Modeling Solidification And Residual Stress In AM-MMCs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM-MMC Solidification Background and Objectives

Additive Manufacturing Metal Matrix Composites (AM-MMCs) represent a significant advancement in materials science, combining the design flexibility of additive manufacturing with the enhanced mechanical properties of metal matrix composites. The evolution of this technology has progressed from traditional casting methods to powder-based additive techniques, enabling unprecedented control over material composition and microstructure. This technological progression has been driven by increasing demands in aerospace, automotive, and defense industries for materials that exhibit superior strength-to-weight ratios, thermal stability, and wear resistance.

The solidification process in AM-MMCs is particularly complex due to the rapid heating and cooling cycles inherent in additive manufacturing processes. These thermal conditions create unique solidification patterns that differ significantly from conventional manufacturing methods. Historical developments in understanding metal solidification have provided foundational knowledge, but the extreme thermal gradients and cooling rates in AM processes introduce new challenges that require specialized modeling approaches.

Current technological trends indicate a growing interest in multi-scale modeling of solidification phenomena, integrating molecular dynamics simulations with continuum mechanics to capture both microscopic and macroscopic behaviors. The integration of machine learning algorithms with physics-based models is also emerging as a promising direction for predicting microstructure evolution during solidification.

The primary objective of modeling solidification and residual stress in AM-MMCs is to establish predictive capabilities that can accurately simulate the formation of microstructures during the manufacturing process and their subsequent impact on mechanical properties. This includes understanding phase transformations, grain growth dynamics, and the development of residual stresses that can significantly affect component performance.

Secondary objectives include optimizing process parameters to minimize defects such as porosity, cracking, and undesired phase formations that commonly occur during rapid solidification. Additionally, there is a critical need to develop models that can predict the interface behavior between the metal matrix and reinforcement materials, as these interfaces often determine the overall composite performance.

Long-term technological goals involve creating digital twins of the AM-MMC manufacturing process that can predict final part properties with high fidelity, enabling virtual qualification of components and reducing the need for extensive physical testing. This would significantly accelerate the adoption of AM-MMCs in critical applications where certification requirements are stringent.

Understanding the fundamental physics of solidification in AM-MMCs will also facilitate the development of novel alloy systems specifically designed for additive manufacturing, potentially leading to materials with property combinations not achievable through conventional manufacturing routes.

The solidification process in AM-MMCs is particularly complex due to the rapid heating and cooling cycles inherent in additive manufacturing processes. These thermal conditions create unique solidification patterns that differ significantly from conventional manufacturing methods. Historical developments in understanding metal solidification have provided foundational knowledge, but the extreme thermal gradients and cooling rates in AM processes introduce new challenges that require specialized modeling approaches.

Current technological trends indicate a growing interest in multi-scale modeling of solidification phenomena, integrating molecular dynamics simulations with continuum mechanics to capture both microscopic and macroscopic behaviors. The integration of machine learning algorithms with physics-based models is also emerging as a promising direction for predicting microstructure evolution during solidification.

The primary objective of modeling solidification and residual stress in AM-MMCs is to establish predictive capabilities that can accurately simulate the formation of microstructures during the manufacturing process and their subsequent impact on mechanical properties. This includes understanding phase transformations, grain growth dynamics, and the development of residual stresses that can significantly affect component performance.

Secondary objectives include optimizing process parameters to minimize defects such as porosity, cracking, and undesired phase formations that commonly occur during rapid solidification. Additionally, there is a critical need to develop models that can predict the interface behavior between the metal matrix and reinforcement materials, as these interfaces often determine the overall composite performance.

Long-term technological goals involve creating digital twins of the AM-MMC manufacturing process that can predict final part properties with high fidelity, enabling virtual qualification of components and reducing the need for extensive physical testing. This would significantly accelerate the adoption of AM-MMCs in critical applications where certification requirements are stringent.

Understanding the fundamental physics of solidification in AM-MMCs will also facilitate the development of novel alloy systems specifically designed for additive manufacturing, potentially leading to materials with property combinations not achievable through conventional manufacturing routes.

