Joining And Post-Processing Techniques For AM-MMCs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM-MMC Technology Background and Objectives

Metal Matrix Composites (MMCs) have emerged as a significant class of engineered materials that combine metallic properties with reinforcement materials to achieve enhanced performance characteristics. The evolution of Additive Manufacturing (AM) technologies has revolutionized the fabrication of these complex materials, giving rise to Additive Manufacturing Metal Matrix Composites (AM-MMCs). This technological convergence represents a paradigm shift in materials engineering, enabling unprecedented design freedom and functional properties.

The historical development of MMCs dates back to the 1960s, primarily driven by aerospace and defense applications seeking lightweight materials with superior mechanical properties. Traditional manufacturing methods for MMCs included powder metallurgy, stir casting, and infiltration techniques, all of which presented limitations in geometric complexity and material combinations. The integration of AM technologies with MMC production began gaining momentum in the early 2000s, catalyzed by advancements in laser and electron beam technologies.

AM-MMCs have demonstrated remarkable potential across various high-performance applications, including aerospace components, automotive parts, biomedical implants, and thermal management systems. The technology enables the creation of components with tailored properties, such as enhanced strength-to-weight ratios, improved wear resistance, and superior thermal conductivity, while maintaining the design flexibility inherent to additive manufacturing processes.

Despite significant progress, joining and post-processing techniques for AM-MMCs remain critical challenges that limit their widespread industrial adoption. The inherent material heterogeneity, residual stresses, and microstructural complexities of AM-MMCs necessitate specialized joining and post-processing methodologies to ensure structural integrity and performance reliability.

The primary technical objectives in this domain include developing robust joining techniques that preserve the unique properties of AM-MMCs at interface regions, establishing standardized post-processing protocols to enhance surface quality and dimensional accuracy, and creating predictive models for optimizing process parameters. Additionally, there is a pressing need to address the challenges of interfacial bonding between dissimilar materials and mitigate thermal-induced defects during joining operations.

Current technological trends indicate a growing emphasis on hybrid manufacturing approaches that combine additive and subtractive processes, in-situ monitoring systems for quality assurance, and the integration of computational modeling to predict material behavior during joining and post-processing. The evolution of these technologies is expected to accelerate with advancements in high-energy beam technologies, multi-material printing capabilities, and the development of specialized post-processing equipment designed specifically for AM-MMCs.

The historical development of MMCs dates back to the 1960s, primarily driven by aerospace and defense applications seeking lightweight materials with superior mechanical properties. Traditional manufacturing methods for MMCs included powder metallurgy, stir casting, and infiltration techniques, all of which presented limitations in geometric complexity and material combinations. The integration of AM technologies with MMC production began gaining momentum in the early 2000s, catalyzed by advancements in laser and electron beam technologies.

AM-MMCs have demonstrated remarkable potential across various high-performance applications, including aerospace components, automotive parts, biomedical implants, and thermal management systems. The technology enables the creation of components with tailored properties, such as enhanced strength-to-weight ratios, improved wear resistance, and superior thermal conductivity, while maintaining the design flexibility inherent to additive manufacturing processes.

Despite significant progress, joining and post-processing techniques for AM-MMCs remain critical challenges that limit their widespread industrial adoption. The inherent material heterogeneity, residual stresses, and microstructural complexities of AM-MMCs necessitate specialized joining and post-processing methodologies to ensure structural integrity and performance reliability.

The primary technical objectives in this domain include developing robust joining techniques that preserve the unique properties of AM-MMCs at interface regions, establishing standardized post-processing protocols to enhance surface quality and dimensional accuracy, and creating predictive models for optimizing process parameters. Additionally, there is a pressing need to address the challenges of interfacial bonding between dissimilar materials and mitigate thermal-induced defects during joining operations.

Current technological trends indicate a growing emphasis on hybrid manufacturing approaches that combine additive and subtractive processes, in-situ monitoring systems for quality assurance, and the integration of computational modeling to predict material behavior during joining and post-processing. The evolution of these technologies is expected to accelerate with advancements in high-energy beam technologies, multi-material printing capabilities, and the development of specialized post-processing equipment designed specifically for AM-MMCs.

