Computational Fluid Dynamics Models For VAM Resin Flow

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFD Modeling Evolution and Objectives

Computational Fluid Dynamics (CFD) has evolved significantly since its inception in the 1960s, transforming from simple two-dimensional simulations to sophisticated three-dimensional models capable of handling complex multiphase flows. In the context of Vinyl Ester Acrylate Monomer (VAM) resin flow, CFD modeling has become an indispensable tool for understanding and optimizing manufacturing processes in composite materials production, particularly in industries such as aerospace, automotive, and renewable energy.

The historical trajectory of CFD modeling for resin flow began with basic Navier-Stokes equations applied to simplified geometries. By the 1980s, finite element methods enabled more accurate representations of complex mold cavities. The 1990s witnessed the integration of non-Newtonian fluid models, critical for capturing the unique rheological properties of VAM resins, which exhibit shear-thinning behavior and temperature-dependent viscosity profiles.

The early 2000s marked a pivotal advancement with the introduction of multiphase flow models that could simulate the interaction between resin and reinforcement fibers, addressing challenges such as void formation and permeability variations. Parallel computing capabilities developed in the 2010s enabled higher resolution simulations with reduced computational time, making industrial applications more feasible.

Current CFD modeling for VAM resin flow incorporates sophisticated features including cure kinetics models, which account for the exothermic polymerization reactions that significantly affect flow behavior. These models track the evolution of viscosity as a function of both temperature and degree of cure, providing crucial insights into process windows for manufacturing operations.

The primary objectives of modern CFD modeling in this domain are multifaceted. First, to accurately predict fill patterns and pressure distributions during mold filling processes, enabling optimization of injection strategies and vent locations. Second, to minimize cycle times while ensuring complete impregnation of reinforcement structures, thereby reducing manufacturing costs and improving part quality.

Additional objectives include predicting and mitigating defects such as dry spots, resin-rich areas, and thermal gradients that can lead to residual stresses and warpage. Advanced models aim to optimize fiber orientation and distribution, which directly impact the mechanical properties of the final composite structure.

Looking forward, the field is moving toward fully coupled thermo-chemo-mechanical models that can simultaneously account for heat transfer, chemical reactions, and mechanical deformations during processing. Machine learning integration represents another frontier, where data-driven approaches complement physics-based models to improve prediction accuracy and computational efficiency for VAM resin flow simulations.

The historical trajectory of CFD modeling for resin flow began with basic Navier-Stokes equations applied to simplified geometries. By the 1980s, finite element methods enabled more accurate representations of complex mold cavities. The 1990s witnessed the integration of non-Newtonian fluid models, critical for capturing the unique rheological properties of VAM resins, which exhibit shear-thinning behavior and temperature-dependent viscosity profiles.

The early 2000s marked a pivotal advancement with the introduction of multiphase flow models that could simulate the interaction between resin and reinforcement fibers, addressing challenges such as void formation and permeability variations. Parallel computing capabilities developed in the 2010s enabled higher resolution simulations with reduced computational time, making industrial applications more feasible.

Current CFD modeling for VAM resin flow incorporates sophisticated features including cure kinetics models, which account for the exothermic polymerization reactions that significantly affect flow behavior. These models track the evolution of viscosity as a function of both temperature and degree of cure, providing crucial insights into process windows for manufacturing operations.

The primary objectives of modern CFD modeling in this domain are multifaceted. First, to accurately predict fill patterns and pressure distributions during mold filling processes, enabling optimization of injection strategies and vent locations. Second, to minimize cycle times while ensuring complete impregnation of reinforcement structures, thereby reducing manufacturing costs and improving part quality.

Additional objectives include predicting and mitigating defects such as dry spots, resin-rich areas, and thermal gradients that can lead to residual stresses and warpage. Advanced models aim to optimize fiber orientation and distribution, which directly impact the mechanical properties of the final composite structure.

Looking forward, the field is moving toward fully coupled thermo-chemo-mechanical models that can simultaneously account for heat transfer, chemical reactions, and mechanical deformations during processing. Machine learning integration represents another frontier, where data-driven approaches complement physics-based models to improve prediction accuracy and computational efficiency for VAM resin flow simulations.

