Butane's Influence on the Advancement of Trace Gas Detection Equipment

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Detection Evolution

The evolution of butane detection technology has played a significant role in advancing trace gas detection equipment. This progression can be traced through several key stages, each marked by notable technological breakthroughs and improvements in detection capabilities.

In the early stages, butane detection primarily relied on simple chemical reactions and rudimentary sensors. These methods, while functional, lacked precision and were limited in their ability to detect trace amounts of butane. The advent of gas chromatography in the 1950s marked a significant leap forward, allowing for more accurate separation and identification of butane from other gases.

The 1970s and 1980s saw the introduction of infrared spectroscopy techniques for butane detection. This non-destructive method offered improved sensitivity and selectivity, enabling the detection of lower concentrations of butane in complex gas mixtures. Fourier Transform Infrared (FTIR) spectroscopy, in particular, became a powerful tool for butane analysis, providing high-resolution spectra and rapid measurement capabilities.

The late 1990s and early 2000s witnessed the emergence of semiconductor-based sensors for butane detection. These solid-state devices offered advantages in terms of miniaturization, low power consumption, and potential for mass production. Metal oxide semiconductor (MOS) sensors became particularly popular for their ability to detect butane at parts-per-million (ppm) levels.

In recent years, the development of advanced optical sensing technologies has further revolutionized butane detection. Tunable diode laser absorption spectroscopy (TDLAS) has emerged as a highly sensitive and selective method for trace gas detection, capable of measuring butane concentrations in the parts-per-billion (ppb) range. This technology has found applications in environmental monitoring, industrial process control, and safety systems.

The integration of microelectromechanical systems (MEMS) technology with gas sensing principles has led to the creation of highly compact and sensitive butane detectors. These miniaturized devices have enabled the development of portable and wearable gas detection equipment, expanding the range of applications for butane monitoring.

Most recently, the incorporation of artificial intelligence and machine learning algorithms into butane detection systems has enhanced data analysis and interpretation capabilities. These advanced computational techniques allow for real-time processing of complex spectral data, improving the accuracy and reliability of butane measurements in diverse environmental conditions.

In the early stages, butane detection primarily relied on simple chemical reactions and rudimentary sensors. These methods, while functional, lacked precision and were limited in their ability to detect trace amounts of butane. The advent of gas chromatography in the 1950s marked a significant leap forward, allowing for more accurate separation and identification of butane from other gases.

The 1970s and 1980s saw the introduction of infrared spectroscopy techniques for butane detection. This non-destructive method offered improved sensitivity and selectivity, enabling the detection of lower concentrations of butane in complex gas mixtures. Fourier Transform Infrared (FTIR) spectroscopy, in particular, became a powerful tool for butane analysis, providing high-resolution spectra and rapid measurement capabilities.

The late 1990s and early 2000s witnessed the emergence of semiconductor-based sensors for butane detection. These solid-state devices offered advantages in terms of miniaturization, low power consumption, and potential for mass production. Metal oxide semiconductor (MOS) sensors became particularly popular for their ability to detect butane at parts-per-million (ppm) levels.

In recent years, the development of advanced optical sensing technologies has further revolutionized butane detection. Tunable diode laser absorption spectroscopy (TDLAS) has emerged as a highly sensitive and selective method for trace gas detection, capable of measuring butane concentrations in the parts-per-billion (ppb) range. This technology has found applications in environmental monitoring, industrial process control, and safety systems.

The integration of microelectromechanical systems (MEMS) technology with gas sensing principles has led to the creation of highly compact and sensitive butane detectors. These miniaturized devices have enabled the development of portable and wearable gas detection equipment, expanding the range of applications for butane monitoring.

Most recently, the incorporation of artificial intelligence and machine learning algorithms into butane detection systems has enhanced data analysis and interpretation capabilities. These advanced computational techniques allow for real-time processing of complex spectral data, improving the accuracy and reliability of butane measurements in diverse environmental conditions.

Market Demand Analysis

The market demand for trace gas detection equipment has been significantly influenced by the increasing focus on butane detection across various industries. The oil and gas sector, in particular, has shown a growing need for advanced butane detection technologies to ensure safety in production, storage, and transportation processes. This demand is driven by stringent regulatory requirements and the industry's commitment to minimizing environmental impact and workplace hazards.

