Precision Alignment In Volumetric Additive Manufacturing Systems

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric Additive Manufacturing Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing technology, moving beyond traditional layer-by-layer approaches to enable the simultaneous solidification of an entire volume of material. This revolutionary approach emerged in the early 2010s as researchers sought to overcome the speed limitations and mechanical anisotropy inherent in conventional additive manufacturing methods. The technology has evolved from conceptual demonstrations to increasingly sophisticated systems capable of producing complex geometries with unprecedented speed.

The fundamental principle behind VAM involves projecting patterned light into a photosensitive resin volume, causing selective polymerization throughout the entire material simultaneously. This approach stands in stark contrast to traditional methods that build objects sequentially, layer by layer. Early iterations of VAM technology faced significant challenges in achieving precise spatial control of the solidification process, particularly in maintaining alignment between multiple projection sources.

Recent technological advancements have focused on improving the precision alignment capabilities of VAM systems, which is critical for ensuring dimensional accuracy and structural integrity of fabricated parts. The evolution of digital light processing (DLP) technology, computed tomography (CT) principles, and advanced optical systems has contributed significantly to enhancing the capabilities of VAM systems. These developments have enabled the creation of more complex geometries with higher resolution and improved material properties.

The primary objective of precision alignment in VAM systems is to achieve sub-micron accuracy in the spatial coordination of multiple projection sources, ensuring that the intended geometry is faithfully reproduced throughout the entire volume of the printed object. This requires sophisticated calibration techniques, real-time monitoring systems, and adaptive control algorithms to compensate for optical distortions and material property variations during the printing process.

Current research aims to develop robust alignment methodologies that can maintain precision across varying scales, from microscale features to macroscale objects. Additionally, there is a growing focus on expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composite materials, which would significantly broaden the application scope of VAM technology.

The technology trajectory suggests that VAM systems are evolving toward higher resolution, faster production speeds, and greater material versatility. As precision alignment techniques continue to improve, VAM is positioned to address critical manufacturing challenges in industries ranging from medical devices and aerospace components to consumer electronics and automotive parts, where complex internal structures and high-performance requirements demand advanced manufacturing solutions.

The fundamental principle behind VAM involves projecting patterned light into a photosensitive resin volume, causing selective polymerization throughout the entire material simultaneously. This approach stands in stark contrast to traditional methods that build objects sequentially, layer by layer. Early iterations of VAM technology faced significant challenges in achieving precise spatial control of the solidification process, particularly in maintaining alignment between multiple projection sources.

Recent technological advancements have focused on improving the precision alignment capabilities of VAM systems, which is critical for ensuring dimensional accuracy and structural integrity of fabricated parts. The evolution of digital light processing (DLP) technology, computed tomography (CT) principles, and advanced optical systems has contributed significantly to enhancing the capabilities of VAM systems. These developments have enabled the creation of more complex geometries with higher resolution and improved material properties.

The primary objective of precision alignment in VAM systems is to achieve sub-micron accuracy in the spatial coordination of multiple projection sources, ensuring that the intended geometry is faithfully reproduced throughout the entire volume of the printed object. This requires sophisticated calibration techniques, real-time monitoring systems, and adaptive control algorithms to compensate for optical distortions and material property variations during the printing process.

Current research aims to develop robust alignment methodologies that can maintain precision across varying scales, from microscale features to macroscale objects. Additionally, there is a growing focus on expanding the range of compatible materials beyond photopolymers to include ceramics, metals, and composite materials, which would significantly broaden the application scope of VAM technology.

The technology trajectory suggests that VAM systems are evolving toward higher resolution, faster production speeds, and greater material versatility. As precision alignment techniques continue to improve, VAM is positioned to address critical manufacturing challenges in industries ranging from medical devices and aerospace components to consumer electronics and automotive parts, where complex internal structures and high-performance requirements demand advanced manufacturing solutions.

Market Analysis for High-Precision 3D Printing Solutions

The global market for high-precision 3D printing solutions has experienced significant growth in recent years, driven by increasing demand for advanced manufacturing capabilities across various industries. The volumetric additive manufacturing segment, particularly systems requiring precision alignment, represents a rapidly expanding niche within this broader market.

The current market size for high-precision 3D printing technologies is estimated at $2.3 billion, with projections indicating growth to reach $5.7 billion by 2027, representing a compound annual growth rate of 19.8%. This growth is primarily fueled by industries requiring micro-scale precision and complex geometries, including medical devices, aerospace components, and advanced electronics.

