Customized Dental Applications Of Volumetric Additive Manufacturing

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dental 3D Printing Evolution and Objectives

The evolution of dental applications in 3D printing represents a significant technological advancement in the field of dentistry. Traditional dental manufacturing processes have historically been labor-intensive, time-consuming, and prone to human error. The introduction of additive manufacturing technologies in the dental industry began in the early 2000s, primarily with stereolithography (SLA) and digital light processing (DLP) techniques for creating dental models and surgical guides.

The technological progression accelerated around 2010 with the development of more sophisticated 3D printing technologies capable of producing functional dental prosthetics. This marked a shift from merely creating prototypes to manufacturing end-use dental products. By 2015, selective laser sintering (SLS) and selective laser melting (SLM) technologies enabled the production of metal dental frameworks and crowns with unprecedented precision.

Volumetric additive manufacturing (VAM) represents the latest breakthrough in this evolutionary timeline. Unlike traditional layer-by-layer 3D printing methods, VAM creates entire volumes simultaneously through photopolymerization, dramatically reducing production time while maintaining high resolution. This technology emerged around 2019 and has been rapidly advancing since then, particularly in its application to dental materials.

The primary objectives of customized dental applications using volumetric additive manufacturing are multifaceted. First, there is a drive to achieve superior precision in dental restorations, aiming for micron-level accuracy to ensure perfect fit and patient comfort. Second, significant emphasis is placed on reducing production time, with the goal of enabling same-day dental solutions in clinical settings.

Material innovation constitutes another critical objective, focusing on developing biocompatible resins and composites that mimic natural dental tissues in both appearance and mechanical properties. Additionally, there is a push toward cost-effectiveness, making advanced dental solutions more accessible to a broader patient population.

The integration of digital workflows represents a fundamental objective, connecting intraoral scanning, computer-aided design, and volumetric manufacturing into a seamless process. Looking forward, research is increasingly focused on developing multi-material printing capabilities that can simultaneously produce dental restorations with varying material properties, mimicking the complex structure of natural teeth.

The trajectory of this technology points toward increasingly personalized dental care, where treatments are precisely tailored to individual patient anatomy and requirements, ultimately improving clinical outcomes and patient satisfaction.

The technological progression accelerated around 2010 with the development of more sophisticated 3D printing technologies capable of producing functional dental prosthetics. This marked a shift from merely creating prototypes to manufacturing end-use dental products. By 2015, selective laser sintering (SLS) and selective laser melting (SLM) technologies enabled the production of metal dental frameworks and crowns with unprecedented precision.

Volumetric additive manufacturing (VAM) represents the latest breakthrough in this evolutionary timeline. Unlike traditional layer-by-layer 3D printing methods, VAM creates entire volumes simultaneously through photopolymerization, dramatically reducing production time while maintaining high resolution. This technology emerged around 2019 and has been rapidly advancing since then, particularly in its application to dental materials.

The primary objectives of customized dental applications using volumetric additive manufacturing are multifaceted. First, there is a drive to achieve superior precision in dental restorations, aiming for micron-level accuracy to ensure perfect fit and patient comfort. Second, significant emphasis is placed on reducing production time, with the goal of enabling same-day dental solutions in clinical settings.

Material innovation constitutes another critical objective, focusing on developing biocompatible resins and composites that mimic natural dental tissues in both appearance and mechanical properties. Additionally, there is a push toward cost-effectiveness, making advanced dental solutions more accessible to a broader patient population.

The integration of digital workflows represents a fundamental objective, connecting intraoral scanning, computer-aided design, and volumetric manufacturing into a seamless process. Looking forward, research is increasingly focused on developing multi-material printing capabilities that can simultaneously produce dental restorations with varying material properties, mimicking the complex structure of natural teeth.

The trajectory of this technology points toward increasingly personalized dental care, where treatments are precisely tailored to individual patient anatomy and requirements, ultimately improving clinical outcomes and patient satisfaction.

Market Analysis for Customized Dental Solutions

The global market for customized dental solutions utilizing volumetric additive manufacturing is experiencing robust growth, driven by increasing demand for personalized dental care and technological advancements. The market size for digital dentistry, which encompasses customized dental applications, was valued at approximately $13.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 9.7% through 2030.