In the industrial manufacturing sector, the use of butane as a raw material or fuel has necessitated more accurate and reliable detection methods. Companies are seeking equipment that can provide real-time monitoring and early warning systems to prevent potential accidents and maintain compliance with safety standards. This has led to a surge in demand for portable and fixed gas detection devices capable of detecting butane at very low concentrations.

The automotive industry has also contributed to the market growth for butane detection equipment. With the increasing use of liquefied petroleum gas (LPG) as an alternative fuel, there is a rising need for leak detection systems in vehicles and refueling stations. This has opened up new opportunities for manufacturers of trace gas detection equipment to develop specialized solutions for the automotive sector.

Environmental monitoring agencies and research institutions have shown a keen interest in advanced butane detection technologies. The ability to accurately measure trace amounts of butane in the atmosphere is crucial for studying air quality, climate change, and urban pollution levels. This has created a niche market for high-sensitivity equipment capable of detecting butane at parts per billion (ppb) levels.

The consumer electronics market has also emerged as a potential growth area for miniaturized butane detection technologies. With the increasing awareness of indoor air quality, there is a growing demand for smart home devices that can detect and alert users to the presence of harmful gases, including butane.

Market analysis indicates that the global trace gas detection equipment market, including butane detection, is expected to grow steadily over the next five years. Factors such as increasing industrialization, stringent safety regulations, and growing environmental concerns are driving this growth. North America and Europe currently lead the market, but rapid industrialization in Asia-Pacific regions is creating new opportunities for market expansion.

The demand for more sophisticated, multi-gas detection systems that can simultaneously detect butane along with other gases is on the rise. End-users are increasingly looking for integrated solutions that offer improved accuracy, faster response times, and enhanced connectivity features for remote monitoring and data analysis.

In the industrial manufacturing sector, the use of butane as a raw material or fuel has necessitated more accurate and reliable detection methods. Companies are seeking equipment that can provide real-time monitoring and early warning systems to prevent potential accidents and maintain compliance with safety standards. This has led to a surge in demand for portable and fixed gas detection devices capable of detecting butane at very low concentrations.

The automotive industry has also contributed to the market growth for butane detection equipment. With the increasing use of liquefied petroleum gas (LPG) as an alternative fuel, there is a rising need for leak detection systems in vehicles and refueling stations. This has opened up new opportunities for manufacturers of trace gas detection equipment to develop specialized solutions for the automotive sector.

Environmental monitoring agencies and research institutions have shown a keen interest in advanced butane detection technologies. The ability to accurately measure trace amounts of butane in the atmosphere is crucial for studying air quality, climate change, and urban pollution levels. This has created a niche market for high-sensitivity equipment capable of detecting butane at parts per billion (ppb) levels.

The consumer electronics market has also emerged as a potential growth area for miniaturized butane detection technologies. With the increasing awareness of indoor air quality, there is a growing demand for smart home devices that can detect and alert users to the presence of harmful gases, including butane.

Market analysis indicates that the global trace gas detection equipment market, including butane detection, is expected to grow steadily over the next five years. Factors such as increasing industrialization, stringent safety regulations, and growing environmental concerns are driving this growth. North America and Europe currently lead the market, but rapid industrialization in Asia-Pacific regions is creating new opportunities for market expansion.

The demand for more sophisticated, multi-gas detection systems that can simultaneously detect butane along with other gases is on the rise. End-users are increasingly looking for integrated solutions that offer improved accuracy, faster response times, and enhanced connectivity features for remote monitoring and data analysis.

Current Challenges

The advancement of trace gas detection equipment, particularly in relation to butane detection, faces several significant challenges. One of the primary obstacles is the need for improved sensitivity and selectivity in detecting butane at low concentrations. Current technologies often struggle to differentiate butane from other similar hydrocarbons, leading to potential false positives or inaccurate measurements.

Another challenge lies in the miniaturization of detection equipment while maintaining high performance. As industries demand more portable and compact solutions, researchers are grappling with the task of reducing device size without compromising detection capabilities. This miniaturization effort is particularly crucial for applications in confined spaces or remote locations where traditional bulky equipment is impractical.

The issue of cross-sensitivity remains a persistent problem in butane detection. Many sensors designed for butane can also respond to other gases, such as propane or methane, which can lead to erroneous readings. Developing sensors with higher specificity to butane is an ongoing challenge that requires innovative approaches in material science and sensor design.

Environmental factors pose additional challenges to the reliability of trace gas detection equipment. Temperature fluctuations, humidity changes, and the presence of interfering substances can all affect the accuracy of butane measurements. Creating robust systems that can maintain consistent performance across various environmental conditions is a key area of focus for researchers and engineers.

