Hybrid AM Processes For High-Performance MMC Components

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid AM Evolution and Objectives

Hybrid Additive Manufacturing (HAM) has emerged as a transformative approach in the manufacturing landscape over the past decade. The evolution of HAM technologies began in the early 2000s with rudimentary combinations of additive and subtractive processes, primarily focused on polymer-based materials. By 2010, researchers had begun exploring metal-based hybrid systems, marking a significant shift toward high-performance applications.

The technological progression accelerated around 2015 when major industrial players like GE, Siemens, and DMG MORI introduced commercial hybrid systems combining directed energy deposition with CNC machining capabilities. This period represented a crucial inflection point, as these systems demonstrated the feasibility of producing complex metal components with improved surface finish and dimensional accuracy compared to traditional AM processes.

For metal matrix composites (MMCs), the evolution has been particularly noteworthy. Initial efforts focused on ex-situ reinforcement approaches, where pre-fabricated reinforcement materials were incorporated into metal matrices during the build process. Recent advancements have shifted toward in-situ reinforcement techniques, enabling the formation of reinforcement phases during the deposition process itself, resulting in more homogeneous microstructures and enhanced mechanical properties.

The primary objective of current hybrid AM research for MMCs is to develop integrated manufacturing processes that can simultaneously address multiple challenges: achieving complex geometries, ensuring dimensional accuracy, optimizing material properties, and maintaining production efficiency. Specifically, researchers aim to overcome the limitations of traditional manufacturing methods in producing high-performance MMC components with tailored properties for aerospace, automotive, and defense applications.

Another critical objective is to establish process parameters that enable precise control over the microstructure and composition of MMCs throughout the component volume. This includes developing strategies for gradient materials where reinforcement concentration varies spatially to optimize local mechanical properties according to specific loading conditions.

Looking forward, the field is moving toward closed-loop control systems that integrate real-time monitoring and feedback mechanisms to ensure consistent quality and properties. The ultimate goal is to create manufacturing platforms capable of producing certified MMC components with predictable performance characteristics that meet or exceed those of conventionally manufactured counterparts, while simultaneously offering design freedom and reduced material waste.

The technological progression accelerated around 2015 when major industrial players like GE, Siemens, and DMG MORI introduced commercial hybrid systems combining directed energy deposition with CNC machining capabilities. This period represented a crucial inflection point, as these systems demonstrated the feasibility of producing complex metal components with improved surface finish and dimensional accuracy compared to traditional AM processes.

For metal matrix composites (MMCs), the evolution has been particularly noteworthy. Initial efforts focused on ex-situ reinforcement approaches, where pre-fabricated reinforcement materials were incorporated into metal matrices during the build process. Recent advancements have shifted toward in-situ reinforcement techniques, enabling the formation of reinforcement phases during the deposition process itself, resulting in more homogeneous microstructures and enhanced mechanical properties.

The primary objective of current hybrid AM research for MMCs is to develop integrated manufacturing processes that can simultaneously address multiple challenges: achieving complex geometries, ensuring dimensional accuracy, optimizing material properties, and maintaining production efficiency. Specifically, researchers aim to overcome the limitations of traditional manufacturing methods in producing high-performance MMC components with tailored properties for aerospace, automotive, and defense applications.

Another critical objective is to establish process parameters that enable precise control over the microstructure and composition of MMCs throughout the component volume. This includes developing strategies for gradient materials where reinforcement concentration varies spatially to optimize local mechanical properties according to specific loading conditions.

Looking forward, the field is moving toward closed-loop control systems that integrate real-time monitoring and feedback mechanisms to ensure consistent quality and properties. The ultimate goal is to create manufacturing platforms capable of producing certified MMC components with predictable performance characteristics that meet or exceed those of conventionally manufactured counterparts, while simultaneously offering design freedom and reduced material waste.

Market Analysis for MMC Components

The global market for Metal Matrix Composite (MMC) components is experiencing robust growth, driven primarily by increasing demand from aerospace, automotive, and defense sectors. Current market valuations place the MMC component industry at approximately $500 million, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching $800 million by the end of the forecast period.

Aerospace applications represent the largest market segment, accounting for nearly 40% of total MMC component consumption. This dominance stems from the critical need for lightweight, high-strength materials capable of withstanding extreme operating conditions. The automotive sector follows closely, comprising about 30% of the market, with particular emphasis on performance vehicles and electric vehicle battery enclosures where thermal management properties of MMCs provide significant advantages.