Healthcare and medical applications constitute approximately 28% of the high-precision 3D printing market, with dental applications showing particularly strong adoption rates. The ability to create patient-specific implants and prosthetics with precise alignment requirements has revolutionized certain medical procedures and created substantial market opportunities.

Aerospace and defense sectors account for 23% of market share, where the demand for lightweight, geometrically complex components with precise alignment tolerances continues to drive adoption. These industries value the ability to consolidate multiple parts into single components while maintaining or improving functional performance.

Regionally, North America leads the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate at 24.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer demand is increasingly focused on systems that can deliver not only high resolution but also exceptional alignment precision between layers or voxels. Market research indicates that 76% of industrial users cite alignment precision as a critical factor in their purchasing decisions for volumetric additive manufacturing systems.

The competitive landscape features established players like Stratasys, 3D Systems, and EOS dominating with 47% combined market share, while specialized high-precision manufacturers like Nanoscribe and Boston Micro Fabrication are gaining traction with innovative solutions specifically addressing alignment challenges in volumetric printing.

Price sensitivity varies significantly by application, with medical and aerospace customers demonstrating willingness to pay premium prices for systems delivering superior alignment precision, while consumer goods manufacturers remain more cost-conscious. The average selling price for industrial-grade high-precision systems with advanced alignment capabilities ranges from $250,000 to $1.2 million.

The current market size for high-precision 3D printing technologies is estimated at $2.3 billion, with projections indicating growth to reach $5.7 billion by 2027, representing a compound annual growth rate of 19.8%. This growth is primarily fueled by industries requiring micro-scale precision and complex geometries, including medical devices, aerospace components, and advanced electronics.

Healthcare and medical applications constitute approximately 28% of the high-precision 3D printing market, with dental applications showing particularly strong adoption rates. The ability to create patient-specific implants and prosthetics with precise alignment requirements has revolutionized certain medical procedures and created substantial market opportunities.

Aerospace and defense sectors account for 23% of market share, where the demand for lightweight, geometrically complex components with precise alignment tolerances continues to drive adoption. These industries value the ability to consolidate multiple parts into single components while maintaining or improving functional performance.

Regionally, North America leads the market with 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate at 24.3% annually, driven by rapid industrialization and significant government investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer demand is increasingly focused on systems that can deliver not only high resolution but also exceptional alignment precision between layers or voxels. Market research indicates that 76% of industrial users cite alignment precision as a critical factor in their purchasing decisions for volumetric additive manufacturing systems.

The competitive landscape features established players like Stratasys, 3D Systems, and EOS dominating with 47% combined market share, while specialized high-precision manufacturers like Nanoscribe and Boston Micro Fabrication are gaining traction with innovative solutions specifically addressing alignment challenges in volumetric printing.

Price sensitivity varies significantly by application, with medical and aerospace customers demonstrating willingness to pay premium prices for systems delivering superior alignment precision, while consumer goods manufacturers remain more cost-conscious. The average selling price for industrial-grade high-precision systems with advanced alignment capabilities ranges from $250,000 to $1.2 million.

Current Alignment Challenges in Volumetric Manufacturing

Volumetric Additive Manufacturing (VAM) systems represent a significant advancement in 3D printing technology, offering unprecedented speed and resolution capabilities. However, these systems face critical alignment challenges that directly impact manufacturing precision and product quality. The primary challenge stems from the need to precisely align multiple projection sources with the photopolymer resin vat, where even minor misalignments can lead to significant structural defects in the final product.

Current VAM systems typically employ multiple digital light processing (DLP) projectors or laser sources that must converge with micrometer-level precision. Thermal drift presents a substantial obstacle, as heat generated during operation causes minute expansions in mechanical components, shifting alignment parameters over time. Studies indicate that temperature variations as small as 2°C can result in alignment deviations exceeding 10 micrometers, which is unacceptable for high-precision applications.

Optical distortion compounds these challenges, particularly in systems utilizing multiple projection sources. Each projector introduces unique distortion patterns that must be compensated for in real-time. The correction algorithms currently available struggle to account for the complex interactions between multiple optical paths, especially when projecting into mediums with varying refractive indices like photopolymer resins.