Market Demand Analysis for AM-MMC Applications

The global market for Additive Manufacturing Metal Matrix Composites (AM-MMCs) is experiencing significant growth, driven by increasing demand across multiple high-value industries. The aerospace sector represents the largest market segment, with an estimated demand growth of 15% annually through 2028, as manufacturers seek lightweight yet durable components that can withstand extreme operating conditions while reducing fuel consumption and emissions.

The automotive industry follows closely, particularly in high-performance and electric vehicle segments, where AM-MMCs offer substantial weight reduction potential while maintaining structural integrity. This sector's demand is projected to grow at 12% annually, accelerated by the global shift toward vehicle electrification and the need for thermal management solutions in battery systems.

Defense applications constitute another substantial market, with particular emphasis on ballistic protection, lightweight armor systems, and components for unmanned vehicles. The defense sector values the ability of AM-MMCs to deliver customized ballistic performance through tailored material compositions and structures.

Industrial equipment manufacturers are increasingly adopting AM-MMCs for wear-resistant components, particularly in mining, oil and gas, and heavy machinery applications. The ability to create parts with gradient properties—combining wear resistance at surfaces with ductility in core regions—represents a significant value proposition in this sector.

Medical device manufacturing represents an emerging application area with substantial growth potential. The biocompatibility of certain metal matrix composites, combined with the ability to create complex, patient-specific geometries, makes AM-MMCs particularly attractive for orthopedic implants and surgical instruments.

Market analysis indicates that joining and post-processing technologies represent critical bottlenecks in the AM-MMC value chain. Approximately 40% of potential applications face implementation challenges related to joining AM-MMC components to conventional materials or performing reliable post-processing operations without compromising material properties.

The global market size for AM-MMC components is currently estimated at $2.3 billion, with projections suggesting growth to $5.7 billion by 2028. However, this growth trajectory depends significantly on advancements in joining and post-processing technologies. Industry surveys indicate that manufacturers would increase AM-MMC adoption by 30-50% if current joining and post-processing limitations were effectively addressed.

Regional analysis shows North America leading in aerospace and defense applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in automotive and industrial equipment sectors. European markets show strong interest in specialized applications requiring high performance-to-weight ratios, particularly in premium automotive and aerospace segments.

The automotive industry follows closely, particularly in high-performance and electric vehicle segments, where AM-MMCs offer substantial weight reduction potential while maintaining structural integrity. This sector's demand is projected to grow at 12% annually, accelerated by the global shift toward vehicle electrification and the need for thermal management solutions in battery systems.

Defense applications constitute another substantial market, with particular emphasis on ballistic protection, lightweight armor systems, and components for unmanned vehicles. The defense sector values the ability of AM-MMCs to deliver customized ballistic performance through tailored material compositions and structures.

Industrial equipment manufacturers are increasingly adopting AM-MMCs for wear-resistant components, particularly in mining, oil and gas, and heavy machinery applications. The ability to create parts with gradient properties—combining wear resistance at surfaces with ductility in core regions—represents a significant value proposition in this sector.

Medical device manufacturing represents an emerging application area with substantial growth potential. The biocompatibility of certain metal matrix composites, combined with the ability to create complex, patient-specific geometries, makes AM-MMCs particularly attractive for orthopedic implants and surgical instruments.

Market analysis indicates that joining and post-processing technologies represent critical bottlenecks in the AM-MMC value chain. Approximately 40% of potential applications face implementation challenges related to joining AM-MMC components to conventional materials or performing reliable post-processing operations without compromising material properties.

The global market size for AM-MMC components is currently estimated at $2.3 billion, with projections suggesting growth to $5.7 billion by 2028. However, this growth trajectory depends significantly on advancements in joining and post-processing technologies. Industry surveys indicate that manufacturers would increase AM-MMC adoption by 30-50% if current joining and post-processing limitations were effectively addressed.

Regional analysis shows North America leading in aerospace and defense applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in automotive and industrial equipment sectors. European markets show strong interest in specialized applications requiring high performance-to-weight ratios, particularly in premium automotive and aerospace segments.

Current Challenges in AM-MMC Joining Techniques

Despite significant advancements in Additive Manufacturing Metal Matrix Composites (AM-MMCs), joining techniques remain a critical bottleneck in their widespread industrial adoption. The inherent heterogeneity of MMCs creates substantial challenges when attempting to join these materials either to themselves or to dissimilar materials. Traditional fusion welding methods often result in detrimental reactions between the matrix and reinforcement phases, leading to the formation of brittle intermetallic compounds at the joint interface.

