Porosity And Defect Mitigation Strategies In AM-MMCs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM-MMC Porosity Background and Objectives

Additive Manufacturing Metal Matrix Composites (AM-MMCs) represent a significant advancement in materials engineering, combining the design flexibility of additive manufacturing with the enhanced properties of metal matrix composites. The evolution of this technology has progressed from early experimental stages in the 1990s to increasingly sophisticated applications in aerospace, automotive, and defense industries over the past decade.

Porosity remains one of the most critical challenges in AM-MMCs, significantly affecting mechanical properties, thermal conductivity, and overall part reliability. Historically, porosity issues have limited the widespread industrial adoption of these materials despite their promising performance characteristics. The formation mechanisms of porosity in AM-MMCs are multifaceted, stemming from gas entrapment during powder bed fusion processes, insufficient fusion between layers, thermal gradient-induced shrinkage, and the unique challenges presented by reinforcement particles.

Recent technological trends indicate a growing focus on multi-scale approaches to porosity control, combining process parameter optimization with advanced material design. The integration of in-situ monitoring systems and machine learning algorithms for real-time defect detection represents a promising direction in the field's evolution. Additionally, post-processing techniques such as hot isostatic pressing (HIP) have shown considerable effectiveness in reducing porosity levels, though they add complexity and cost to the manufacturing workflow.

The primary technical objectives for porosity mitigation in AM-MMCs include reducing overall porosity to less than 1% by volume while maintaining or enhancing the composite's mechanical properties. Achieving consistent porosity distribution throughout complex geometries presents another significant challenge, particularly in parts with varying cross-sections or intricate internal features. Furthermore, developing scalable solutions that can transition from laboratory settings to industrial production environments remains a critical goal.

Understanding the relationship between processing parameters, material composition, and resultant porosity characteristics constitutes a fundamental research objective. This includes investigating the influence of laser power, scan speed, hatch spacing, and layer thickness on pore formation and distribution. The interaction between reinforcement particles and the metal matrix during solidification presents unique challenges that require specialized mitigation strategies beyond those employed for conventional metal additive manufacturing.

The ultimate aim of porosity mitigation research in AM-MMCs is to enable the reliable production of high-performance components with predictable properties for safety-critical applications. This necessitates not only reducing the overall porosity but also controlling the size, morphology, and spatial distribution of unavoidable pores to minimize their impact on mechanical performance and fatigue life.

Porosity remains one of the most critical challenges in AM-MMCs, significantly affecting mechanical properties, thermal conductivity, and overall part reliability. Historically, porosity issues have limited the widespread industrial adoption of these materials despite their promising performance characteristics. The formation mechanisms of porosity in AM-MMCs are multifaceted, stemming from gas entrapment during powder bed fusion processes, insufficient fusion between layers, thermal gradient-induced shrinkage, and the unique challenges presented by reinforcement particles.

Recent technological trends indicate a growing focus on multi-scale approaches to porosity control, combining process parameter optimization with advanced material design. The integration of in-situ monitoring systems and machine learning algorithms for real-time defect detection represents a promising direction in the field's evolution. Additionally, post-processing techniques such as hot isostatic pressing (HIP) have shown considerable effectiveness in reducing porosity levels, though they add complexity and cost to the manufacturing workflow.

The primary technical objectives for porosity mitigation in AM-MMCs include reducing overall porosity to less than 1% by volume while maintaining or enhancing the composite's mechanical properties. Achieving consistent porosity distribution throughout complex geometries presents another significant challenge, particularly in parts with varying cross-sections or intricate internal features. Furthermore, developing scalable solutions that can transition from laboratory settings to industrial production environments remains a critical goal.

Understanding the relationship between processing parameters, material composition, and resultant porosity characteristics constitutes a fundamental research objective. This includes investigating the influence of laser power, scan speed, hatch spacing, and layer thickness on pore formation and distribution. The interaction between reinforcement particles and the metal matrix during solidification presents unique challenges that require specialized mitigation strategies beyond those employed for conventional metal additive manufacturing.