The need for real-time, continuous monitoring presents another hurdle. Many current systems require periodic sampling or have significant response times, which can be inadequate for applications requiring immediate detection of butane leaks or concentration changes. Developing sensors with faster response times and the ability to provide continuous data is crucial for enhancing safety and process control in industries where butane is present.

Cost-effectiveness is also a major consideration in the advancement of trace gas detection equipment. While high-end laboratory instruments can achieve excellent sensitivity and selectivity, their cost often prohibits widespread adoption in industrial or consumer applications. Striking a balance between performance and affordability remains a significant challenge for manufacturers and researchers alike.

Lastly, the integration of trace gas detection equipment with modern data analytics and IoT systems presents both opportunities and challenges. While such integration can greatly enhance the utility of detection systems, it also introduces complexities in data management, cybersecurity, and system interoperability. Addressing these challenges is crucial for realizing the full potential of advanced butane detection technologies in smart industrial and environmental monitoring applications.

Another challenge lies in the miniaturization of detection equipment while maintaining high performance. As industries demand more portable and compact solutions, researchers are grappling with the task of reducing device size without compromising detection capabilities. This miniaturization effort is particularly crucial for applications in confined spaces or remote locations where traditional bulky equipment is impractical.

The issue of cross-sensitivity remains a persistent problem in butane detection. Many sensors designed for butane can also respond to other gases, such as propane or methane, which can lead to erroneous readings. Developing sensors with higher specificity to butane is an ongoing challenge that requires innovative approaches in material science and sensor design.

Environmental factors pose additional challenges to the reliability of trace gas detection equipment. Temperature fluctuations, humidity changes, and the presence of interfering substances can all affect the accuracy of butane measurements. Creating robust systems that can maintain consistent performance across various environmental conditions is a key area of focus for researchers and engineers.

The need for real-time, continuous monitoring presents another hurdle. Many current systems require periodic sampling or have significant response times, which can be inadequate for applications requiring immediate detection of butane leaks or concentration changes. Developing sensors with faster response times and the ability to provide continuous data is crucial for enhancing safety and process control in industries where butane is present.

Cost-effectiveness is also a major consideration in the advancement of trace gas detection equipment. While high-end laboratory instruments can achieve excellent sensitivity and selectivity, their cost often prohibits widespread adoption in industrial or consumer applications. Striking a balance between performance and affordability remains a significant challenge for manufacturers and researchers alike.

Lastly, the integration of trace gas detection equipment with modern data analytics and IoT systems presents both opportunities and challenges. While such integration can greatly enhance the utility of detection systems, it also introduces complexities in data management, cybersecurity, and system interoperability. Addressing these challenges is crucial for realizing the full potential of advanced butane detection technologies in smart industrial and environmental monitoring applications.

Existing Detection Methods

01 Optical detection methods for trace gases

Various optical techniques are employed for trace gas detection, including spectroscopy and laser-based methods. These approaches offer high sensitivity and selectivity for detecting minute concentrations of gases. Advanced optical systems can measure absorption, emission, or scattering of light to identify and quantify trace gases in different environments.- Optical detection methods: Trace gas detection equipment often employs optical detection methods, such as spectroscopy techniques. These methods utilize the interaction between light and gas molecules to identify and quantify trace gases. Advanced optical systems can achieve high sensitivity and selectivity in detecting various gases at low concentrations.

- Cavity-enhanced absorption spectroscopy: This technique enhances the detection capability of trace gas equipment by using optical cavities to increase the effective path length of light through the sample. It allows for improved sensitivity and lower detection limits compared to traditional absorption spectroscopy methods, enabling the detection of trace gases at parts-per-billion or even parts-per-trillion levels.

- Electrochemical sensors: Electrochemical sensors are widely used in trace gas detection equipment due to their high sensitivity and selectivity. These sensors operate by measuring the electrical current or potential change resulting from the interaction between the target gas and the sensor's electrodes. They can detect various gases at low concentrations and are often used in portable and continuous monitoring applications.

- Mass spectrometry techniques: Mass spectrometry is a powerful analytical technique used in trace gas detection equipment. It separates and identifies gas molecules based on their mass-to-charge ratio, allowing for highly sensitive and selective detection of multiple gases simultaneously. Advanced mass spectrometry systems can detect trace gases at extremely low concentrations and provide detailed compositional analysis.