Mechanical vibration further exacerbates alignment issues, with high-frequency vibrations from motors, cooling systems, and environmental factors introducing micro-movements that disrupt projection accuracy. Current vibration dampening solutions add significant weight and cost to systems without fully resolving the issue, particularly in industrial environments where external vibration sources cannot be controlled.

Calibration drift represents another significant challenge, as VAM systems require frequent recalibration to maintain precision. Current calibration methods are time-consuming, often requiring system downtime of several hours, which significantly impacts production efficiency. The lack of automated, in-process calibration capabilities means that alignment errors may go undetected until they manifest as defects in finished parts.

Software compensation approaches have shown promise but remain limited by computational constraints. Real-time correction of alignment errors requires substantial processing power, creating latency issues that can compromise manufacturing speed—one of VAM's primary advantages. Current algorithms struggle to balance processing requirements with the need for instantaneous adjustments.

Material-related challenges also affect alignment precision, as resin shrinkage during curing creates unpredictable distortions that vary based on geometry and exposure patterns. These material-specific behaviors are difficult to model accurately, leading to discrepancies between designed and manufactured components that cannot be fully addressed through alignment improvements alone.

Current VAM systems typically employ multiple digital light processing (DLP) projectors or laser sources that must converge with micrometer-level precision. Thermal drift presents a substantial obstacle, as heat generated during operation causes minute expansions in mechanical components, shifting alignment parameters over time. Studies indicate that temperature variations as small as 2°C can result in alignment deviations exceeding 10 micrometers, which is unacceptable for high-precision applications.

Optical distortion compounds these challenges, particularly in systems utilizing multiple projection sources. Each projector introduces unique distortion patterns that must be compensated for in real-time. The correction algorithms currently available struggle to account for the complex interactions between multiple optical paths, especially when projecting into mediums with varying refractive indices like photopolymer resins.

Mechanical vibration further exacerbates alignment issues, with high-frequency vibrations from motors, cooling systems, and environmental factors introducing micro-movements that disrupt projection accuracy. Current vibration dampening solutions add significant weight and cost to systems without fully resolving the issue, particularly in industrial environments where external vibration sources cannot be controlled.

Calibration drift represents another significant challenge, as VAM systems require frequent recalibration to maintain precision. Current calibration methods are time-consuming, often requiring system downtime of several hours, which significantly impacts production efficiency. The lack of automated, in-process calibration capabilities means that alignment errors may go undetected until they manifest as defects in finished parts.

Software compensation approaches have shown promise but remain limited by computational constraints. Real-time correction of alignment errors requires substantial processing power, creating latency issues that can compromise manufacturing speed—one of VAM's primary advantages. Current algorithms struggle to balance processing requirements with the need for instantaneous adjustments.

Material-related challenges also affect alignment precision, as resin shrinkage during curing creates unpredictable distortions that vary based on geometry and exposure patterns. These material-specific behaviors are difficult to model accurately, leading to discrepancies between designed and manufactured components that cannot be fully addressed through alignment improvements alone.

Existing Precision Alignment Methodologies and Implementations

01 Optical alignment systems for volumetric additive manufacturing

Optical alignment systems are crucial for ensuring precision in volumetric additive manufacturing. These systems use cameras, sensors, and laser-based measurement tools to align the build platform, projection systems, and other components. Advanced optical techniques such as interferometry and structured light projection help achieve micron-level precision, ensuring accurate part geometry and dimensional stability throughout the manufacturing process.- Optical alignment systems for volumetric additive manufacturing: Optical alignment systems are crucial for ensuring precision in volumetric additive manufacturing. These systems utilize cameras, sensors, and laser-based measurement tools to align the printing components with high accuracy. Advanced optical technologies enable real-time monitoring and adjustment of the printing process, ensuring that each layer is precisely positioned relative to previous layers. This approach significantly improves the dimensional accuracy and structural integrity of the final printed objects.

- Mechanical calibration mechanisms for print head alignment: Mechanical calibration mechanisms are essential for maintaining precise alignment of print heads in volumetric additive manufacturing systems. These mechanisms include automated adjustment systems, reference frames, and kinematic couplings that ensure consistent positioning during the printing process. Regular calibration routines compensate for mechanical wear and environmental factors that might affect alignment. The integration of high-precision actuators allows for micrometer-level adjustments, significantly enhancing the manufacturing accuracy.