Dental professionals worldwide are increasingly adopting digital workflows, with a significant shift toward customized solutions that offer improved patient outcomes. North America currently holds the largest market share at 38%, followed by Europe at 31% and Asia-Pacific at 24%, with the latter showing the fastest growth trajectory due to expanding healthcare infrastructure and rising disposable incomes.

Consumer demand for aesthetic dentistry has surged, with patient expectations for faster treatment times and improved comfort driving market expansion. The dental implants segment represents the largest application area, accounting for 42% of the customized dental solutions market, followed by orthodontics (28%) and prosthodontics (21%).

Volumetric additive manufacturing specifically addresses key market needs by enabling rapid production of patient-specific dental devices with complex geometries. The technology reduces production time by up to 70% compared to traditional manufacturing methods, creating significant cost efficiencies for dental laboratories and clinics.

Insurance coverage for customized dental solutions varies globally, with higher reimbursement rates in developed markets contributing to faster adoption. However, emerging markets are showing increased private spending on premium dental services, creating new growth opportunities.

Demographic trends further support market expansion, with aging populations requiring more extensive dental work and younger generations showing greater willingness to invest in cosmetic dental procedures. The global population aged 65 and above is expected to double by 2050, creating sustained demand for dental prosthetics and implants.

Market challenges include the high initial investment costs for volumetric additive manufacturing equipment, which ranges from $50,000 to $200,000 depending on capabilities, creating barriers to entry for smaller dental practices. Regulatory approval processes for novel dental materials compatible with volumetric printing also present commercialization hurdles.

The COVID-19 pandemic accelerated digital transformation in dentistry, with contactless workflows and reduced chair time becoming priorities. This shift has created lasting changes in consumer expectations and practice operations, further driving demand for efficient manufacturing technologies like volumetric additive manufacturing.

Dental professionals worldwide are increasingly adopting digital workflows, with a significant shift toward customized solutions that offer improved patient outcomes. North America currently holds the largest market share at 38%, followed by Europe at 31% and Asia-Pacific at 24%, with the latter showing the fastest growth trajectory due to expanding healthcare infrastructure and rising disposable incomes.

Consumer demand for aesthetic dentistry has surged, with patient expectations for faster treatment times and improved comfort driving market expansion. The dental implants segment represents the largest application area, accounting for 42% of the customized dental solutions market, followed by orthodontics (28%) and prosthodontics (21%).

Volumetric additive manufacturing specifically addresses key market needs by enabling rapid production of patient-specific dental devices with complex geometries. The technology reduces production time by up to 70% compared to traditional manufacturing methods, creating significant cost efficiencies for dental laboratories and clinics.

Insurance coverage for customized dental solutions varies globally, with higher reimbursement rates in developed markets contributing to faster adoption. However, emerging markets are showing increased private spending on premium dental services, creating new growth opportunities.

Demographic trends further support market expansion, with aging populations requiring more extensive dental work and younger generations showing greater willingness to invest in cosmetic dental procedures. The global population aged 65 and above is expected to double by 2050, creating sustained demand for dental prosthetics and implants.

Market challenges include the high initial investment costs for volumetric additive manufacturing equipment, which ranges from $50,000 to $200,000 depending on capabilities, creating barriers to entry for smaller dental practices. Regulatory approval processes for novel dental materials compatible with volumetric printing also present commercialization hurdles.

The COVID-19 pandemic accelerated digital transformation in dentistry, with contactless workflows and reduced chair time becoming priorities. This shift has created lasting changes in consumer expectations and practice operations, further driving demand for efficient manufacturing technologies like volumetric additive manufacturing.

Current Volumetric AM Technologies in Dentistry

Volumetric Additive Manufacturing (VAM) has emerged as a transformative technology in the dental industry, offering unprecedented capabilities for creating customized dental applications. Currently, several volumetric AM technologies are being applied in dentistry, each with distinct characteristics and applications.

Computed Axial Lithography (CAL) represents one of the most promising volumetric AM technologies in dental applications. This approach utilizes synchronized illumination from multiple angles to create three-dimensional structures within photosensitive resins. In dental contexts, CAL enables the production of highly detailed crowns, bridges, and aligners with exceptional surface finish and dimensional accuracy, typically achieving precision within 50-100 microns.