VAM Resin Market Demand Analysis

The global Vinyl Acetate Monomer (VAM) resin market has been experiencing significant growth, driven primarily by increasing demand across various end-use industries including adhesives, paints and coatings, textiles, and packaging. The market value reached approximately 8.5 billion USD in 2022 and is projected to grow at a compound annual growth rate of 5.2% through 2030, indicating robust demand for VAM-based products.

The construction industry represents the largest consumer segment for VAM resins, accounting for nearly 35% of total consumption. This is attributed to the extensive use of VAM-based adhesives and coatings in building materials, flooring applications, and architectural finishes. The growing construction activities in emerging economies, particularly in Asia-Pacific and Latin America, are substantially contributing to market expansion.

Packaging applications constitute the second-largest market segment, with approximately 28% market share. The shift toward sustainable and recyclable packaging solutions has increased the demand for VAM resins in flexible packaging, labels, and specialty films. Consumer preference for lightweight, durable packaging materials has further accelerated this trend.

The automotive sector has emerged as a rapidly growing application area for VAM resins, particularly in interior components, adhesives, and protective coatings. With the automotive industry's focus on lightweight materials and improved fuel efficiency, VAM-based composites offer significant advantages, driving a projected growth rate of 6.3% in this segment.

Geographically, Asia-Pacific dominates the VAM resin market with approximately 42% of global consumption, led by China, India, and South Korea. North America and Europe follow with 25% and 22% market shares respectively, while Latin America and Middle East & Africa account for the remaining 11%.

A critical market driver is the increasing focus on computational fluid dynamics (CFD) modeling for VAM resin flow optimization. Manufacturers are investing in advanced simulation technologies to improve production efficiency, reduce material waste, and enhance product quality. This trend is particularly evident in high-performance applications where precise control of resin flow characteristics is essential.

Environmental regulations are significantly influencing market dynamics, with growing demand for low-VOC and formaldehyde-free VAM formulations. This has prompted manufacturers to develop eco-friendly alternatives, creating new market opportunities while posing challenges for traditional production methods.

Supply chain disruptions and raw material price volatility remain significant challenges for market growth. The VAM resin industry is highly dependent on ethylene and acetic acid availability, making it vulnerable to fluctuations in petrochemical markets. Consequently, manufacturers are increasingly exploring computational modeling to optimize formulations and reduce dependency on specific raw materials.

The construction industry represents the largest consumer segment for VAM resins, accounting for nearly 35% of total consumption. This is attributed to the extensive use of VAM-based adhesives and coatings in building materials, flooring applications, and architectural finishes. The growing construction activities in emerging economies, particularly in Asia-Pacific and Latin America, are substantially contributing to market expansion.

Packaging applications constitute the second-largest market segment, with approximately 28% market share. The shift toward sustainable and recyclable packaging solutions has increased the demand for VAM resins in flexible packaging, labels, and specialty films. Consumer preference for lightweight, durable packaging materials has further accelerated this trend.

The automotive sector has emerged as a rapidly growing application area for VAM resins, particularly in interior components, adhesives, and protective coatings. With the automotive industry's focus on lightweight materials and improved fuel efficiency, VAM-based composites offer significant advantages, driving a projected growth rate of 6.3% in this segment.

Geographically, Asia-Pacific dominates the VAM resin market with approximately 42% of global consumption, led by China, India, and South Korea. North America and Europe follow with 25% and 22% market shares respectively, while Latin America and Middle East & Africa account for the remaining 11%.

A critical market driver is the increasing focus on computational fluid dynamics (CFD) modeling for VAM resin flow optimization. Manufacturers are investing in advanced simulation technologies to improve production efficiency, reduce material waste, and enhance product quality. This trend is particularly evident in high-performance applications where precise control of resin flow characteristics is essential.

Environmental regulations are significantly influencing market dynamics, with growing demand for low-VOC and formaldehyde-free VAM formulations. This has prompted manufacturers to develop eco-friendly alternatives, creating new market opportunities while posing challenges for traditional production methods.