- Software-based alignment correction algorithms: Advanced software algorithms play a critical role in achieving precision alignment in volumetric additive manufacturing. These algorithms process data from various sensors to detect misalignments and automatically implement corrections during the printing process. Machine learning techniques are increasingly being employed to predict and compensate for potential alignment issues before they affect print quality. The software systems can also analyze historical printing data to optimize alignment parameters for specific materials and geometries.

- Multi-axis positioning systems for volumetric printing: Multi-axis positioning systems enable precise movement and alignment in volumetric additive manufacturing. These systems incorporate high-resolution encoders, precision motors, and advanced control systems to achieve accurate positioning in three or more axes. Some implementations include 6-axis robotic arms or specialized gantry systems that can position printing elements with sub-micron precision. The integration of feedback control loops ensures that positioning errors are continuously detected and corrected throughout the manufacturing process.

- Thermal compensation techniques for alignment stability: Thermal effects can significantly impact alignment precision in volumetric additive manufacturing systems. Advanced thermal compensation techniques include temperature monitoring sensors, active cooling systems, and materials with controlled thermal expansion properties. Some systems incorporate real-time thermal mapping to predict and counteract dimensional changes during the printing process. Environmental chambers with precise temperature control are also used to maintain consistent operating conditions, ensuring alignment stability throughout extended printing operations.

02 Mechanical calibration mechanisms for precision alignment

Mechanical calibration mechanisms are employed to achieve and maintain precise alignment in volumetric additive manufacturing systems. These include motorized stages with multi-axis adjustment capabilities, kinematic mounts, and high-precision actuators that allow for fine positional adjustments. Automated calibration routines periodically check and correct alignment parameters to compensate for thermal drift and mechanical wear, ensuring consistent manufacturing quality.Expand Specific Solutions03 Software-based alignment correction and compensation

Software solutions play a vital role in volumetric additive manufacturing alignment by implementing algorithms that detect and correct misalignments in real-time. These systems use image processing, machine learning, and computational geometry to analyze build data and make dynamic adjustments. Digital twins of the manufacturing system enable predictive alignment correction, while closed-loop feedback systems continuously monitor and adjust the manufacturing process to maintain precision throughout complex builds.Expand Specific Solutions04 Multi-material registration and alignment techniques

Specialized alignment techniques are required for multi-material volumetric additive manufacturing to ensure precise registration between different material layers or components. These systems employ fiducial markers, reference features, and specialized alignment patterns to achieve accurate material positioning. Advanced vision systems track material boundaries and interfaces, while specialized hardware ensures consistent material deposition alignment across multiple print heads or material delivery systems.Expand Specific Solutions05 Thermal management for alignment stability

Thermal management systems are essential for maintaining alignment stability in volumetric additive manufacturing. These include active cooling systems, temperature-controlled build chambers, and thermally-stable structural components that minimize expansion and contraction during the manufacturing process. Thermal sensors monitor temperature gradients across the system, while compensation algorithms adjust alignment parameters based on thermal conditions to maintain dimensional accuracy throughout extended build operations.Expand Specific Solutions

Leading Companies in Volumetric Additive Manufacturing

Precision Alignment in Volumetric Additive Manufacturing Systems is currently in a growth phase, with the market expanding rapidly due to increasing industrial applications. The global market size is projected to reach significant value as manufacturing industries adopt these advanced technologies. Technologically, the field is maturing with established players like EOS GmbH and General Electric leading innovation in industrial-scale systems, while newer entrants such as Readily3D and Inkbit are advancing novel approaches with vision-based and AI-driven solutions. Companies including Siemens, TRUMPF, and Additive Industries are developing integrated precision alignment technologies, while research institutions like Lawrence Livermore National Security and Naval Research Laboratory contribute fundamental advancements. The ecosystem shows a balance between established industrial manufacturers and specialized additive manufacturing innovators working to enhance precision, reliability, and production efficiency.

