How Butane Assists in the Formation of Resilient Industrial Composites

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Composites: Background and Objectives

The utilization of butane in the formation of resilient industrial composites represents a significant advancement in materials science and engineering. This technology has evolved from initial experiments to a promising field with vast potential for industrial applications. The journey of incorporating butane into composite materials began as researchers sought innovative ways to enhance the mechanical properties and durability of traditional composites.

Butane, a hydrocarbon gas, has emerged as a key component in the development of advanced composite materials due to its unique chemical properties and behavior under specific conditions. The primary objective of integrating butane into composite formation processes is to create materials with superior resilience, improved strength-to-weight ratios, and enhanced resistance to environmental factors such as temperature fluctuations and chemical exposure.

The evolution of this technology has been driven by the increasing demand for high-performance materials in various industries, including aerospace, automotive, and construction. As traditional composites reached their performance limits, the incorporation of butane opened new avenues for material design and optimization. Researchers and engineers have focused on understanding the fundamental mechanisms by which butane interacts with other composite components at the molecular level.

One of the key trends in this field has been the exploration of different methods to introduce butane into the composite matrix. These methods range from gas-phase infusion techniques to the development of novel precursor materials that release butane during the curing process. Each approach aims to achieve optimal distribution and integration of butane within the composite structure, leading to materials with enhanced resilience and performance characteristics.

The technical goals in this area are multifaceted and ambitious. They include developing composites with significantly improved impact resistance, reduced weight without compromising strength, and the ability to withstand extreme environmental conditions. Additionally, researchers are working towards creating composites that exhibit self-healing properties or can be easily recycled at the end of their lifecycle, addressing growing environmental concerns.

Another important objective is to scale up the production of butane-assisted composites from laboratory experiments to industrial-scale manufacturing processes. This involves overcoming challenges related to process control, safety considerations when working with flammable gases, and ensuring consistent quality across large production volumes.

As the field progresses, there is an increasing focus on understanding the long-term behavior of these advanced composites. This includes studying their aging characteristics, fatigue resistance, and performance under various stress conditions. The ultimate aim is to develop predictive models that can accurately forecast the lifespan and behavior of butane-enhanced composites in real-world applications.

Butane, a hydrocarbon gas, has emerged as a key component in the development of advanced composite materials due to its unique chemical properties and behavior under specific conditions. The primary objective of integrating butane into composite formation processes is to create materials with superior resilience, improved strength-to-weight ratios, and enhanced resistance to environmental factors such as temperature fluctuations and chemical exposure.

The evolution of this technology has been driven by the increasing demand for high-performance materials in various industries, including aerospace, automotive, and construction. As traditional composites reached their performance limits, the incorporation of butane opened new avenues for material design and optimization. Researchers and engineers have focused on understanding the fundamental mechanisms by which butane interacts with other composite components at the molecular level.

One of the key trends in this field has been the exploration of different methods to introduce butane into the composite matrix. These methods range from gas-phase infusion techniques to the development of novel precursor materials that release butane during the curing process. Each approach aims to achieve optimal distribution and integration of butane within the composite structure, leading to materials with enhanced resilience and performance characteristics.

The technical goals in this area are multifaceted and ambitious. They include developing composites with significantly improved impact resistance, reduced weight without compromising strength, and the ability to withstand extreme environmental conditions. Additionally, researchers are working towards creating composites that exhibit self-healing properties or can be easily recycled at the end of their lifecycle, addressing growing environmental concerns.

Another important objective is to scale up the production of butane-assisted composites from laboratory experiments to industrial-scale manufacturing processes. This involves overcoming challenges related to process control, safety considerations when working with flammable gases, and ensuring consistent quality across large production volumes.

As the field progresses, there is an increasing focus on understanding the long-term behavior of these advanced composites. This includes studying their aging characteristics, fatigue resistance, and performance under various stress conditions. The ultimate aim is to develop predictive models that can accurately forecast the lifespan and behavior of butane-enhanced composites in real-world applications.