- Preconcentration and sample preparation: To enhance the detection capability of trace gas equipment, various preconcentration and sample preparation techniques are employed. These methods involve concentrating the target gases from a large volume of air into a smaller volume, effectively increasing their concentration before analysis. Techniques such as thermal desorption, cryogenic trapping, and membrane separation can significantly improve the overall sensitivity and detection limits of the equipment.

02 Electrochemical sensors for gas detection

Electrochemical sensors are widely used in trace gas detection equipment due to their high sensitivity and compact size. These sensors operate by measuring the electrical current generated when target gases interact with the sensing electrode. They can detect various gases at low concentrations and are often used in portable devices for environmental monitoring and industrial safety applications.Expand Specific Solutions03 Mass spectrometry for trace gas analysis

Mass spectrometry is a powerful technique for trace gas detection, offering high sensitivity and the ability to identify multiple gases simultaneously. This method ionizes gas molecules and separates them based on their mass-to-charge ratio, allowing for precise identification and quantification of trace gases in complex mixtures.Expand Specific Solutions04 Cavity-enhanced absorption spectroscopy

Cavity-enhanced absorption spectroscopy is an advanced technique for trace gas detection that uses optical cavities to increase the effective path length of light through a sample. This method significantly enhances sensitivity, allowing for detection of extremely low gas concentrations. It is particularly useful for monitoring atmospheric trace gases and in industrial process control.Expand Specific Solutions05 Miniaturized and portable gas detection systems

Recent advancements in trace gas detection focus on developing miniaturized and portable systems. These compact devices integrate various sensing technologies, such as microelectromechanical systems (MEMS) and nanostructured materials, to achieve high sensitivity in a small form factor. They enable on-site, real-time monitoring of trace gases in diverse applications, including environmental studies and personal safety.Expand Specific Solutions

Key Industry Players

The competitive landscape for butane's influence on trace gas detection equipment advancement is characterized by a mature market with steady growth. The global gas detection equipment market, valued at around $4 billion, is expected to expand at a CAGR of 5-6% over the next five years. Technological maturity varies, with established players like Agilent Technologies and Draeger Safety leading in innovation. Emerging companies such as SeekOps are introducing novel mobile-monitoring technologies, while research institutions like the University of Surrey and Jilin University contribute to fundamental advancements. Major petrochemical companies like SABIC and LG Chem are also investing in related technologies, indicating the industry's strategic importance across multiple sectors.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced gas chromatography-mass spectrometry (GC-MS) systems specifically optimized for trace butane detection. Their latest GC-MS models incorporate innovative ion source designs and high-efficiency electron multipliers, enabling detection limits in the parts-per-trillion range for butane and other hydrocarbons[1]. The company has also introduced novel sample preparation techniques, such as solid-phase microextraction (SPME) fibers coated with specially engineered polymers, to enhance butane extraction efficiency from complex matrices[3]. Additionally, Agilent has developed custom software algorithms for automated peak identification and quantification of trace butane levels in chromatograms, significantly improving analysis speed and accuracy[5].

Strengths: Industry-leading sensitivity and selectivity for butane detection, comprehensive solution from sample prep to data analysis. Weaknesses: High instrument cost, requires skilled operators for optimal performance.

Draeger Safety, Inc.

Technical Solution: Draeger Safety has pioneered portable infrared (IR) gas detection technology for butane and other hydrocarbons. Their latest handheld devices utilize tunable diode laser spectroscopy (TDLS) to achieve highly selective butane detection with minimal cross-interference from other gases[2]. The company has also developed novel photoacoustic spectroscopy (PAS) sensors that offer excellent sensitivity for butane at lower cost than traditional IR methods[4]. Draeger's gas detectors incorporate advanced signal processing algorithms and machine learning techniques to compensate for environmental factors and improve measurement stability in field conditions[6].

Strengths: Rugged, portable designs suitable for field use, fast response times for real-time monitoring. Weaknesses: Lower absolute sensitivity compared to lab-based methods, limited multi-gas analysis capabilities.