EOS GmbH

Technical Solution: EOS has developed advanced precision alignment systems for their Direct Metal Laser Sintering (DMLS) and polymer-based additive manufacturing technologies. Their approach to volumetric precision focuses on comprehensive calibration and monitoring throughout the build process. The EOS DMLS systems employ a sophisticated optical train with multiple calibration points that ensure precise laser positioning across the entire build volume. Their EOSTATE Monitoring Suite provides real-time quality assurance through multiple sensor systems that track melt pool dynamics, powder bed conditions, and system parameters[9]. For precision alignment, EOS implements a proprietary calibration methodology that maps the entire build volume and compensates for optical distortions, thermal expansion, and mechanical tolerances. This includes regular automated laser path verification using reference markers embedded in the build platform. Their latest systems incorporate machine learning algorithms that analyze sensor data to predict and prevent deviations before they occur, maintaining volumetric accuracy within 50 microns even for large industrial parts[10]. EOS has also pioneered multi-laser configurations with sophisticated alignment protocols that ensure seamless transitions between laser fields without visible seams or dimensional inconsistencies.

Strengths: Exceptional repeatability across multiple builds and machines, comprehensive quality monitoring systems integrated into production workflow, and extensive material development expertise ensuring optimal process parameters. Weaknesses: Higher initial investment costs compared to some competitors, complex setup and calibration requirements, and proprietary material ecosystem that can limit flexibility.

Readily3D SA

Technical Solution: Readily3D has developed a volumetric additive manufacturing system called "Tomolite" that utilizes tomographic projection technology for precision alignment. Their approach employs a rotating cylindrical container filled with photosensitive resin where multiple projections of light patterns are synchronized with the rotation to create complex 3D structures in seconds rather than hours. The system achieves precision alignment through advanced optical calibration algorithms that compensate for refractive distortions at the container interfaces and ensure accurate light pattern positioning throughout the volume. Their proprietary software implements real-time feedback mechanisms that monitor and adjust projection parameters during fabrication to maintain dimensional accuracy down to 40 microns across the entire build volume[1]. The technology enables the creation of complex internal structures without support materials, particularly beneficial for biomedical applications where they've demonstrated printing of functional tissue scaffolds with precisely controlled microchannels[2].

Strengths: Extremely fast production times (seconds vs. hours), ability to create complex internal geometries without support structures, and excellent resolution for soft tissue applications. Weaknesses: Limited material compatibility primarily focused on soft polymers, relatively small build volumes compared to traditional additive manufacturing, and higher initial equipment costs.

Key Patents and Research in Volumetric Alignment Technology

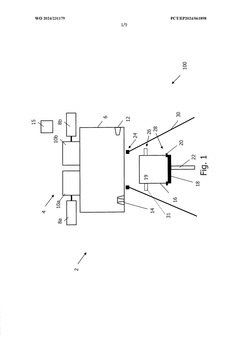

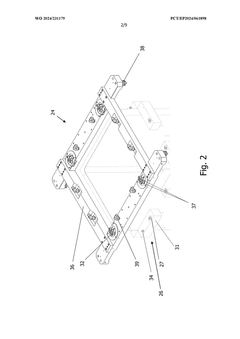

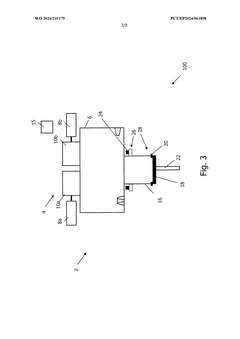

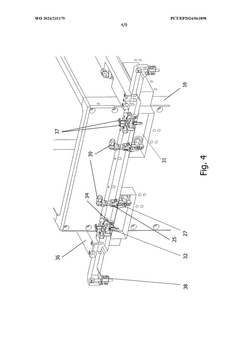

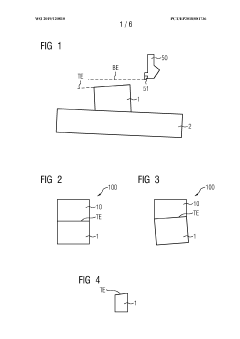

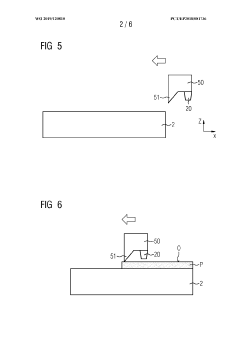

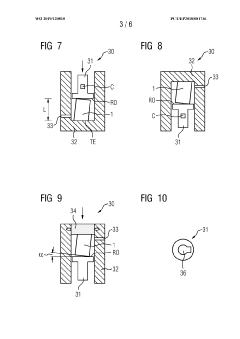

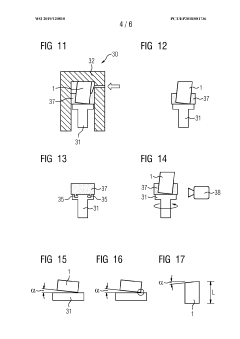

Production apparatus for the additive manufacture of three-dimensional workpieces, building cylinder for use with the production apparatus, and method

PatentWO2024231179A1

Innovation

- A manufacturing apparatus with an exchangeable construction cylinder and a coupling system that aligns and holds the cylinder in a predetermined position, using a combination of clamping systems and fluid circuits for precise alignment and secure holding, allowing for the use of interchangeable cylinders and maintaining positional accuracy during the manufacturing process.