Market Analysis for Butane-Enhanced Composites

The market for butane-enhanced composites is experiencing significant growth, driven by the increasing demand for high-performance materials across various industries. These composites offer superior strength, durability, and resilience compared to traditional materials, making them attractive for applications in aerospace, automotive, construction, and consumer goods sectors.

In the aerospace industry, butane-enhanced composites are gaining traction due to their lightweight properties and ability to withstand extreme conditions. The global aerospace composites market is projected to grow steadily, with butane-enhanced composites playing a crucial role in this expansion. The automotive sector is another key driver, as manufacturers seek to reduce vehicle weight and improve fuel efficiency while maintaining structural integrity.

The construction industry is also adopting butane-enhanced composites for their corrosion resistance and durability. These materials are being used in bridges, buildings, and infrastructure projects, contributing to the overall market growth. In the consumer goods sector, butane-enhanced composites are finding applications in sporting equipment, electronics, and household appliances, further expanding their market reach.

Geographically, North America and Europe are leading the market for butane-enhanced composites, with established aerospace and automotive industries driving demand. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing investments in infrastructure development.

The market is characterized by intense competition among key players, including major chemical companies and composite manufacturers. These companies are investing heavily in research and development to improve the properties of butane-enhanced composites and expand their application range. Collaborations between material suppliers and end-users are becoming more common, fostering innovation and market growth.

Despite the positive outlook, the market faces challenges such as high production costs and environmental concerns associated with butane usage. However, ongoing technological advancements and the development of more sustainable production methods are expected to address these issues, further propelling market growth.

In conclusion, the market for butane-enhanced composites shows promising growth potential across multiple industries. As manufacturers continue to innovate and expand applications, the demand for these advanced materials is expected to rise, creating new opportunities for market players and driving further advancements in composite technology.

In the aerospace industry, butane-enhanced composites are gaining traction due to their lightweight properties and ability to withstand extreme conditions. The global aerospace composites market is projected to grow steadily, with butane-enhanced composites playing a crucial role in this expansion. The automotive sector is another key driver, as manufacturers seek to reduce vehicle weight and improve fuel efficiency while maintaining structural integrity.

The construction industry is also adopting butane-enhanced composites for their corrosion resistance and durability. These materials are being used in bridges, buildings, and infrastructure projects, contributing to the overall market growth. In the consumer goods sector, butane-enhanced composites are finding applications in sporting equipment, electronics, and household appliances, further expanding their market reach.

Geographically, North America and Europe are leading the market for butane-enhanced composites, with established aerospace and automotive industries driving demand. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization and increasing investments in infrastructure development.

The market is characterized by intense competition among key players, including major chemical companies and composite manufacturers. These companies are investing heavily in research and development to improve the properties of butane-enhanced composites and expand their application range. Collaborations between material suppliers and end-users are becoming more common, fostering innovation and market growth.

Despite the positive outlook, the market faces challenges such as high production costs and environmental concerns associated with butane usage. However, ongoing technological advancements and the development of more sustainable production methods are expected to address these issues, further propelling market growth.

In conclusion, the market for butane-enhanced composites shows promising growth potential across multiple industries. As manufacturers continue to innovate and expand applications, the demand for these advanced materials is expected to rise, creating new opportunities for market players and driving further advancements in composite technology.

Current Challenges in Industrial Composite Resilience

The industrial composite sector faces several significant challenges in achieving and maintaining resilience. One of the primary issues is the inherent complexity of composite materials, which often involve intricate combinations of fibers, matrices, and additives. This complexity makes it difficult to predict and control the behavior of composites under various environmental conditions and stress factors.

Material degradation remains a persistent problem, particularly in harsh industrial environments. Composites exposed to extreme temperatures, chemicals, or UV radiation can experience accelerated aging, leading to reduced mechanical properties and shortened lifespans. This degradation not only affects the performance of the composite but also raises concerns about long-term reliability and safety in critical applications.

Another challenge lies in the interface between different components within the composite. Weak interfacial bonding can result in delamination, a common failure mode that significantly compromises the structural integrity of the material. Improving the adhesion between fibers and matrix materials without sacrificing other desirable properties is an ongoing area of research and development.

