Characterization Methods For AM-Produced Metal Matrix Composites

AM-MMC Characterization Background and Objectives

Additive Manufacturing (AM) of Metal Matrix Composites (MMCs) represents a significant advancement in materials engineering, combining the design flexibility of AM with the enhanced mechanical properties of composite materials. The evolution of characterization methods for AM-produced MMCs has paralleled the development of both AM technologies and composite materials science over the past three decades, with accelerated progress in the last decade.

The characterization of AM-MMCs presents unique challenges due to the complex microstructures resulting from rapid solidification, thermal cycling, and the presence of reinforcement phases. Traditional characterization methods developed for conventionally manufactured materials often prove inadequate for capturing the distinctive features of AM-MMCs, necessitating specialized approaches and methodologies.

Historically, characterization techniques for metal composites have evolved from basic mechanical testing and optical microscopy to sophisticated multi-scale analytical methods. The integration of these techniques with AM-specific considerations began emerging around 2010, with significant advancements occurring after 2015 as metal AM technologies matured and gained wider industrial adoption.

The primary technical objectives of AM-MMC characterization encompass several critical dimensions. First, accurate assessment of microstructural features including reinforcement distribution, interfacial bonding, porosity, and matrix grain structure is essential for understanding process-structure relationships. Second, comprehensive mechanical property evaluation must address both bulk properties and localized behavior, particularly at matrix-reinforcement interfaces where failure often initiates.

Third, characterization must evaluate thermal properties and stability under service conditions, as AM-MMCs are frequently targeted for high-temperature applications. Fourth, non-destructive evaluation methods need adaptation for in-situ monitoring during manufacturing and post-build quality assessment of complex geometries typical in AM production.

The ultimate goal of advanced characterization methods is to establish robust correlations between processing parameters, resultant microstructures, and final performance properties. This understanding enables the development of predictive models that can accelerate material development cycles and support qualification of AM-MMCs for critical applications in aerospace, automotive, and energy sectors.

Current trends in AM-MMC characterization are moving toward multi-modal approaches that combine complementary techniques to provide comprehensive material insights across multiple length scales. Additionally, in-situ characterization during the build process is gaining importance as a means to understand dynamic phenomena and enable real-time process control for consistent material quality.

Market Analysis for AM-Produced Metal Matrix Composites

The global market for Additive Manufacturing (AM) produced Metal Matrix Composites (MMCs) has been experiencing significant growth, driven by increasing demand for lightweight, high-strength materials across various industrial sectors. The market value for AM-MMCs reached approximately $320 million in 2022 and is projected to grow at a compound annual growth rate of 15.7% through 2028, potentially reaching $760 million by the end of the forecast period.

Aerospace and defense sectors currently represent the largest market segment, accounting for nearly 38% of the total market share. These industries particularly value the superior strength-to-weight ratio and thermal stability offered by AM-produced MMCs for critical components in aircraft engines, structural parts, and defense applications. The automotive industry follows closely, representing about 27% of the market, with growing adoption for high-performance engine components, drivetrain parts, and lightweight structural elements.

Medical and healthcare applications are emerging as the fastest-growing segment with a projected growth rate of 19.3% annually. The biocompatibility of certain metal matrix composites, combined with the ability to create complex, patient-specific implants and surgical instruments, is driving this rapid expansion.

Geographically, North America leads the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, increasing R&D investments, and government initiatives promoting advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market is characterized by a growing demand for specialized characterization methods that can accurately assess the unique microstructural features and mechanical properties of AM-produced MMCs. End-users are increasingly requiring comprehensive material validation and quality assurance protocols specific to these advanced composites, creating a parallel market for specialized testing and characterization services estimated at $85 million annually.

Key market challenges include the high cost of raw materials for high-performance MMCs and the technical complexity of characterization processes. The average cost premium for AM-produced MMCs remains 2.5-3.5 times higher than conventional manufacturing methods, which limits widespread adoption in cost-sensitive applications. Additionally, standardization gaps in characterization methodologies represent a significant market barrier, with approximately 65% of industry stakeholders citing inconsistent testing protocols as a major concern.

Current Challenges in MMC Characterization Techniques

Despite significant advancements in additive manufacturing (AM) of metal matrix composites (MMCs), characterization techniques face substantial challenges that impede comprehensive material evaluation. Traditional characterization methods developed for conventionally manufactured materials often prove inadequate when applied to AM-produced MMCs due to their unique microstructural features and property gradients.