Market Analysis for AM-MMC Applications

The Additive Manufacturing Metal Matrix Composites (AM-MMCs) market is experiencing significant growth, driven by increasing demand for high-performance materials in aerospace, automotive, and defense sectors. Current market valuations indicate that the global AM-MMCs market reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate of 14.8% through 2028. This growth trajectory is primarily fueled by the superior mechanical properties, thermal stability, and weight reduction capabilities that AM-MMCs offer compared to conventional materials.

Aerospace applications currently dominate the AM-MMC market share, accounting for roughly 38% of total consumption. The industry's stringent requirements for lightweight, high-strength components with excellent thermal resistance make AM-MMCs particularly attractive for engine components, structural elements, and heat management systems. Major aerospace manufacturers have reported 15-25% weight reduction in critical components while maintaining or improving performance metrics.

The automotive sector represents the fastest-growing application segment, with a projected growth rate of 17.2% annually. As automotive manufacturers increasingly focus on vehicle lightweighting to improve fuel efficiency and reduce emissions, AM-MMCs offer compelling advantages over traditional materials. Particularly in high-performance and electric vehicles, where thermal management and structural integrity are paramount concerns, AM-MMCs provide solutions that conventional materials cannot match.

Defense applications constitute approximately 22% of the current market, with particular emphasis on ballistic protection, structural components for military vehicles, and specialized equipment requiring exceptional mechanical properties under extreme conditions. The ability to model solidification and residual stress in AM-MMCs is especially critical in this sector, where performance reliability is non-negotiable.

Industrial equipment applications represent a growing market segment (15% share), particularly in sectors requiring components with exceptional wear resistance, thermal stability, and mechanical strength. Mining, oil and gas, and heavy machinery industries are increasingly adopting AM-MMC components for critical applications where traditional materials fail to meet performance requirements.

Market analysis reveals that North America currently leads global consumption (41%), followed by Europe (32%) and Asia-Pacific (21%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by rapid industrialization, increasing defense spending, and growing aerospace manufacturing capabilities in countries like China, India, and South Korea.

The ability to accurately model solidification and residual stress in AM-MMCs represents a critical competitive advantage in this market landscape, as it directly impacts product quality, performance predictability, and manufacturing efficiency. Companies that master these modeling capabilities can expect to capture premium market segments where performance requirements are most stringent.

Aerospace applications currently dominate the AM-MMC market share, accounting for roughly 38% of total consumption. The industry's stringent requirements for lightweight, high-strength components with excellent thermal resistance make AM-MMCs particularly attractive for engine components, structural elements, and heat management systems. Major aerospace manufacturers have reported 15-25% weight reduction in critical components while maintaining or improving performance metrics.

The automotive sector represents the fastest-growing application segment, with a projected growth rate of 17.2% annually. As automotive manufacturers increasingly focus on vehicle lightweighting to improve fuel efficiency and reduce emissions, AM-MMCs offer compelling advantages over traditional materials. Particularly in high-performance and electric vehicles, where thermal management and structural integrity are paramount concerns, AM-MMCs provide solutions that conventional materials cannot match.

Defense applications constitute approximately 22% of the current market, with particular emphasis on ballistic protection, structural components for military vehicles, and specialized equipment requiring exceptional mechanical properties under extreme conditions. The ability to model solidification and residual stress in AM-MMCs is especially critical in this sector, where performance reliability is non-negotiable.

Industrial equipment applications represent a growing market segment (15% share), particularly in sectors requiring components with exceptional wear resistance, thermal stability, and mechanical strength. Mining, oil and gas, and heavy machinery industries are increasingly adopting AM-MMC components for critical applications where traditional materials fail to meet performance requirements.

Market analysis reveals that North America currently leads global consumption (41%), followed by Europe (32%) and Asia-Pacific (21%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by rapid industrialization, increasing defense spending, and growing aerospace manufacturing capabilities in countries like China, India, and South Korea.

The ability to accurately model solidification and residual stress in AM-MMCs represents a critical competitive advantage in this market landscape, as it directly impacts product quality, performance predictability, and manufacturing efficiency. Companies that master these modeling capabilities can expect to capture premium market segments where performance requirements are most stringent.