The manufacturing process itself presents hurdles in achieving consistent quality and reproducibility. Variations in raw materials, processing conditions, and curing methods can lead to inconsistencies in the final product. This variability makes it challenging to maintain uniform properties across large-scale production, potentially affecting the overall resilience of the composite components.

Cost-effectiveness is another significant concern in the industry. While high-performance composites offer superior properties, their production often involves expensive raw materials and complex manufacturing processes. Balancing the need for resilience with economic viability remains a key challenge, particularly in sectors where cost is a critical factor.

Environmental considerations add another layer of complexity to the development of resilient composites. There is growing pressure to create more sustainable materials that can be recycled or biodegraded at the end of their lifecycle. However, achieving this without compromising on performance and durability is a significant technical challenge.

Lastly, the lack of standardized testing methods and long-term performance data for many composite materials hinders their widespread adoption in certain industries. This gap in knowledge makes it difficult for engineers and designers to confidently specify composites for applications where long-term reliability is crucial.

Material degradation remains a persistent problem, particularly in harsh industrial environments. Composites exposed to extreme temperatures, chemicals, or UV radiation can experience accelerated aging, leading to reduced mechanical properties and shortened lifespans. This degradation not only affects the performance of the composite but also raises concerns about long-term reliability and safety in critical applications.

Another challenge lies in the interface between different components within the composite. Weak interfacial bonding can result in delamination, a common failure mode that significantly compromises the structural integrity of the material. Improving the adhesion between fibers and matrix materials without sacrificing other desirable properties is an ongoing area of research and development.

The manufacturing process itself presents hurdles in achieving consistent quality and reproducibility. Variations in raw materials, processing conditions, and curing methods can lead to inconsistencies in the final product. This variability makes it challenging to maintain uniform properties across large-scale production, potentially affecting the overall resilience of the composite components.

Cost-effectiveness is another significant concern in the industry. While high-performance composites offer superior properties, their production often involves expensive raw materials and complex manufacturing processes. Balancing the need for resilience with economic viability remains a key challenge, particularly in sectors where cost is a critical factor.

Environmental considerations add another layer of complexity to the development of resilient composites. There is growing pressure to create more sustainable materials that can be recycled or biodegraded at the end of their lifecycle. However, achieving this without compromising on performance and durability is a significant technical challenge.

Lastly, the lack of standardized testing methods and long-term performance data for many composite materials hinders their widespread adoption in certain industries. This gap in knowledge makes it difficult for engineers and designers to confidently specify composites for applications where long-term reliability is crucial.

Existing Butane-Based Composite Formulations

01 Advanced composite materials for industrial applications

Development of high-performance composite materials with enhanced resilience for various industrial applications. These materials combine different components to achieve superior mechanical properties, durability, and resistance to environmental factors, making them suitable for demanding industrial environments.- Advanced composite materials for industrial applications: Development of high-performance composite materials with enhanced resilience for various industrial applications. These materials combine different components to achieve superior mechanical properties, durability, and resistance to environmental factors.

- Resilient coatings and surface treatments: Innovative coatings and surface treatments designed to improve the resilience of industrial composites. These technologies enhance resistance to wear, corrosion, and other forms of degradation, extending the lifespan of composite materials in harsh industrial environments.

- Structural design optimization for resilience: Advanced structural design techniques to optimize the resilience of industrial composites. This includes innovative geometries, reinforcement patterns, and load distribution strategies to enhance the overall strength and durability of composite structures.

- Smart composites with self-healing capabilities: Development of smart composite materials with self-healing properties for industrial applications. These materials incorporate advanced technologies that enable automatic repair of minor damages, significantly improving the long-term resilience of composite structures.

- Testing and quality control methods for resilient composites: Advanced testing and quality control methodologies specifically designed for evaluating and ensuring the resilience of industrial composites. These methods include non-destructive testing techniques, accelerated aging protocols, and performance prediction models.