Innovative Sensor Tech

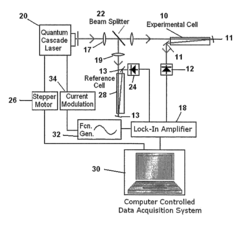

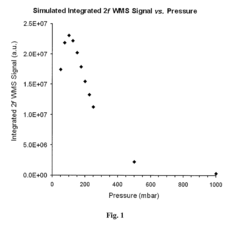

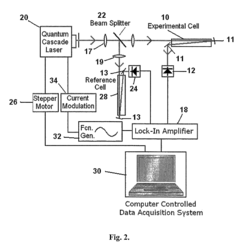

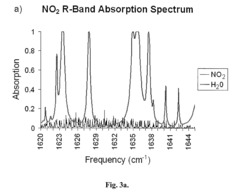

Method and apparatus for trace gas detection using integrated wavelength modulated spectra across multiple lines

PatentInactiveUS8395777B2

Innovation

- The implementation of wavelength modulation spectroscopy with a tunable laser, integrating the absolute value of spectra across multiple absorption lines, enhances sensitivity by several orders of magnitude by utilizing a sinusoidal frequency modulation and lock-in amplifier techniques, allowing for precise detection of trace gas species like NO2.

Method of chemical marking of batches of carbon dioxide in order to ensure traceability

PatentActiveUS20160290978A1

Innovation

- A method involving the formulation and injection of a unique chemical tracer into CO2 batches, combined with a computerized traceability system for identification, allowing the batch to be uniquely identifiable and traceable through its composition analysis, even during changes in state or container transfer.

Regulatory Framework

The regulatory framework surrounding butane and its influence on trace gas detection equipment has evolved significantly in recent years, driven by increasing environmental concerns and safety standards. Governmental bodies and international organizations have implemented stringent regulations to monitor and control butane emissions, necessitating advancements in detection technologies.

In the United States, the Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) that include provisions for monitoring volatile organic compounds (VOCs) like butane. These standards have prompted the development of more sensitive and accurate trace gas detection equipment capable of measuring butane concentrations at parts per billion (ppb) levels.

The European Union has also implemented strict regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program, which requires comprehensive monitoring of chemical substances, including butane. This regulatory pressure has led to innovations in portable and continuous monitoring systems for butane detection in industrial settings and urban environments.

In the oil and gas industry, regulations such as the EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) have mandated the use of advanced leak detection and repair (LDAR) programs. These regulations have spurred the development of optical gas imaging cameras and other sophisticated technologies capable of detecting butane leaks with high precision.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, have also played a crucial role in advancing butane detection equipment. OSHA's permissible exposure limits (PELs) for butane have necessitated the creation of personal monitoring devices and alarm systems that can quickly alert workers to dangerous concentrations of the gas.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific guidelines for gas detection equipment, including those used for butane. ISO 26142:2010, for example, outlines performance requirements for hydrogen detection apparatus, which has influenced the design of multi-gas detectors that can simultaneously measure butane and other gases.

The regulatory landscape has also driven advancements in calibration and quality assurance procedures for butane detection equipment. Agencies like the National Institute of Standards and Technology (NIST) in the United States have developed certified reference materials and standardized methods for calibrating and validating trace gas detection instruments, ensuring their accuracy and reliability in regulatory compliance scenarios.

As global efforts to combat climate change intensify, regulations targeting greenhouse gas emissions have indirectly influenced butane detection technologies. While butane itself is not a major greenhouse gas, its role as a precursor to tropospheric ozone formation has led to its inclusion in broader air quality monitoring initiatives, further driving innovation in detection equipment.

In the United States, the Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) that include provisions for monitoring volatile organic compounds (VOCs) like butane. These standards have prompted the development of more sensitive and accurate trace gas detection equipment capable of measuring butane concentrations at parts per billion (ppb) levels.

The European Union has also implemented strict regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program, which requires comprehensive monitoring of chemical substances, including butane. This regulatory pressure has led to innovations in portable and continuous monitoring systems for butane detection in industrial settings and urban environments.

In the oil and gas industry, regulations such as the EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) have mandated the use of advanced leak detection and repair (LDAR) programs. These regulations have spurred the development of optical gas imaging cameras and other sophisticated technologies capable of detecting butane leaks with high precision.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, have also played a crucial role in advancing butane detection equipment. OSHA's permissible exposure limits (PELs) for butane have necessitated the creation of personal monitoring devices and alarm systems that can quickly alert workers to dangerous concentrations of the gas.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific guidelines for gas detection equipment, including those used for butane. ISO 26142:2010, for example, outlines performance requirements for hydrogen detection apparatus, which has influenced the design of multi-gas detectors that can simultaneously measure butane and other gases.