Current Challenges in Residual Stress Modeling

Residual stress modeling in Additive Manufacturing Metal Matrix Composites (AM-MMCs) faces significant challenges that impede accurate prediction and control. The multi-physics nature of the AM process creates complex thermal histories that are difficult to capture in computational models. Temperature gradients during rapid heating and cooling cycles generate thermal stresses that transform into residual stresses upon solidification, with rates exceeding 10^3-10^6 K/s in many AM processes.

The heterogeneous microstructure of MMCs presents a fundamental modeling challenge. The presence of reinforcement particles creates local stress concentrations and alters the stress distribution patterns compared to homogeneous materials. Current models struggle to accurately represent the interface between matrix and reinforcement, where stress concentrations are most pronounced and failure often initiates.

Scale bridging remains a persistent issue in residual stress modeling. Microscale phenomena at particle-matrix interfaces must be connected to macroscale component behavior, requiring multi-scale modeling approaches that are computationally intensive. Most existing models make simplifying assumptions that compromise accuracy when applied to complex AM-MMC systems.

Material property data presents another significant obstacle. Temperature-dependent properties for novel MMC compositions are often unavailable or incomplete, particularly at the extreme temperatures experienced during AM processes. This data gap forces researchers to rely on extrapolations or approximations that introduce uncertainty into model predictions.

Validation methodologies for residual stress models are limited by measurement challenges. Non-destructive techniques like neutron diffraction provide incomplete stress field information, while destructive methods alter the very stresses being measured. This creates a circular problem where models cannot be fully validated against experimental data.

Computational efficiency remains a barrier to industrial implementation. High-fidelity models incorporating microstructural details and phase transformations require substantial computing resources, making them impractical for routine use in production environments. Simplified models sacrifice accuracy for speed, creating an unresolved tension between precision and practicality.

The dynamic nature of reinforcement particle distribution during the AM process introduces additional complexity. Particle migration, agglomeration, and orientation changes during solidification alter local stress distributions in ways that current models cannot predict accurately. This dynamic behavior creates path-dependent stress states that require sophisticated tracking mechanisms rarely implemented in existing frameworks.

The heterogeneous microstructure of MMCs presents a fundamental modeling challenge. The presence of reinforcement particles creates local stress concentrations and alters the stress distribution patterns compared to homogeneous materials. Current models struggle to accurately represent the interface between matrix and reinforcement, where stress concentrations are most pronounced and failure often initiates.

Scale bridging remains a persistent issue in residual stress modeling. Microscale phenomena at particle-matrix interfaces must be connected to macroscale component behavior, requiring multi-scale modeling approaches that are computationally intensive. Most existing models make simplifying assumptions that compromise accuracy when applied to complex AM-MMC systems.

Material property data presents another significant obstacle. Temperature-dependent properties for novel MMC compositions are often unavailable or incomplete, particularly at the extreme temperatures experienced during AM processes. This data gap forces researchers to rely on extrapolations or approximations that introduce uncertainty into model predictions.

Validation methodologies for residual stress models are limited by measurement challenges. Non-destructive techniques like neutron diffraction provide incomplete stress field information, while destructive methods alter the very stresses being measured. This creates a circular problem where models cannot be fully validated against experimental data.

Computational efficiency remains a barrier to industrial implementation. High-fidelity models incorporating microstructural details and phase transformations require substantial computing resources, making them impractical for routine use in production environments. Simplified models sacrifice accuracy for speed, creating an unresolved tension between precision and practicality.

The dynamic nature of reinforcement particle distribution during the AM process introduces additional complexity. Particle migration, agglomeration, and orientation changes during solidification alter local stress distributions in ways that current models cannot predict accurately. This dynamic behavior creates path-dependent stress states that require sophisticated tracking mechanisms rarely implemented in existing frameworks.

State-of-the-Art Residual Stress Simulation Methods

01 Solidification control in AM-MMCs

Controlling the solidification process in additive manufacturing of metal matrix composites is crucial for achieving desired microstructures and properties. This involves managing cooling rates, thermal gradients, and solidification fronts during the manufacturing process. Techniques such as controlled heat input, substrate preheating, and specialized cooling strategies can be employed to manipulate the solidification behavior, resulting in improved material properties and reduced defects in the final components.- Solidification control methods in AM-MMCs: Various methods can be employed to control the solidification process in additive manufacturing of metal matrix composites. These include precise temperature control during deposition, controlled cooling rates, and specific heat treatment protocols. By managing the solidification parameters, manufacturers can achieve desired microstructures, reduce defects, and enhance the mechanical properties of the final components. These techniques are particularly important for ensuring uniform distribution of reinforcement materials within the metal matrix.