The ultimate aim of porosity mitigation research in AM-MMCs is to enable the reliable production of high-performance components with predictable properties for safety-critical applications. This necessitates not only reducing the overall porosity but also controlling the size, morphology, and spatial distribution of unavoidable pores to minimize their impact on mechanical performance and fatigue life.

Market Analysis for Defect-Free AM-MMCs

The global market for defect-free Additive Manufacturing Metal Matrix Composites (AM-MMCs) is experiencing robust growth, driven by increasing demand across aerospace, automotive, and medical industries. Current market valuations indicate that the AM-MMC sector is expanding at a compound annual growth rate of approximately 20%, with particular acceleration in applications requiring high-performance materials with minimal structural defects.

Aerospace remains the dominant market segment, accounting for nearly 40% of the total demand for defect-free AM-MMCs. This is primarily due to stringent quality requirements and the critical nature of components used in aircraft engines, structural elements, and space applications. The automotive industry follows closely, representing about 30% of the market share, with growing adoption in high-performance vehicles and electric vehicle battery enclosures where thermal management and weight reduction are crucial.

Market research indicates a significant price premium for defect-free AM-MMCs compared to conventional manufacturing methods. End-users demonstrate willingness to pay 25-35% more for components with guaranteed low porosity and defect rates, particularly in critical applications where failure is not an option. This premium pricing structure has created a lucrative niche for manufacturers who can consistently deliver high-quality AM-MMCs.

Regional analysis shows North America leading the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to witness the fastest growth rate in the coming years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer surveys reveal that reliability and consistency in material properties rank as the top purchasing criteria for AM-MMC components, followed by mechanical performance and cost considerations. The market is increasingly demanding certification standards and quality assurance protocols specific to AM-MMCs, creating opportunities for testing and certification service providers.

Emerging application areas showing promising growth include biomedical implants, where defect-free structures are essential for long-term performance, and renewable energy components such as wind turbine parts and hydrogen storage systems. These sectors are expected to contribute significantly to market expansion over the next five years.

Supply chain analysis indicates that material suppliers are a critical bottleneck in the AM-MMC ecosystem, with limited sources of high-quality metal powders and reinforcement materials suitable for defect-free manufacturing. This constraint presents both a challenge for scaling production and an opportunity for materials companies to develop specialized offerings for this growing market.

Aerospace remains the dominant market segment, accounting for nearly 40% of the total demand for defect-free AM-MMCs. This is primarily due to stringent quality requirements and the critical nature of components used in aircraft engines, structural elements, and space applications. The automotive industry follows closely, representing about 30% of the market share, with growing adoption in high-performance vehicles and electric vehicle battery enclosures where thermal management and weight reduction are crucial.

Market research indicates a significant price premium for defect-free AM-MMCs compared to conventional manufacturing methods. End-users demonstrate willingness to pay 25-35% more for components with guaranteed low porosity and defect rates, particularly in critical applications where failure is not an option. This premium pricing structure has created a lucrative niche for manufacturers who can consistently deliver high-quality AM-MMCs.

Regional analysis shows North America leading the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to witness the fastest growth rate in the coming years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer surveys reveal that reliability and consistency in material properties rank as the top purchasing criteria for AM-MMC components, followed by mechanical performance and cost considerations. The market is increasingly demanding certification standards and quality assurance protocols specific to AM-MMCs, creating opportunities for testing and certification service providers.

Emerging application areas showing promising growth include biomedical implants, where defect-free structures are essential for long-term performance, and renewable energy components such as wind turbine parts and hydrogen storage systems. These sectors are expected to contribute significantly to market expansion over the next five years.

Supply chain analysis indicates that material suppliers are a critical bottleneck in the AM-MMC ecosystem, with limited sources of high-quality metal powders and reinforcement materials suitable for defect-free manufacturing. This constraint presents both a challenge for scaling production and an opportunity for materials companies to develop specialized offerings for this growing market.