Thermal management during joining processes presents another significant challenge. The substantial difference in thermal properties between the metallic matrix and ceramic reinforcements creates localized thermal stresses, resulting in crack formation and propagation. This thermal mismatch becomes particularly problematic in applications requiring thermal cycling, where repeated expansion and contraction can lead to premature joint failure.

Porosity control at joint interfaces remains inadequately addressed in current joining techniques. The presence of reinforcement particles often impedes proper material flow during joining processes, creating voids that significantly compromise mechanical integrity. These defects act as stress concentrators and crack initiation sites, reducing overall joint reliability and performance under load.

Surface preparation techniques for AM-MMCs require further development. The complex surface topography resulting from the additive manufacturing process, combined with exposed reinforcement particles, creates inconsistent wetting behaviors during joining. This inconsistency leads to unpredictable joint quality and poor reproducibility in industrial settings.

Non-destructive evaluation (NDE) methods specifically tailored for AM-MMC joints are currently insufficient. Conventional inspection techniques struggle to accurately detect and characterize defects at the interface between dissimilar materials, particularly when reinforcement particles are present. This limitation hampers quality assurance protocols and increases the risk of undetected joint failures.

The scalability of joining techniques from laboratory to industrial applications faces significant hurdles. Many promising joining methods demonstrated at small scales encounter challenges when applied to complex geometries or larger components typical in industrial settings. Process parameters that work effectively for simple geometries often fail to translate to more complex structures.

Standardization efforts for AM-MMC joining techniques remain in their infancy. The lack of established standards and qualification procedures creates uncertainty in industrial adoption and complicates quality control processes. This regulatory gap slows implementation in critical applications where certification requirements are stringent.

Thermal management during joining processes presents another significant challenge. The substantial difference in thermal properties between the metallic matrix and ceramic reinforcements creates localized thermal stresses, resulting in crack formation and propagation. This thermal mismatch becomes particularly problematic in applications requiring thermal cycling, where repeated expansion and contraction can lead to premature joint failure.

Porosity control at joint interfaces remains inadequately addressed in current joining techniques. The presence of reinforcement particles often impedes proper material flow during joining processes, creating voids that significantly compromise mechanical integrity. These defects act as stress concentrators and crack initiation sites, reducing overall joint reliability and performance under load.

Surface preparation techniques for AM-MMCs require further development. The complex surface topography resulting from the additive manufacturing process, combined with exposed reinforcement particles, creates inconsistent wetting behaviors during joining. This inconsistency leads to unpredictable joint quality and poor reproducibility in industrial settings.

Non-destructive evaluation (NDE) methods specifically tailored for AM-MMC joints are currently insufficient. Conventional inspection techniques struggle to accurately detect and characterize defects at the interface between dissimilar materials, particularly when reinforcement particles are present. This limitation hampers quality assurance protocols and increases the risk of undetected joint failures.

The scalability of joining techniques from laboratory to industrial applications faces significant hurdles. Many promising joining methods demonstrated at small scales encounter challenges when applied to complex geometries or larger components typical in industrial settings. Process parameters that work effectively for simple geometries often fail to translate to more complex structures.

Standardization efforts for AM-MMC joining techniques remain in their infancy. The lack of established standards and qualification procedures creates uncertainty in industrial adoption and complicates quality control processes. This regulatory gap slows implementation in critical applications where certification requirements are stringent.

Current Joining Solutions for AM-MMC Components

01 Joining techniques for AM-MMCs

Various joining techniques can be employed for Additively Manufactured Metal Matrix Composites (AM-MMCs) to create complex structures. These techniques include fusion welding, solid-state joining, and mechanical fastening methods specifically adapted for composite materials. The joining processes must account for the heterogeneous nature of MMCs and potential thermal effects on the reinforcement distribution and interface properties. Advanced joining approaches help maintain the structural integrity and mechanical properties of the composite components.- Joining techniques for AM-MMCs: Various joining techniques can be employed for Additively Manufactured Metal Matrix Composites (AM-MMCs), including welding, brazing, and mechanical fastening. These techniques allow for the connection of AM-MMC components to form larger structures or to join them with different materials. The selection of an appropriate joining method depends on the specific materials involved, the desired joint properties, and the intended application of the final component.