Regional analysis reveals North America as the leading market for MMC components, holding approximately 35% market share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India making substantial investments in advanced manufacturing capabilities to support their expanding aerospace and automotive industries.

Customer demand patterns indicate a growing preference for customized MMC solutions with specific property profiles tailored to application requirements. This trend aligns perfectly with the capabilities of hybrid additive manufacturing processes, which offer unprecedented design flexibility and material property customization compared to traditional manufacturing methods.

Price sensitivity varies significantly across application sectors. While aerospace and defense customers prioritize performance over cost, automotive manufacturers seek a more balanced cost-performance ratio, creating distinct market segments with different value propositions. The average price premium for MMC components over conventional alternatives ranges from 30% to 120%, depending on complexity and performance requirements.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements and specialized reinforcement materials. These constraints may impact market growth if not addressed through material innovation or supply diversification strategies. Additionally, regulatory frameworks regarding recyclability and end-of-life management of MMC components are evolving, potentially creating both challenges and opportunities for market participants.

Competitive intelligence indicates increasing market consolidation, with major materials science corporations expanding their MMC capabilities through strategic acquisitions of specialized manufacturers. This trend suggests growing recognition of the market's long-term potential and the strategic importance of establishing early technological leadership in hybrid additive manufacturing processes for MMC components.

Aerospace applications represent the largest market segment, accounting for nearly 40% of total MMC component consumption. This dominance stems from the critical need for lightweight, high-strength materials capable of withstanding extreme operating conditions. The automotive sector follows closely, comprising about 30% of the market, with particular emphasis on performance vehicles and electric vehicle battery enclosures where thermal management properties of MMCs provide significant advantages.

Regional analysis reveals North America as the leading market for MMC components, holding approximately 35% market share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India making substantial investments in advanced manufacturing capabilities to support their expanding aerospace and automotive industries.

Customer demand patterns indicate a growing preference for customized MMC solutions with specific property profiles tailored to application requirements. This trend aligns perfectly with the capabilities of hybrid additive manufacturing processes, which offer unprecedented design flexibility and material property customization compared to traditional manufacturing methods.

Price sensitivity varies significantly across application sectors. While aerospace and defense customers prioritize performance over cost, automotive manufacturers seek a more balanced cost-performance ratio, creating distinct market segments with different value propositions. The average price premium for MMC components over conventional alternatives ranges from 30% to 120%, depending on complexity and performance requirements.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements and specialized reinforcement materials. These constraints may impact market growth if not addressed through material innovation or supply diversification strategies. Additionally, regulatory frameworks regarding recyclability and end-of-life management of MMC components are evolving, potentially creating both challenges and opportunities for market participants.

Competitive intelligence indicates increasing market consolidation, with major materials science corporations expanding their MMC capabilities through strategic acquisitions of specialized manufacturers. This trend suggests growing recognition of the market's long-term potential and the strategic importance of establishing early technological leadership in hybrid additive manufacturing processes for MMC components.

Technical Barriers in Hybrid Metal AM

Despite significant advancements in hybrid additive manufacturing (AM) for metal matrix composites (MMCs), several critical technical barriers continue to impede widespread industrial adoption. The integration of multiple manufacturing processes introduces complex challenges that require innovative solutions to achieve high-performance components.

Material compatibility issues represent a fundamental barrier in hybrid metal AM processes. The disparate thermal properties between matrix materials and reinforcement phases often lead to residual stresses, microcracking, and delamination during fabrication. This incompatibility is particularly pronounced when combining dissimilar metals or incorporating ceramic reinforcements into metallic matrices, resulting in weak interfacial bonding and compromised mechanical integrity.

Process parameter optimization remains exceptionally challenging due to the multivariable nature of hybrid manufacturing. Each integrated process introduces its own set of parameters that interact in complex, often unpredictable ways. The parameter space becomes exponentially larger compared to single-process AM, making traditional trial-and-error approaches impractical and necessitating advanced modeling and machine learning techniques for efficient optimization.

Thermal management presents another significant barrier. The repeated heating and cooling cycles inherent in layer-by-layer processing create thermal gradients that can lead to distortion, warping, and undesirable microstructural changes. These effects are amplified in hybrid processes where different thermal histories are imposed by sequential manufacturing steps, potentially degrading the carefully engineered properties of previously processed regions.