Supply chain disruptions and raw material price volatility remain significant challenges for market growth. The VAM resin industry is highly dependent on ethylene and acetic acid availability, making it vulnerable to fluctuations in petrochemical markets. Consequently, manufacturers are increasingly exploring computational modeling to optimize formulations and reduce dependency on specific raw materials.

Current CFD Techniques and Limitations

Computational Fluid Dynamics (CFD) has become an essential tool for modeling and predicting resin flow behavior in Vacuum Assisted Molding (VAM) processes. Current CFD techniques employ various mathematical models to simulate the complex multiphase flow phenomena occurring during resin infusion. The most prevalent approach utilizes Darcy's Law, which describes fluid flow through porous media by relating flow velocity to pressure gradient, permeability, and fluid viscosity.

Commercial CFD software packages such as ANSYS Fluent, COMSOL Multiphysics, and PAM-RTM have developed specialized modules for composite manufacturing simulations. These platforms implement finite element methods (FEM) or finite volume methods (FVM) to discretize the governing equations and solve for pressure and velocity fields throughout the preform during infusion.

Despite significant advancements, current CFD techniques face several limitations when modeling VAM resin flow. The heterogeneous nature of fiber preforms presents a major challenge, as local variations in fiber volume fraction and orientation create permeability fluctuations that are difficult to characterize accurately. Most models rely on homogenized permeability tensors that fail to capture microscale flow phenomena critical to void formation prediction.

Time-dependent phenomena pose another significant limitation. The dynamic compaction of preforms under vacuum pressure and the progressive saturation of fibers alter local permeability during infusion. Current models struggle to incorporate these evolving boundary conditions and material properties, often relying on simplistic assumptions that compromise accuracy.

Computational efficiency remains a persistent challenge, particularly for large, complex parts with multiple reinforcement layers. Full 3D simulations with adequate mesh resolution to capture flow front progression accurately require substantial computational resources, limiting their practical application in industrial settings where rapid design iterations are necessary.

The treatment of air-resin interfaces presents additional complications. Current models employ volume of fluid (VOF) or level set methods to track the flow front, but accurately capturing the interface dynamics, especially around fiber tows where capillary effects become significant, remains problematic. This limitation affects the prediction of void formation and migration, critical quality factors in VAM processes.

Temperature and cure kinetics integration represents another frontier in CFD modeling of VAM processes. While some advanced models couple flow simulations with heat transfer and cure kinetics, the computational complexity increases substantially, and validation of these integrated models remains challenging due to limited experimental data on simultaneous flow-cure interactions.

Commercial CFD software packages such as ANSYS Fluent, COMSOL Multiphysics, and PAM-RTM have developed specialized modules for composite manufacturing simulations. These platforms implement finite element methods (FEM) or finite volume methods (FVM) to discretize the governing equations and solve for pressure and velocity fields throughout the preform during infusion.

Despite significant advancements, current CFD techniques face several limitations when modeling VAM resin flow. The heterogeneous nature of fiber preforms presents a major challenge, as local variations in fiber volume fraction and orientation create permeability fluctuations that are difficult to characterize accurately. Most models rely on homogenized permeability tensors that fail to capture microscale flow phenomena critical to void formation prediction.

Time-dependent phenomena pose another significant limitation. The dynamic compaction of preforms under vacuum pressure and the progressive saturation of fibers alter local permeability during infusion. Current models struggle to incorporate these evolving boundary conditions and material properties, often relying on simplistic assumptions that compromise accuracy.

Computational efficiency remains a persistent challenge, particularly for large, complex parts with multiple reinforcement layers. Full 3D simulations with adequate mesh resolution to capture flow front progression accurately require substantial computational resources, limiting their practical application in industrial settings where rapid design iterations are necessary.

The treatment of air-resin interfaces presents additional complications. Current models employ volume of fluid (VOF) or level set methods to track the flow front, but accurately capturing the interface dynamics, especially around fiber tows where capillary effects become significant, remains problematic. This limitation affects the prediction of void formation and migration, critical quality factors in VAM processes.

Temperature and cure kinetics integration represents another frontier in CFD modeling of VAM processes. While some advanced models couple flow simulations with heat transfer and cure kinetics, the computational complexity increases substantially, and validation of these integrated models remains challenging due to limited experimental data on simultaneous flow-cure interactions.