- Residual stress reduction techniques: Residual stresses in AM-MMCs can be mitigated through various approaches including pre-heating of substrates, post-process heat treatments, and optimized scanning strategies. These techniques help to minimize thermal gradients during fabrication, which are a primary cause of residual stress formation. Implementing stress relief processes after manufacturing can significantly improve the dimensional stability and fatigue resistance of the components, preventing warping and cracking that might otherwise occur.

- Reinforcement distribution and interface control: The distribution of reinforcement particles and the quality of interfaces between the matrix and reinforcements significantly affect the solidification behavior and residual stress development in AM-MMCs. Techniques such as ultrasonic vibration, electromagnetic stirring, and specialized powder preparation methods can be employed to achieve uniform distribution of reinforcements. Controlling the wettability and chemical reactions at the interfaces helps prevent the formation of brittle phases and ensures strong bonding, which contributes to reduced residual stresses and improved mechanical properties.

- In-situ monitoring and process control: Advanced monitoring systems can be integrated into AM processes to observe solidification dynamics and residual stress development in real-time. These systems utilize thermal imaging, acoustic sensors, and other measurement techniques to provide feedback for process adjustments. Implementing closed-loop control systems allows for dynamic modification of process parameters based on the monitored data, enabling manufacturers to maintain optimal conditions throughout the build process and minimize residual stress formation while ensuring proper solidification.

- Novel alloy and composite designs for AM: Developing specialized alloy compositions and composite structures specifically designed for additive manufacturing can help address solidification and residual stress challenges. These materials may incorporate elements that promote favorable solidification characteristics, such as grain refiners or elements that modify the solidification range. Some designs feature engineered microstructures that can better accommodate thermal stresses during processing. Advanced metal matrix composites may also include functionally graded structures or reinforcement architectures that help distribute and minimize residual stresses throughout the component.

02 Residual stress management techniques

Residual stresses in AM-MMCs can significantly affect component performance and dimensional accuracy. Various techniques have been developed to manage these stresses, including post-processing heat treatments, in-situ process monitoring, and optimized build strategies. Controlled cooling paths, stress-relief annealing, and strategic build orientation can help minimize residual stress accumulation. Advanced simulation models can predict stress distribution, enabling process parameter optimization to reduce detrimental residual stresses in the final parts.Expand Specific Solutions03 Reinforcement distribution and interface control

The distribution of reinforcement materials within the metal matrix and the quality of interfaces between matrix and reinforcements significantly impact the mechanical properties and stress distribution in AM-MMCs. Techniques for achieving uniform reinforcement distribution include specialized powder preparation, optimized energy input parameters, and controlled material feeding systems. Interface engineering approaches focus on promoting strong bonding between matrix and reinforcements while minimizing detrimental reactions that could lead to weak interfaces or brittle phases, thereby improving load transfer and reducing stress concentration.Expand Specific Solutions04 Thermal management during AM processing

Effective thermal management during additive manufacturing of metal matrix composites is essential for controlling solidification behavior and residual stress development. This includes strategies such as substrate heating, controlled cooling rates, and optimized scan strategies to maintain appropriate temperature gradients. Advanced monitoring systems can provide real-time temperature feedback to adjust process parameters dynamically. Proper thermal management helps prevent thermal shock, crack formation, and distortion while promoting desired microstructural development and minimizing residual stress accumulation.Expand Specific Solutions05 Computational modeling for process optimization

Computational modeling and simulation tools are increasingly used to predict and optimize solidification behavior and residual stress development in AM-MMCs. These models incorporate multiphysics approaches to simulate heat transfer, fluid flow, phase transformations, and mechanical behavior during the manufacturing process. Finite element analysis and computational fluid dynamics help identify optimal process parameters and build strategies to achieve desired microstructures while minimizing residual stresses. Machine learning algorithms can further enhance predictive capabilities by correlating process parameters with material properties and performance outcomes.Expand Specific Solutions

