Comparative Study of Solenoid and Servo Valves in Industrial Robotics

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid vs Servo Valves: Background and Objectives

The field of industrial robotics has witnessed significant advancements in recent years, with valve technology playing a crucial role in enhancing the precision and efficiency of robotic systems. This comparative study focuses on two key valve technologies: solenoid valves and servo valves, both of which have found extensive applications in industrial robotics.

Solenoid valves, introduced in the early 20th century, have been a staple in industrial automation for decades. These electromechanical devices use an electromagnetic coil to control the movement of a plunger, which in turn regulates the flow of fluids or gases. Their simplicity, reliability, and cost-effectiveness have made them a popular choice in various robotic applications, particularly in pneumatic systems.

Servo valves, on the other hand, emerged in the mid-20th century as a more sophisticated alternative. These valves utilize closed-loop feedback control to achieve precise positioning and flow control. By incorporating sensors and advanced control algorithms, servo valves offer superior accuracy and responsiveness compared to their solenoid counterparts.

The evolution of both technologies has been driven by the increasing demands of industrial robotics for higher precision, faster response times, and improved energy efficiency. As robotic systems become more complex and versatile, the need for advanced valve technologies has grown exponentially. This has led to continuous innovations in both solenoid and servo valve designs, pushing the boundaries of their capabilities and applications.

The primary objective of this comparative study is to provide a comprehensive analysis of solenoid and servo valves within the context of industrial robotics. By examining their respective strengths, limitations, and areas of application, we aim to offer valuable insights for engineers, researchers, and decision-makers in the field.

This study will explore the fundamental principles underlying each technology, their current state of development, and the challenges they face in meeting the evolving requirements of industrial robotics. Additionally, we will investigate the market trends, key players, and future prospects for both solenoid and servo valves in the robotics industry.

By conducting this in-depth comparison, we seek to identify the most suitable valve technology for specific robotic applications, considering factors such as performance, cost, reliability, and maintenance requirements. Furthermore, this study aims to highlight potential areas for technological advancement and cross-pollination between the two valve types, potentially leading to hybrid solutions that combine the best features of both technologies.

Ultimately, this comparative analysis will serve as a valuable resource for guiding future research and development efforts in valve technology for industrial robotics, contributing to the ongoing evolution of automation and manufacturing processes.

Solenoid valves, introduced in the early 20th century, have been a staple in industrial automation for decades. These electromechanical devices use an electromagnetic coil to control the movement of a plunger, which in turn regulates the flow of fluids or gases. Their simplicity, reliability, and cost-effectiveness have made them a popular choice in various robotic applications, particularly in pneumatic systems.

Servo valves, on the other hand, emerged in the mid-20th century as a more sophisticated alternative. These valves utilize closed-loop feedback control to achieve precise positioning and flow control. By incorporating sensors and advanced control algorithms, servo valves offer superior accuracy and responsiveness compared to their solenoid counterparts.

The evolution of both technologies has been driven by the increasing demands of industrial robotics for higher precision, faster response times, and improved energy efficiency. As robotic systems become more complex and versatile, the need for advanced valve technologies has grown exponentially. This has led to continuous innovations in both solenoid and servo valve designs, pushing the boundaries of their capabilities and applications.

The primary objective of this comparative study is to provide a comprehensive analysis of solenoid and servo valves within the context of industrial robotics. By examining their respective strengths, limitations, and areas of application, we aim to offer valuable insights for engineers, researchers, and decision-makers in the field.

This study will explore the fundamental principles underlying each technology, their current state of development, and the challenges they face in meeting the evolving requirements of industrial robotics. Additionally, we will investigate the market trends, key players, and future prospects for both solenoid and servo valves in the robotics industry.

By conducting this in-depth comparison, we seek to identify the most suitable valve technology for specific robotic applications, considering factors such as performance, cost, reliability, and maintenance requirements. Furthermore, this study aims to highlight potential areas for technological advancement and cross-pollination between the two valve types, potentially leading to hybrid solutions that combine the best features of both technologies.

Ultimately, this comparative analysis will serve as a valuable resource for guiding future research and development efforts in valve technology for industrial robotics, contributing to the ongoing evolution of automation and manufacturing processes.

Market Demand Analysis for Industrial Robotics Valves

The market demand for valves in industrial robotics has been experiencing significant growth, driven by the increasing adoption of automation across various manufacturing sectors. This trend is particularly evident in industries such as automotive, electronics, and aerospace, where precision and efficiency are paramount. The global industrial robotics market, which heavily relies on advanced valve technologies, is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years.