Existing CFD Solutions for Resin Flow Modeling

01 CFD modeling for resin transfer molding processes

Computational fluid dynamics models are used to simulate and optimize resin flow in transfer molding processes. These models help predict how resin will flow through fiber preforms, allowing manufacturers to optimize mold designs, injection points, and process parameters. The simulations can account for factors such as viscosity changes, cure kinetics, and fiber permeability to accurately predict filling patterns and potential defects.- CFD modeling for resin transfer molding processes: Computational fluid dynamics models are used to simulate and optimize resin transfer molding (RTM) processes. These models help predict resin flow behavior through fiber preforms, considering factors such as viscosity, permeability, and pressure gradients. By accurately modeling the filling process, manufacturers can optimize mold designs, injection strategies, and process parameters to reduce cycle times and minimize defects such as dry spots or voids.

- Flow simulation in composite manufacturing: Computational models are developed to simulate resin flow in composite manufacturing processes, particularly for complex geometries and advanced materials. These simulations account for the interaction between resin and reinforcement fibers, including capillary effects and fiber wetting behavior. The models help predict flow front progression, curing kinetics, and potential manufacturing issues, enabling engineers to design more efficient production processes for composite parts.

- Multi-physics simulation for resin curing and flow: Advanced computational models integrate multiple physical phenomena including resin flow, heat transfer, and curing reactions. These multi-physics simulations capture the complex interactions between temperature, viscosity, degree of cure, and flow behavior. By accounting for these coupled phenomena, engineers can better predict and control resin behavior during processing, leading to improved part quality and more consistent manufacturing outcomes.

- Machine learning enhanced CFD for resin flow prediction: Machine learning techniques are being integrated with traditional CFD approaches to enhance resin flow prediction accuracy and computational efficiency. These hybrid models use training data from physical experiments to improve simulation accuracy, particularly for complex material behaviors that are difficult to capture with conventional models. The machine learning algorithms can also optimize process parameters in real-time, adapting to changing conditions during manufacturing.

- Digital twins for resin processing optimization: Digital twin technology combines real-time process data with computational fluid dynamics models to create virtual representations of resin processing systems. These digital twins enable continuous monitoring and optimization of resin flow during manufacturing. By comparing actual process data with simulation results, the system can detect deviations, predict potential defects, and automatically adjust process parameters to maintain optimal conditions throughout the production cycle.

02 Flow front tracking and void formation prediction

Advanced CFD models for resin flow incorporate algorithms to track the flow front progression and predict void formation during composite manufacturing. These models analyze the interaction between resin and reinforcement materials to identify potential air trapping, dry spots, or incomplete impregnation. By simulating these phenomena, manufacturers can adjust process parameters to minimize defects and improve part quality.Expand Specific Solutions03 Multi-physics simulation approaches for resin systems

Multi-physics simulation approaches combine fluid dynamics with thermal, chemical, and mechanical analyses to provide comprehensive modeling of resin behavior. These integrated models account for temperature-dependent viscosity, exothermic curing reactions, and the resulting mechanical properties of the final part. This holistic approach enables more accurate prediction of resin flow patterns, cure cycles, and part performance.Expand Specific Solutions04 Machine learning and AI integration with CFD for resin flow optimization

Machine learning and artificial intelligence techniques are being integrated with traditional CFD models to enhance resin flow predictions and process optimization. These advanced computational approaches use historical data and real-time feedback to improve simulation accuracy and develop adaptive control strategies. The AI-enhanced models can identify optimal processing windows, predict potential defects, and suggest corrective actions during manufacturing.Expand Specific Solutions05 Digital twin technology for real-time resin flow monitoring

Digital twin technology combines CFD models with sensor data to create virtual representations of actual manufacturing processes for real-time resin flow monitoring. These systems continuously compare simulated predictions with actual process measurements to detect deviations and enable immediate adjustments. The digital twin approach allows for adaptive control of resin flow parameters, reducing variability and improving consistency in composite part production.Expand Specific Solutions