Leading Research Groups and Industrial Players

The additive manufacturing of metal matrix composites (AM-MMCs) market is currently in an early growth phase, characterized by increasing adoption across aerospace, automotive, and industrial sectors. The global market size for AM-MMCs is expanding rapidly, projected to reach significant value as manufacturers seek lightweight, high-performance materials with enhanced mechanical properties. Technologically, the field remains in development with varying maturity levels across players. Leading companies like General Electric and Siemens Energy are advancing solidification modeling and residual stress prediction capabilities, while research institutions including Monash University and Sun Yat-Sen University contribute fundamental scientific understanding. Specialized manufacturers such as BeamIT, Norsk Titanium, and MRL Materials Resources are developing proprietary processes to overcome technical challenges in stress management during solidification, positioning themselves as key innovators in this emerging field.

General Electric Company

Technical Solution: GE has developed comprehensive multi-physics simulation frameworks specifically for metal additive manufacturing processes. Their approach integrates thermal-mechanical-metallurgical models to predict solidification microstructures and residual stress distributions in AM-MMCs. GE utilizes high-fidelity computational models that account for phase transformations, grain growth kinetics, and thermal gradients during rapid solidification. Their proprietary software suite incorporates machine learning algorithms to optimize process parameters based on material-specific properties and desired mechanical characteristics. GE's models can predict defect formation mechanisms including porosity, cracking susceptibility, and distortion in complex geometries, enabling pre-build compensation strategies for dimensional accuracy.

Strengths: Extensive validation through industrial applications across aerospace components; integration with digital twin capabilities for real-time process monitoring. Weaknesses: Computationally intensive models requiring significant processing resources; primarily optimized for GE's own AM systems rather than universal application.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has pioneered advanced multi-scale modeling approaches for AM-MMCs that bridge microscale solidification phenomena with macroscale component performance. Their technology integrates cellular automata and finite element methods to simulate grain structure evolution during rapid solidification processes typical in metal additive manufacturing. Siemens' models account for the unique thermal cycling experienced in layer-by-layer building, capturing the repeated partial melting and resolidification that influences residual stress accumulation. Their simulation platform incorporates material-specific constitutive models that account for temperature-dependent properties and phase transformations, enabling accurate prediction of distortion and residual stress distributions in complex energy system components.

Strengths: Seamless integration with CAD/CAM workflows; extensive material database for energy sector alloys; validated through large-scale industrial components. Weaknesses: Models require extensive calibration for new material systems; computational efficiency challenges for full-scale industrial components.

Critical Patents and Literature in AM-MMC Modeling

A device. apparatus and method of additive manufacturing metal components. alloy components or metal matrix composite components

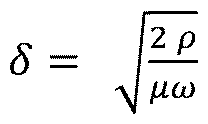

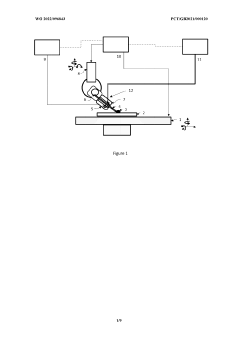

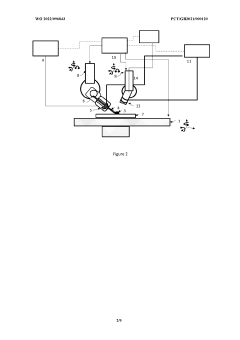

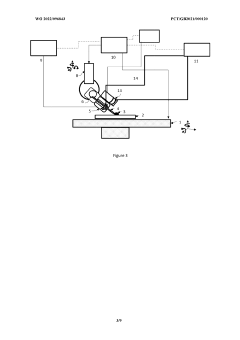

PatentWO2022096843A1

Innovation

- The use of high-frequency alternating current induction heating to selectively melt only the outer surface of feedstock materials, reducing energy consumption and heat-induced issues, and employing a shielding gas to enhance fusion with the deposition layer, allowing for partial melting and layer-by-layer construction of metal alloys and metal matrix composites.