Within this burgeoning market, both solenoid and servo valves play crucial roles in controlling fluid flow and pressure in robotic systems. Solenoid valves, known for their simplicity and cost-effectiveness, are witnessing steady demand in applications where binary (on/off) control is sufficient. These valves are particularly popular in pick-and-place robots and assembly line automation, where rapid cycling and reliability are essential.

Servo valves, on the other hand, are experiencing a surge in demand due to their superior precision and ability to provide proportional control. As industrial robots become more sophisticated, requiring finer motion control and force feedback, servo valves are increasingly preferred in high-end applications such as robotic welding, painting, and material handling. The market for servo valves in robotics is expected to grow at a faster rate compared to solenoid valves, reflecting the industry's shift towards more complex and precise automation solutions.

The automotive industry remains a key driver of demand for both valve types in robotics. As car manufacturers strive for higher quality and efficiency, they are investing heavily in robotic systems that require advanced valve technologies. Similarly, the electronics industry, with its need for ultra-precise assembly and handling of delicate components, is fueling the demand for high-performance servo valves in robotic applications.

Emerging trends in collaborative robotics and Industry 4.0 are also shaping the market demand for valves. As robots are designed to work alongside humans, there is an increasing need for valves that can provide smooth, controlled movements and quick response times. This trend is particularly beneficial for servo valve manufacturers, as these valves offer the necessary precision and flexibility required in collaborative environments.

Geographically, Asia-Pacific is expected to dominate the market for industrial robotics valves, with China and Japan leading in both production and consumption. North America and Europe follow closely, driven by their strong manufacturing bases and continuous technological advancements in robotics.

Within this burgeoning market, both solenoid and servo valves play crucial roles in controlling fluid flow and pressure in robotic systems. Solenoid valves, known for their simplicity and cost-effectiveness, are witnessing steady demand in applications where binary (on/off) control is sufficient. These valves are particularly popular in pick-and-place robots and assembly line automation, where rapid cycling and reliability are essential.

Servo valves, on the other hand, are experiencing a surge in demand due to their superior precision and ability to provide proportional control. As industrial robots become more sophisticated, requiring finer motion control and force feedback, servo valves are increasingly preferred in high-end applications such as robotic welding, painting, and material handling. The market for servo valves in robotics is expected to grow at a faster rate compared to solenoid valves, reflecting the industry's shift towards more complex and precise automation solutions.

The automotive industry remains a key driver of demand for both valve types in robotics. As car manufacturers strive for higher quality and efficiency, they are investing heavily in robotic systems that require advanced valve technologies. Similarly, the electronics industry, with its need for ultra-precise assembly and handling of delicate components, is fueling the demand for high-performance servo valves in robotic applications.

Emerging trends in collaborative robotics and Industry 4.0 are also shaping the market demand for valves. As robots are designed to work alongside humans, there is an increasing need for valves that can provide smooth, controlled movements and quick response times. This trend is particularly beneficial for servo valve manufacturers, as these valves offer the necessary precision and flexibility required in collaborative environments.

Geographically, Asia-Pacific is expected to dominate the market for industrial robotics valves, with China and Japan leading in both production and consumption. North America and Europe follow closely, driven by their strong manufacturing bases and continuous technological advancements in robotics.

Current Challenges in Valve Technology for Robotics

The field of industrial robotics is currently grappling with several significant challenges in valve technology. One of the primary issues is the need for increased precision and responsiveness in valve operations. As robotic systems become more sophisticated and are required to perform increasingly complex tasks, the demand for valves that can provide precise control over fluid flow and pressure has intensified.

Solenoid and servo valves, while both widely used in robotics, each present their own set of challenges. Solenoid valves, known for their simplicity and reliability, often struggle with providing the level of fine control required in advanced robotic applications. Their binary on-off nature limits their ability to modulate flow accurately, which can be a significant drawback in tasks requiring nuanced movements or force control.

Servo valves, on the other hand, offer superior precision but face challenges in terms of cost, complexity, and maintenance. The intricate components of servo valves make them more prone to wear and tear, potentially leading to increased downtime and maintenance costs. Additionally, the higher power consumption of servo valves compared to solenoid valves can be a concern in energy-efficient robotic designs.

Another critical challenge is the miniaturization of valve technology. As robots become smaller and more agile, there is a growing need for compact valve solutions that do not compromise on performance. This miniaturization effort is particularly challenging when it comes to maintaining the required flow rates and response times in a smaller form factor.