Current Challenges in AM-MMC Porosity Control

Porosity control remains one of the most significant challenges in Additive Manufacturing of Metal Matrix Composites (AM-MMCs). The complex interaction between the matrix material and reinforcement particles during the manufacturing process creates unique porosity issues that differ from conventional metal AM processes. Currently, several critical challenges impede the achievement of fully dense AM-MMC parts.

Process parameter optimization presents a fundamental challenge due to the heterogeneous nature of MMCs. The presence of reinforcement particles alters the melt pool dynamics, heat transfer characteristics, and solidification behavior compared to unreinforced metals. This necessitates specific parameter sets for each matrix-reinforcement combination, creating a vast parameter space that is difficult to fully explore through traditional experimental approaches.

Powder feedstock quality significantly impacts porosity formation. The irregular morphology and size distribution of reinforcement particles can lead to poor flowability and uneven distribution within the matrix powder. Additionally, moisture absorption and oxidation of powders introduce gas porosity during the melting process. Current powder preparation techniques struggle to achieve consistent mixing ratios and homogeneous distribution of reinforcements.

Thermal gradient management poses another substantial challenge. The difference in thermal properties between matrix and reinforcement materials creates localized thermal gradients during processing. These gradients lead to differential cooling rates, residual stresses, and ultimately, porosity formation at matrix-reinforcement interfaces. The rapid heating and cooling cycles inherent to AM processes exacerbate this issue.

Interface reactions between the matrix and reinforcement materials represent a complex challenge. Chemical reactions at these interfaces can generate gaseous byproducts that become trapped as pores. Additionally, poor wettability between matrix and reinforcement materials creates weak interfaces prone to void formation. Current surface modification techniques for reinforcement particles show limited effectiveness in industrial-scale production.

Post-processing limitations further complicate porosity mitigation efforts. Hot Isostatic Pressing (HIP), a common densification technique, has reduced effectiveness for closed-cell porosity located at matrix-reinforcement interfaces. Additionally, the presence of hard reinforcement particles makes machining and surface finishing operations more challenging, limiting the ability to address near-surface porosity.

Monitoring and control systems lack the resolution and response time needed to detect and correct porosity formation in real-time. Current in-situ monitoring technologies struggle to differentiate between reinforcement particles and pores, particularly at the microscale. This limitation prevents the implementation of closed-loop control systems that could dynamically adjust process parameters to minimize porosity.

Process parameter optimization presents a fundamental challenge due to the heterogeneous nature of MMCs. The presence of reinforcement particles alters the melt pool dynamics, heat transfer characteristics, and solidification behavior compared to unreinforced metals. This necessitates specific parameter sets for each matrix-reinforcement combination, creating a vast parameter space that is difficult to fully explore through traditional experimental approaches.

Powder feedstock quality significantly impacts porosity formation. The irregular morphology and size distribution of reinforcement particles can lead to poor flowability and uneven distribution within the matrix powder. Additionally, moisture absorption and oxidation of powders introduce gas porosity during the melting process. Current powder preparation techniques struggle to achieve consistent mixing ratios and homogeneous distribution of reinforcements.

Thermal gradient management poses another substantial challenge. The difference in thermal properties between matrix and reinforcement materials creates localized thermal gradients during processing. These gradients lead to differential cooling rates, residual stresses, and ultimately, porosity formation at matrix-reinforcement interfaces. The rapid heating and cooling cycles inherent to AM processes exacerbate this issue.

Interface reactions between the matrix and reinforcement materials represent a complex challenge. Chemical reactions at these interfaces can generate gaseous byproducts that become trapped as pores. Additionally, poor wettability between matrix and reinforcement materials creates weak interfaces prone to void formation. Current surface modification techniques for reinforcement particles show limited effectiveness in industrial-scale production.

Post-processing limitations further complicate porosity mitigation efforts. Hot Isostatic Pressing (HIP), a common densification technique, has reduced effectiveness for closed-cell porosity located at matrix-reinforcement interfaces. Additionally, the presence of hard reinforcement particles makes machining and surface finishing operations more challenging, limiting the ability to address near-surface porosity.

