Powder Feedstock Design For AM-Produced MMCs

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM-MMC Powder Feedstock Background and Objectives

Additive Manufacturing (AM) has revolutionized manufacturing processes across various industries, enabling the production of complex geometries with reduced material waste. Within this domain, Metal Matrix Composites (MMCs) represent a significant advancement, combining metallic matrices with reinforcement materials to achieve superior mechanical, thermal, and electrical properties compared to conventional metals and alloys. The development of powder feedstock specifically designed for AM-produced MMCs has emerged as a critical research area over the past decade.

The evolution of powder feedstock technology for MMCs can be traced back to traditional powder metallurgy techniques, which have been adapted and refined to meet the unique requirements of additive manufacturing processes. Early attempts at producing MMCs through AM faced challenges related to powder flowability, homogeneity of reinforcement distribution, and interfacial reactions between matrix and reinforcement materials during the high-energy AM processes.

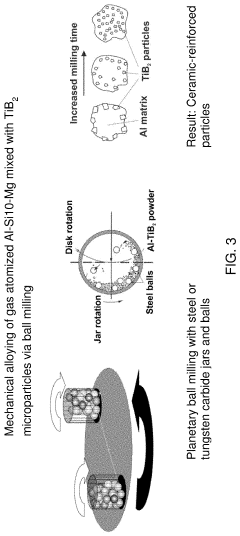

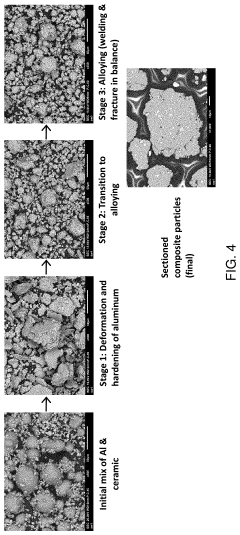

Recent technological advancements have focused on developing specialized powder feedstock preparation methods, including mechanical alloying, spray drying, and in-situ synthesis approaches. These methods aim to create powders with optimal particle size distribution, morphology, and reinforcement integration that can withstand the thermal cycles inherent in AM processes while maintaining the desired microstructural characteristics.

The primary objective of powder feedstock design for AM-produced MMCs is to achieve a balance between processability and final part performance. This involves optimizing powder characteristics such as flowability, packing density, and thermal behavior during laser or electron beam interaction, while ensuring that the reinforcement materials remain effectively distributed and bonded within the metal matrix after solidification.

Another crucial goal is to expand the range of compatible material combinations, enabling the production of MMCs with tailored properties for specific applications. This includes developing feedstock systems that can incorporate various reinforcement types (particles, whiskers, or fibers) and volume fractions while maintaining compatibility with different AM platforms such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), or Directed Energy Deposition (DED).

The technological trajectory points toward increasingly sophisticated powder feedstock designs that enable precise control over reinforcement distribution, orientation, and interfacial characteristics. Future developments aim to address current limitations related to thermal gradients, residual stresses, and microstructural heterogeneity in AM-produced MMCs, potentially through the incorporation of novel coating technologies, functionalized reinforcements, or hierarchical composite structures within the powder feedstock.

As industries continue to demand materials with enhanced performance characteristics, the development of advanced powder feedstock for AM-produced MMCs represents a strategic research direction with significant implications for aerospace, automotive, energy, and biomedical applications.

The evolution of powder feedstock technology for MMCs can be traced back to traditional powder metallurgy techniques, which have been adapted and refined to meet the unique requirements of additive manufacturing processes. Early attempts at producing MMCs through AM faced challenges related to powder flowability, homogeneity of reinforcement distribution, and interfacial reactions between matrix and reinforcement materials during the high-energy AM processes.

Recent technological advancements have focused on developing specialized powder feedstock preparation methods, including mechanical alloying, spray drying, and in-situ synthesis approaches. These methods aim to create powders with optimal particle size distribution, morphology, and reinforcement integration that can withstand the thermal cycles inherent in AM processes while maintaining the desired microstructural characteristics.

The primary objective of powder feedstock design for AM-produced MMCs is to achieve a balance between processability and final part performance. This involves optimizing powder characteristics such as flowability, packing density, and thermal behavior during laser or electron beam interaction, while ensuring that the reinforcement materials remain effectively distributed and bonded within the metal matrix after solidification.