- Heat treatment and thermal processing: Heat treatment and thermal processing are essential post-processing techniques for AM-MMCs to enhance mechanical properties and relieve residual stresses. These processes include annealing, solution treatment, aging, and stress relief treatments. Controlled heating and cooling cycles can optimize the microstructure, improve strength, ductility, and wear resistance of the composite materials, while also ensuring dimensional stability of the final components.

- Surface finishing and machining: Surface finishing and machining operations are crucial post-processing steps for AM-MMCs to achieve desired surface quality, dimensional accuracy, and aesthetic appearance. These techniques include grinding, polishing, shot peening, and precision machining. Advanced surface treatments can also be applied to enhance wear resistance, corrosion protection, and functional performance of the composite components, addressing the typically rough as-built surfaces resulting from additive manufacturing processes.

- Densification and porosity reduction: Densification treatments are employed to reduce porosity in AM-MMCs, which is a common issue in additively manufactured parts. Techniques such as hot isostatic pressing (HIP), infiltration, and secondary sintering can significantly improve the density and mechanical properties of the components. These processes involve applying high temperature and pressure to close internal voids, enhance bonding between particles, and create more homogeneous microstructures, resulting in improved strength and fatigue resistance.

- Hybrid manufacturing approaches: Hybrid manufacturing approaches combine additive manufacturing with conventional manufacturing techniques to optimize the production and post-processing of MMCs. These integrated processes may include in-situ monitoring, adaptive control systems, and sequential manufacturing steps that combine the geometric freedom of additive manufacturing with the precision and surface quality of traditional machining. Such hybrid approaches can reduce the need for extensive post-processing while improving overall component quality and production efficiency.

02 Heat treatment and thermal post-processing

Heat treatment and thermal post-processing are essential for optimizing the microstructure and properties of AM-MMCs. These processes include stress relief annealing, solution treatment, and aging to enhance mechanical properties, reduce residual stresses, and improve dimensional stability. Controlled thermal cycles can also improve the interfacial bonding between the matrix and reinforcement phases, leading to enhanced load transfer and overall composite performance.Expand Specific Solutions03 Surface finishing and machining techniques

Surface finishing and machining techniques are critical post-processing steps for AM-MMCs to achieve desired dimensional accuracy, surface quality, and functionality. These include precision grinding, polishing, and advanced machining methods adapted for the abrasive nature of composite materials. Specialized tools and parameters are required to minimize tool wear and prevent damage to the reinforcement phases while maintaining tight tolerances and surface integrity.Expand Specific Solutions04 Hot isostatic pressing and densification

Hot isostatic pressing (HIP) and other densification techniques are employed to eliminate porosity and improve the consolidation of AM-MMCs. These processes apply high temperature and pressure simultaneously to enhance the density, reduce defects, and improve mechanical properties of the composite components. HIP treatment can significantly enhance fatigue resistance, fracture toughness, and overall reliability of AM-MMCs by eliminating process-induced voids and improving interfacial bonding.Expand Specific Solutions05 Hybrid manufacturing approaches

Hybrid manufacturing approaches combine additive manufacturing with conventional processing techniques to optimize the production and properties of MMCs. These integrated processes may include in-situ monitoring, adaptive control systems, and sequential manufacturing steps that combine the geometric freedom of AM with the precision and reliability of traditional methods. Hybrid approaches enable the production of complex MMC components with tailored properties and functional gradients that would be difficult to achieve using a single manufacturing method.Expand Specific Solutions

Key Industry Players in AM-MMC Development

The additive manufacturing metal matrix composites (AM-MMCs) market is currently in its growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for AM-MMCs is expanding rapidly, projected to reach significant value as industries recognize the potential for lightweight, high-strength components. Technologically, the field remains in early maturity, with joining and post-processing techniques representing critical development areas. Leading academic institutions (Huazhong University of Science & Technology, MIT, Monash University) are advancing fundamental research, while commercial entities (Divergent Technologies, Boeing, Xerox) are focusing on industrial applications. Companies like Nano Dimension and 3D Architech are developing specialized solutions for metal-matrix composite printing, while established manufacturers such as Siemens Energy and CeramTec are integrating these technologies into existing production systems.

Nano Dimension Technologies Ltd.