Method for the additive construction of a structure and computer program product

PatentWO2019120810A1

Innovation

- A method that involves fixing a prefabricated component on a building board with a defined parting plane, using optical measurement tools like strip light scanners to align the processing surface with the parting plane, and adjusting the building board's position using light barriers to prevent collisions, allowing for precise and efficient additive construction.

Materials Science Considerations for Volumetric Manufacturing

The selection of appropriate materials for volumetric additive manufacturing systems represents a critical factor in achieving precision alignment. Unlike traditional layer-by-layer approaches, volumetric manufacturing requires materials with specific photochemical properties that respond predictably to spatial light modulation. Photopolymers used in these systems must demonstrate consistent curing behavior throughout the entire volume while maintaining dimensional stability during the solidification process.

Material viscosity plays a paramount role in alignment precision, as it directly impacts the ability to maintain spatial positioning during fabrication. Lower viscosity resins allow for more rapid reorientation of the material during the manufacturing process but may introduce challenges related to structural integrity before complete curing. Conversely, higher viscosity materials provide better structural support but may impede the achievement of fine feature resolution due to limited molecular mobility.

Refractive index matching between the uncured resin and the cured parts represents another crucial consideration. Mismatches in refractive indices can cause light scattering and refraction, leading to distortions in the projected patterns and subsequent alignment errors. Advanced formulations incorporating refractive index modifiers help minimize these optical aberrations, thereby enhancing overall system precision.

The thermal properties of materials also significantly impact alignment accuracy in volumetric systems. Materials with low coefficients of thermal expansion are preferred to minimize dimensional changes during the exothermic curing process. Additionally, heat dissipation characteristics must be carefully considered to prevent localized overheating that could lead to non-uniform curing and subsequent alignment issues.

Photoinitiator selection and concentration directly influence the spatial resolution achievable in volumetric manufacturing. The absorption spectrum, quantum yield, and diffusion characteristics of these compounds determine the precision with which energy can be delivered to specific regions within the volume. Advanced systems often employ dual-initiator systems that enable finer control over the polymerization process through orthogonal activation mechanisms.

Recent developments in material science have introduced smart resins with built-in alignment markers or traceable additives that facilitate real-time monitoring of the manufacturing process. These innovations allow for closed-loop feedback systems that can dynamically adjust projection patterns to compensate for any detected misalignments, significantly enhancing the precision of the final product.

Material viscosity plays a paramount role in alignment precision, as it directly impacts the ability to maintain spatial positioning during fabrication. Lower viscosity resins allow for more rapid reorientation of the material during the manufacturing process but may introduce challenges related to structural integrity before complete curing. Conversely, higher viscosity materials provide better structural support but may impede the achievement of fine feature resolution due to limited molecular mobility.

Refractive index matching between the uncured resin and the cured parts represents another crucial consideration. Mismatches in refractive indices can cause light scattering and refraction, leading to distortions in the projected patterns and subsequent alignment errors. Advanced formulations incorporating refractive index modifiers help minimize these optical aberrations, thereby enhancing overall system precision.

The thermal properties of materials also significantly impact alignment accuracy in volumetric systems. Materials with low coefficients of thermal expansion are preferred to minimize dimensional changes during the exothermic curing process. Additionally, heat dissipation characteristics must be carefully considered to prevent localized overheating that could lead to non-uniform curing and subsequent alignment issues.

Photoinitiator selection and concentration directly influence the spatial resolution achievable in volumetric manufacturing. The absorption spectrum, quantum yield, and diffusion characteristics of these compounds determine the precision with which energy can be delivered to specific regions within the volume. Advanced systems often employ dual-initiator systems that enable finer control over the polymerization process through orthogonal activation mechanisms.