Tomographic Volumetric Additive Manufacturing (TVAM) has also gained significant traction in dental applications. This technology employs tomographic reconstruction principles to generate complex dental structures in a single exposure process. TVAM systems can produce complete dental models, surgical guides, and prosthetics in 30-60 seconds, compared to hours required by traditional layer-by-layer approaches, representing a substantial workflow improvement for dental laboratories.

Holographic Volumetric Printing (HVP) utilizes interference patterns of coherent light to create dental structures simultaneously throughout a volume of photopolymer. This technology excels in producing gradient structures with varying mechanical properties, which is particularly valuable for dental applications requiring biomimetic characteristics that replicate natural tooth structures.

Xolography, a newer entrant in the dental volumetric AM space, employs two-color photochemistry to achieve high-resolution dental applications. The technology uses two intersecting light beams of different wavelengths to initiate polymerization only at their intersection points, enabling the creation of intricate dental structures with feature sizes down to 25 microns.

Material considerations remain central to current volumetric AM dental applications. Biocompatible photopolymers that meet ISO 10993 and ISO 13485 standards for medical devices are predominantly used, with recent developments focusing on ceramic-loaded resins for permanent dental restorations and antimicrobial materials for orthodontic applications.

Integration with digital workflows represents another critical aspect of current volumetric AM technologies in dentistry. Modern systems incorporate direct compatibility with standard dental CAD software and intraoral scanning technologies, enabling seamless digital workflows from patient scanning to final restoration production. This integration has significantly reduced production times and improved the accuracy of dental appliances, with some systems achieving turnaround times of less than two hours from scan to delivery.

Computed Axial Lithography (CAL) represents one of the most promising volumetric AM technologies in dental applications. This approach utilizes synchronized illumination from multiple angles to create three-dimensional structures within photosensitive resins. In dental contexts, CAL enables the production of highly detailed crowns, bridges, and aligners with exceptional surface finish and dimensional accuracy, typically achieving precision within 50-100 microns.

Tomographic Volumetric Additive Manufacturing (TVAM) has also gained significant traction in dental applications. This technology employs tomographic reconstruction principles to generate complex dental structures in a single exposure process. TVAM systems can produce complete dental models, surgical guides, and prosthetics in 30-60 seconds, compared to hours required by traditional layer-by-layer approaches, representing a substantial workflow improvement for dental laboratories.

Holographic Volumetric Printing (HVP) utilizes interference patterns of coherent light to create dental structures simultaneously throughout a volume of photopolymer. This technology excels in producing gradient structures with varying mechanical properties, which is particularly valuable for dental applications requiring biomimetic characteristics that replicate natural tooth structures.

Xolography, a newer entrant in the dental volumetric AM space, employs two-color photochemistry to achieve high-resolution dental applications. The technology uses two intersecting light beams of different wavelengths to initiate polymerization only at their intersection points, enabling the creation of intricate dental structures with feature sizes down to 25 microns.

Material considerations remain central to current volumetric AM dental applications. Biocompatible photopolymers that meet ISO 10993 and ISO 13485 standards for medical devices are predominantly used, with recent developments focusing on ceramic-loaded resins for permanent dental restorations and antimicrobial materials for orthodontic applications.

Integration with digital workflows represents another critical aspect of current volumetric AM technologies in dentistry. Modern systems incorporate direct compatibility with standard dental CAD software and intraoral scanning technologies, enabling seamless digital workflows from patient scanning to final restoration production. This integration has significantly reduced production times and improved the accuracy of dental appliances, with some systems achieving turnaround times of less than two hours from scan to delivery.

Existing Volumetric Printing Solutions for Dental Applications

01 Volumetric additive manufacturing techniques

Volumetric additive manufacturing (VAM) involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer-by-layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic approaches. VAM offers advantages such as faster build speeds, elimination of support structures, and the ability to create complex internal geometries in a single step.- Volumetric additive manufacturing techniques: Volumetric additive manufacturing involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer by layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic approaches. These methods enable faster production times compared to traditional layer-by-layer processes and can create complex geometries without the need for support structures.

- Materials for volumetric additive manufacturing: Various materials can be used in volumetric additive manufacturing, including photopolymer resins, hydrogels, and composite materials. These materials are formulated to respond to specific light wavelengths or energy sources to achieve rapid solidification throughout a volume. The development of specialized materials with tailored properties is crucial for expanding the applications of volumetric manufacturing techniques.