Durability and reliability under diverse operating conditions pose another significant challenge. Industrial robots often work in harsh environments, exposed to extreme temperatures, vibrations, and potentially corrosive substances. Developing valve technologies that can maintain consistent performance under these conditions while ensuring long-term reliability is a major focus area for researchers and engineers.

The integration of smart features into valve technology is another frontier presenting both opportunities and challenges. There is a growing demand for valves with built-in diagnostics, predictive maintenance capabilities, and the ability to communicate with central control systems. However, implementing these features while maintaining the robustness and simplicity expected in industrial applications is a complex task.

Lastly, the industry faces the challenge of balancing performance improvements with cost-effectiveness. While there is a constant push for more advanced valve technologies, these innovations must be economically viable for widespread adoption in industrial robotics. Finding this balance between cutting-edge performance and affordability remains a key challenge for valve manufacturers and robotics companies alike.

Solenoid and servo valves, while both widely used in robotics, each present their own set of challenges. Solenoid valves, known for their simplicity and reliability, often struggle with providing the level of fine control required in advanced robotic applications. Their binary on-off nature limits their ability to modulate flow accurately, which can be a significant drawback in tasks requiring nuanced movements or force control.

Servo valves, on the other hand, offer superior precision but face challenges in terms of cost, complexity, and maintenance. The intricate components of servo valves make them more prone to wear and tear, potentially leading to increased downtime and maintenance costs. Additionally, the higher power consumption of servo valves compared to solenoid valves can be a concern in energy-efficient robotic designs.

Another critical challenge is the miniaturization of valve technology. As robots become smaller and more agile, there is a growing need for compact valve solutions that do not compromise on performance. This miniaturization effort is particularly challenging when it comes to maintaining the required flow rates and response times in a smaller form factor.

Durability and reliability under diverse operating conditions pose another significant challenge. Industrial robots often work in harsh environments, exposed to extreme temperatures, vibrations, and potentially corrosive substances. Developing valve technologies that can maintain consistent performance under these conditions while ensuring long-term reliability is a major focus area for researchers and engineers.

The integration of smart features into valve technology is another frontier presenting both opportunities and challenges. There is a growing demand for valves with built-in diagnostics, predictive maintenance capabilities, and the ability to communicate with central control systems. However, implementing these features while maintaining the robustness and simplicity expected in industrial applications is a complex task.

Lastly, the industry faces the challenge of balancing performance improvements with cost-effectiveness. While there is a constant push for more advanced valve technologies, these innovations must be economically viable for widespread adoption in industrial robotics. Finding this balance between cutting-edge performance and affordability remains a key challenge for valve manufacturers and robotics companies alike.

Existing Valve Solutions in Industrial Robotics

01 Solenoid valve control systems

Advanced control systems for solenoid valves, including electronic control units and pulse width modulation techniques. These systems improve valve response time, precision, and efficiency in various applications such as fuel injection and hydraulic systems.- Solenoid valve design and operation: Solenoid valves use electromagnetic force to control fluid flow. They consist of a coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. These valves are widely used in various applications due to their fast response and reliability.

- Servo valve control systems: Servo valves are precision control devices that use feedback mechanisms to accurately regulate fluid flow or pressure. They typically incorporate electronic controllers, position sensors, and hydraulic or pneumatic actuators. Servo valves offer high precision and dynamic response, making them suitable for applications requiring precise control.

- Integration of solenoid and servo valves in hydraulic systems: Hydraulic systems often combine solenoid and servo valves to achieve optimal performance. Solenoid valves may be used for on-off control or coarse adjustments, while servo valves provide fine-tuning and precise control. This integration allows for improved system efficiency, responsiveness, and overall control in various industrial and mobile applications.

- Valve diagnostics and monitoring: Advanced diagnostic and monitoring systems for solenoid and servo valves help improve reliability and maintenance. These systems may include sensors to detect valve position, pressure, temperature, and other parameters. Real-time monitoring allows for predictive maintenance, fault detection, and performance optimization of valve systems in critical applications.

- Energy-efficient valve designs: Innovations in solenoid and servo valve designs focus on improving energy efficiency. This includes optimizing coil designs, using low-power electronics, and implementing smart control algorithms. Energy-efficient valves reduce power consumption, heat generation, and operating costs while maintaining high performance in various applications.