Monitoring and control systems lack the resolution and response time needed to detect and correct porosity formation in real-time. Current in-situ monitoring technologies struggle to differentiate between reinforcement particles and pores, particularly at the microscale. This limitation prevents the implementation of closed-loop control systems that could dynamically adjust process parameters to minimize porosity.

State-of-the-Art Porosity Reduction Solutions

01 Porosity reduction techniques in AM-MMCs

Various techniques can be employed to reduce porosity in additively manufactured metal matrix composites. These include optimized process parameters, post-processing treatments, and specialized manufacturing approaches. By controlling factors such as laser power, scanning speed, and powder characteristics, the formation of pores during the additive manufacturing process can be minimized. Post-processing treatments like hot isostatic pressing can further densify the material by closing internal voids under high temperature and pressure conditions.- Porosity reduction techniques in AM-MMCs: Various techniques can be employed to reduce porosity in additively manufactured metal matrix composites. These include optimized process parameters, post-processing treatments, and specialized manufacturing approaches. By controlling factors such as laser power, scanning speed, and powder characteristics, the formation of pores can be minimized. Post-processing treatments like hot isostatic pressing (HIP) can further densify the material by closing internal voids under high pressure and temperature conditions.

- Defect detection and characterization methods: Advanced methods for detecting and characterizing defects in AM-MMCs include non-destructive testing techniques such as X-ray computed tomography, ultrasonic inspection, and optical microscopy. These methods allow for the identification of various defects including porosity, cracks, lack of fusion, and inclusions. Characterization of these defects provides valuable information for process optimization and quality control, enabling manufacturers to improve the mechanical properties and reliability of the final components.

- Influence of processing parameters on porosity formation: Processing parameters significantly influence the formation of porosity in additively manufactured metal matrix composites. Parameters such as laser power, scan speed, hatch spacing, layer thickness, and powder characteristics directly affect the energy input and material consolidation. Optimizing these parameters can minimize defects by ensuring proper melting and fusion between layers. The relationship between these parameters and resulting microstructure is critical for developing processing windows that yield high-density parts with minimal porosity.

- Reinforcement distribution and interface defects: The distribution of reinforcement particles in metal matrix composites and the quality of interfaces between the matrix and reinforcements significantly impact the formation of defects. Poor wetting between the matrix and reinforcement can lead to interfacial porosity and weak bonding. Agglomeration of reinforcement particles can create stress concentration points and void formation. Techniques to improve reinforcement distribution include surface modification of particles, optimized mixing methods, and controlled solidification rates during the additive manufacturing process.

- Post-processing treatments for defect mitigation: Post-processing treatments are essential for mitigating defects in additively manufactured metal matrix composites. Techniques such as hot isostatic pressing, heat treatment, and surface finishing can significantly reduce porosity and improve mechanical properties. Hot isostatic pressing applies high pressure and temperature simultaneously to close internal voids. Heat treatments can relieve residual stresses and homogenize the microstructure. Surface finishing methods like machining and polishing can remove surface defects and improve the overall quality of the components.

02 Defect detection and characterization methods

Advanced methods for detecting and characterizing defects in AM-MMCs are essential for quality control. These methods include non-destructive testing techniques such as X-ray computed tomography, ultrasonic inspection, and optical microscopy. These techniques allow for the identification and measurement of various defects including porosity, cracks, and inclusions. Characterization of defects provides valuable information for process optimization and material property prediction, enabling manufacturers to improve the overall quality of AM-MMCs.Expand Specific Solutions03 Influence of processing parameters on porosity formation

Processing parameters significantly influence the formation of porosity in AM-MMCs. Parameters such as laser power, scanning speed, layer thickness, and powder bed temperature directly affect the melt pool dynamics and solidification behavior. Improper parameter selection can lead to lack-of-fusion defects, gas entrapment, and keyhole porosity. Understanding the relationship between these parameters and porosity formation is crucial for developing optimized manufacturing strategies that minimize defects while maintaining production efficiency.Expand Specific Solutions04 Reinforcement distribution and interface defects