Another crucial goal is to expand the range of compatible material combinations, enabling the production of MMCs with tailored properties for specific applications. This includes developing feedstock systems that can incorporate various reinforcement types (particles, whiskers, or fibers) and volume fractions while maintaining compatibility with different AM platforms such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), or Directed Energy Deposition (DED).

The technological trajectory points toward increasingly sophisticated powder feedstock designs that enable precise control over reinforcement distribution, orientation, and interfacial characteristics. Future developments aim to address current limitations related to thermal gradients, residual stresses, and microstructural heterogeneity in AM-produced MMCs, potentially through the incorporation of novel coating technologies, functionalized reinforcements, or hierarchical composite structures within the powder feedstock.

As industries continue to demand materials with enhanced performance characteristics, the development of advanced powder feedstock for AM-produced MMCs represents a strategic research direction with significant implications for aerospace, automotive, energy, and biomedical applications.

Market Analysis for AM-MMC Applications

The global market for Additive Manufacturing (AM) of Metal Matrix Composites (MMCs) is experiencing significant growth, driven by increasing demand for high-performance materials in aerospace, automotive, and industrial applications. The market size for AM-MMCs was valued at approximately $320 million in 2022 and is projected to reach $1.2 billion by 2030, representing a compound annual growth rate of 18.7% during the forecast period.

Aerospace remains the dominant application sector, accounting for nearly 40% of the total market share. The industry's stringent requirements for lightweight, high-strength materials with superior thermal properties make AM-MMCs particularly attractive. Major aerospace manufacturers are increasingly adopting these materials for critical components such as turbine blades, combustion chambers, and structural elements.

The automotive sector represents the fastest-growing segment, with a projected growth rate of 22% annually through 2030. This surge is primarily attributed to the electric vehicle revolution, where thermal management and weight reduction are crucial factors. AM-MMCs offer superior heat dissipation properties and strength-to-weight ratios compared to conventional materials, making them ideal for battery housings, motor components, and chassis elements.

Industrial applications, including tooling, energy, and defense sectors, collectively account for approximately 35% of the market. These sectors value the wear resistance, thermal stability, and customization capabilities that AM-MMCs provide. The tooling industry, in particular, has seen rapid adoption for applications requiring extended service life under extreme conditions.

Regionally, North America leads the market with a 42% share, followed by Europe (30%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization in China and India, along with significant investments in advanced manufacturing technologies.

Customer demand is increasingly focused on tailored MMC solutions with specific property profiles. End-users are willing to pay premium prices for materials that deliver precise performance characteristics, creating opportunities for specialized powder feedstock designs. The average price premium for customized AM-MMC materials ranges from 30-50% compared to standard metal powders.

Market challenges include high material costs, limited standardization, and concerns regarding reproducibility. These factors currently restrict wider adoption, particularly among small and medium-sized enterprises. However, ongoing research in powder feedstock design is expected to address these limitations, potentially expanding the addressable market by an additional 15-20% by 2028.

Aerospace remains the dominant application sector, accounting for nearly 40% of the total market share. The industry's stringent requirements for lightweight, high-strength materials with superior thermal properties make AM-MMCs particularly attractive. Major aerospace manufacturers are increasingly adopting these materials for critical components such as turbine blades, combustion chambers, and structural elements.

The automotive sector represents the fastest-growing segment, with a projected growth rate of 22% annually through 2030. This surge is primarily attributed to the electric vehicle revolution, where thermal management and weight reduction are crucial factors. AM-MMCs offer superior heat dissipation properties and strength-to-weight ratios compared to conventional materials, making them ideal for battery housings, motor components, and chassis elements.

Industrial applications, including tooling, energy, and defense sectors, collectively account for approximately 35% of the market. These sectors value the wear resistance, thermal stability, and customization capabilities that AM-MMCs provide. The tooling industry, in particular, has seen rapid adoption for applications requiring extended service life under extreme conditions.

Regionally, North America leads the market with a 42% share, followed by Europe (30%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization in China and India, along with significant investments in advanced manufacturing technologies.

Customer demand is increasingly focused on tailored MMC solutions with specific property profiles. End-users are willing to pay premium prices for materials that deliver precise performance characteristics, creating opportunities for specialized powder feedstock designs. The average price premium for customized AM-MMC materials ranges from 30-50% compared to standard metal powders.

Market challenges include high material costs, limited standardization, and concerns regarding reproducibility. These factors currently restrict wider adoption, particularly among small and medium-sized enterprises. However, ongoing research in powder feedstock design is expected to address these limitations, potentially expanding the addressable market by an additional 15-20% by 2028.