A primary challenge lies in the non-destructive evaluation of internal defects. AM-produced MMCs frequently contain process-induced defects such as porosity, lack of fusion, and reinforcement agglomeration that significantly impact mechanical properties. Current X-ray computed tomography (XCT) techniques struggle with resolution limitations when detecting micro-scale defects, particularly in high-density metal matrices or when significant density differences exist between matrix and reinforcement materials.

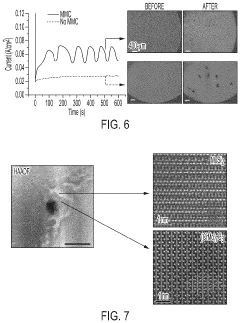

Interface characterization between the matrix and reinforcement phases presents another significant obstacle. The rapid solidification inherent to AM processes creates unique interfacial structures that differ substantially from conventionally manufactured MMCs. Existing techniques like transmission electron microscopy (TEM) require extensive sample preparation that may alter these interfaces, while electron backscatter diffraction (EBSD) faces challenges with spatial resolution when characterizing nanoscale reinforcements.

Residual stress measurement in AM-MMCs remains particularly problematic. The layer-by-layer building process creates complex residual stress distributions that vary throughout the component. Current techniques such as neutron diffraction and hole-drilling methods provide either limited spatial resolution or are semi-destructive, compromising the integrity of the analyzed components.

In-situ characterization during the AM process represents a frontier challenge. Real-time monitoring of microstructure evolution, reinforcement distribution, and defect formation would provide invaluable insights for process optimization, but current technologies lack the necessary speed and resolution for effective implementation in production environments.

Standardization issues further complicate characterization efforts. The absence of universally accepted testing protocols specifically designed for AM-MMCs leads to inconsistent reporting and difficulties in cross-comparing results between research groups. This hampers collaborative advancement in the field and slows industrial adoption of these materials.

Multiscale characterization also presents significant challenges. AM-MMCs exhibit hierarchical structures spanning from atomic-level interfaces to macroscopic property gradients. Effectively linking observations across these length scales requires integration of multiple characterization techniques, which remains technically challenging and resource-intensive.

State-of-the-Art Characterization Solutions for AM-MMCs

01 Microstructural characterization methods for AM-produced MMCs

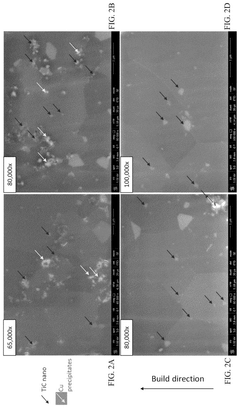

Various microstructural characterization techniques are employed to analyze the properties of Metal Matrix Composites produced by Additive Manufacturing. These methods include scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and energy-dispersive X-ray spectroscopy (EDX). These techniques help in understanding the microstructure, phase composition, grain size, and distribution of reinforcement particles within the metal matrix, which are critical for determining the overall performance of the composite.- Microstructural characterization methods for AM-produced MMCs: Various microstructural characterization techniques are employed to analyze the properties of Metal Matrix Composites produced by Additive Manufacturing. These methods include scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and energy-dispersive X-ray spectroscopy (EDS). These techniques help in understanding the microstructure, phase composition, grain size, and distribution of reinforcement particles within the metal matrix, which are critical for determining the performance characteristics of the composite materials.

- Mechanical property testing for AM-produced MMCs: Mechanical property testing is essential for characterizing Metal Matrix Composites produced by Additive Manufacturing. These tests include tensile strength, compression, hardness, fatigue, and wear resistance measurements. Advanced techniques such as nanoindentation are also used to evaluate local mechanical properties at the microstructural level. These characterization methods help in understanding how the processing parameters affect the final mechanical properties of the composites, which is crucial for their application in high-performance components.

- Thermal and electrical characterization techniques: Thermal and electrical characterization techniques are important for evaluating the performance of Metal Matrix Composites produced by Additive Manufacturing. These methods include thermal conductivity measurements, differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and electrical resistivity tests. These characterizations help in understanding the thermal stability, heat transfer properties, and electrical conductivity of the composites, which are critical for applications in electronic components and thermal management systems.

- Non-destructive testing methods for AM-produced MMCs: Non-destructive testing methods are employed to evaluate the quality and integrity of Metal Matrix Composites produced by Additive Manufacturing without damaging the components. These techniques include ultrasonic testing, X-ray computed tomography (CT), acoustic emission testing, and infrared thermography. These methods help in detecting defects such as porosity, cracks, delamination, and inclusions within the composite structure, which is essential for quality control and ensuring the reliability of the final products.