Equipment integration and process synchronization pose substantial engineering challenges. Current hybrid systems often consist of modified or combined standalone machines rather than purpose-built integrated platforms. This results in alignment issues, calibration difficulties, and process interruptions that compromise dimensional accuracy and surface quality. The lack of standardized interfaces between different manufacturing modules further complicates system integration.

Quality control and in-situ monitoring capabilities remain underdeveloped for hybrid processes. The complex nature of multi-process manufacturing makes it difficult to implement effective real-time monitoring systems that can detect defects across different process stages. This limitation hinders closed-loop control implementation and makes quality assurance particularly challenging for high-performance applications where reliability is paramount.

Scalability and cost-effectiveness represent persistent barriers to industrial adoption. Current hybrid AM systems typically have low throughput and high operational costs compared to conventional manufacturing methods. The complexity of equipment, specialized material requirements, and extensive post-processing needs contribute to economic barriers that must be overcome to enable broader implementation in production environments.

Material compatibility issues represent a fundamental barrier in hybrid metal AM processes. The disparate thermal properties between matrix materials and reinforcement phases often lead to residual stresses, microcracking, and delamination during fabrication. This incompatibility is particularly pronounced when combining dissimilar metals or incorporating ceramic reinforcements into metallic matrices, resulting in weak interfacial bonding and compromised mechanical integrity.

Process parameter optimization remains exceptionally challenging due to the multivariable nature of hybrid manufacturing. Each integrated process introduces its own set of parameters that interact in complex, often unpredictable ways. The parameter space becomes exponentially larger compared to single-process AM, making traditional trial-and-error approaches impractical and necessitating advanced modeling and machine learning techniques for efficient optimization.

Thermal management presents another significant barrier. The repeated heating and cooling cycles inherent in layer-by-layer processing create thermal gradients that can lead to distortion, warping, and undesirable microstructural changes. These effects are amplified in hybrid processes where different thermal histories are imposed by sequential manufacturing steps, potentially degrading the carefully engineered properties of previously processed regions.

Equipment integration and process synchronization pose substantial engineering challenges. Current hybrid systems often consist of modified or combined standalone machines rather than purpose-built integrated platforms. This results in alignment issues, calibration difficulties, and process interruptions that compromise dimensional accuracy and surface quality. The lack of standardized interfaces between different manufacturing modules further complicates system integration.

Quality control and in-situ monitoring capabilities remain underdeveloped for hybrid processes. The complex nature of multi-process manufacturing makes it difficult to implement effective real-time monitoring systems that can detect defects across different process stages. This limitation hinders closed-loop control implementation and makes quality assurance particularly challenging for high-performance applications where reliability is paramount.

Scalability and cost-effectiveness represent persistent barriers to industrial adoption. Current hybrid AM systems typically have low throughput and high operational costs compared to conventional manufacturing methods. The complexity of equipment, specialized material requirements, and extensive post-processing needs contribute to economic barriers that must be overcome to enable broader implementation in production environments.

Current Hybrid AM Solutions for MMC Components

01 Laser-based hybrid additive manufacturing for MMCs

Laser-based hybrid additive manufacturing processes combine laser technology with other manufacturing methods to produce high-performance metal matrix composites. These processes include laser metal deposition, laser sintering, and laser cladding, which enable precise control over material properties and microstructure. The integration of laser technology allows for localized heating and rapid solidification, resulting in enhanced mechanical properties and reduced thermal distortion in the final MMC components.- Laser-based hybrid additive manufacturing for MMCs: Laser-based hybrid additive manufacturing processes combine laser technology with other manufacturing methods to produce high-performance metal matrix composites. These processes include laser metal deposition, selective laser melting, and laser-assisted techniques that enable precise control over material properties. The integration of laser technology allows for enhanced microstructural control, improved bonding between matrix and reinforcement materials, and the ability to create complex geometries with superior mechanical properties.

- Powder-based hybrid manufacturing techniques for MMCs: Powder-based hybrid manufacturing techniques combine traditional powder metallurgy with advanced additive manufacturing processes to create high-performance metal matrix composites. These methods involve the precise deposition and consolidation of metal powders and reinforcement materials layer by layer. The techniques allow for controlled distribution of reinforcement particles, customized material compositions, and the ability to create functionally graded materials with optimized properties for specific applications.