Current Challenges in Powder Feedstock for MMCs

Despite significant advancements in additive manufacturing (AM) technologies for metal matrix composites (MMCs), powder feedstock design remains a critical bottleneck limiting widespread industrial adoption. The heterogeneous nature of MMC powders presents substantial challenges in achieving consistent powder flow properties, which directly impacts process stability and reproducibility. Current powder mixing techniques struggle to maintain homogeneous distribution of reinforcement particles within the metal matrix, resulting in agglomeration issues that create structural weaknesses in final components.

Particle size compatibility between matrix and reinforcement materials represents another significant challenge. The optimal size ratio for ensuring proper bonding while maintaining flowability remains elusive, with most commercial solutions offering compromised performance. This incompatibility often leads to segregation during the powder spreading phase of AM processes, creating compositional gradients throughout the built part.

The reactivity between reinforcement particles and matrix materials during high-temperature AM processes introduces additional complications. Undesired interfacial reactions can form brittle intermetallic compounds that degrade mechanical properties. Current surface treatment methods for reinforcement particles provide insufficient protection against these reactions, particularly in laser-based AM systems where localized temperatures can exceed 2000°C.

Powder recyclability presents a substantial economic and sustainability challenge. The differential melting behavior between matrix and reinforcement materials results in selective consumption during processing, altering the composition of recycled powder. This compositional drift compromises quality consistency in subsequent builds, yet effective monitoring and compensation strategies remain underdeveloped.

Scalable production of specialized MMC powders faces significant hurdles in maintaining quality while reducing costs. Current production methods like mechanical alloying and spray atomization struggle to deliver consistent results at industrial scales. The high cost of specialized MMC powders (often 3-5 times higher than conventional metal powders) severely restricts broader adoption across manufacturing sectors.

Health and safety concerns associated with handling fine reinforcement particles (particularly ceramic nanoparticles) impose additional operational constraints. Current containment solutions often compromise powder handling efficiency, creating a difficult balance between safety protocols and manufacturing productivity.

Standardization remains notably absent in the MMC powder feedstock domain. The lack of universally accepted testing methodologies and quality metrics hampers cross-comparison between different powder solutions and slows industry-wide adoption. This standardization gap particularly affects newer reinforcement materials like carbon nanotubes and graphene, where quality assessment protocols are still evolving.

Particle size compatibility between matrix and reinforcement materials represents another significant challenge. The optimal size ratio for ensuring proper bonding while maintaining flowability remains elusive, with most commercial solutions offering compromised performance. This incompatibility often leads to segregation during the powder spreading phase of AM processes, creating compositional gradients throughout the built part.

The reactivity between reinforcement particles and matrix materials during high-temperature AM processes introduces additional complications. Undesired interfacial reactions can form brittle intermetallic compounds that degrade mechanical properties. Current surface treatment methods for reinforcement particles provide insufficient protection against these reactions, particularly in laser-based AM systems where localized temperatures can exceed 2000°C.

Powder recyclability presents a substantial economic and sustainability challenge. The differential melting behavior between matrix and reinforcement materials results in selective consumption during processing, altering the composition of recycled powder. This compositional drift compromises quality consistency in subsequent builds, yet effective monitoring and compensation strategies remain underdeveloped.

Scalable production of specialized MMC powders faces significant hurdles in maintaining quality while reducing costs. Current production methods like mechanical alloying and spray atomization struggle to deliver consistent results at industrial scales. The high cost of specialized MMC powders (often 3-5 times higher than conventional metal powders) severely restricts broader adoption across manufacturing sectors.

Health and safety concerns associated with handling fine reinforcement particles (particularly ceramic nanoparticles) impose additional operational constraints. Current containment solutions often compromise powder handling efficiency, creating a difficult balance between safety protocols and manufacturing productivity.

Standardization remains notably absent in the MMC powder feedstock domain. The lack of universally accepted testing methodologies and quality metrics hampers cross-comparison between different powder solutions and slows industry-wide adoption. This standardization gap particularly affects newer reinforcement materials like carbon nanotubes and graphene, where quality assessment protocols are still evolving.