The distribution of reinforcement particles and the quality of matrix-reinforcement interfaces are critical factors affecting the performance of AM-MMCs. Poor distribution can lead to agglomeration of reinforcement particles, creating weak spots and potential crack initiation sites. Interface defects such as poor bonding or chemical reactions between the matrix and reinforcement can compromise the mechanical properties of the composite. Techniques to improve reinforcement distribution include powder pre-treatment, ultrasonic assistance during processing, and specialized feeding mechanisms.Expand Specific Solutions05 Post-processing treatments for defect mitigation

Post-processing treatments play a crucial role in mitigating defects in AM-MMCs. Techniques such as hot isostatic pressing, heat treatment, and surface finishing can significantly reduce porosity and improve mechanical properties. Hot isostatic pressing applies high temperature and pressure to close internal voids, while heat treatments can relieve residual stresses and improve microstructural homogeneity. Surface finishing techniques like machining, polishing, and shot peening can address surface defects and improve fatigue performance by removing stress concentrators.Expand Specific Solutions

Leading Organizations in AM-MMC Research and Development

The additive manufacturing metal matrix composites (AM-MMCs) market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and industrial sectors. The global market size for AM-MMCs is expanding rapidly, driven by demand for lightweight, high-performance components. Technologically, porosity and defect mitigation remains a critical challenge, with varying levels of maturity across key players. Leading organizations like CEA, Taiwan Semiconductor Manufacturing, and NASA are advancing process optimization techniques, while academic institutions including National University of Singapore and University of North Carolina are contributing fundamental research. Industrial manufacturers such as MTU Aero Engines and GM Global Technology Operations are developing application-specific solutions, focusing on real-world implementation of defect reduction strategies to enhance mechanical properties and reliability of AM-MMC components.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics (NUAA) has developed innovative porosity mitigation strategies for AM-MMCs through their Advanced Manufacturing Technology Research Center. Their approach focuses on tailored process parameters for specific metal matrix-reinforcement combinations, particularly aluminum and titanium matrices with ceramic reinforcements. NUAA has pioneered a multi-scale modeling framework that predicts defect formation based on material properties, process parameters, and environmental conditions. Their technology includes specialized powder preparation techniques involving mechanical alloying and surface modification of reinforcement particles to enhance wettability and distribution uniformity. NUAA has developed novel scan strategies with variable energy density distribution that accounts for the thermal conductivity differences between matrix and reinforcement materials, significantly reducing thermal gradient-induced stresses and associated defects. Their research includes innovative post-processing techniques combining hot isostatic pressing with specialized heat treatment cycles designed to simultaneously close porosity and optimize interfacial bonding between matrix and reinforcement phases. Additionally, NUAA has created an integrated quality control system using infrared thermography and acoustic emission monitoring to detect defect formation in real-time during the manufacturing process.

Strengths: Strong expertise in aerospace-grade materials and applications; extensive experience with aluminum and titanium-based composites; integrated approach combining simulation and experimental validation. Weaknesses: Some technologies still at laboratory scale requiring industrial validation; solutions primarily optimized for aerospace applications may require adaptation for other sectors; limited international visibility compared to Western institutions despite technical excellence.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed comprehensive defect mitigation strategies for AM-MMCs through their Advanced Materials and Manufacturing Technologies division. Their approach leverages synchrotron-based X-ray characterization techniques to provide unprecedented insights into defect formation mechanisms during the additive manufacturing process. Argonne has pioneered high-energy X-ray diffraction microscopy (HEDM) and X-ray computed tomography (XCT) methods specifically calibrated for AM-MMCs, enabling real-time observation of porosity evolution during processing. Their technology suite includes AI-driven process parameter optimization that correlates laser power, scan speed, hatch spacing, and layer thickness with resultant microstructure and defect characteristics. Argonne has developed specialized feedstock preparation techniques involving controlled atmosphere atomization and surface functionalization of reinforcement particles to enhance matrix-reinforcement compatibility and reduce agglomeration-induced porosity. Their approach also incorporates multi-scale modeling frameworks that predict thermal gradients, melt pool dynamics, and solidification behavior specific to composite materials, enabling preventive design strategies for complex geometries and material combinations.