02 Servo valve designs and mechanisms

Innovative servo valve designs incorporating feedback mechanisms, position sensors, and actuators. These designs enhance valve accuracy, responsiveness, and adaptability in fluid control systems, particularly in aerospace and industrial automation applications.Expand Specific Solutions03 Integration of solenoid and servo valves in hydraulic systems

Combining solenoid and servo valves in hydraulic systems to leverage the strengths of both valve types. This integration improves system performance, control precision, and energy efficiency in applications such as heavy machinery and manufacturing equipment.Expand Specific Solutions04 Miniaturization and compact designs

Development of compact and miniaturized solenoid and servo valve designs for space-constrained applications. These designs maintain performance while reducing size and weight, making them suitable for portable devices and aerospace systems.Expand Specific Solutions05 Energy-efficient valve technologies

Innovations in energy-efficient solenoid and servo valve technologies, including low-power consumption designs and energy recovery systems. These advancements reduce operational costs and environmental impact in various industrial and automotive applications.Expand Specific Solutions

Key Players in Solenoid and Servo Valve Manufacturing

The comparative study of solenoid and servo valves in industrial robotics reflects a mature yet evolving technological landscape. The market is characterized by established players like Robert Bosch GmbH, Danfoss A/S, and Eaton Corp., alongside emerging specialists such as Domin Fluid Power Ltd. and ValveTech, Inc. The industry is in a growth phase, driven by increasing automation across sectors. While solenoid valves represent a more traditional technology, servo valves offer higher precision and control, indicating a shift towards more advanced solutions. The market size is substantial, with applications spanning automotive, aerospace, and manufacturing industries, suggesting significant potential for further innovation and market expansion.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid and servo valve technologies for industrial robotics applications. Their solenoid valves utilize a patented plunger design that reduces response time by up to 30% compared to conventional designs[1]. For servo valves, Bosch employs a high-precision spool and sleeve assembly with integrated position feedback, achieving positioning accuracy of ±0.1% of full stroke[2]. The company's valve solutions incorporate smart diagnostics and predictive maintenance capabilities, leveraging IoT connectivity to monitor valve performance and predict failures before they occur[3]. Bosch's valves are designed for energy efficiency, with power consumption reduced by up to 40% through optimized electromagnetic circuits and materials[4].

Strengths: High precision, fast response times, energy efficiency, and smart diagnostics. Weaknesses: Higher initial cost compared to basic valve solutions, may require specialized maintenance.

Eaton Corp.

Technical Solution: Eaton's approach to solenoid and servo valves in industrial robotics focuses on modularity and customization. Their AxisPro® servo valves feature a modular design allowing for easy configuration and field serviceability[1]. The valves utilize advanced spool technology with overlap control, providing flow accuracy within ±3% of command signal[2]. Eaton's solenoid valves employ a dual-coil design for redundancy and fail-safe operation, crucial in critical robotic applications[3]. The company has also developed a proprietary electronic control system that allows for precise pressure and flow control, with response times as low as 5 milliseconds[4]. Eaton's valves are designed with energy efficiency in mind, incorporating low-power holding circuits that reduce power consumption by up to 50% during steady-state operation[5].

Strengths: Modular design, high customization potential, redundancy features, and energy efficiency. Weaknesses: May have a steeper learning curve for integration due to advanced features.

Core Innovations in Solenoid and Servo Valve Design

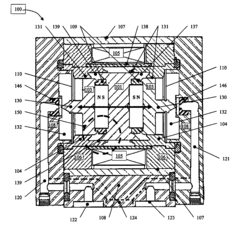

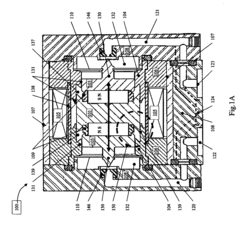

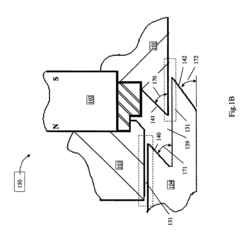

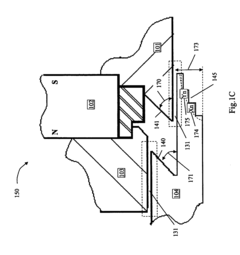

Servo valve with miniature embedded force motor with stiffened armature

PatentInactiveUS20050279415A1

Innovation

- A compact servo valve structure with an embedded force motor, featuring a bobbin assembly with magnetic and non-magnetic components, a moving armature assembly with disc-shaped permanent magnets, and a stator coil that produces differential magnetic forces to control pilot valves, ensuring no sliding contact and optimized linear force over armature travel.