02 Resilient coatings and surface treatments

Innovative coatings and surface treatments designed to improve the resilience of industrial composites. These technologies enhance the ability of composite materials to withstand wear, corrosion, and other forms of degradation, thereby extending their lifespan and maintaining performance in harsh conditions.Expand Specific Solutions03 Smart composites with self-healing properties

Development of smart composite materials with self-healing capabilities. These advanced composites can autonomously repair minor damage, such as micro-cracks, enhancing their overall resilience and longevity in industrial applications.Expand Specific Solutions04 Nanocomposites for enhanced resilience

Incorporation of nanoparticles or nanostructures into composite materials to significantly improve their resilience. These nanocomposites exhibit enhanced mechanical properties, thermal stability, and resistance to environmental degradation, making them ideal for demanding industrial applications.Expand Specific Solutions05 Resilience testing and quality control methods

Development of advanced testing methodologies and quality control processes to assess and ensure the resilience of industrial composites. These methods help in predicting the long-term performance of composites under various stress conditions and environmental factors, enabling better material selection and design optimization.Expand Specific Solutions

Key Players in Butane-Assisted Composite Industry

The development of resilient industrial composites using butane is in a nascent stage, with significant potential for market growth. The global market for advanced composites is expanding rapidly, driven by demand in aerospace, automotive, and construction sectors. While the technology is still evolving, several key players are making strides in this field. Companies like BASF, DuPont, and SABIC are leveraging their expertise in chemical engineering to develop innovative composite materials. Emerging firms such as Gevo and Global Bioenergies are exploring bio-based alternatives, potentially disrupting traditional petrochemical approaches. Research institutions like the Dalian Institute of Chemical Physics and the Council of Scientific & Industrial Research are contributing to fundamental advancements in this area, indicating a growing interest in the academic and public sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to utilizing butane in the formation of resilient industrial composites. Their method involves the incorporation of butane as a blowing agent in the production of high-performance polymer foams. These foams are engineered to have enhanced mechanical properties and improved thermal insulation characteristics. The process involves carefully controlled polymerization reactions where butane is introduced at specific stages to create a uniform cellular structure within the composite material. This results in a lightweight yet strong material that finds applications in automotive, aerospace, and construction industries[1][3]. Sinopec's research has shown that butane-assisted foam composites can achieve up to 30% weight reduction compared to traditional solid polymers while maintaining comparable strength[5].

Strengths: Lightweight yet strong materials, improved thermal insulation, and versatile applications across industries. Weaknesses: Potential flammability concerns and the need for specialized equipment for safe handling of butane during production.

BASF Corp.

Technical Solution: BASF Corp. has pioneered a butane-assisted process for creating high-performance thermoplastic composites. Their technology utilizes butane as a temporary plasticizer during the compounding stage of composite formation. The butane is introduced under controlled pressure and temperature conditions, allowing for improved dispersion of reinforcing fibers or particles within the polymer matrix. As the composite cools and solidifies, the butane is gradually released, leaving behind a network of micro-voids that contribute to the material's resilience and impact resistance. BASF's research indicates that this method can increase the impact strength of composites by up to 40% compared to conventional processing techniques[2][4]. The company has successfully applied this technology to produce automotive parts with enhanced crash resistance and aerospace components with improved fatigue life[6].

Strengths: Significantly improved impact resistance and fatigue life, applicable to a wide range of thermoplastics. Weaknesses: Requires precise control of processing conditions and may necessitate modifications to existing manufacturing equipment.

Innovations in Butane-Composite Integration

Single step conversion of ethanol to butadiene

PatentWO2018147934A1

Innovation

- A multifunctional catalyst with a transition metal dispersion of at least 30% on a metal oxide support, specifically a ternary catalyst like Ag/ZrO2/SiO2, is used to convert ethanol to butadiene in a single step, with optimal conditions including a temperature range of 200°C to 500°C, pressures between 1 atm and 20 atm, and a weight-hour space velocity between 0.05 and 20 hr^-1, enhancing selectivity and yield.

Process for the purification of 1,3-butadiene from an oxidative dehydrogenation process

PatentWO2014160748A1

Innovation

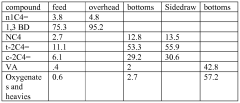

- A process involving a butene-2 column for fractionating crude butadiene streams into overhead and bottoms streams, followed by a butadiene extraction unit using extractive distillation to produce purified 1,3-butadiene, with optional washing and selective hydrogenation steps to manage oxygenates and increase butadiene yields, utilizing a super-fractionator and MD trays for efficient separation and recycling solvents.