Current Powder Design Solutions for Metal Matrix Composites

01 Powder feedstock composition for additive manufacturing

Specialized powder compositions designed for additive manufacturing processes such as 3D printing and selective laser sintering. These compositions typically include metal alloys, polymers, or ceramic materials with specific particle size distributions and flow characteristics to ensure optimal processing. The feedstock may contain binders, flow agents, and other additives to improve printability and final part properties.- Powder feedstock compositions for additive manufacturing: Various powder feedstock compositions have been developed specifically for additive manufacturing processes such as 3D printing and selective laser sintering. These compositions typically include metal, ceramic, or polymer powders with specific particle size distributions and morphologies to ensure optimal flowability and processability. The compositions may also include binders, surfactants, or other additives to improve the printing quality and final part properties.

- Powder delivery and dispensing systems: Specialized systems for delivering and dispensing powder feedstock materials have been developed for various industrial applications. These systems include mechanisms for controlling powder flow rates, preventing agglomeration, and ensuring uniform distribution. Features such as vibration assistance, pressurized chambers, and precision metering devices help maintain consistent powder delivery for manufacturing processes.

- Powder feedstock treatment and modification methods: Various methods for treating and modifying powder feedstock materials have been developed to enhance their properties and performance. These include thermal treatments, surface modifications, particle coating techniques, and granulation processes. Such treatments can improve flowability, reduce moisture sensitivity, enhance sintering behavior, and provide specific functional properties to the final products manufactured using these powders.

- Recycling and reuse of powder feedstock materials: Technologies and methods for recycling and reusing powder feedstock materials in manufacturing processes have been developed to improve sustainability and reduce costs. These include systems for collecting unused powder, removing contaminants, restoring particle properties, and blending with virgin material. Quality control methods ensure that recycled powder maintains the necessary characteristics for producing high-quality parts.

- Specialized powder feedstock formulations for specific applications: Customized powder feedstock formulations have been developed for specific industrial applications with unique requirements. These include biocompatible powders for medical implants, high-temperature resistant materials for aerospace components, electrically conductive formulations for electronic applications, and environmentally friendly alternatives to traditional materials. The formulations often combine multiple materials to achieve specific performance characteristics in the final products.

02 Powder delivery and handling systems

Systems and methods for storing, transporting, and dispensing powder feedstock materials in manufacturing processes. These include specialized hoppers, conveying mechanisms, and dispensing devices designed to maintain powder quality and ensure consistent flow rates. Such systems often incorporate features to prevent agglomeration, contamination, and segregation of powder particles during handling.Expand Specific Solutions03 Powder feedstock processing techniques

Methods for processing raw materials into powder feedstock with specific characteristics. These techniques include atomization, grinding, milling, and classification processes to achieve desired particle morphology, size distribution, and surface properties. Advanced processing may involve surface treatments, coating, or alloying to enhance the performance of the powder in subsequent manufacturing steps.Expand Specific Solutions04 Powder feedstock for thermal spray applications

Specialized powder materials formulated for thermal spray coating processes such as plasma spray, HVOF, and flame spray. These powders are designed with specific particle size ranges, morphologies, and compositions to create functional coatings with desired properties like wear resistance, thermal barriers, or corrosion protection. The feedstock may include metals, ceramics, cermets, or composite materials tailored for specific coating applications.Expand Specific Solutions05 Polymer and composite powder feedstock

Powder materials based on polymers or polymer-matrix composites for various manufacturing processes. These include thermoplastic and thermosetting polymers, often reinforced with fillers like glass fibers, carbon fibers, or mineral additives. Such feedstocks are formulated with specific melt flow properties, particle sizes, and additive packages to enhance processability and final product performance in applications ranging from rotational molding to selective laser sintering.Expand Specific Solutions

Leading Companies in AM-MMC Powder Development

The metal matrix composite (MMC) powder feedstock design for additive manufacturing is currently in a growth phase, with the market expanding rapidly due to increasing applications in aerospace, automotive, and defense sectors. The global market size for AM-produced MMCs is projected to reach significant value as industries seek lightweight, high-performance materials. Technologically, the field remains in early maturity, with leading players developing proprietary solutions. Companies like ArcelorMittal, Boeing, RTX Corp, and Divergent Technologies are advancing commercial applications, while research institutions such as Johns Hopkins University and Lawrence Livermore National Security are driving fundamental innovations. Chinese entities including Xian Bright Laser Technologies are making significant progress in powder development, creating a competitive global landscape where material design expertise and processing capabilities determine market leadership.

The Boeing Co.