Strengths: World-class characterization capabilities including access to Advanced Photon Source; multidisciplinary expertise spanning materials science, physics, and computational modeling; strong connections to both academic and industrial partners. Weaknesses: Some technologies require specialized equipment not readily available in industrial settings; solutions may prioritize scientific understanding over immediate industrial implementation; transfer of technologies to production environments requires significant adaptation.

Critical Patents in AM-MMC Defect Control

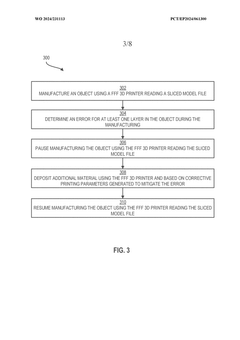

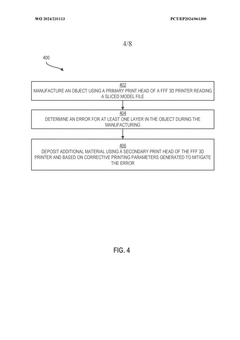

Defect mitigation in additive manufacturing

PatentWO2024231113A1

Innovation

- A method using a fused filament fabrication (FFF) 3D printer that reads a sliced model file, determines errors in real-time, pauses manufacturing, deposits additional material based on corrective printing parameters, and resumes printing, potentially utilizing a secondary print head for concurrent correction or updating the model file to incorporate corrections for future prints, aided by machine learning for error prediction and correction.

Additive manufacturing of composite powders

PatentActiveUS20220134429A1

Innovation

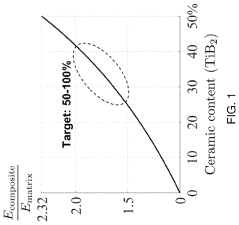

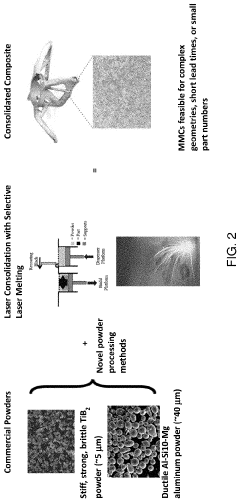

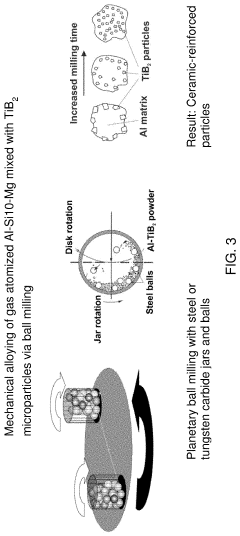

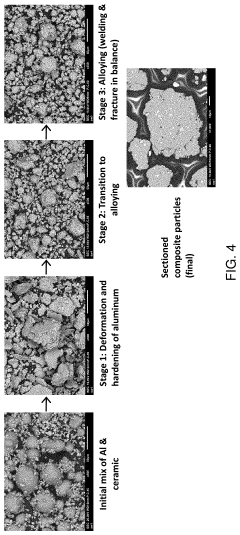

- A method involving the mechanical alloying of metal and ceramic powders using high-energy ball milling to create a monodisperse alloyed powder, which is then laser sintered to form a composite with a high ceramic content, enabling the production of lightweight, high-strength materials with complex geometries and improved thermal stability.

Material-Process Parameter Relationships

The relationship between material properties and process parameters in Additive Manufacturing of Metal Matrix Composites (AM-MMCs) represents a critical domain for understanding and mitigating porosity and defects. Process parameters such as laser power, scanning speed, hatch spacing, and layer thickness directly influence the thermal history of the material during fabrication, which in turn affects microstructure development and defect formation mechanisms.