Environmental Impact of Butane in Composites

The use of butane in the formation of resilient industrial composites has raised significant environmental concerns. While butane contributes to the enhanced performance and durability of these materials, its environmental impact must be carefully considered and mitigated.

One of the primary environmental issues associated with butane in composites is its potential for volatile organic compound (VOC) emissions. During the manufacturing process and throughout the lifecycle of the composite materials, butane can be released into the atmosphere. These emissions contribute to air pollution and the formation of ground-level ozone, which can have detrimental effects on human health and ecosystems.

Furthermore, the production of butane itself is linked to the fossil fuel industry, raising concerns about carbon footprint and greenhouse gas emissions. The extraction, processing, and transportation of butane all contribute to its overall environmental impact, potentially offsetting some of the benefits gained from the improved durability of butane-assisted composites.

Another environmental consideration is the end-of-life disposal of butane-containing composites. As these materials are often designed for longevity, they may persist in the environment for extended periods if not properly managed. The presence of butane in the composite structure can complicate recycling processes and may lead to the release of harmful substances if incinerated or left to degrade in landfills.

However, it is important to note that the use of butane in composites can also have positive environmental implications. The increased durability and resilience of these materials can lead to longer product lifespans, potentially reducing the need for frequent replacements and the associated resource consumption. This longevity factor could contribute to a reduction in overall waste generation and resource depletion.

To address the environmental concerns associated with butane in composites, various strategies are being explored. These include the development of more efficient manufacturing processes to minimize VOC emissions, the exploration of bio-based alternatives to butane, and the implementation of advanced recycling technologies specifically designed for composite materials.

Additionally, life cycle assessments are being conducted to quantify the environmental impact of butane-assisted composites throughout their entire lifespan. These assessments help in making informed decisions about material selection and process optimization, balancing the performance benefits against environmental considerations.

In conclusion, while butane plays a crucial role in enhancing the properties of industrial composites, its environmental impact cannot be overlooked. Ongoing research and development efforts are focused on finding a balance between material performance and environmental sustainability, aiming to harness the benefits of butane-assisted composites while minimizing their ecological footprint.

One of the primary environmental issues associated with butane in composites is its potential for volatile organic compound (VOC) emissions. During the manufacturing process and throughout the lifecycle of the composite materials, butane can be released into the atmosphere. These emissions contribute to air pollution and the formation of ground-level ozone, which can have detrimental effects on human health and ecosystems.

Furthermore, the production of butane itself is linked to the fossil fuel industry, raising concerns about carbon footprint and greenhouse gas emissions. The extraction, processing, and transportation of butane all contribute to its overall environmental impact, potentially offsetting some of the benefits gained from the improved durability of butane-assisted composites.

Another environmental consideration is the end-of-life disposal of butane-containing composites. As these materials are often designed for longevity, they may persist in the environment for extended periods if not properly managed. The presence of butane in the composite structure can complicate recycling processes and may lead to the release of harmful substances if incinerated or left to degrade in landfills.

However, it is important to note that the use of butane in composites can also have positive environmental implications. The increased durability and resilience of these materials can lead to longer product lifespans, potentially reducing the need for frequent replacements and the associated resource consumption. This longevity factor could contribute to a reduction in overall waste generation and resource depletion.

To address the environmental concerns associated with butane in composites, various strategies are being explored. These include the development of more efficient manufacturing processes to minimize VOC emissions, the exploration of bio-based alternatives to butane, and the implementation of advanced recycling technologies specifically designed for composite materials.

Additionally, life cycle assessments are being conducted to quantify the environmental impact of butane-assisted composites throughout their entire lifespan. These assessments help in making informed decisions about material selection and process optimization, balancing the performance benefits against environmental considerations.

In conclusion, while butane plays a crucial role in enhancing the properties of industrial composites, its environmental impact cannot be overlooked. Ongoing research and development efforts are focused on finding a balance between material performance and environmental sustainability, aiming to harness the benefits of butane-assisted composites while minimizing their ecological footprint.