Leading Companies in CFD and VAM Resin Technology

The Computational Fluid Dynamics (CFD) modeling for VAM resin flow is currently in a growth phase, with the market expanding due to increasing demand for high-performance composite materials across aerospace, automotive, and energy sectors. The global market size is estimated to reach $2-3 billion by 2025, driven by the need for more efficient manufacturing processes. From a technical maturity perspective, academic institutions like Beihang University, Tianjin University, and Xi'an Jiaotong University are leading fundamental research, while commercial players including Siemens AG, IBM, and Resonac Corp. are developing industry-specific applications. The technology is transitioning from research to practical implementation, with specialized companies like FXGear and E8 Co. focusing on simulation-based digital twin solutions that integrate CFD modeling with manufacturing processes.

Siemens AG

Technical Solution: Siemens has developed advanced Computational Fluid Dynamics (CFD) solutions specifically for VAM resin flow through their Simcenter STAR-CCM+ software. Their approach integrates multiphase flow modeling with specialized algorithms for tracking the resin front progression during mold filling processes. The technology employs Volume of Fluid (VOF) methods combined with adaptive mesh refinement to accurately capture the interface between resin and air during the infusion process. Siemens' solution incorporates non-Newtonian fluid models that account for the complex rheological behavior of VAM resins, including temperature and cure-dependent viscosity changes. Their models also integrate with thermal solvers to simulate the exothermic curing reactions that significantly affect flow behavior. The platform allows for virtual optimization of injection strategies, vent locations, and mold designs before physical prototyping.

Strengths: Comprehensive integration with manufacturing digital twins allows for end-to-end process simulation. Their multiphysics approach effectively couples flow, thermal, and structural analyses. Weaknesses: High computational requirements may limit real-time applications, and the complexity of the software requires specialized expertise for effective implementation.

Toray Engineering Co., Ltd.

Technical Solution: Toray Engineering has pioneered specialized CFD models for VAM resin flow simulation in composite manufacturing processes. Their proprietary technology, TORAY-FLOW, implements a hybrid finite element/finite volume approach specifically calibrated for thermoset resin systems including VAM-based formulations. The solution incorporates permeability tensor calculations for various fiber architectures and compaction states, enabling accurate prediction of flow front advancement through complex preform geometries. Toray's models account for capillary effects and dual-scale flow phenomena (micro/macro porosity) that are critical in VAM resin infusion processes. Their simulation platform integrates cure kinetics models that capture the changing rheological properties during polymerization, allowing for prediction of potential manufacturing defects such as dry spots and void formation. The technology has been validated across multiple industrial applications including aerospace components and automotive structural parts.

Strengths: Deep expertise in composite materials gives their models exceptional accuracy for fiber-reinforced applications. Their solutions are optimized for industrial-scale components with complex geometries. Weaknesses: Models may be less adaptable to non-standard resin formulations outside their validated database, and the specialized nature of their software limits broader application flexibility.

Key Algorithms for VAM Resin Flow Simulation

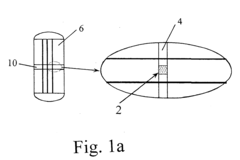

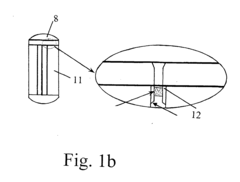

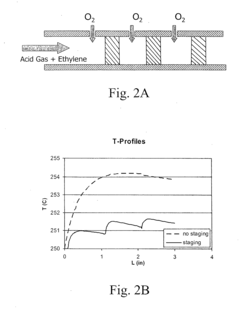

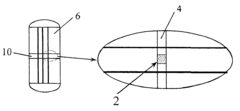

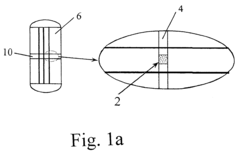

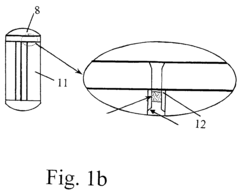

Process and apparatus for improved methods for making vinyl acetate monomer (VAM)

PatentInactiveUS20060116528A1

Innovation

- A method involving a catalyst-containing reaction channel where ethylene, acetic acid, and dioxygen are passed through, with staged addition and optimized molar ratios, to achieve high conversion of ethylene to vinyl acetate or carbon dioxide with low selectivity to carbon dioxide, utilizing microchannel reactors for improved safety and efficiency.

