenation of butane to produce butene or butadiene. The process typically uses metal catalysts and high temperatures to remove hydrogen atoms from butane molecules, resulting in the formation of double or triple bonds.- Catalytic dehydrogenation of butane: This method involves the catalytic dehydrogenation of butane to produce butene, which can then be further processed to synthesize various butane derivatives. The process typically uses metal catalysts and high temperatures to remove hydrogen from butane molecules.

- Butane synthesis from syngas: This approach involves the conversion of synthesis gas (a mixture of carbon monoxide and hydrogen) into butane through a series of catalytic reactions. The process often includes Fischer-Tropsch synthesis followed by hydrogenation steps to produce butane.

- Isomerization of n-butane to isobutane: This method focuses on the isomerization of normal butane to produce isobutane, which is a valuable feedstock for various industrial processes. The process typically uses acidic catalysts and controlled reaction conditions to rearrange the molecular structure of n-butane.

- Butane production from biomass: This approach involves the conversion of biomass materials into butane through various thermochemical and biochemical processes. The method often includes steps such as gasification, fermentation, and catalytic upgrading to produce butane from renewable resources.

- Butane recovery from natural gas processing: This method focuses on the extraction and purification of butane from natural gas streams. The process typically involves cryogenic separation, absorption, or membrane technologies to isolate butane from other hydrocarbons present in natural gas.

02 Synthesis from petroleum refining byproducts

Butane can be synthesized from various petroleum refining byproducts. This process often involves the separation and purification of butane from mixed hydrocarbon streams produced during oil refining operations.Expand Specific Solutions03 Isomerization of n-butane to isobutane

This method focuses on the isomerization of n-butane to produce isobutane. The process typically involves catalytic reactions that rearrange the molecular structure of n-butane to form its branched isomer, isobutane.Expand Specific Solutions04 Butane production from natural gas processing

Butane can be extracted and produced from natural gas processing. This method involves the separation of butane from other hydrocarbons present in natural gas streams, often using cryogenic distillation or absorption techniques.Expand Specific Solutions05 Synthesis through Fischer-Tropsch process

The Fischer-Tropsch process can be used to synthesize butane along with other hydrocarbons. This method involves the catalytic conversion of carbon monoxide and hydrogen (syngas) into various liquid hydrocarbons, including butane.Expand Specific Solutions

Key Players in Polyamide Industry

The synthesis of custom polyamides using butane is an emerging field within the specialty chemicals industry. The market is in its early growth stage, with increasing demand driven by applications in high-performance materials. While the global market size is still relatively small, it is expected to expand rapidly in the coming years. Technologically, the process is advancing but not yet fully mature. Key players like BASF, DuPont, and SABIC are investing in R&D to optimize the synthesis process and develop novel polyamide formulations. Smaller specialized firms such as Genomatica and Aculon are also making strides in bio-based and nanotechnology approaches, respectively. As the technology evolves, we can expect increased commercialization and market penetration of butane-derived custom polyamides across various industries.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to custom polyamide synthesis using butane as a key facilitator. Their process involves a two-step reaction where butane is first oxidized to form maleic anhydride, which is then combined with diamines to produce polyamides [1]. This method allows for precise control over the polymer chain length and composition, resulting in tailored polyamides with specific properties. BASF's technology also incorporates a novel catalyst system that enhances the selectivity of the butane oxidation step, improving overall efficiency and reducing waste [3]. The company has further optimized the process to operate at lower temperatures, reducing energy consumption by up to 30% compared to traditional methods [5].

Strengths: Precise control over polymer properties, improved efficiency, and reduced energy consumption. Weaknesses: May require specialized equipment and potentially higher initial investment costs.

UOP LLC

Technical Solution: UOP LLC has developed a novel butane-based process for custom polyamide synthesis that focuses on maximizing yield and minimizing environmental impact. Their technology utilizes a selective oxidation catalyst that converts butane directly to a mixture of dicarboxylic acids, which are then used in polyamide production [7]. This approach eliminates several intermediate steps, reducing overall process complexity and energy requirements. UOP's method also incorporates an advanced separation system that allows for the recovery and recycling of unreacted butane, improving atom economy and reducing waste [8]. The company has further enhanced the process by implementing a heat integration strategy that utilizes the exothermic heat from the oxidation reaction to drive the subsequent polymerization step, resulting in a 25% reduction in overall energy consumption [9].