Technical Solution: Boeing has developed a sophisticated powder feedstock design approach for metal matrix composites focused on aerospace applications requiring exceptional performance under extreme conditions. Their technology centers on aluminum and titanium-based matrices reinforced with precisely engineered ceramic particles to achieve specific property profiles. Boeing's approach incorporates a proprietary powder preparation method that utilizes controlled mechanical alloying to create intimate mixing between matrix and reinforcement materials while maintaining optimal particle morphology for AM processing. Their process includes specialized surface treatments for reinforcement particles that enhance wettability and bonding with the metal matrix while preventing unwanted chemical reactions during laser processing. Boeing has developed comprehensive powder characterization protocols that evaluate not just size distribution and morphology, but also dynamic flow characteristics under conditions that simulate the actual AM process. Their feedstock design includes precise control of oxygen content and moisture levels, with specialized handling protocols to prevent contamination. Boeing's MMC powders are designed with thermal management in mind, with tailored thermal conductivity pathways created through strategic reinforcement distribution patterns.

Strengths: Extensive experience in qualifying materials for flight-critical applications; vertical integration of material development with component design and testing; sophisticated modeling capabilities that predict material performance under complex loading conditions. Weaknesses: Solutions often optimized specifically for aerospace applications with less focus on cost-effectiveness for other industries; longer development and qualification cycles; proprietary nature of many technologies limits broader industry adoption.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security LLC has developed a sophisticated powder feedstock design approach for AM-produced MMCs focused on high-performance applications in defense and energy sectors. Their technology utilizes a multi-scale modeling framework that predicts optimal powder characteristics based on desired final part properties. LLNL's approach incorporates advanced powder synthesis techniques including chemical vapor deposition (CVD) coating of reinforcement particles to enhance matrix-reinforcement interfaces and prevent undesirable reactions during laser processing. They've pioneered the use of hierarchical reinforcement structures where nanoscale reinforcements are pre-integrated into microscale powder particles, creating multi-scale strengthening mechanisms. Their process includes precise control of oxygen content (typically maintained below 200ppm) and moisture levels to prevent processing defects. LLNL has developed specialized powder characterization techniques including dynamic X-ray imaging to understand powder behavior during laser interaction in real-time. Their feedstock designs have demonstrated success with refractory metal matrices (tungsten, molybdenum) reinforced with carbides and borides, achieving operating temperatures exceeding 2000°C while maintaining structural integrity.

Strengths: Cutting-edge computational modeling capabilities that accelerate material development; access to advanced characterization facilities including synchrotron radiation sources; strong scientific foundation with numerous peer-reviewed publications. Weaknesses: Technologies may be restricted due to national security considerations; solutions often prioritize performance over cost-effectiveness; limited commercial-scale production experience compared to industrial manufacturers.

Key Technical Innovations in MMC Powder Formulation

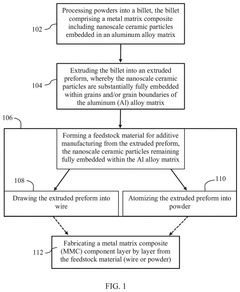

Method of fabricating a metal matrix composite (MMC) feedstock material for additive manufacturing, and method of additively manufacturing a MMC component

PatentPendingUS20250065399A1

Innovation

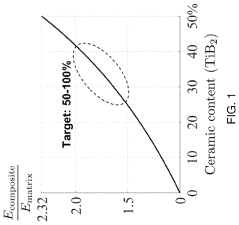

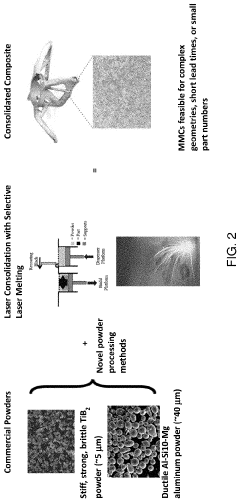

- A method involving the processing of powders into a billet using powder metallurgy, followed by extrusion to fully embed nanoscale ceramic particles within the aluminum alloy matrix, ensuring they remain embedded during the formation of feedstock materials for additive manufacturing.

Additive manufacturing of composite powders

PatentActiveUS20220134429A1

Innovation

- A method involving the mechanical alloying of metal and ceramic powders using high-energy ball milling to create a monodisperse alloyed powder, which is then laser sintered to form a composite with a high ceramic content, enabling the production of lightweight, high-strength materials with complex geometries and improved thermal stability.