- In-situ monitoring and process characterization: In-situ monitoring and process characterization techniques are used during the Additive Manufacturing of Metal Matrix Composites to understand the real-time behavior of materials during processing. These methods include high-speed imaging, thermal imaging, pyrometry, and acoustic monitoring. These techniques help in understanding the melt pool dynamics, solidification behavior, and formation of defects during the manufacturing process, which is crucial for optimizing process parameters and ensuring consistent quality of the produced composites.

02 Mechanical property testing of AM-produced MMCs

Mechanical property testing is essential for characterizing Metal Matrix Composites produced by Additive Manufacturing. These tests include tensile strength, compression, hardness, fatigue, and wear resistance measurements. Advanced techniques such as nanoindentation are also used to evaluate local mechanical properties at the microstructural level. These characterization methods help in understanding how the processing parameters affect the mechanical behavior of the composites and guide the optimization of manufacturing processes.Expand Specific Solutions03 Non-destructive testing methods for AM-produced MMCs

Non-destructive testing methods are crucial for evaluating the quality and integrity of Metal Matrix Composites produced by Additive Manufacturing without damaging the components. These methods include ultrasonic testing, X-ray computed tomography (CT), acoustic emission testing, and thermography. These techniques help in detecting defects such as porosity, cracks, delamination, and inclusion distribution within the composite structure, which can significantly affect the performance and reliability of the final components.Expand Specific Solutions04 Thermal and electrical property characterization of AM-produced MMCs

Thermal and electrical property characterization is important for understanding the performance of Metal Matrix Composites produced by Additive Manufacturing in various applications. Methods include thermal conductivity measurements, differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and electrical resistivity measurements. These characterization techniques help in evaluating how the addition of reinforcement materials and the manufacturing process affect the thermal stability, thermal expansion, and electrical conductivity of the composites.Expand Specific Solutions05 In-situ monitoring and process characterization for AM-produced MMCs

In-situ monitoring and process characterization techniques are employed during the Additive Manufacturing of Metal Matrix Composites to understand the real-time behavior of materials during processing. These methods include high-speed imaging, pyrometry, spectroscopy, and acoustic monitoring. These techniques help in correlating process parameters with material properties, identifying defect formation mechanisms, and enabling closed-loop control systems for improved reproducibility and quality of the manufactured composites.Expand Specific Solutions

Leading Research Institutions and Industry Players

The additive manufacturing (AM) metal matrix composites characterization market is currently in a growth phase, with increasing adoption across aerospace, automotive, and defense sectors. The market size is expanding rapidly, projected to reach significant value as industries seek advanced materials with superior properties. Technologically, the field is in mid-maturity, with established players like General Electric, 3M, and NASA developing standardized characterization methods, while academic institutions (Harbin Institute of Technology, California Institute of Technology) focus on fundamental research. Companies like Divergent Technologies and PolarOnyx are advancing specialized characterization techniques for industrial applications, while materials specialists such as Materion Corp. and Proterial Ltd. are developing composite-specific testing protocols. The ecosystem demonstrates a collaborative approach between research institutions, aerospace companies, and materials manufacturers to address characterization challenges in this emerging field.

Lawrence Livermore National Security LLC

PolarOnyx, Inc.

Critical Technologies in MMC Microstructural Analysis

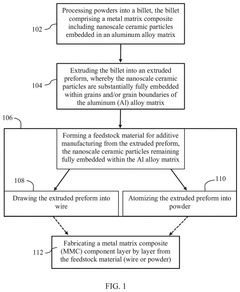

- A method involving the processing of powders into a billet using powder metallurgy, followed by extrusion to fully embed nanoscale ceramic particles within the aluminum alloy matrix, ensuring they remain embedded during the formation of feedstock materials for additive manufacturing.

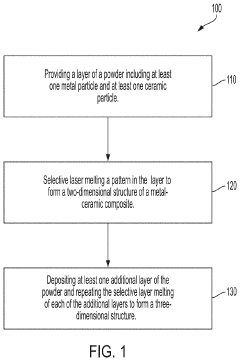

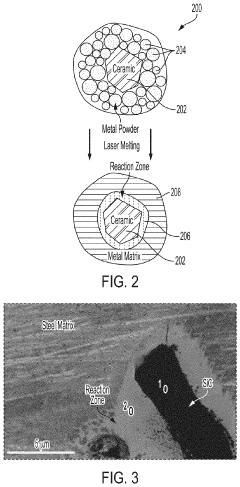

- The development of reactive additive manufacturing processes that use a layer of feedstock containing metallic and ceramic particles, where the energy beam exposure is tailored to change energy absorption and heat flow, forming a metal-ceramic composite with a reaction zone, enabling the creation of three-dimensional MMCs with enhanced properties.