Servo valve with miniature embedded force motor with stiffened armature

PatentInactiveEP1766275A2

Innovation

- A compact servo valve structure with an embedded force motor featuring a bobbin assembly, yoke, and non-magnetic bobbin elements, where the armature assembly includes disc-shaped permanent magnets and poppet ends, supported by Archimedes springs and cylindrical bearings, allowing for magnetic coupling and differential force generation without sliding contact, enhancing stiffness and resistance to vibrations.

Energy Efficiency Comparison of Valve Types

Energy efficiency is a critical factor in the selection and implementation of valve systems in industrial robotics. When comparing solenoid and servo valves, their energy consumption patterns and overall efficiency play a significant role in determining their suitability for various applications. Solenoid valves, known for their simplicity and reliability, operate on an on-off principle, consuming energy primarily during state changes. In contrast, servo valves offer more precise control but require continuous power to maintain their position.

The energy efficiency of solenoid valves is generally higher in applications with infrequent switching requirements. These valves consume minimal power in their steady state, making them ideal for systems where long periods of inactivity are common. However, their efficiency can decrease in high-frequency switching scenarios due to the surge current required during each activation. Servo valves, while consuming more power continuously, provide superior energy efficiency in applications demanding frequent, precise adjustments.

In industrial robotics, the choice between solenoid and servo valves often depends on the specific task requirements. For robotic arms performing repetitive, high-precision movements, servo valves typically offer better overall energy efficiency despite their higher baseline power consumption. This is due to their ability to make minute adjustments without full valve actuation, reducing unnecessary energy expenditure.

Thermal considerations also impact the energy efficiency comparison. Solenoid valves can generate significant heat during operation, especially in high-duty cycle applications. This heat generation represents wasted energy and may necessitate additional cooling systems, further impacting overall system efficiency. Servo valves, with their more controlled operation, generally produce less heat, potentially reducing the need for auxiliary cooling and improving system-wide energy efficiency.

Recent advancements in valve technology have led to the development of hybrid solutions that aim to combine the benefits of both valve types. These innovations include energy-efficient solenoid valves with improved coil designs and smart servo valves with power-saving modes. Such developments are narrowing the efficiency gap between the two valve types, offering industrial robotics designers more flexible options for optimizing energy consumption.

When evaluating the energy efficiency of valve systems in industrial robotics, it's crucial to consider the entire operational cycle, including standby power, activation energy, and the frequency of valve actuation. A comprehensive analysis should also account for the indirect energy impacts, such as heat generation and the power requirements of associated control systems. By carefully weighing these factors, engineers can select the most energy-efficient valve solution for their specific robotic application, balancing performance needs with energy conservation goals.

The energy efficiency of solenoid valves is generally higher in applications with infrequent switching requirements. These valves consume minimal power in their steady state, making them ideal for systems where long periods of inactivity are common. However, their efficiency can decrease in high-frequency switching scenarios due to the surge current required during each activation. Servo valves, while consuming more power continuously, provide superior energy efficiency in applications demanding frequent, precise adjustments.

In industrial robotics, the choice between solenoid and servo valves often depends on the specific task requirements. For robotic arms performing repetitive, high-precision movements, servo valves typically offer better overall energy efficiency despite their higher baseline power consumption. This is due to their ability to make minute adjustments without full valve actuation, reducing unnecessary energy expenditure.

Thermal considerations also impact the energy efficiency comparison. Solenoid valves can generate significant heat during operation, especially in high-duty cycle applications. This heat generation represents wasted energy and may necessitate additional cooling systems, further impacting overall system efficiency. Servo valves, with their more controlled operation, generally produce less heat, potentially reducing the need for auxiliary cooling and improving system-wide energy efficiency.

Recent advancements in valve technology have led to the development of hybrid solutions that aim to combine the benefits of both valve types. These innovations include energy-efficient solenoid valves with improved coil designs and smart servo valves with power-saving modes. Such developments are narrowing the efficiency gap between the two valve types, offering industrial robotics designers more flexible options for optimizing energy consumption.

When evaluating the energy efficiency of valve systems in industrial robotics, it's crucial to consider the entire operational cycle, including standby power, activation energy, and the frequency of valve actuation. A comprehensive analysis should also account for the indirect energy impacts, such as heat generation and the power requirements of associated control systems. By carefully weighing these factors, engineers can select the most energy-efficient valve solution for their specific robotic application, balancing performance needs with energy conservation goals.