- Friction-based hybrid processes for MMC fabrication: Friction-based hybrid processes combine friction stir processing or welding with additive manufacturing techniques to produce high-performance metal matrix composites. These processes utilize mechanical energy to create localized heating and plastic deformation, facilitating the incorporation and distribution of reinforcement materials within the metal matrix. The resulting composites exhibit enhanced mechanical properties, improved wear resistance, and superior thermal stability compared to conventionally manufactured materials.

- Ultrasonic-assisted hybrid additive manufacturing for MMCs: Ultrasonic-assisted hybrid additive manufacturing processes incorporate ultrasonic vibrations during the deposition or consolidation stages to enhance the properties of metal matrix composites. The ultrasonic energy improves the dispersion of reinforcement particles, reduces porosity, and promotes grain refinement in the metal matrix. This approach results in MMCs with improved mechanical properties, enhanced bonding between matrix and reinforcements, and more uniform microstructures suitable for high-performance applications.

- Multi-material hybrid additive manufacturing for functionally graded MMCs: Multi-material hybrid additive manufacturing processes enable the production of functionally graded metal matrix composites with spatially varying compositions and properties. These techniques combine different additive manufacturing methods to deposit and consolidate multiple materials simultaneously or sequentially. The resulting MMCs feature tailored properties in specific regions, allowing for optimized performance characteristics such as enhanced wear resistance, improved thermal management, and superior mechanical strength in targeted areas of the component.

02 Powder-based hybrid manufacturing techniques for MMCs

Powder-based hybrid manufacturing techniques involve the combination of powder metallurgy with additive manufacturing processes to create high-performance metal matrix composites. These techniques utilize metal powders as the matrix material and incorporate reinforcement particles to enhance mechanical properties. The hybrid approach allows for better control over the distribution of reinforcement particles within the metal matrix, resulting in improved strength, wear resistance, and thermal stability of the final MMC components.Expand Specific Solutions03 Friction stir processing combined with additive manufacturing

The integration of friction stir processing with additive manufacturing creates a hybrid process for producing high-performance metal matrix composites. This approach uses the mechanical stirring action of friction stir processing to achieve uniform dispersion of reinforcement particles within the metal matrix. The combination with additive manufacturing allows for complex geometries while maintaining excellent mechanical properties. This hybrid process results in MMCs with improved strength, ductility, and wear resistance compared to conventional manufacturing methods.Expand Specific Solutions04 In-situ reinforcement formation during hybrid additive manufacturing

In-situ reinforcement formation during hybrid additive manufacturing involves chemical reactions that occur during the manufacturing process to create reinforcement phases within the metal matrix. This approach eliminates the need for pre-mixed composite powders and allows for better interfacial bonding between the matrix and reinforcement. The controlled formation of reinforcement phases during the manufacturing process results in MMCs with enhanced mechanical properties, thermal stability, and wear resistance, making them suitable for high-performance applications.Expand Specific Solutions05 Multi-material deposition strategies for functionally graded MMCs

Multi-material deposition strategies in hybrid additive manufacturing enable the production of functionally graded metal matrix composites with spatially varying compositions and properties. These strategies involve the controlled deposition of different materials or varying concentrations of reinforcement particles throughout the component. The resulting functionally graded MMCs exhibit tailored properties in different regions, such as wear resistance in surface areas and toughness in core regions, making them ideal for high-performance applications with complex loading conditions.Expand Specific Solutions

Leading Companies in Hybrid AM and MMC Production

Hybrid Additive Manufacturing for Metal Matrix Composites is currently in an early growth phase, with the market expected to reach $500 million by 2028. The technology maturity varies across applications, with aerospace leading adoption. Key players demonstrate different specialization levels: GE, RTX, and Lockheed Martin focus on aerospace applications; Airbus and Spirit AeroSystems are developing lightweight structural components; while academic institutions like Nanjing Tech University and Harbin Institute of Technology are advancing fundamental research. Alvant and Advanced Composite Co. are pioneering specialized MMC solutions, while automotive manufacturers (Volkswagen, Volvo) are exploring weight reduction applications. The competitive landscape shows a balance between established aerospace corporations, specialized material developers, and research institutions driving innovation.