Process and apparatus for improved methods for making vinyl acetate monomer (VAM)

PatentInactiveUS8029748B2

Innovation

- A method involving a catalyst-containing reaction channel where ethylene, acetic acid, and dioxygen are passed through to form vinyl acetate monomer, with specific conditions ensuring at least 20% ethylene conversion to vinyl acetate or carbon dioxide, and at least 40% acetic acid conversion, while maintaining low carbon dioxide selectivity, potentially using staged addition and microchannel reactors for improved efficiency.

Material Property Characterization Methods

Accurate characterization of material properties is fundamental to developing reliable Computational Fluid Dynamics (CFD) models for Vinyl Acetate Monomer (VAM) resin flow. The rheological behavior of VAM resins presents unique challenges due to their complex non-Newtonian characteristics, temperature sensitivity, and cure kinetics during processing. Various experimental methods have been developed to quantify these properties with precision.

Rheological characterization typically employs rotational rheometers to measure viscosity as a function of shear rate, temperature, and degree of cure. Parallel plate and cone-plate geometries are commonly utilized for VAM resins, with temperature sweeps ranging from ambient to processing conditions (typically 80-180°C). Dynamic mechanical analysis (DMA) provides complementary data on viscoelastic properties, particularly useful for capturing the transition from liquid to solid state during curing.

Thermal characterization methods include Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), which are essential for determining cure kinetics parameters, glass transition temperatures, and thermal stability. These measurements inform the energy equations in CFD models and help predict temperature-dependent behavior during processing.

Surface tension and contact angle measurements using pendant drop or Wilhelmy plate methods provide critical data for modeling the interaction between VAM resins and mold surfaces. These parameters significantly influence flow front progression and void formation in processes like Vacuum Assisted Resin Transfer Molding (VARTM).

Permeability testing represents another crucial characterization method, particularly for fiber reinforcements used with VAM resins. Darcy's law-based experiments using radial or rectilinear flow setups help determine the permeability tensor that governs resin flow through porous media. Multi-scale characterization approaches have emerged to correlate microscopic fiber architecture with macroscopic permeability values.

Advanced imaging techniques such as micro-CT scanning and in-situ process monitoring provide validation data for CFD models. These methods allow researchers to observe actual flow patterns and compare them with simulation predictions, enabling iterative refinement of material property inputs.

Standardization efforts by organizations like ASTM International have improved the reliability and reproducibility of these characterization methods. However, challenges remain in capturing the full complexity of VAM resin behavior, particularly during cure reactions where material properties evolve dynamically. Recent developments in high-throughput characterization methods and machine learning approaches show promise for more comprehensive material property databases to support increasingly sophisticated CFD modeling capabilities.

Rheological characterization typically employs rotational rheometers to measure viscosity as a function of shear rate, temperature, and degree of cure. Parallel plate and cone-plate geometries are commonly utilized for VAM resins, with temperature sweeps ranging from ambient to processing conditions (typically 80-180°C). Dynamic mechanical analysis (DMA) provides complementary data on viscoelastic properties, particularly useful for capturing the transition from liquid to solid state during curing.

Thermal characterization methods include Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), which are essential for determining cure kinetics parameters, glass transition temperatures, and thermal stability. These measurements inform the energy equations in CFD models and help predict temperature-dependent behavior during processing.

Surface tension and contact angle measurements using pendant drop or Wilhelmy plate methods provide critical data for modeling the interaction between VAM resins and mold surfaces. These parameters significantly influence flow front progression and void formation in processes like Vacuum Assisted Resin Transfer Molding (VARTM).

Permeability testing represents another crucial characterization method, particularly for fiber reinforcements used with VAM resins. Darcy's law-based experiments using radial or rectilinear flow setups help determine the permeability tensor that governs resin flow through porous media. Multi-scale characterization approaches have emerged to correlate microscopic fiber architecture with macroscopic permeability values.