The regulatory landscape has also driven advancements in calibration and quality assurance procedures for butane detection equipment. Agencies like the National Institute of Standards and Technology (NIST) in the United States have developed certified reference materials and standardized methods for calibrating and validating trace gas detection instruments, ensuring their accuracy and reliability in regulatory compliance scenarios.

As global efforts to combat climate change intensify, regulations targeting greenhouse gas emissions have indirectly influenced butane detection technologies. While butane itself is not a major greenhouse gas, its role as a precursor to tropospheric ozone formation has led to its inclusion in broader air quality monitoring initiatives, further driving innovation in detection equipment.

Environmental Impact

The environmental impact of butane's influence on trace gas detection equipment is multifaceted and significant. As detection technologies advance, the ability to accurately measure butane and other trace gases has improved substantially, leading to enhanced environmental monitoring and protection efforts.

Butane, a volatile organic compound (VOC), is a common air pollutant that contributes to the formation of ground-level ozone and smog. The development of more sensitive and precise trace gas detection equipment has enabled researchers and environmental agencies to better quantify butane emissions from various sources, including industrial processes, vehicle exhaust, and natural gas leaks.

This improved detection capability has had a profound impact on air quality management strategies. By accurately measuring butane concentrations in real-time, authorities can implement more effective pollution control measures and assess the efficacy of existing regulations. For instance, the ability to detect minute quantities of butane has led to the identification of previously unrecognized emission sources, allowing for targeted mitigation efforts.

Furthermore, the advancement of trace gas detection equipment has facilitated more comprehensive studies on the atmospheric chemistry of butane and its role in the formation of secondary pollutants. This enhanced understanding has contributed to the development of more sophisticated air quality models, which are crucial for predicting pollution events and formulating long-term environmental policies.

In the realm of climate change research, improved butane detection has provided valuable insights into the global carbon cycle. As a hydrocarbon, butane contributes to greenhouse gas emissions, and accurate measurements of its atmospheric concentrations help refine climate models and projections. This data is essential for assessing the effectiveness of climate change mitigation strategies and informing international environmental agreements.

The environmental impact extends beyond air quality to include ecosystem health. Trace gas detection equipment capable of measuring butane has enabled researchers to study its effects on plant physiology and biodiversity. This has led to a better understanding of how atmospheric pollutants interact with various ecosystems, informing conservation efforts and environmental impact assessments.

In the industrial sector, the ability to detect trace amounts of butane has significantly improved workplace safety and environmental compliance. Advanced detection equipment allows for early warning of potential leaks or emissions, reducing the risk of accidents and minimizing environmental contamination. This has led to the development of more stringent safety protocols and emission control technologies across various industries.

Butane, a volatile organic compound (VOC), is a common air pollutant that contributes to the formation of ground-level ozone and smog. The development of more sensitive and precise trace gas detection equipment has enabled researchers and environmental agencies to better quantify butane emissions from various sources, including industrial processes, vehicle exhaust, and natural gas leaks.

This improved detection capability has had a profound impact on air quality management strategies. By accurately measuring butane concentrations in real-time, authorities can implement more effective pollution control measures and assess the efficacy of existing regulations. For instance, the ability to detect minute quantities of butane has led to the identification of previously unrecognized emission sources, allowing for targeted mitigation efforts.

Furthermore, the advancement of trace gas detection equipment has facilitated more comprehensive studies on the atmospheric chemistry of butane and its role in the formation of secondary pollutants. This enhanced understanding has contributed to the development of more sophisticated air quality models, which are crucial for predicting pollution events and formulating long-term environmental policies.

In the realm of climate change research, improved butane detection has provided valuable insights into the global carbon cycle. As a hydrocarbon, butane contributes to greenhouse gas emissions, and accurate measurements of its atmospheric concentrations help refine climate models and projections. This data is essential for assessing the effectiveness of climate change mitigation strategies and informing international environmental agreements.

The environmental impact extends beyond air quality to include ecosystem health. Trace gas detection equipment capable of measuring butane has enabled researchers to study its effects on plant physiology and biodiversity. This has led to a better understanding of how atmospheric pollutants interact with various ecosystems, informing conservation efforts and environmental impact assessments.

In the industrial sector, the ability to detect trace amounts of butane has significantly improved workplace safety and environmental compliance. Advanced detection equipment allows for early warning of potential leaks or emissions, reducing the risk of accidents and minimizing environmental contamination. This has led to the development of more stringent safety protocols and emission control technologies across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!