- Light projection and control systems: Advanced light projection and control systems are essential components of volumetric additive manufacturing. These systems include digital light processing (DLP) projectors, spatial light modulators, and specialized optics that enable precise control of light patterns in three dimensions. The synchronization of multiple light sources and the modulation of light intensity patterns allow for the creation of complex 3D structures in a single exposure.

- Process optimization and control algorithms: Sophisticated algorithms are developed to optimize and control the volumetric additive manufacturing process. These include computational methods for determining optimal light dose distributions, real-time feedback control systems, and predictive models that account for material properties and curing kinetics. These algorithms enhance manufacturing precision, reduce defects, and improve the overall quality of produced parts.

- Applications and integration with other manufacturing processes: Volumetric additive manufacturing is being applied across various fields including medical device fabrication, microfluidics, and custom part production. The technology is also being integrated with other manufacturing processes to create hybrid approaches that leverage the advantages of multiple techniques. This integration enables the production of components with complex geometries and functional properties that would be difficult to achieve using conventional manufacturing methods.

02 Photosensitive resins for volumetric printing

Specialized photosensitive resins are critical for volumetric additive manufacturing processes. These materials are designed to cure only when exposed to specific light patterns or when multiple light beams intersect. Advanced formulations include oxygen inhibition systems, photoinitiators with specific absorption spectra, and viscosity modifiers to enable rapid solidification while maintaining optical clarity throughout the printing process.Expand Specific Solutions03 Light projection systems for volumetric manufacturing

Sophisticated light projection systems are essential components of volumetric additive manufacturing. These systems use digital light processing (DLP), spatial light modulators, or multiple synchronized light sources to project patterned light into photosensitive resin. Advanced optical arrangements enable precise control of light distribution throughout the volume, with techniques such as computed tomography principles applied to create complex 3D geometries in a single exposure.Expand Specific Solutions04 Thermal and multi-material volumetric printing

Innovations in volumetric additive manufacturing extend beyond photopolymerization to include thermal approaches and multi-material capabilities. These systems use focused thermal energy, ultrasound, or multiple energy sources to selectively solidify materials within a volume. Advanced systems incorporate multiple material reservoirs and precise delivery mechanisms to create functionally graded materials or complex composite structures with varying mechanical, electrical, or optical properties.Expand Specific Solutions05 Software and computational methods for volumetric manufacturing

Specialized software and computational methods are crucial for volumetric additive manufacturing. These include algorithms for computing optimal light projection patterns, real-time feedback control systems, and simulation tools that account for light scattering, absorption, and material response. Advanced computational approaches incorporate machine learning to optimize manufacturing parameters, predict material behavior, and compensate for optical distortions to achieve high-precision parts.Expand Specific Solutions

Leading Dental AM Companies and Research Institutions

The volumetric additive manufacturing market for customized dental applications is currently in a growth phase, with an expanding market size driven by increasing demand for personalized dental solutions. The technology maturity varies across different applications, with clear aligner technology being the most advanced segment. Leading players like Align Technology have established dominant positions through proprietary systems and extensive patent portfolios. Traditional dental companies such as Straumann, DENTSPLY, and Ivoclar Vivadent are actively integrating 3D printing into their workflows. Specialized additive manufacturing firms including Carbon, Stratasys, and EOS provide critical technology infrastructure. Emerging players like Lightforce Orthodontics and polySpectra are introducing innovative materials and processes, while academic institutions such as MIT and Cornell University contribute to fundamental research advancing the field.

Align Technology, Inc.

Technical Solution: Align Technology has pioneered volumetric additive manufacturing for dental applications through their iTero Element 5D imaging system and proprietary clear aligner production process. Their technology utilizes digital light processing (DLP) to create highly accurate 3D printed dental models with resolution down to 50 microns. The company's manufacturing process involves a multi-stage approach where patient-specific dental scans are converted into volumetric data, which is then processed through proprietary algorithms to optimize print orientation and support structures. Align's system can produce up to 50,000 unique aligner molds daily with minimal material waste. Their recent innovations include integration of real-time monitoring systems that adjust light intensity during printing to ensure consistent material properties throughout complex dental geometries[1][3]. The company has also developed specialized biocompatible resins that meet regulatory requirements for long-term oral use while maintaining dimensional stability under varying temperature and moisture conditions.