Advanced imaging techniques such as micro-CT scanning and in-situ process monitoring provide validation data for CFD models. These methods allow researchers to observe actual flow patterns and compare them with simulation predictions, enabling iterative refinement of material property inputs.

Standardization efforts by organizations like ASTM International have improved the reliability and reproducibility of these characterization methods. However, challenges remain in capturing the full complexity of VAM resin behavior, particularly during cure reactions where material properties evolve dynamically. Recent developments in high-throughput characterization methods and machine learning approaches show promise for more comprehensive material property databases to support increasingly sophisticated CFD modeling capabilities.

Validation Techniques and Experimental Correlation

Validation of Computational Fluid Dynamics (CFD) models for Vacuum-Assisted Molding (VAM) resin flow requires rigorous experimental correlation to ensure accuracy and reliability. The primary validation techniques involve comparing simulation predictions with experimental measurements under controlled conditions. These comparisons typically focus on key parameters such as flow front progression, pressure distribution, fill time, and void formation patterns.

Laboratory-scale validation experiments often utilize transparent molds with embedded sensors to capture real-time flow behavior. High-resolution cameras and pressure transducers provide quantitative data for direct comparison with CFD predictions. The correlation process typically involves statistical analysis of predicted versus measured values, with acceptable validation thresholds depending on the specific application requirements and industry standards.

Permeability characterization represents a critical aspect of validation, as accurate permeability values are essential inputs for reliable CFD models. Standard test methods such as radial flow experiments and unidirectional flow tests help establish fabric-specific permeability tensors. These experimentally determined values are then incorporated into the CFD models to improve prediction accuracy.

Scale-up validation presents significant challenges, as laboratory-validated models may not perfectly translate to production-scale processes. Researchers address this through dimensional analysis and the development of non-dimensional parameters that maintain relevance across different scales. Industrial case studies involving full-scale component manufacturing provide valuable validation data, though they introduce additional variables that complicate direct comparisons.

Sensitivity analysis forms another crucial validation technique, wherein model parameters are systematically varied to assess their impact on simulation outcomes. This helps identify which input parameters require the most precise experimental characterization and which have negligible effects on prediction accuracy. Monte Carlo simulations often complement this approach by quantifying uncertainty propagation through the model.

Recent advances in validation techniques include Digital Image Correlation (DIC) for strain field mapping during resin infusion, in-situ viscosity monitoring systems, and fiber orientation tracking technologies. These provide richer datasets for more comprehensive model validation beyond simple flow front tracking. Machine learning algorithms are increasingly employed to optimize the correlation between experimental and simulation data, particularly for complex geometries and variable process conditions.

Laboratory-scale validation experiments often utilize transparent molds with embedded sensors to capture real-time flow behavior. High-resolution cameras and pressure transducers provide quantitative data for direct comparison with CFD predictions. The correlation process typically involves statistical analysis of predicted versus measured values, with acceptable validation thresholds depending on the specific application requirements and industry standards.

Permeability characterization represents a critical aspect of validation, as accurate permeability values are essential inputs for reliable CFD models. Standard test methods such as radial flow experiments and unidirectional flow tests help establish fabric-specific permeability tensors. These experimentally determined values are then incorporated into the CFD models to improve prediction accuracy.

Scale-up validation presents significant challenges, as laboratory-validated models may not perfectly translate to production-scale processes. Researchers address this through dimensional analysis and the development of non-dimensional parameters that maintain relevance across different scales. Industrial case studies involving full-scale component manufacturing provide valuable validation data, though they introduce additional variables that complicate direct comparisons.

Sensitivity analysis forms another crucial validation technique, wherein model parameters are systematically varied to assess their impact on simulation outcomes. This helps identify which input parameters require the most precise experimental characterization and which have negligible effects on prediction accuracy. Monte Carlo simulations often complement this approach by quantifying uncertainty propagation through the model.

Recent advances in validation techniques include Digital Image Correlation (DIC) for strain field mapping during resin infusion, in-situ viscosity monitoring systems, and fiber orientation tracking technologies. These provide richer datasets for more comprehensive model validation beyond simple flow front tracking. Machine learning algorithms are increasingly employed to optimize the correlation between experimental and simulation data, particularly for complex geometries and variable process conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!