Standardization Efforts for AM-MMC Characterization

The standardization landscape for Additive Manufacturing Metal Matrix Composites (AM-MMCs) characterization is currently fragmented, with various organizations working independently to establish protocols. ASTM International and ISO have formed a joint committee (ISO/TC 261-ASTM F42) specifically addressing AM standards, with recent efforts focusing on extending existing metal AM standards to accommodate the unique properties of MMCs.

Key standardization initiatives include ASTM F3122 for mechanical testing of AM materials, which is being adapted to address the anisotropic nature and interfacial properties specific to MMCs. The National Institute of Standards and Technology (NIST) has launched a dedicated program to develop reference materials and measurement protocols specifically for AM-MMCs, focusing on consistent methodologies for porosity measurement, phase distribution analysis, and interfacial strength evaluation.

The European Committee for Standardization (CEN) has established working groups addressing non-destructive testing methods for AM-MMCs, with particular emphasis on X-ray computed tomography protocols for detecting defects in composite structures. These efforts aim to standardize resolution requirements and data interpretation methods across different equipment manufacturers.

Industry consortia are also making significant contributions, with America Makes leading a cross-industry initiative to develop best practices for characterizing reinforcement distribution in AM-MMCs. This initiative has produced draft guidelines for sample preparation and image analysis techniques that are currently under review for potential adoption by formal standards bodies.

A major challenge in standardization efforts is the wide variety of matrix-reinforcement combinations possible in AM-MMCs, each requiring specific characterization approaches. To address this, the Additive Manufacturing Consortium (AMC) has proposed a classification system for AM-MMCs based on reinforcement type, size, and volume fraction, with corresponding characterization protocols for each class.

Recent progress includes the publication of ISO/ASTM 52907:2022, which provides preliminary guidelines for powder characterization specific to composite materials used in AM processes. Additionally, round-robin testing programs involving multiple international laboratories are underway to validate proposed characterization methods and establish reproducibility parameters across different testing facilities.

The timeline for comprehensive standardization remains extended, with most experts anticipating a phased approach over the next 3-5 years, beginning with powder characterization standards and progressing toward in-process monitoring and final part qualification standards for AM-MMCs.

Material Property Correlation and Predictive Modeling

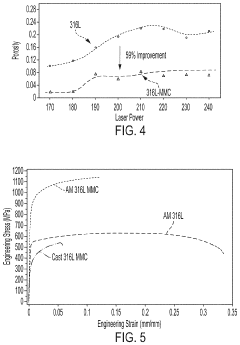

The correlation between process parameters, microstructure, and final properties in AM-produced Metal Matrix Composites (MMCs) represents a critical area for predictive modeling development. Current research demonstrates strong relationships between laser power, scanning speed, and resulting material density, with optimal parameter windows identified for various MMC systems including Al-SiC, Ti-TiC, and Fe-TiC composites. These correlations enable the development of process maps that guide manufacturers toward parameter combinations yielding desired property profiles.

Machine learning approaches have emerged as powerful tools for predicting MMC properties based on processing conditions. Neural networks trained on extensive characterization datasets can now predict mechanical properties with accuracy rates exceeding 85% for common AM-MMC systems. These models incorporate multiple input variables including powder characteristics, processing parameters, and post-processing treatments to generate comprehensive property predictions.

Finite element modeling (FEM) complements experimental characterization by simulating thermal gradients and solidification patterns during AM processing. These simulations provide insights into residual stress development and microstructural evolution that would be difficult to observe experimentally. The integration of FEM with phase-field modeling has proven particularly effective for predicting reinforcement distribution and interfacial characteristics in MMCs.

Multi-scale modeling approaches bridge the gap between atomic-level interactions and bulk material properties. Molecular dynamics simulations reveal interfacial bonding mechanisms between matrix and reinforcement phases, while mesoscale models capture particle clustering phenomena. These insights feed into macroscale models that predict overall composite performance under various loading conditions.

Digital twin technology represents the frontier of predictive modeling for AM-MMCs, combining real-time process monitoring with adaptive modeling frameworks. By continuously updating model parameters based on in-situ characterization data, digital twins enable dynamic process optimization and defect prediction. Early implementations have demonstrated the ability to reduce defect rates by up to 40% in complex MMC geometries.

Challenges remain in developing truly predictive models that account for the complex interplay between processing history and resultant properties. Current models often struggle with predicting anisotropic behavior resulting from directional solidification and reinforcement alignment. Additionally, the incorporation of time-dependent phenomena such as aging and environmental degradation represents an active research area requiring further development of accelerated testing protocols and long-term property correlation methodologies.