Strengths: Proprietary end-to-end digital workflow integration from scanning to manufacturing; high-volume production capability; extensive material science expertise for dental-specific applications. Weaknesses: Closed ecosystem limits third-party material compatibility; higher cost compared to traditional manufacturing methods; requires significant computational resources for processing complex volumetric data.

Lightforce Orthodontics, Inc.

Technical Solution: Lightforce Orthodontics has pioneered a fully digital approach to customized orthodontic treatment through their proprietary volumetric additive manufacturing platform. Their technology centers on creating fully customized, 3D-printed ceramic brackets tailored to each patient's unique tooth morphology. Using advanced computational algorithms, Lightforce converts CBCT and intraoral scan data into precise volumetric models that account for both the external tooth geometry and internal structures. Their manufacturing process employs a specialized ceramic slurry with proprietary additives that enable high-resolution printing (down to 25 microns) while maintaining the material properties necessary for orthodontic applications[7]. The company's unique "digital bracket system" incorporates patient-specific anatomical features directly into the bracket design, allowing for more precise tooth movement with reduced treatment time. Each bracket is printed with embedded identification markers that ensure proper placement during bonding procedures. Lightforce's cloud-based treatment planning software allows orthodontists to visualize and modify treatment plans in real-time, with the manufacturing system automatically adjusting bracket parameters to achieve the desired tooth movements[8]. Recent advancements include the integration of AI-driven force prediction models that optimize bracket design for more efficient tooth movement patterns.

Strengths: Fully customized bracket system that adapts to individual tooth morphology; reduced chair time through precise bracket fit and positioning; elimination of bracket inventory management for practices. Weaknesses: Higher initial cost compared to traditional bracket systems; requires complete digital workflow adoption; limited to ceramic material options currently.

Key Patents and Innovations in Dental Volumetric AM

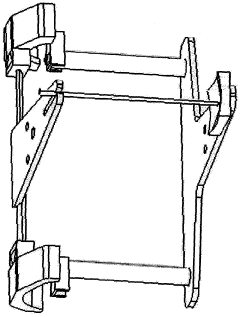

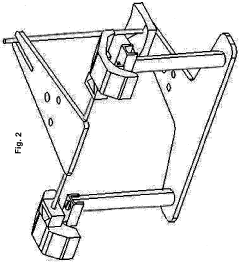

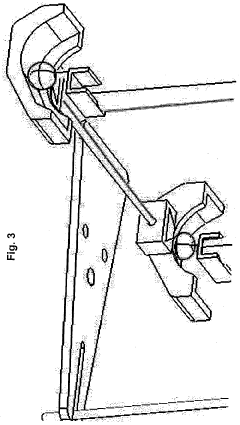

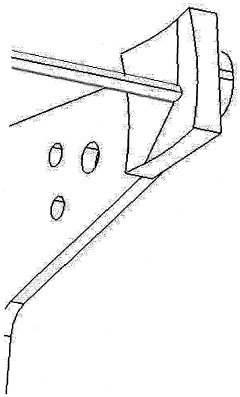

Method for the generative production of individual dental preformed parts for articulators

PatentWO2008113313A1

Innovation

- The method employs additive manufacturing processes to directly produce dental molded parts and functional components using patient data, eliminating intermediate steps and material-related errors, and integrates these components into an articulator for precise simulation and production of customized dentures.

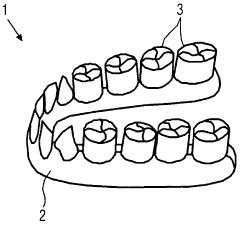

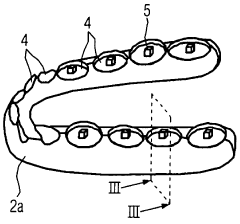

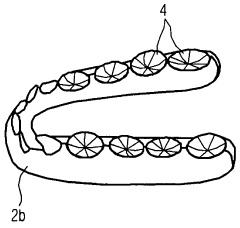

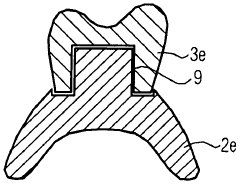

Method concerning the modelling and production of an artificial set of teeth

PatentWO2008081003A1

Innovation

- The use of computer-aided rapid prototyping methods, such as 3D laser lithography, for producing gum-colored base parts and teeth, allowing for precise modeling and integration of wear-resistant layers, with optional post-processing for color and mechanical fastening, enabling customized and durable artificial dentures.