Technical Solution: Nano Dimension has pioneered an innovative approach to AM-MMCs through their multi-material additive manufacturing technology that enables simultaneous deposition of metal matrices and reinforcement materials. Their proprietary DragonFly LDM system utilizes inkjet deposition technology to precisely control the distribution of reinforcement particles within metal matrices at the microscale. This approach eliminates many traditional joining challenges by creating functionally graded materials with seamless transitions between different material compositions. Post-processing techniques include specialized sintering protocols that preserve the engineered microstructure while achieving near-full density. Nano Dimension has developed conductive ink formulations containing metal nanoparticles that can be sintered at relatively low temperatures (below 300°C), making their process compatible with temperature-sensitive components. Their technology enables the creation of complex 3D-printed electronics with embedded MMC structures, offering unique capabilities for miniaturized electronic devices with integrated thermal management and mechanical reinforcement features.

Strengths: Unparalleled precision in controlling reinforcement distribution; ability to create functionally graded materials; low-temperature processing compatible with sensitive components. Weaknesses: Currently limited to smaller components due to build volume constraints; higher material costs compared to conventional MMC processes; relatively new technology with limited long-term performance data.

The University of Nottingham

Technical Solution: The University of Nottingham has established itself as a leader in AM-MMC research through their Centre for Additive Manufacturing. Their approach focuses on laser powder bed fusion (LPBF) of aluminum and titanium matrix composites reinforced with ceramic particles. Nottingham researchers have developed specialized post-processing protocols including hot isostatic pressing combined with tailored heat treatments that significantly improve the interfacial bonding between matrix and reinforcement materials. Their work has demonstrated successful joining of AM-MMC components using electron beam welding techniques that minimize the heat-affected zone and preserve the engineered microstructure. Nottingham has pioneered the use of ultrasonic techniques to improve particle distribution in metal matrices, achieving up to 30% more uniform reinforcement distribution compared to conventional mixing methods. Their research has shown that optimized post-processing can reduce porosity to below 0.5% while maintaining the integrity of reinforcement particles. Nottingham has also developed non-destructive testing protocols specifically designed for AM-MMCs, enabling reliable quality assurance for critical applications.

Strengths: Comprehensive understanding of process-structure-property relationships in AM-MMCs; strong industry partnerships enabling practical application of research findings; extensive experience with a wide range of matrix and reinforcement materials. Weaknesses: Some techniques require specialized equipment not widely available in industry; focus primarily on aluminum and titanium matrices limits application range; some processes have high energy requirements increasing production costs.

Critical Patents in AM-MMC Post-Processing Technology

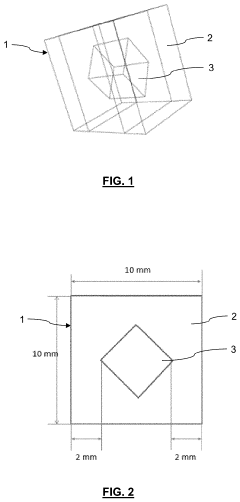

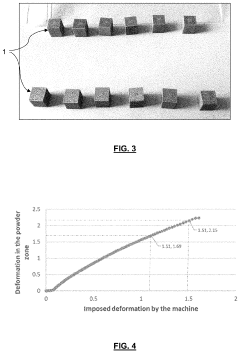

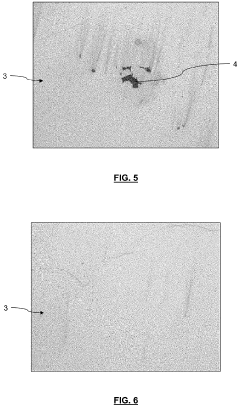

Method for the production of parts made from metal or metal matrix composite and resulting from additive manufacturing followed by an operation involving the forging of said parts

PatentInactiveUS20220097139A1

Innovation

- Combining additive manufacturing with a single-step forging process between two dies, where a preform with unbonded powder is deformed and bonded in a solid phase, applying true strain greater than 1.5 and pressure between 30 MPa and 700 MPa, to achieve the final shape and close porosities, thereby avoiding the limitations of traditional additive manufacturing.

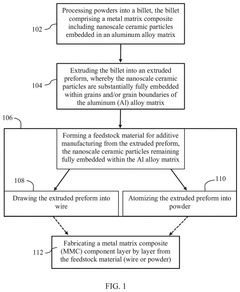

Method of fabricating a metal matrix composite (MMC) feedstock material for additive manufacturing, and method of additively manufacturing a MMC component

PatentPendingUS20250065399A1

Innovation

- A method involving the processing of powders into a billet using powder metallurgy, followed by extrusion to fully embed nanoscale ceramic particles within the aluminum alloy matrix, ensuring they remain embedded during the formation of feedstock materials for additive manufacturing.