General Electric Company

Technical Solution: General Electric has developed a comprehensive hybrid additive manufacturing approach for metal matrix composites (MMCs) that combines direct metal laser sintering (DMLS) with infiltration casting techniques. Their process utilizes a two-step methodology where a porous metal scaffold is first created using DMLS, followed by precision infiltration of secondary phase materials to form high-performance MMCs. GE's proprietary system incorporates in-situ monitoring with thermal imaging cameras and laser profilometry to ensure dimensional accuracy and material integrity throughout the manufacturing process. The company has successfully implemented this technology in aerospace components, particularly for jet engine parts requiring exceptional heat resistance and mechanical properties. Their process allows for complex internal cooling channels and optimized microstructures that would be impossible with conventional manufacturing. GE has reported up to 30% weight reduction in certain components while maintaining or improving mechanical properties compared to traditional superalloys.

Strengths: GE's extensive experience in aerospace applications provides deep domain knowledge for critical applications. Their integrated quality control systems ensure high reliability for safety-critical components. Weaknesses: The process requires significant capital investment and specialized expertise, limiting accessibility. Processing times remain longer than conventional manufacturing, affecting production throughput.

RTX Corp.

Technical Solution: RTX Corp. (formerly Raytheon Technologies) has pioneered a hybrid additive manufacturing approach for MMCs that integrates directed energy deposition (DED) with friction stir processing (FSP). Their system utilizes a multi-material deposition head capable of precisely controlling the distribution of reinforcement particles within the metal matrix. The process begins with DED to create near-net-shape components with controlled reinforcement distribution, followed by FSP to refine the microstructure and eliminate porosity. RTX's technology incorporates real-time adaptive control systems that monitor thermal conditions and adjust processing parameters accordingly, ensuring consistent material properties throughout complex geometries. This approach has been particularly successful for high-temperature aerospace applications, including missile components and propulsion systems. RTX has documented improvements in thermal stability up to 200°C higher than conventional alloys, while maintaining excellent mechanical properties and corrosion resistance. The company has also developed specialized post-processing techniques to optimize surface finish and dimensional accuracy.

Strengths: RTX's dual-process approach achieves superior microstructural control and near-zero porosity in final components. Their adaptive control systems enable consistent quality across varying geometries. Weaknesses: The multi-step process increases manufacturing time and cost compared to single-process approaches. The technology requires specialized equipment that limits widespread adoption outside aerospace and defense sectors.

Key Patents in Hybrid Metal Matrix Composite Manufacturing

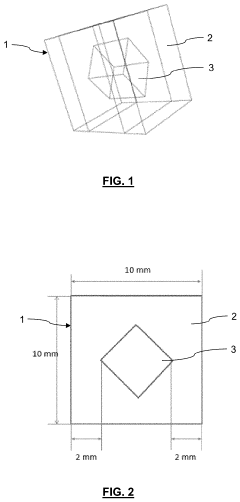

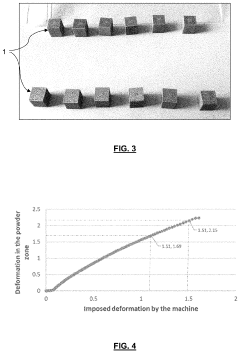

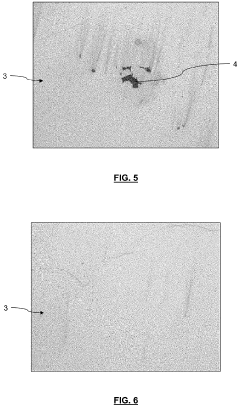

Method for the production of parts made from metal or metal matrix composite and resulting from additive manufacturing followed by an operation involving the forging of said parts

PatentInactiveUS20220097139A1

Innovation

- Combining additive manufacturing with a single-step forging process between two dies, where a preform with unbonded powder is deformed and bonded in a solid phase, applying true strain greater than 1.5 and pressure between 30 MPa and 700 MPa, to achieve the final shape and close porosities, thereby avoiding the limitations of traditional additive manufacturing.