Powder characteristics, including particle size distribution, morphology, and flowability, demonstrate significant correlations with porosity formation. Finer powders typically yield higher density parts but may exhibit poor flowability, leading to uneven layer deposition. Studies have shown that optimizing powder size distribution can reduce porosity by up to 30% in selective laser melting (SLM) processes for aluminum matrix composites.

The thermal conductivity of the matrix material plays a decisive role in heat dissipation during processing. Materials with higher thermal conductivity, such as aluminum, require different processing windows compared to lower conductivity matrices like titanium. For instance, aluminum-based MMCs typically require higher scan speeds (800-1200 mm/s) to prevent excessive melt pool dimensions and associated keyhole porosity.

Reinforcement characteristics—particularly volume fraction, size, and distribution—significantly impact processability. Higher reinforcement loadings (>15 vol%) typically necessitate increased energy input to ensure proper matrix melting while avoiding reinforcement degradation. Nano-sized reinforcements (<100 nm) present different challenges than micro-sized particles (>1 μm), with the former more prone to agglomeration but less likely to cause large-scale porosity.

The wettability between reinforcement and matrix materials constitutes another crucial parameter relationship. Poor wettability leads to interfacial porosity and weak bonding. Surface modification techniques for reinforcements, such as metallic coatings or chemical treatments, have demonstrated up to 40% improvement in interfacial bonding strength and corresponding reduction in interfacial porosity.

Energy density, expressed as the ratio of laser power to the product of scan speed, hatch spacing, and layer thickness, serves as a consolidated parameter that correlates strongly with porosity formation. The optimal energy density window varies significantly based on material composition, with typical ranges for aluminum MMCs between 50-150 J/mm³, while titanium-based systems may require 80-200 J/mm³ for minimal porosity.

Atmosphere control during processing demonstrates notable effects on oxide formation and gas porosity. Oxygen content below 100 ppm in the build chamber has been correlated with significantly reduced oxide inclusion defects in reactive matrix materials such as aluminum and titanium MMCs.

Powder characteristics, including particle size distribution, morphology, and flowability, demonstrate significant correlations with porosity formation. Finer powders typically yield higher density parts but may exhibit poor flowability, leading to uneven layer deposition. Studies have shown that optimizing powder size distribution can reduce porosity by up to 30% in selective laser melting (SLM) processes for aluminum matrix composites.

The thermal conductivity of the matrix material plays a decisive role in heat dissipation during processing. Materials with higher thermal conductivity, such as aluminum, require different processing windows compared to lower conductivity matrices like titanium. For instance, aluminum-based MMCs typically require higher scan speeds (800-1200 mm/s) to prevent excessive melt pool dimensions and associated keyhole porosity.

Reinforcement characteristics—particularly volume fraction, size, and distribution—significantly impact processability. Higher reinforcement loadings (>15 vol%) typically necessitate increased energy input to ensure proper matrix melting while avoiding reinforcement degradation. Nano-sized reinforcements (<100 nm) present different challenges than micro-sized particles (>1 μm), with the former more prone to agglomeration but less likely to cause large-scale porosity.

The wettability between reinforcement and matrix materials constitutes another crucial parameter relationship. Poor wettability leads to interfacial porosity and weak bonding. Surface modification techniques for reinforcements, such as metallic coatings or chemical treatments, have demonstrated up to 40% improvement in interfacial bonding strength and corresponding reduction in interfacial porosity.

Energy density, expressed as the ratio of laser power to the product of scan speed, hatch spacing, and layer thickness, serves as a consolidated parameter that correlates strongly with porosity formation. The optimal energy density window varies significantly based on material composition, with typical ranges for aluminum MMCs between 50-150 J/mm³, while titanium-based systems may require 80-200 J/mm³ for minimal porosity.

Atmosphere control during processing demonstrates notable effects on oxide formation and gas porosity. Oxygen content below 100 ppm in the build chamber has been correlated with significantly reduced oxide inclusion defects in reactive matrix materials such as aluminum and titanium MMCs.