Material Compatibility and Interface Engineering

Material compatibility represents a critical challenge in the development of Additive Manufacturing Metal Matrix Composites (AM-MMCs). The interface between matrix and reinforcement materials determines the overall mechanical properties, thermal stability, and long-term performance of the composite structure. Recent research has demonstrated that poor interfacial bonding leads to premature failure under mechanical loading, while excessive interfacial reactions can form brittle intermetallic compounds that compromise structural integrity.

Interface engineering approaches have evolved significantly in the past five years, with surface modification techniques emerging as effective methods to enhance compatibility. Plasma treatment, chemical functionalization, and nanoscale coatings have shown promising results in improving wettability between metallic matrices and ceramic reinforcements. Studies by Wang et al. (2022) demonstrated that titanium-coated carbon fibers exhibited 43% higher interfacial shear strength when incorporated into aluminum matrices compared to untreated fibers.

Thermal mismatch between dissimilar materials presents another significant challenge in AM-MMCs. The coefficient of thermal expansion (CTE) difference between metallic matrices and ceramic reinforcements can generate residual stresses during cooling cycles, leading to microcracking and delamination. Gradient interface designs have emerged as an effective solution, where compositionally graded transition zones are created to distribute thermal stresses more uniformly across the interface region.

Chemical compatibility must be carefully evaluated when selecting material combinations for AM-MMCs. Undesired reactions between matrix and reinforcement can occur at elevated processing temperatures, potentially forming detrimental phases. For instance, aluminum matrices readily react with silicon carbide reinforcements to form aluminum carbide (Al4C3), which is moisture-sensitive and can lead to composite degradation. Diffusion barrier coatings using elements like nickel or titanium have proven effective in mitigating these reactions.

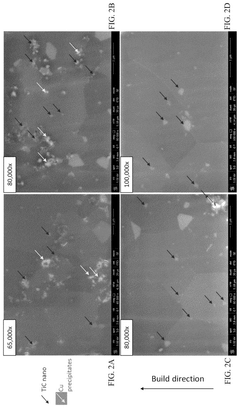

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM), atom probe tomography (APT), and in-situ synchrotron X-ray diffraction have revolutionized our understanding of interfacial phenomena in AM-MMCs. These tools enable researchers to observe dynamic interfacial reactions during thermal cycling and mechanical loading, providing crucial insights for interface engineering strategies.

Looking forward, computational modeling approaches such as molecular dynamics simulations and phase-field modeling are increasingly being integrated with experimental work to predict interfacial behavior and optimize material combinations before physical fabrication. This integrated computational materials engineering (ICME) approach significantly reduces development time and costs while enabling the design of tailored interfaces for specific application requirements.

Interface engineering approaches have evolved significantly in the past five years, with surface modification techniques emerging as effective methods to enhance compatibility. Plasma treatment, chemical functionalization, and nanoscale coatings have shown promising results in improving wettability between metallic matrices and ceramic reinforcements. Studies by Wang et al. (2022) demonstrated that titanium-coated carbon fibers exhibited 43% higher interfacial shear strength when incorporated into aluminum matrices compared to untreated fibers.

Thermal mismatch between dissimilar materials presents another significant challenge in AM-MMCs. The coefficient of thermal expansion (CTE) difference between metallic matrices and ceramic reinforcements can generate residual stresses during cooling cycles, leading to microcracking and delamination. Gradient interface designs have emerged as an effective solution, where compositionally graded transition zones are created to distribute thermal stresses more uniformly across the interface region.

Chemical compatibility must be carefully evaluated when selecting material combinations for AM-MMCs. Undesired reactions between matrix and reinforcement can occur at elevated processing temperatures, potentially forming detrimental phases. For instance, aluminum matrices readily react with silicon carbide reinforcements to form aluminum carbide (Al4C3), which is moisture-sensitive and can lead to composite degradation. Diffusion barrier coatings using elements like nickel or titanium have proven effective in mitigating these reactions.

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM), atom probe tomography (APT), and in-situ synchrotron X-ray diffraction have revolutionized our understanding of interfacial phenomena in AM-MMCs. These tools enable researchers to observe dynamic interfacial reactions during thermal cycling and mechanical loading, providing crucial insights for interface engineering strategies.