Reliability and Maintenance Considerations for Valves

In the realm of industrial robotics, the reliability and maintenance of valves play a crucial role in ensuring optimal performance and longevity of robotic systems. Both solenoid and servo valves are widely used in these applications, each with its own set of considerations for reliability and maintenance.

Solenoid valves, known for their simplicity and cost-effectiveness, generally require less frequent maintenance due to their fewer moving parts. However, they are susceptible to wear and tear, particularly in high-cycle applications. Regular inspection of the solenoid coil, plunger, and seals is essential to prevent failures. Preventive maintenance typically involves cleaning, lubricating, and replacing worn components. The lifespan of solenoid valves can be extended through proper sizing and selection to match the specific application requirements.

Servo valves, on the other hand, offer higher precision and control but come with increased complexity. This complexity translates to more intricate maintenance procedures and potentially higher failure rates if not properly maintained. Regular calibration is crucial to maintain accuracy and responsiveness. Contamination is a significant concern for servo valves, necessitating the use of high-quality filtration systems and regular fluid analysis. Predictive maintenance techniques, such as vibration analysis and performance monitoring, can help identify potential issues before they lead to failure.

For both valve types, environmental factors such as temperature, humidity, and exposure to corrosive substances can significantly impact reliability. Implementing appropriate protection measures and selecting materials suitable for the operating environment is essential. Additionally, proper installation and alignment are critical to prevent premature wear and ensure optimal performance.

Maintenance strategies for both solenoid and servo valves should include regular inspection schedules, documentation of maintenance activities, and tracking of valve performance over time. This data can be invaluable for identifying trends and optimizing maintenance intervals. Training of maintenance personnel is also crucial, particularly for the more complex servo valve systems.

In terms of reliability, solenoid valves generally offer higher Mean Time Between Failures (MTBF) due to their simpler design. However, when failures do occur, they are often more catastrophic, potentially leading to longer downtime. Servo valves, while potentially having lower MTBF, often exhibit more gradual degradation, allowing for planned maintenance before complete failure occurs.

Ultimately, the choice between solenoid and servo valves in industrial robotics applications should consider not only performance requirements but also the long-term reliability and maintenance implications. Factors such as the criticality of the application, available maintenance resources, and the overall cost of ownership should be carefully evaluated to determine the most suitable valve type for a given robotic system.

Solenoid valves, known for their simplicity and cost-effectiveness, generally require less frequent maintenance due to their fewer moving parts. However, they are susceptible to wear and tear, particularly in high-cycle applications. Regular inspection of the solenoid coil, plunger, and seals is essential to prevent failures. Preventive maintenance typically involves cleaning, lubricating, and replacing worn components. The lifespan of solenoid valves can be extended through proper sizing and selection to match the specific application requirements.

Servo valves, on the other hand, offer higher precision and control but come with increased complexity. This complexity translates to more intricate maintenance procedures and potentially higher failure rates if not properly maintained. Regular calibration is crucial to maintain accuracy and responsiveness. Contamination is a significant concern for servo valves, necessitating the use of high-quality filtration systems and regular fluid analysis. Predictive maintenance techniques, such as vibration analysis and performance monitoring, can help identify potential issues before they lead to failure.

For both valve types, environmental factors such as temperature, humidity, and exposure to corrosive substances can significantly impact reliability. Implementing appropriate protection measures and selecting materials suitable for the operating environment is essential. Additionally, proper installation and alignment are critical to prevent premature wear and ensure optimal performance.

Maintenance strategies for both solenoid and servo valves should include regular inspection schedules, documentation of maintenance activities, and tracking of valve performance over time. This data can be invaluable for identifying trends and optimizing maintenance intervals. Training of maintenance personnel is also crucial, particularly for the more complex servo valve systems.

In terms of reliability, solenoid valves generally offer higher Mean Time Between Failures (MTBF) due to their simpler design. However, when failures do occur, they are often more catastrophic, potentially leading to longer downtime. Servo valves, while potentially having lower MTBF, often exhibit more gradual degradation, allowing for planned maintenance before complete failure occurs.

Ultimately, the choice between solenoid and servo valves in industrial robotics applications should consider not only performance requirements but also the long-term reliability and maintenance implications. Factors such as the criticality of the application, available maintenance resources, and the overall cost of ownership should be carefully evaluated to determine the most suitable valve type for a given robotic system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!