Biocompatibility and Material Science Considerations

The biocompatibility of materials used in volumetric additive manufacturing (VAM) for dental applications represents a critical consideration that directly impacts clinical outcomes and patient safety. These materials must not only meet stringent mechanical and functional requirements but also demonstrate excellent biocompatibility profiles when in contact with oral tissues. Current research focuses on photopolymerizable resins that can be rapidly cured through volumetric light projection while maintaining biocompatibility with oral mucosa, pulpal tissues, and surrounding bone structures.

Material science advancements have led to the development of specialized dental resins containing biocompatible monomers, oligomers, and photoinitiators that minimize cytotoxicity while providing necessary mechanical properties. These formulations typically incorporate methacrylate-based compounds modified with biocompatible functional groups to reduce inflammatory responses and enhance tissue integration. Recent innovations include the incorporation of antimicrobial agents and bioactive fillers that promote tissue regeneration while preventing secondary infections.

The mechanical properties of VAM-produced dental components must closely mimic those of natural dental structures. This requires careful material engineering to achieve appropriate elastic modulus, flexural strength, and wear resistance. Researchers have developed gradient materials that can transition from rigid to more flexible properties within a single printed structure, better replicating the natural dentin-enamel junction and improving long-term performance of dental restorations.

Surface characteristics of VAM-printed dental devices significantly influence their biological performance. Nano-scale surface modifications can enhance cell adhesion and proliferation while reducing bacterial colonization. Advanced material formulations now incorporate controlled surface topography features that promote specific cellular responses while maintaining printability through volumetric techniques. These developments represent a significant advancement over traditional dental materials, which often lack such sophisticated surface engineering capabilities.

Regulatory considerations present substantial challenges for new dental materials. Materials must undergo comprehensive biocompatibility testing according to ISO 10993 standards, including cytotoxicity, sensitization, irritation, and genotoxicity assessments. Additionally, dental-specific standards such as ISO 7405 impose further requirements for materials intended for use in the oral environment. The development of standardized testing protocols specifically for VAM dental materials remains an active area of research, as traditional testing methods may not fully capture the unique characteristics of volumetrically printed structures.

Long-term stability in the oral environment presents another critical material science challenge. VAM-produced dental devices must maintain their mechanical integrity and biocompatibility despite exposure to saliva, temperature fluctuations, pH variations, and mechanical stresses. Recent research has focused on developing cross-linking strategies and composite formulations that enhance hydrolytic stability while preserving biocompatibility profiles over extended periods.

Material science advancements have led to the development of specialized dental resins containing biocompatible monomers, oligomers, and photoinitiators that minimize cytotoxicity while providing necessary mechanical properties. These formulations typically incorporate methacrylate-based compounds modified with biocompatible functional groups to reduce inflammatory responses and enhance tissue integration. Recent innovations include the incorporation of antimicrobial agents and bioactive fillers that promote tissue regeneration while preventing secondary infections.

The mechanical properties of VAM-produced dental components must closely mimic those of natural dental structures. This requires careful material engineering to achieve appropriate elastic modulus, flexural strength, and wear resistance. Researchers have developed gradient materials that can transition from rigid to more flexible properties within a single printed structure, better replicating the natural dentin-enamel junction and improving long-term performance of dental restorations.

Surface characteristics of VAM-printed dental devices significantly influence their biological performance. Nano-scale surface modifications can enhance cell adhesion and proliferation while reducing bacterial colonization. Advanced material formulations now incorporate controlled surface topography features that promote specific cellular responses while maintaining printability through volumetric techniques. These developments represent a significant advancement over traditional dental materials, which often lack such sophisticated surface engineering capabilities.

Regulatory considerations present substantial challenges for new dental materials. Materials must undergo comprehensive biocompatibility testing according to ISO 10993 standards, including cytotoxicity, sensitization, irritation, and genotoxicity assessments. Additionally, dental-specific standards such as ISO 7405 impose further requirements for materials intended for use in the oral environment. The development of standardized testing protocols specifically for VAM dental materials remains an active area of research, as traditional testing methods may not fully capture the unique characteristics of volumetrically printed structures.