Material Characterization Methods for AM-MMC Powders

Effective characterization of powder feedstock is critical for the successful development of metal matrix composites (MMCs) produced through additive manufacturing (AM) processes. The complex nature of these composite powders necessitates comprehensive analytical approaches to ensure optimal performance in final components.

Particle size distribution analysis represents a fundamental characterization method for AM-MMC powders, typically performed using laser diffraction techniques or dynamic image analysis. These methods provide critical data on D10, D50, and D90 values, which directly influence powder flowability, packing density, and ultimately the quality of printed parts. For MMC applications, maintaining appropriate size ratios between matrix and reinforcement particles is essential to achieve desired mechanical properties.

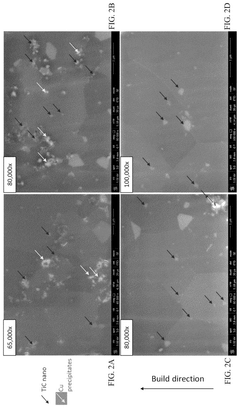

Morphological assessment through scanning electron microscopy (SEM) reveals crucial information about particle shape, surface roughness, and satellite formation. These characteristics significantly impact powder flowability and laser-powder interaction during the AM process. For MMC powders, morphological analysis also helps verify the distribution of reinforcement particles within or on the surface of matrix particles, which affects the homogeneity of the final composite structure.

Chemical composition verification using energy-dispersive X-ray spectroscopy (EDS), X-ray fluorescence (XRF), or inductively coupled plasma mass spectrometry (ICP-MS) ensures that powders meet specified elemental requirements. For MMCs, these techniques help confirm the presence and proportion of reinforcement materials and detect potential contaminants that could compromise mechanical properties or process stability.

Flowability and spreadability measurements using Hall flowmeter, angle of repose tests, or powder rheometers provide insights into how powders will perform during the AM process. These properties are particularly important for MMCs, as the addition of reinforcement particles often alters flow behavior compared to conventional metal powders, potentially affecting layer formation and density.

Thermal analysis techniques such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) help understand the melting behavior, phase transformations, and thermal stability of MMC powders. This information is crucial for optimizing process parameters, especially laser power and scan strategies, to achieve proper consolidation while maintaining the integrity of reinforcement phases.

Advanced characterization methods including X-ray diffraction (XRD) for crystallographic analysis and X-ray computed tomography (CT) for internal structure visualization provide deeper insights into MMC powder properties. These techniques help identify phase distributions, interfacial characteristics between matrix and reinforcement materials, and potential pre-existing defects that could affect final part performance.

Particle size distribution analysis represents a fundamental characterization method for AM-MMC powders, typically performed using laser diffraction techniques or dynamic image analysis. These methods provide critical data on D10, D50, and D90 values, which directly influence powder flowability, packing density, and ultimately the quality of printed parts. For MMC applications, maintaining appropriate size ratios between matrix and reinforcement particles is essential to achieve desired mechanical properties.

Morphological assessment through scanning electron microscopy (SEM) reveals crucial information about particle shape, surface roughness, and satellite formation. These characteristics significantly impact powder flowability and laser-powder interaction during the AM process. For MMC powders, morphological analysis also helps verify the distribution of reinforcement particles within or on the surface of matrix particles, which affects the homogeneity of the final composite structure.

Chemical composition verification using energy-dispersive X-ray spectroscopy (EDS), X-ray fluorescence (XRF), or inductively coupled plasma mass spectrometry (ICP-MS) ensures that powders meet specified elemental requirements. For MMCs, these techniques help confirm the presence and proportion of reinforcement materials and detect potential contaminants that could compromise mechanical properties or process stability.

Flowability and spreadability measurements using Hall flowmeter, angle of repose tests, or powder rheometers provide insights into how powders will perform during the AM process. These properties are particularly important for MMCs, as the addition of reinforcement particles often alters flow behavior compared to conventional metal powders, potentially affecting layer formation and density.

Thermal analysis techniques such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) help understand the melting behavior, phase transformations, and thermal stability of MMC powders. This information is crucial for optimizing process parameters, especially laser power and scan strategies, to achieve proper consolidation while maintaining the integrity of reinforcement phases.

Advanced characterization methods including X-ray diffraction (XRD) for crystallographic analysis and X-ray computed tomography (CT) for internal structure visualization provide deeper insights into MMC powder properties. These techniques help identify phase distributions, interfacial characteristics between matrix and reinforcement materials, and potential pre-existing defects that could affect final part performance.

