High-Throughput Fabrication Enabled By Volumetric Additive Manufacturing

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Evolution and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the evolution of additive manufacturing technologies. Unlike traditional layer-by-layer approaches, VAM simultaneously solidifies an entire volume of photopolymer resin, dramatically accelerating production speeds from hours to minutes or even seconds. This revolutionary technique emerged from the convergence of advanced optics, computational algorithms, and material science breakthroughs over the past decade.

The historical trajectory of VAM began with early conceptual work in the 2010s, gaining significant momentum around 2017 when researchers at Lawrence Livermore National Laboratory demonstrated the first practical implementation using computed axial lithography. This technique, inspired by medical tomography, projects synchronized patterns of light from multiple angles into photosensitive resin, creating complex three-dimensional structures without mechanical movement of the build platform.

Subsequent evolution has focused on overcoming initial limitations in resolution, material compatibility, and scalability. Recent advancements have pushed resolution boundaries below 100 microns, expanded compatible material portfolios to include functional resins with mechanical, electrical, and biocompatible properties, and increased build volumes while maintaining rapid production speeds.

The primary objective of VAM technology development is to enable truly high-throughput additive manufacturing for industrial applications. Specific technical goals include achieving sub-50 micron resolution across larger build volumes, developing multi-material capabilities for heterogeneous structures, and creating closed-loop feedback systems for real-time quality control during solidification processes.

Another critical objective is expanding the material ecosystem to include high-performance engineering polymers, ceramics, and potentially metal-polymer composites. This diversification would significantly broaden VAM's application potential across industries including medical devices, consumer electronics, automotive components, and aerospace parts.

From a manufacturing perspective, VAM aims to bridge the gap between traditional mass production techniques and customized manufacturing by offering unprecedented production speeds without sacrificing geometric complexity or customization capabilities. The technology targets production rates 10-100 times faster than conventional additive manufacturing while maintaining comparable or superior part quality.

Looking forward, the evolution trajectory points toward integrated manufacturing systems that combine VAM with automated post-processing, quality inspection, and assembly operations to create end-to-end digital manufacturing platforms capable of transforming production paradigms across multiple industries.

The historical trajectory of VAM began with early conceptual work in the 2010s, gaining significant momentum around 2017 when researchers at Lawrence Livermore National Laboratory demonstrated the first practical implementation using computed axial lithography. This technique, inspired by medical tomography, projects synchronized patterns of light from multiple angles into photosensitive resin, creating complex three-dimensional structures without mechanical movement of the build platform.

Subsequent evolution has focused on overcoming initial limitations in resolution, material compatibility, and scalability. Recent advancements have pushed resolution boundaries below 100 microns, expanded compatible material portfolios to include functional resins with mechanical, electrical, and biocompatible properties, and increased build volumes while maintaining rapid production speeds.

The primary objective of VAM technology development is to enable truly high-throughput additive manufacturing for industrial applications. Specific technical goals include achieving sub-50 micron resolution across larger build volumes, developing multi-material capabilities for heterogeneous structures, and creating closed-loop feedback systems for real-time quality control during solidification processes.

Another critical objective is expanding the material ecosystem to include high-performance engineering polymers, ceramics, and potentially metal-polymer composites. This diversification would significantly broaden VAM's application potential across industries including medical devices, consumer electronics, automotive components, and aerospace parts.

From a manufacturing perspective, VAM aims to bridge the gap between traditional mass production techniques and customized manufacturing by offering unprecedented production speeds without sacrificing geometric complexity or customization capabilities. The technology targets production rates 10-100 times faster than conventional additive manufacturing while maintaining comparable or superior part quality.

Looking forward, the evolution trajectory points toward integrated manufacturing systems that combine VAM with automated post-processing, quality inspection, and assembly operations to create end-to-end digital manufacturing platforms capable of transforming production paradigms across multiple industries.

Market Demand for High-Throughput Manufacturing Solutions

The global manufacturing landscape is witnessing a significant shift towards high-throughput production methods, with volumetric additive manufacturing emerging as a revolutionary technology to meet escalating market demands. Traditional manufacturing processes often struggle with production speed limitations, creating bottlenecks that impede supply chain efficiency and market responsiveness.

Market research indicates that industries including aerospace, automotive, medical devices, and consumer electronics are actively seeking manufacturing solutions that can dramatically reduce production time while maintaining quality standards. The global additive manufacturing market, valued at approximately $13.7 billion in 2021, is projected to grow at a compound annual growth rate of 20.8% through 2030, with high-throughput solutions representing the fastest-growing segment.