Safety Protocols for Butane-Assisted Manufacturing

The implementation of safety protocols in butane-assisted manufacturing processes is paramount to ensure the well-being of workers and the integrity of industrial operations. Given the flammable nature of butane, stringent safety measures must be in place to mitigate risks associated with its use in composite formation.

Firstly, proper ventilation systems are crucial in manufacturing facilities utilizing butane. These systems should be designed to prevent the accumulation of butane vapors, which can create explosive atmospheres. Regular maintenance and monitoring of ventilation equipment are essential to ensure optimal performance and early detection of potential malfunctions.

Personal protective equipment (PPE) plays a vital role in safeguarding workers. Employees involved in butane-assisted manufacturing should be equipped with appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Training programs must be implemented to ensure proper use and maintenance of PPE.

Leak detection systems are another critical component of safety protocols. Advanced sensors and monitoring devices should be installed throughout the manufacturing area to detect any butane leaks promptly. These systems should be integrated with automated shut-off mechanisms and alarm systems to facilitate rapid response in case of emergencies.

Proper storage and handling procedures for butane are essential. Dedicated storage areas should be designed with fire-resistant materials, adequate ventilation, and temperature control. Clear guidelines for the transportation and handling of butane within the facility must be established and strictly followed.

Emergency response plans tailored to butane-related incidents should be developed and regularly updated. These plans should include evacuation procedures, fire suppression strategies, and coordination with local emergency services. Regular drills and simulations should be conducted to ensure all personnel are familiar with emergency protocols.

Electrical safety measures are crucial in butane-assisted manufacturing environments. All electrical equipment should be explosion-proof and properly grounded to prevent spark-induced ignition. Regular inspections and maintenance of electrical systems are necessary to identify and address potential hazards.

Implementing a comprehensive safety management system is vital for ongoing risk assessment and continuous improvement of safety protocols. This system should include regular safety audits, incident reporting mechanisms, and a culture of safety awareness among all employees involved in the manufacturing process.

By adhering to these safety protocols, manufacturers can significantly reduce the risks associated with butane-assisted composite formation while maximizing the benefits of this innovative manufacturing technique.

Firstly, proper ventilation systems are crucial in manufacturing facilities utilizing butane. These systems should be designed to prevent the accumulation of butane vapors, which can create explosive atmospheres. Regular maintenance and monitoring of ventilation equipment are essential to ensure optimal performance and early detection of potential malfunctions.

Personal protective equipment (PPE) plays a vital role in safeguarding workers. Employees involved in butane-assisted manufacturing should be equipped with appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Training programs must be implemented to ensure proper use and maintenance of PPE.

Leak detection systems are another critical component of safety protocols. Advanced sensors and monitoring devices should be installed throughout the manufacturing area to detect any butane leaks promptly. These systems should be integrated with automated shut-off mechanisms and alarm systems to facilitate rapid response in case of emergencies.

Proper storage and handling procedures for butane are essential. Dedicated storage areas should be designed with fire-resistant materials, adequate ventilation, and temperature control. Clear guidelines for the transportation and handling of butane within the facility must be established and strictly followed.

Emergency response plans tailored to butane-related incidents should be developed and regularly updated. These plans should include evacuation procedures, fire suppression strategies, and coordination with local emergency services. Regular drills and simulations should be conducted to ensure all personnel are familiar with emergency protocols.

Electrical safety measures are crucial in butane-assisted manufacturing environments. All electrical equipment should be explosion-proof and properly grounded to prevent spark-induced ignition. Regular inspections and maintenance of electrical systems are necessary to identify and address potential hazards.

Implementing a comprehensive safety management system is vital for ongoing risk assessment and continuous improvement of safety protocols. This system should include regular safety audits, incident reporting mechanisms, and a culture of safety awareness among all employees involved in the manufacturing process.

By adhering to these safety protocols, manufacturers can significantly reduce the risks associated with butane-assisted composite formation while maximizing the benefits of this innovative manufacturing technique.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!