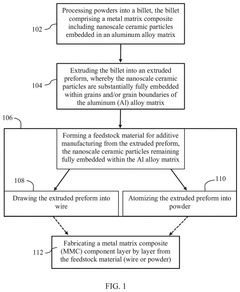

Method of fabricating a metal matrix composite (MMC) feedstock material for additive manufacturing, and method of additively manufacturing a MMC component

PatentPendingUS20250065399A1

Innovation

- A method involving the processing of powders into a billet using powder metallurgy, followed by extrusion to fully embed nanoscale ceramic particles within the aluminum alloy matrix, ensuring they remain embedded during the formation of feedstock materials for additive manufacturing.

Material Characterization and Quality Control Methods

Material characterization and quality control represent critical aspects in the development of hybrid additive manufacturing processes for high-performance metal matrix composite components. The complex nature of these composites, combining metallic matrices with reinforcement materials, necessitates sophisticated analytical techniques to ensure consistent quality and performance.

X-ray computed tomography (XCT) has emerged as a powerful non-destructive testing method for examining the internal structure of metal matrix composites. This technique provides three-dimensional visualization of reinforcement distribution, porosity levels, and interfacial bonding quality. Recent advancements in high-resolution XCT systems allow for detection of defects as small as 1-5 μm, critical for identifying potential failure points in high-performance components.

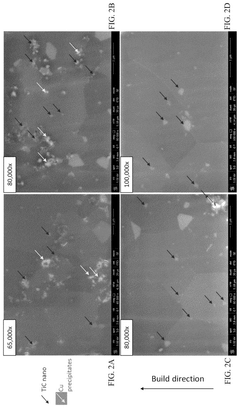

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed microstructural analysis and elemental mapping of hybrid manufactured components. These techniques are particularly valuable for characterizing the matrix-reinforcement interface, where mechanical properties are often determined. The integration of electron backscatter diffraction (EBSD) further enables grain structure analysis, essential for understanding the unique microstructures formed during hybrid manufacturing processes.

Mechanical property verification through standardized testing protocols represents another crucial quality control measure. Tensile, compression, and fatigue testing provide quantitative assessment of component performance, while hardness mapping across different regions helps identify potential weak points or inconsistencies in the manufacturing process. Nanoindentation techniques have gained prominence for characterizing local mechanical properties at the microstructural level.

In-situ monitoring systems have revolutionized quality control in hybrid additive manufacturing. Thermal imaging cameras, high-speed photography, and acoustic emission sensors provide real-time data during the manufacturing process, enabling early detection of defects and process instabilities. Machine learning algorithms increasingly complement these systems by identifying patterns and anomalies that might escape human observation.

Residual stress measurement techniques, including neutron diffraction and hole-drilling methods, address a significant challenge in hybrid manufacturing processes. Understanding and controlling residual stresses is essential for preventing warpage, delamination, and premature failure in metal matrix composite components.

Standardization efforts are gradually emerging to establish consistent quality control protocols specific to hybrid additive manufacturing. Organizations such as ASTM International and ISO are developing specialized standards that address the unique challenges of these advanced manufacturing processes, providing a framework for industry-wide quality assurance.

X-ray computed tomography (XCT) has emerged as a powerful non-destructive testing method for examining the internal structure of metal matrix composites. This technique provides three-dimensional visualization of reinforcement distribution, porosity levels, and interfacial bonding quality. Recent advancements in high-resolution XCT systems allow for detection of defects as small as 1-5 μm, critical for identifying potential failure points in high-performance components.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed microstructural analysis and elemental mapping of hybrid manufactured components. These techniques are particularly valuable for characterizing the matrix-reinforcement interface, where mechanical properties are often determined. The integration of electron backscatter diffraction (EBSD) further enables grain structure analysis, essential for understanding the unique microstructures formed during hybrid manufacturing processes.

Mechanical property verification through standardized testing protocols represents another crucial quality control measure. Tensile, compression, and fatigue testing provide quantitative assessment of component performance, while hardness mapping across different regions helps identify potential weak points or inconsistencies in the manufacturing process. Nanoindentation techniques have gained prominence for characterizing local mechanical properties at the microstructural level.

In-situ monitoring systems have revolutionized quality control in hybrid additive manufacturing. Thermal imaging cameras, high-speed photography, and acoustic emission sensors provide real-time data during the manufacturing process, enabling early detection of defects and process instabilities. Machine learning algorithms increasingly complement these systems by identifying patterns and anomalies that might escape human observation.