Sustainability Aspects of AM-MMC Manufacturing

The sustainability of Additive Manufacturing Metal Matrix Composites (AM-MMCs) represents a critical dimension in evaluating their long-term viability and environmental impact. Current porosity and defect mitigation strategies must be assessed not only for their technical effectiveness but also for their sustainability implications.

Energy consumption during AM-MMC manufacturing presents significant sustainability challenges. Process parameters optimization strategies that reduce porosity often require higher energy inputs, particularly in powder bed fusion and directed energy deposition techniques. Recent research indicates that optimized scanning strategies can reduce energy consumption by 15-20% while maintaining defect mitigation effectiveness, presenting a promising direction for sustainable manufacturing.

Material efficiency constitutes another crucial sustainability aspect. Traditional defect mitigation approaches frequently involve excess material usage or post-processing steps that generate substantial waste. Advanced powder recycling systems specifically designed for MMCs have demonstrated the ability to reclaim up to 95% of unused powders while maintaining material integrity, significantly reducing the environmental footprint of AM-MMC production.

Life cycle assessment (LCA) studies of AM-MMC manufacturing reveal that defect prevention strategies generally offer superior sustainability outcomes compared to defect correction approaches. Preventative measures implemented during the design and printing phases typically consume fewer resources than post-processing treatments required to address existing defects. This finding underscores the importance of integrating sustainability considerations into early-stage process development.

The environmental impact of auxiliary materials used in defect mitigation deserves particular attention. Chemical treatments and binding agents employed to reduce porosity often contain environmentally persistent compounds. Recent innovations in biodegradable binding agents and water-soluble support structures represent promising advances toward more environmentally responsible AM-MMC manufacturing.

Regulatory frameworks increasingly influence sustainability practices in AM-MMC production. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are driving manufacturers to develop closed-loop defect mitigation strategies that minimize waste generation and facilitate material recovery at end-of-life.

Economic sustainability must also be considered alongside environmental factors. While some advanced defect mitigation technologies require significant initial investment, their long-term benefits often include reduced material waste, lower energy consumption, and decreased rejection rates, ultimately improving economic sustainability through total cost reduction over the product lifecycle.

Energy consumption during AM-MMC manufacturing presents significant sustainability challenges. Process parameters optimization strategies that reduce porosity often require higher energy inputs, particularly in powder bed fusion and directed energy deposition techniques. Recent research indicates that optimized scanning strategies can reduce energy consumption by 15-20% while maintaining defect mitigation effectiveness, presenting a promising direction for sustainable manufacturing.

Material efficiency constitutes another crucial sustainability aspect. Traditional defect mitigation approaches frequently involve excess material usage or post-processing steps that generate substantial waste. Advanced powder recycling systems specifically designed for MMCs have demonstrated the ability to reclaim up to 95% of unused powders while maintaining material integrity, significantly reducing the environmental footprint of AM-MMC production.

Life cycle assessment (LCA) studies of AM-MMC manufacturing reveal that defect prevention strategies generally offer superior sustainability outcomes compared to defect correction approaches. Preventative measures implemented during the design and printing phases typically consume fewer resources than post-processing treatments required to address existing defects. This finding underscores the importance of integrating sustainability considerations into early-stage process development.

The environmental impact of auxiliary materials used in defect mitigation deserves particular attention. Chemical treatments and binding agents employed to reduce porosity often contain environmentally persistent compounds. Recent innovations in biodegradable binding agents and water-soluble support structures represent promising advances toward more environmentally responsible AM-MMC manufacturing.

Regulatory frameworks increasingly influence sustainability practices in AM-MMC production. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are driving manufacturers to develop closed-loop defect mitigation strategies that minimize waste generation and facilitate material recovery at end-of-life.

Economic sustainability must also be considered alongside environmental factors. While some advanced defect mitigation technologies require significant initial investment, their long-term benefits often include reduced material waste, lower energy consumption, and decreased rejection rates, ultimately improving economic sustainability through total cost reduction over the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!