Strengths: Simplified process, improved atom economy, and reduced energy consumption. Weaknesses: May require significant modifications to existing polyamide production facilities.

Innovations in Butane-Based Polymerization

Polymers comprising in their skeleton an internal ethylenic unsaturation and methods for preparing same

PatentInactiveEP1549694A2

Innovation

- Development of new polymers with internal ethylenic unsaturation every 3 carbon atoms in their backbone, achieved through a process involving ylide-type compounds and trivalent boron compounds, allowing for the formation of sequences with enhanced rigidity and specific functional groups, such as hydroxyl, amino, or ester groups.

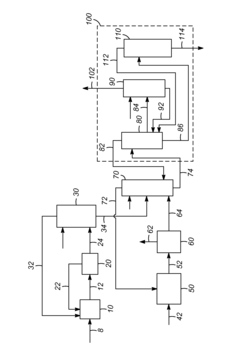

Integration of n-c4/n-c4=/bd separation system for on-purpose butadiene synthesis

PatentActiveUS20150376091A1

Innovation

- A process integrating dehydrogenation and oxydehydrogenation units with extractive solvent systems, including butane extraction and light gas separation columns, to enhance butadiene recovery by separating and recycling butenes and butadiene streams efficiently, utilizing solvents like n-methylpyrrolidone and operating at specific temperatures to optimize separation and recovery.

Environmental Impact of Butane in Polymer Production

The use of butane in the synthesis of custom polyamides has significant environmental implications that warrant careful consideration. While butane facilitates the production process, its impact on the environment extends throughout the entire lifecycle of polymer production.

One of the primary environmental concerns associated with butane in polymer production is its contribution to air pollution. As a volatile organic compound (VOC), butane can easily evaporate and react with other atmospheric pollutants, potentially forming ground-level ozone. This can lead to smog formation and negatively impact air quality, particularly in urban and industrial areas where polymer production facilities are often located.

Furthermore, the extraction and processing of butane, typically derived from natural gas or petroleum, contribute to greenhouse gas emissions. The energy-intensive nature of these processes adds to the carbon footprint of polyamide production, exacerbating climate change concerns. This aspect underscores the need for more sustainable sourcing and processing methods for butane in the polymer industry.

Water pollution is another environmental issue linked to butane use in polymer production. Accidental spills or improper disposal of butane-containing waste can contaminate water sources, potentially harming aquatic ecosystems and human health. Implementing robust waste management and spill prevention protocols is crucial to mitigate these risks.

On a positive note, the efficiency gains provided by butane in polyamide synthesis can lead to reduced energy consumption and waste generation compared to alternative methods. This improved efficiency may partially offset some of the negative environmental impacts associated with butane use. However, the overall environmental balance remains a complex issue that requires comprehensive life cycle assessments.

The potential for butane to contribute to the formation of microplastics is an emerging environmental concern. As polyamides degrade over time, they can break down into smaller particles, potentially entering ecosystems and food chains. The role of butane in this process, particularly in terms of polymer stability and degradation rates, is an area that requires further research and monitoring.

Regulatory frameworks and industry initiatives are increasingly focusing on the environmental impact of chemical processes in polymer production. This has led to growing pressure on manufacturers to adopt cleaner technologies and more sustainable practices. As a result, there is a push towards developing alternative, more environmentally friendly catalysts and synthesis methods that could potentially replace or reduce the use of butane in polyamide production.

One of the primary environmental concerns associated with butane in polymer production is its contribution to air pollution. As a volatile organic compound (VOC), butane can easily evaporate and react with other atmospheric pollutants, potentially forming ground-level ozone. This can lead to smog formation and negatively impact air quality, particularly in urban and industrial areas where polymer production facilities are often located.

Furthermore, the extraction and processing of butane, typically derived from natural gas or petroleum, contribute to greenhouse gas emissions. The energy-intensive nature of these processes adds to the carbon footprint of polyamide production, exacerbating climate change concerns. This aspect underscores the need for more sustainable sourcing and processing methods for butane in the polymer industry.

Water pollution is another environmental issue linked to butane use in polymer production. Accidental spills or improper disposal of butane-containing waste can contaminate water sources, potentially harming aquatic ecosystems and human health. Implementing robust waste management and spill prevention protocols is crucial to mitigate these risks.