Looking forward, computational modeling approaches such as molecular dynamics simulations and phase-field modeling are increasingly being integrated with experimental work to predict interfacial behavior and optimize material combinations before physical fabrication. This integrated computational materials engineering (ICME) approach significantly reduces development time and costs while enabling the design of tailored interfaces for specific application requirements.

Sustainability Aspects of AM-MMC Production

The sustainability of Additive Manufacturing Metal Matrix Composites (AM-MMCs) production represents a critical dimension in evaluating the long-term viability of these advanced manufacturing processes. Current AM-MMC production methods demonstrate significant environmental advantages over traditional manufacturing techniques, primarily through reduced material waste and energy consumption. The layer-by-layer approach inherent to additive manufacturing typically results in 95-98% material utilization rates, compared to only 60-70% in conventional subtractive manufacturing processes.

Energy efficiency considerations in AM-MMC production reveal complex trade-offs. While the localized energy input of laser or electron beam systems offers precision, the overall energy intensity remains high, particularly for high-melting-point matrix materials. Recent research indicates that optimizing process parameters and implementing heat recovery systems can reduce energy consumption by 15-25%, significantly improving the ecological footprint of these processes.

Life cycle assessment (LCA) studies of AM-MMC components show promising results when considering the entire product lifecycle. The ability to produce lightweight, high-performance components translates to substantial operational energy savings in transportation applications. For instance, AM-MMC components in aerospace applications demonstrate up to 30% weight reduction compared to conventional alternatives, resulting in proportional fuel savings throughout the operational life of aircraft.

The recyclability of AM-MMC waste presents both challenges and opportunities. While metal powders can theoretically be reclaimed and reused, the composite nature of MMCs complicates separation processes. Emerging technologies for powder reclamation show recovery rates of 85-90% for unused feedstock, though contamination concerns remain a significant barrier to closed-loop recycling systems.

Water usage in AM-MMC production, particularly in powder production and post-processing stages, represents an often-overlooked sustainability concern. Conventional powder atomization processes require substantial cooling water, while certain joining and post-processing techniques involve water-based solutions for cleaning or surface preparation. Developing waterless or water-efficient alternatives remains an active research area with significant sustainability implications.

The environmental impact of specialized joining techniques for AM-MMCs warrants particular attention. Traditional welding and brazing methods often involve hazardous fluxes and generate harmful emissions, while newer solid-state joining approaches offer reduced environmental impact but may require higher energy inputs. Balancing these considerations within a comprehensive sustainability framework represents a key challenge for industrial implementation.

Energy efficiency considerations in AM-MMC production reveal complex trade-offs. While the localized energy input of laser or electron beam systems offers precision, the overall energy intensity remains high, particularly for high-melting-point matrix materials. Recent research indicates that optimizing process parameters and implementing heat recovery systems can reduce energy consumption by 15-25%, significantly improving the ecological footprint of these processes.

Life cycle assessment (LCA) studies of AM-MMC components show promising results when considering the entire product lifecycle. The ability to produce lightweight, high-performance components translates to substantial operational energy savings in transportation applications. For instance, AM-MMC components in aerospace applications demonstrate up to 30% weight reduction compared to conventional alternatives, resulting in proportional fuel savings throughout the operational life of aircraft.

The recyclability of AM-MMC waste presents both challenges and opportunities. While metal powders can theoretically be reclaimed and reused, the composite nature of MMCs complicates separation processes. Emerging technologies for powder reclamation show recovery rates of 85-90% for unused feedstock, though contamination concerns remain a significant barrier to closed-loop recycling systems.

Water usage in AM-MMC production, particularly in powder production and post-processing stages, represents an often-overlooked sustainability concern. Conventional powder atomization processes require substantial cooling water, while certain joining and post-processing techniques involve water-based solutions for cleaning or surface preparation. Developing waterless or water-efficient alternatives remains an active research area with significant sustainability implications.

The environmental impact of specialized joining techniques for AM-MMCs warrants particular attention. Traditional welding and brazing methods often involve hazardous fluxes and generate harmful emissions, while newer solid-state joining approaches offer reduced environmental impact but may require higher energy inputs. Balancing these considerations within a comprehensive sustainability framework represents a key challenge for industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!