Recent developments in material science have introduced smart resins with built-in alignment markers or traceable additives that facilitate real-time monitoring of the manufacturing process. These innovations allow for closed-loop feedback systems that can dynamically adjust projection patterns to compensate for any detected misalignments, significantly enhancing the precision of the final product.

Quality Control Standards for Additive Manufacturing Systems

Quality control standards for additive manufacturing systems, particularly those focused on volumetric manufacturing, have evolved significantly to address the unique challenges of precision alignment. These standards now encompass comprehensive frameworks that manufacturers must adhere to in order to ensure consistent product quality and dimensional accuracy.

The International Organization for Standardization (ISO) has developed several key standards specifically addressing precision alignment in additive manufacturing, including ISO 17296 and ISO/ASTM 52900 series. These standards define terminology, test methods, and quality parameters essential for maintaining alignment precision in volumetric systems.

ASTM International has complemented these efforts with standards such as ASTM F3301, which outlines post-processing techniques to enhance dimensional accuracy. Additionally, the American Society for Mechanical Engineers (ASME) has contributed Y14.46, focusing on geometric dimensioning and tolerancing principles applicable to additively manufactured parts.

Quality control standards for volumetric additive manufacturing systems typically require multi-level verification processes. These include pre-build system calibration, in-process monitoring using advanced sensor arrays, and post-build verification through metrology techniques such as computed tomography and structured light scanning. The standards specify maximum allowable deviations based on application requirements, with medical and aerospace applications demanding tolerances as tight as ±10 micrometers.

Material-specific standards have also emerged, recognizing that different materials exhibit varying degrees of shrinkage, warpage, and thermal expansion. These standards prescribe specific alignment compensation algorithms and calibration procedures tailored to material properties, ensuring dimensional stability across diverse material portfolios.

Process parameter validation forms another critical component of quality control standards. This includes standardized procedures for validating laser path accuracy, projection system alignment, and resin vat positioning in volumetric systems. The standards mandate regular recalibration intervals and define acceptable drift parameters between calibration cycles.

Documentation requirements constitute a significant aspect of these standards, mandating detailed records of alignment verification procedures, measurement results, and corrective actions. This documentation chain ensures traceability and facilitates continuous improvement of alignment precision over time.

Recent updates to quality control standards have incorporated machine learning approaches for predictive quality assurance, allowing systems to anticipate alignment issues before they manifest in finished parts. These advanced standards are driving the industry toward closed-loop control systems that can automatically detect and correct alignment deviations during the build process.

The International Organization for Standardization (ISO) has developed several key standards specifically addressing precision alignment in additive manufacturing, including ISO 17296 and ISO/ASTM 52900 series. These standards define terminology, test methods, and quality parameters essential for maintaining alignment precision in volumetric systems.

ASTM International has complemented these efforts with standards such as ASTM F3301, which outlines post-processing techniques to enhance dimensional accuracy. Additionally, the American Society for Mechanical Engineers (ASME) has contributed Y14.46, focusing on geometric dimensioning and tolerancing principles applicable to additively manufactured parts.

Quality control standards for volumetric additive manufacturing systems typically require multi-level verification processes. These include pre-build system calibration, in-process monitoring using advanced sensor arrays, and post-build verification through metrology techniques such as computed tomography and structured light scanning. The standards specify maximum allowable deviations based on application requirements, with medical and aerospace applications demanding tolerances as tight as ±10 micrometers.

Material-specific standards have also emerged, recognizing that different materials exhibit varying degrees of shrinkage, warpage, and thermal expansion. These standards prescribe specific alignment compensation algorithms and calibration procedures tailored to material properties, ensuring dimensional stability across diverse material portfolios.

Process parameter validation forms another critical component of quality control standards. This includes standardized procedures for validating laser path accuracy, projection system alignment, and resin vat positioning in volumetric systems. The standards mandate regular recalibration intervals and define acceptable drift parameters between calibration cycles.

Documentation requirements constitute a significant aspect of these standards, mandating detailed records of alignment verification procedures, measurement results, and corrective actions. This documentation chain ensures traceability and facilitates continuous improvement of alignment precision over time.

Recent updates to quality control standards have incorporated machine learning approaches for predictive quality assurance, allowing systems to anticipate alignment issues before they manifest in finished parts. These advanced standards are driving the industry toward closed-loop control systems that can automatically detect and correct alignment deviations during the build process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!