Aluminium composite with metallic reinforcements

PatentInactiveIN5769CHE2015A

Innovation

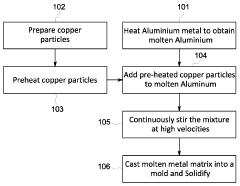

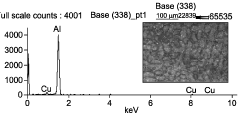

- A conventional foundry process using stir casting to disperse copper particles into molten aluminum, creating a homogeneous composite with improved mechanical and wear properties, which can be secondary processed at lower energy levels.

Material Characterization Techniques for Validation

Validation of computational models for solidification and residual stress in Additive Manufacturing Metal Matrix Composites (AM-MMCs) requires sophisticated material characterization techniques. X-ray diffraction (XRD) stands as a primary method for residual stress measurement, allowing non-destructive analysis of crystallographic changes and strain distributions within the material. The technique measures lattice spacing alterations caused by residual stresses, providing quantitative data on stress magnitude and direction. For AM-MMCs specifically, synchrotron-based XRD offers enhanced resolution for detecting stress variations at the matrix-reinforcement interfaces.

Neutron diffraction complements XRD by providing deeper penetration into metal components, enabling stress measurement throughout the bulk material rather than just surface layers. This becomes particularly valuable for thick AM-MMC components where internal stress distributions significantly impact mechanical performance. The technique can differentiate between thermal residual stresses and mechanical residual stresses, offering insights into the complex stress states unique to composite materials.

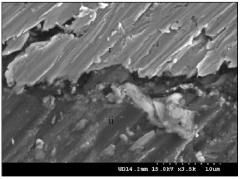

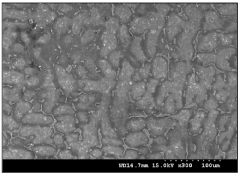

Microstructural validation employs scanning electron microscopy (SEM) coupled with electron backscatter diffraction (EBSD) to correlate predicted solidification patterns with actual grain structures. These techniques reveal grain orientation, size distribution, and morphology, which directly influence residual stress development. For AM-MMCs, high-resolution transmission electron microscopy (TEM) becomes essential for examining the matrix-reinforcement interfaces where stress concentrations typically occur.

Thermal characterization techniques, including differential scanning calorimetry (DSC) and thermomechanical analysis (TMA), provide critical data on phase transformations and thermal expansion coefficients. These parameters serve as essential inputs for computational models and validation benchmarks. Dilatometry measurements during simulated thermal cycles can verify predicted dimensional changes during solidification and cooling processes.

Mechanical testing protocols such as micro-hardness mapping, nanoindentation, and digital image correlation during tensile testing offer quantitative validation of predicted stress-strain relationships. These techniques can identify localized property variations resulting from residual stress fields. For AM-MMCs, instrumented indentation testing provides insights into the elastic-plastic behavior at different locations within the heterogeneous microstructure.

Non-destructive evaluation methods including ultrasonic testing, acoustic emission, and computed tomography enable in-situ monitoring of defect formation and residual stress evolution. These techniques are particularly valuable for validating time-dependent aspects of solidification models and for detecting stress-induced defects before they lead to component failure.

Neutron diffraction complements XRD by providing deeper penetration into metal components, enabling stress measurement throughout the bulk material rather than just surface layers. This becomes particularly valuable for thick AM-MMC components where internal stress distributions significantly impact mechanical performance. The technique can differentiate between thermal residual stresses and mechanical residual stresses, offering insights into the complex stress states unique to composite materials.

Microstructural validation employs scanning electron microscopy (SEM) coupled with electron backscatter diffraction (EBSD) to correlate predicted solidification patterns with actual grain structures. These techniques reveal grain orientation, size distribution, and morphology, which directly influence residual stress development. For AM-MMCs, high-resolution transmission electron microscopy (TEM) becomes essential for examining the matrix-reinforcement interfaces where stress concentrations typically occur.

Thermal characterization techniques, including differential scanning calorimetry (DSC) and thermomechanical analysis (TMA), provide critical data on phase transformations and thermal expansion coefficients. These parameters serve as essential inputs for computational models and validation benchmarks. Dilatometry measurements during simulated thermal cycles can verify predicted dimensional changes during solidification and cooling processes.

Mechanical testing protocols such as micro-hardness mapping, nanoindentation, and digital image correlation during tensile testing offer quantitative validation of predicted stress-strain relationships. These techniques can identify localized property variations resulting from residual stress fields. For AM-MMCs, instrumented indentation testing provides insights into the elastic-plastic behavior at different locations within the heterogeneous microstructure.