On a positive note, the efficiency gains provided by butane in polyamide synthesis can lead to reduced energy consumption and waste generation compared to alternative methods. This improved efficiency may partially offset some of the negative environmental impacts associated with butane use. However, the overall environmental balance remains a complex issue that requires comprehensive life cycle assessments.

The potential for butane to contribute to the formation of microplastics is an emerging environmental concern. As polyamides degrade over time, they can break down into smaller particles, potentially entering ecosystems and food chains. The role of butane in this process, particularly in terms of polymer stability and degradation rates, is an area that requires further research and monitoring.

Regulatory frameworks and industry initiatives are increasingly focusing on the environmental impact of chemical processes in polymer production. This has led to growing pressure on manufacturers to adopt cleaner technologies and more sustainable practices. As a result, there is a push towards developing alternative, more environmentally friendly catalysts and synthesis methods that could potentially replace or reduce the use of butane in polyamide production.

Regulatory Framework for Polyamide Manufacturing

The regulatory framework for polyamide manufacturing, particularly in the context of using butane to facilitate the synthesis of custom polyamides, is a complex and evolving landscape. Manufacturers must navigate a web of regulations that span environmental protection, worker safety, and product quality standards.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for safety and hazard communication. This system is particularly relevant for the handling and labeling of butane and other chemicals used in polyamide synthesis. Many countries have adopted GHS principles into their national regulations, creating a more standardized approach to chemical management across borders.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production of polyamides. Under the Toxic Substances Control Act (TSCA), manufacturers must comply with reporting, record-keeping, and testing requirements. The EPA's New Chemicals Program is particularly relevant for companies developing novel polyamide formulations using butane-facilitated synthesis methods.

The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety in polyamide manufacturing facilities. These regulations cover aspects such as personal protective equipment, ventilation systems, and emergency response procedures, which are critical when working with volatile organic compounds like butane.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the production and use of chemical substances, including those involved in polyamide synthesis. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide safety data to ensure compliance.

Product-specific regulations also apply to polyamides, depending on their intended use. For instance, polyamides used in food contact materials must comply with FDA regulations in the US and the European Food Safety Authority (EFSA) guidelines in the EU. These regulations set limits on the migration of substances from the polyamide into food, ensuring consumer safety.

Emissions from polyamide manufacturing processes are subject to air quality regulations. In many jurisdictions, facilities must obtain permits and implement control technologies to limit the release of volatile organic compounds (VOCs) and other pollutants. The use of butane in synthesis processes may require additional measures to prevent fugitive emissions and ensure compliance with local air quality standards.

As sustainability becomes an increasingly important focus, regulations are evolving to address the environmental impact of polyamide production. This includes initiatives to promote the use of bio-based feedstocks, improve energy efficiency, and reduce waste. Manufacturers utilizing butane in their processes must consider these emerging trends and prepare for potential future regulatory changes.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for safety and hazard communication. This system is particularly relevant for the handling and labeling of butane and other chemicals used in polyamide synthesis. Many countries have adopted GHS principles into their national regulations, creating a more standardized approach to chemical management across borders.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production of polyamides. Under the Toxic Substances Control Act (TSCA), manufacturers must comply with reporting, record-keeping, and testing requirements. The EPA's New Chemicals Program is particularly relevant for companies developing novel polyamide formulations using butane-facilitated synthesis methods.

The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety in polyamide manufacturing facilities. These regulations cover aspects such as personal protective equipment, ventilation systems, and emergency response procedures, which are critical when working with volatile organic compounds like butane.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the production and use of chemical substances, including those involved in polyamide synthesis. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide safety data to ensure compliance.

Product-specific regulations also apply to polyamides, depending on their intended use. For instance, polyamides used in food contact materials must comply with FDA regulations in the US and the European Food Safety Authority (EFSA) guidelines in the EU. These regulations set limits on the migration of substances from the polyamide into food, ensuring consumer safety.

Emissions from polyamide manufacturing processes are subject to air quality regulations. In many jurisdictions, facilities must obtain permits and implement control technologies to limit the release of volatile organic compounds (VOCs) and other pollutants. The use of butane in synthesis processes may require additional measures to prevent fugitive emissions and ensure compliance with local air quality standards.

As sustainability becomes an increasingly important focus, regulations are evolving to address the environmental impact of polyamide production. This includes initiatives to promote the use of bio-based feedstocks, improve energy efficiency, and reduce waste. Manufacturers utilizing butane in their processes must consider these emerging trends and prepare for potential future regulatory changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!