Residual stress measurement techniques, including neutron diffraction and hole-drilling methods, address a significant challenge in hybrid manufacturing processes. Understanding and controlling residual stresses is essential for preventing warpage, delamination, and premature failure in metal matrix composite components.

Standardization efforts are gradually emerging to establish consistent quality control protocols specific to hybrid additive manufacturing. Organizations such as ASTM International and ISO are developing specialized standards that address the unique challenges of these advanced manufacturing processes, providing a framework for industry-wide quality assurance.

Sustainability Aspects of Hybrid AM Processes

Sustainability considerations are increasingly becoming central to manufacturing processes, and hybrid additive manufacturing (AM) for metal matrix composites (MMCs) presents both challenges and opportunities in this domain. The integration of multiple manufacturing techniques in hybrid AM processes offers potential sustainability advantages through material efficiency improvements and waste reduction compared to traditional manufacturing methods.

Energy consumption represents a significant sustainability concern in hybrid AM processes for MMCs. These processes typically combine energy-intensive techniques such as laser powder bed fusion or directed energy deposition with conventional manufacturing methods. Research indicates that optimizing process parameters and developing more efficient energy management systems could reduce energy requirements by 15-30% compared to current implementations, significantly lowering the carbon footprint of component production.

Material utilization efficiency stands as a key sustainability advantage of hybrid AM processes. Unlike conventional subtractive manufacturing that can waste up to 90% of raw materials for complex components, hybrid AM approaches for MMCs demonstrate material utilization rates of 80-95%. This efficiency is particularly important considering the rare and strategic metals often incorporated in high-performance MMCs, such as titanium, nickel, and cobalt-based alloys reinforced with ceramic particles.

The lifecycle assessment of hybrid AM processes reveals promising environmental benefits. Studies comparing traditional manufacturing with hybrid AM for MMC components show potential reductions in greenhouse gas emissions by 25-40% across the entire product lifecycle. This improvement stems from reduced material waste, localized production capabilities, and the potential for component lightweighting that reduces environmental impacts during the use phase.

Recycling and circular economy principles present both opportunities and challenges for hybrid AM MMC components. The complex material compositions in MMCs can complicate end-of-life recycling processes. However, emerging technologies for material separation and recovery show promise for improving recyclability rates. Additionally, hybrid AM processes enable design optimization for disassembly and material recovery, supporting circular economy principles.

Water usage in hybrid AM processes for MMCs is generally lower than in conventional manufacturing, particularly for processes that eliminate or reduce coolant requirements. However, certain hybrid approaches incorporating electrochemical or chemical processes may introduce water quality concerns that require careful management and treatment systems to minimize environmental impact.

Energy consumption represents a significant sustainability concern in hybrid AM processes for MMCs. These processes typically combine energy-intensive techniques such as laser powder bed fusion or directed energy deposition with conventional manufacturing methods. Research indicates that optimizing process parameters and developing more efficient energy management systems could reduce energy requirements by 15-30% compared to current implementations, significantly lowering the carbon footprint of component production.

Material utilization efficiency stands as a key sustainability advantage of hybrid AM processes. Unlike conventional subtractive manufacturing that can waste up to 90% of raw materials for complex components, hybrid AM approaches for MMCs demonstrate material utilization rates of 80-95%. This efficiency is particularly important considering the rare and strategic metals often incorporated in high-performance MMCs, such as titanium, nickel, and cobalt-based alloys reinforced with ceramic particles.

The lifecycle assessment of hybrid AM processes reveals promising environmental benefits. Studies comparing traditional manufacturing with hybrid AM for MMC components show potential reductions in greenhouse gas emissions by 25-40% across the entire product lifecycle. This improvement stems from reduced material waste, localized production capabilities, and the potential for component lightweighting that reduces environmental impacts during the use phase.

Recycling and circular economy principles present both opportunities and challenges for hybrid AM MMC components. The complex material compositions in MMCs can complicate end-of-life recycling processes. However, emerging technologies for material separation and recovery show promise for improving recyclability rates. Additionally, hybrid AM processes enable design optimization for disassembly and material recovery, supporting circular economy principles.

Water usage in hybrid AM processes for MMCs is generally lower than in conventional manufacturing, particularly for processes that eliminate or reduce coolant requirements. However, certain hybrid approaches incorporating electrochemical or chemical processes may introduce water quality concerns that require careful management and treatment systems to minimize environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!