A primary market driver is the increasing demand for mass customization capabilities. Modern consumers and industrial clients alike seek personalized products without the traditional cost premiums associated with customization. Volumetric additive manufacturing addresses this need by enabling rapid production of customized components without sacrificing throughput or requiring extensive retooling.

Supply chain resilience has emerged as another critical market factor following global disruptions. Companies are increasingly investing in technologies that enable on-demand, localized production capabilities to mitigate supply chain vulnerabilities. High-throughput volumetric manufacturing provides the speed and flexibility needed to implement such strategies effectively.

The healthcare sector represents a particularly promising market, with demand for patient-specific medical devices growing at 17% annually. Volumetric manufacturing's ability to rapidly produce complex, biocompatible structures positions it ideally for applications ranging from prosthetics to tissue engineering scaffolds.

Industrial surveys reveal that manufacturing executives rank production speed as their third most important consideration when evaluating new manufacturing technologies, behind only quality and cost. This represents a significant shift from previous years when speed ranked consistently lower, highlighting the increasing premium placed on throughput capabilities.

Environmental considerations are also driving market demand, as high-throughput volumetric manufacturing typically generates less waste than traditional subtractive methods. With sustainability initiatives becoming central to corporate strategy across industries, manufacturing technologies that reduce material waste while maintaining production efficiency are gaining market traction.

The market for high-throughput manufacturing solutions is further bolstered by the trend toward shorter product lifecycles, particularly in consumer electronics and automotive industries. These sectors require manufacturing technologies that can rapidly transition between product iterations without extensive downtime or retooling costs.

Market research indicates that industries including aerospace, automotive, medical devices, and consumer electronics are actively seeking manufacturing solutions that can dramatically reduce production time while maintaining quality standards. The global additive manufacturing market, valued at approximately $13.7 billion in 2021, is projected to grow at a compound annual growth rate of 20.8% through 2030, with high-throughput solutions representing the fastest-growing segment.

A primary market driver is the increasing demand for mass customization capabilities. Modern consumers and industrial clients alike seek personalized products without the traditional cost premiums associated with customization. Volumetric additive manufacturing addresses this need by enabling rapid production of customized components without sacrificing throughput or requiring extensive retooling.

Supply chain resilience has emerged as another critical market factor following global disruptions. Companies are increasingly investing in technologies that enable on-demand, localized production capabilities to mitigate supply chain vulnerabilities. High-throughput volumetric manufacturing provides the speed and flexibility needed to implement such strategies effectively.

The healthcare sector represents a particularly promising market, with demand for patient-specific medical devices growing at 17% annually. Volumetric manufacturing's ability to rapidly produce complex, biocompatible structures positions it ideally for applications ranging from prosthetics to tissue engineering scaffolds.

Industrial surveys reveal that manufacturing executives rank production speed as their third most important consideration when evaluating new manufacturing technologies, behind only quality and cost. This represents a significant shift from previous years when speed ranked consistently lower, highlighting the increasing premium placed on throughput capabilities.

Environmental considerations are also driving market demand, as high-throughput volumetric manufacturing typically generates less waste than traditional subtractive methods. With sustainability initiatives becoming central to corporate strategy across industries, manufacturing technologies that reduce material waste while maintaining production efficiency are gaining market traction.

The market for high-throughput manufacturing solutions is further bolstered by the trend toward shorter product lifecycles, particularly in consumer electronics and automotive industries. These sectors require manufacturing technologies that can rapidly transition between product iterations without extensive downtime or retooling costs.

Current State and Barriers in Volumetric Additive Manufacturing

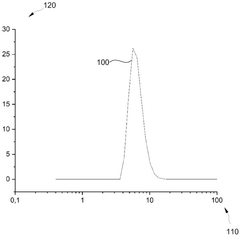

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, enabling the simultaneous solidification of an entire volume rather than layer-by-layer fabrication. Currently, VAM technologies primarily utilize photopolymerization principles, with two dominant approaches: computed axial lithography (CAL) and holographic volumetric printing. These methods have demonstrated remarkable fabrication speeds, with reports indicating production times of 30-60 seconds for complex structures that would require hours using conventional methods.

The state-of-the-art in VAM has achieved resolution capabilities ranging from 50-300 micrometers, with build volumes typically limited to 80-100 cubic centimeters. Recent advancements have focused on expanding material compatibility beyond standard photopolymers to include ceramic suspensions, hydrogels, and composite materials. Notable research institutions advancing this field include Lawrence Livermore National Laboratory, UC Berkeley, and ETH Zurich, alongside emerging commercial entities like Readily3D and Xolo.