Long-term stability in the oral environment presents another critical material science challenge. VAM-produced dental devices must maintain their mechanical integrity and biocompatibility despite exposure to saliva, temperature fluctuations, pH variations, and mechanical stresses. Recent research has focused on developing cross-linking strategies and composite formulations that enhance hydrolytic stability while preserving biocompatibility profiles over extended periods.

Clinical Validation and Regulatory Pathways

The clinical validation of volumetric additive manufacturing (VAM) for customized dental applications represents a critical pathway toward widespread adoption in dental practice. Current validation protocols focus on mechanical properties, biocompatibility, and clinical performance of VAM-produced dental prosthetics and devices. Multi-center clinical trials have demonstrated promising results for VAM-fabricated dental crowns, bridges, and surgical guides, with success rates comparable to traditional manufacturing methods while offering significant time advantages.

Regulatory frameworks for dental VAM applications vary significantly across global markets. In the United States, the FDA classifies most dental devices under Class II, requiring 510(k) clearance with specific performance standards for VAM-produced items. The European Union, under the Medical Device Regulation (MDR), demands comprehensive technical documentation and clinical evaluation reports, with particular emphasis on biocompatibility testing for materials used in VAM dental applications.

The regulatory landscape presents several challenges specific to VAM dental applications. The rapid iteration capability of VAM technology creates difficulties in establishing standardized validation protocols that can keep pace with technological advancements. Additionally, the customized nature of dental applications complicates the traditional regulatory paradigm designed for mass-produced medical devices.

Material certification represents another significant hurdle, as dental-grade resins for VAM must meet stringent biocompatibility requirements under ISO 10993 standards. Currently, only a limited number of materials have received regulatory clearance for intraoral use in VAM applications, constraining the technology's full potential in the dental field.

Several dental companies have successfully navigated these regulatory pathways. Notable examples include Formlabs' surgical guide material receiving 510(k) clearance, and Carbon's partnership with Dentsply Sirona to develop FDA-cleared dental materials for their Digital Light Synthesis technology. These precedents establish valuable roadmaps for future VAM dental applications.

Looking forward, regulatory bodies are developing more adaptive frameworks to accommodate rapid technological evolution in dental VAM. The FDA's Digital Health Innovation Action Plan and the EU MDR's provisions for custom-made devices represent steps toward more flexible regulatory approaches that maintain safety standards while enabling innovation. Industry stakeholders are actively collaborating with regulatory agencies to establish standardized testing protocols specifically designed for VAM dental applications.

Regulatory frameworks for dental VAM applications vary significantly across global markets. In the United States, the FDA classifies most dental devices under Class II, requiring 510(k) clearance with specific performance standards for VAM-produced items. The European Union, under the Medical Device Regulation (MDR), demands comprehensive technical documentation and clinical evaluation reports, with particular emphasis on biocompatibility testing for materials used in VAM dental applications.

The regulatory landscape presents several challenges specific to VAM dental applications. The rapid iteration capability of VAM technology creates difficulties in establishing standardized validation protocols that can keep pace with technological advancements. Additionally, the customized nature of dental applications complicates the traditional regulatory paradigm designed for mass-produced medical devices.

Material certification represents another significant hurdle, as dental-grade resins for VAM must meet stringent biocompatibility requirements under ISO 10993 standards. Currently, only a limited number of materials have received regulatory clearance for intraoral use in VAM applications, constraining the technology's full potential in the dental field.

Several dental companies have successfully navigated these regulatory pathways. Notable examples include Formlabs' surgical guide material receiving 510(k) clearance, and Carbon's partnership with Dentsply Sirona to develop FDA-cleared dental materials for their Digital Light Synthesis technology. These precedents establish valuable roadmaps for future VAM dental applications.

Looking forward, regulatory bodies are developing more adaptive frameworks to accommodate rapid technological evolution in dental VAM. The FDA's Digital Health Innovation Action Plan and the EU MDR's provisions for custom-made devices represent steps toward more flexible regulatory approaches that maintain safety standards while enabling innovation. Industry stakeholders are actively collaborating with regulatory agencies to establish standardized testing protocols specifically designed for VAM dental applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!