Sustainability Aspects of MMC Powder Production

The sustainability of Metal Matrix Composite (MMC) powder production for additive manufacturing represents a critical consideration in the evolving landscape of advanced manufacturing technologies. Current production methods for MMC powders often involve energy-intensive processes with significant environmental footprints, necessitating a comprehensive sustainability assessment across the entire value chain.

Primary environmental concerns in MMC powder production include high energy consumption during atomization processes, where temperatures exceeding 1500°C are commonly required. This energy intensity translates to substantial carbon emissions, particularly when non-renewable energy sources power these operations. Additionally, the extraction and processing of rare or strategic metals used in MMCs, such as titanium, cobalt, and various rare earth elements, involve significant land disruption and potential ecosystem damage.

Water usage presents another sustainability challenge, with conventional powder production methods requiring substantial volumes for cooling and processing. Closed-loop water systems have emerged as a promising solution, potentially reducing freshwater consumption by 60-75% compared to traditional open systems. Similarly, material efficiency remains problematic, with typical powder production yields ranging from 60-85%, resulting in considerable waste generation.

Recent innovations are addressing these sustainability gaps through several approaches. Hydrogen-based reduction processes are replacing carbon-intensive methods, potentially reducing CO₂ emissions by 30-50%. Recycling pathways for metal powders are advancing, with technologies capable of reprocessing used powders while maintaining critical material properties. These developments are particularly significant for expensive reinforcement materials commonly used in MMCs.

Life cycle assessment (LCA) studies indicate that the environmental impact of MMC powder production can be reduced by 25-40% through implementation of renewable energy sources and optimized process parameters. Furthermore, the development of bio-derived binders and environmentally benign surfactants for powder processing represents an emerging frontier in sustainable MMC production.

Regulatory frameworks are increasingly influencing sustainability practices in MMC powder production. The European Union's Critical Raw Materials Act and similar regulations worldwide are driving manufacturers toward more sustainable sourcing and processing methods. Industry leaders are responding by establishing sustainability metrics and reporting standards specific to metal powder production, creating benchmarks for environmental performance.

The economic dimension of sustainability cannot be overlooked, as more sustainable production methods often command premium pricing initially but may offer long-term cost advantages through resource efficiency and regulatory compliance. This economic-environmental balance will significantly influence the adoption trajectory of sustainable MMC powder production technologies in coming years.

Primary environmental concerns in MMC powder production include high energy consumption during atomization processes, where temperatures exceeding 1500°C are commonly required. This energy intensity translates to substantial carbon emissions, particularly when non-renewable energy sources power these operations. Additionally, the extraction and processing of rare or strategic metals used in MMCs, such as titanium, cobalt, and various rare earth elements, involve significant land disruption and potential ecosystem damage.

Water usage presents another sustainability challenge, with conventional powder production methods requiring substantial volumes for cooling and processing. Closed-loop water systems have emerged as a promising solution, potentially reducing freshwater consumption by 60-75% compared to traditional open systems. Similarly, material efficiency remains problematic, with typical powder production yields ranging from 60-85%, resulting in considerable waste generation.

Recent innovations are addressing these sustainability gaps through several approaches. Hydrogen-based reduction processes are replacing carbon-intensive methods, potentially reducing CO₂ emissions by 30-50%. Recycling pathways for metal powders are advancing, with technologies capable of reprocessing used powders while maintaining critical material properties. These developments are particularly significant for expensive reinforcement materials commonly used in MMCs.

Life cycle assessment (LCA) studies indicate that the environmental impact of MMC powder production can be reduced by 25-40% through implementation of renewable energy sources and optimized process parameters. Furthermore, the development of bio-derived binders and environmentally benign surfactants for powder processing represents an emerging frontier in sustainable MMC production.

Regulatory frameworks are increasingly influencing sustainability practices in MMC powder production. The European Union's Critical Raw Materials Act and similar regulations worldwide are driving manufacturers toward more sustainable sourcing and processing methods. Industry leaders are responding by establishing sustainability metrics and reporting standards specific to metal powder production, creating benchmarks for environmental performance.

The economic dimension of sustainability cannot be overlooked, as more sustainable production methods often command premium pricing initially but may offer long-term cost advantages through resource efficiency and regulatory compliance. This economic-environmental balance will significantly influence the adoption trajectory of sustainable MMC powder production technologies in coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!