Non-destructive evaluation methods including ultrasonic testing, acoustic emission, and computed tomography enable in-situ monitoring of defect formation and residual stress evolution. These techniques are particularly valuable for validating time-dependent aspects of solidification models and for detecting stress-induced defects before they lead to component failure.

Computational Resources and Implementation Strategies

The computational demands for accurately modeling solidification and residual stress in Additive Manufacturing Metal Matrix Composites (AM-MMCs) are exceptionally high, requiring strategic allocation of resources and implementation approaches. High-fidelity simulations necessitate significant computing power, with multi-physics models often demanding parallel processing capabilities across multiple CPU cores or GPU acceleration. Current industry benchmarks indicate that comprehensive AM-MMC simulations typically require workstations with minimum specifications of 32GB RAM, 8+ CPU cores, and dedicated GPUs with at least 8GB VRAM.

Cloud computing platforms have emerged as viable alternatives to on-premises infrastructure, offering scalable resources that can be dynamically allocated based on simulation complexity. Services such as AWS, Google Cloud, and Microsoft Azure provide specialized high-performance computing (HPC) instances optimized for computational fluid dynamics and finite element analysis, essential components in AM-MMC modeling. These platforms enable researchers to access petaflop-scale computing power without significant capital investment.

Implementation strategies must balance computational efficiency with model accuracy. Multi-scale modeling approaches have proven effective, where different physical phenomena are simulated at appropriate scales to optimize computational resources. For instance, melt pool dynamics may be modeled at the microscale, while thermal history and residual stress development can be addressed at the mesoscale or macroscale. This hierarchical approach reduces overall computational requirements while maintaining simulation fidelity.

Code optimization represents another critical implementation strategy. Techniques such as adaptive mesh refinement, where mesh density increases only in regions of high gradient or interest, can significantly reduce computational overhead. Similarly, employing reduced-order models for less critical aspects of the simulation can preserve resources for more complex phenomena. Benchmarking indicates that optimized code can achieve 3-5x performance improvements compared to standard implementations.

Parallel computing frameworks like OpenMP and MPI enable efficient distribution of computational tasks across available hardware resources. For AM-MMC simulations specifically, domain decomposition methods have demonstrated superior scaling properties, allowing simulations to be partitioned across multiple computing nodes. Recent advancements in GPU acceleration through CUDA or OpenCL have shown particular promise for thermal and fluid dynamics calculations, with speedups of 10-20x compared to CPU-only implementations for certain simulation components.

Cloud computing platforms have emerged as viable alternatives to on-premises infrastructure, offering scalable resources that can be dynamically allocated based on simulation complexity. Services such as AWS, Google Cloud, and Microsoft Azure provide specialized high-performance computing (HPC) instances optimized for computational fluid dynamics and finite element analysis, essential components in AM-MMC modeling. These platforms enable researchers to access petaflop-scale computing power without significant capital investment.

Implementation strategies must balance computational efficiency with model accuracy. Multi-scale modeling approaches have proven effective, where different physical phenomena are simulated at appropriate scales to optimize computational resources. For instance, melt pool dynamics may be modeled at the microscale, while thermal history and residual stress development can be addressed at the mesoscale or macroscale. This hierarchical approach reduces overall computational requirements while maintaining simulation fidelity.

Code optimization represents another critical implementation strategy. Techniques such as adaptive mesh refinement, where mesh density increases only in regions of high gradient or interest, can significantly reduce computational overhead. Similarly, employing reduced-order models for less critical aspects of the simulation can preserve resources for more complex phenomena. Benchmarking indicates that optimized code can achieve 3-5x performance improvements compared to standard implementations.

Parallel computing frameworks like OpenMP and MPI enable efficient distribution of computational tasks across available hardware resources. For AM-MMC simulations specifically, domain decomposition methods have demonstrated superior scaling properties, allowing simulations to be partitioned across multiple computing nodes. Recent advancements in GPU acceleration through CUDA or OpenCL have shown particular promise for thermal and fluid dynamics calculations, with speedups of 10-20x compared to CPU-only implementations for certain simulation components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!