Despite promising developments, significant technical barriers impede widespread industrial adoption. The foremost challenge remains the limited material selection, as VAM requires specialized photopolymers with specific optical properties that balance light penetration and absorption characteristics. This constraint severely restricts application versatility compared to established additive manufacturing technologies.

Resolution limitations present another substantial hurdle. While VAM excels in speed, achieving sub-50 micrometer resolution remains challenging due to light scattering effects and optical system constraints. This restricts applications requiring high precision or fine feature definition, particularly in microfluidics and biomedical devices.

Build volume constraints also present significant challenges. Scaling VAM to larger volumes encounters fundamental physics limitations related to light penetration depth and energy distribution uniformity throughout the resin volume. These factors create a technical ceiling that currently prevents fabrication of larger industrial components.

Process control and repeatability issues further complicate industrial implementation. The complex interplay between light projection patterns, resin chemistry, and solidification dynamics creates variability that impacts dimensional accuracy and mechanical properties. Current systems lack robust in-process monitoring capabilities necessary for quality assurance in production environments.

Infrastructure requirements pose additional barriers, as VAM systems demand sophisticated optical setups, specialized resin handling systems, and advanced computational resources for tomographic reconstruction algorithms. These requirements translate to high equipment costs and technical expertise needs that limit accessibility beyond research environments.

Addressing these barriers requires interdisciplinary research spanning materials science, optical engineering, and computational methods to unlock the full potential of volumetric manufacturing for high-throughput industrial applications.

The state-of-the-art in VAM has achieved resolution capabilities ranging from 50-300 micrometers, with build volumes typically limited to 80-100 cubic centimeters. Recent advancements have focused on expanding material compatibility beyond standard photopolymers to include ceramic suspensions, hydrogels, and composite materials. Notable research institutions advancing this field include Lawrence Livermore National Laboratory, UC Berkeley, and ETH Zurich, alongside emerging commercial entities like Readily3D and Xolo.

Despite promising developments, significant technical barriers impede widespread industrial adoption. The foremost challenge remains the limited material selection, as VAM requires specialized photopolymers with specific optical properties that balance light penetration and absorption characteristics. This constraint severely restricts application versatility compared to established additive manufacturing technologies.

Resolution limitations present another substantial hurdle. While VAM excels in speed, achieving sub-50 micrometer resolution remains challenging due to light scattering effects and optical system constraints. This restricts applications requiring high precision or fine feature definition, particularly in microfluidics and biomedical devices.

Build volume constraints also present significant challenges. Scaling VAM to larger volumes encounters fundamental physics limitations related to light penetration depth and energy distribution uniformity throughout the resin volume. These factors create a technical ceiling that currently prevents fabrication of larger industrial components.

Process control and repeatability issues further complicate industrial implementation. The complex interplay between light projection patterns, resin chemistry, and solidification dynamics creates variability that impacts dimensional accuracy and mechanical properties. Current systems lack robust in-process monitoring capabilities necessary for quality assurance in production environments.

Infrastructure requirements pose additional barriers, as VAM systems demand sophisticated optical setups, specialized resin handling systems, and advanced computational resources for tomographic reconstruction algorithms. These requirements translate to high equipment costs and technical expertise needs that limit accessibility beyond research environments.

Addressing these barriers requires interdisciplinary research spanning materials science, optical engineering, and computational methods to unlock the full potential of volumetric manufacturing for high-throughput industrial applications.

Existing High-Throughput Volumetric Manufacturing Approaches

01 Volumetric additive manufacturing techniques

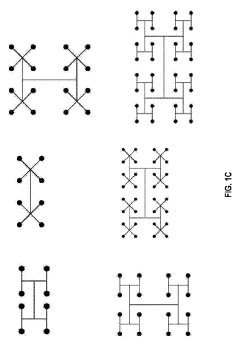

Volumetric additive manufacturing (VAM) enables the simultaneous solidification of an entire 3D object within a photosensitive resin. This approach differs from traditional layer-by-layer methods by creating objects in a single step, significantly increasing production speed. The technique typically uses computed tomography principles with synchronized light projections from multiple angles to selectively cure specific volumes within the resin, allowing for high-throughput fabrication of complex structures without the need for support materials.- Volumetric additive manufacturing techniques: Volumetric additive manufacturing (VAM) enables the simultaneous solidification of an entire volume of material, rather than layer-by-layer fabrication. This approach significantly increases production speed and throughput compared to traditional additive manufacturing methods. VAM techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic stereolithography, which use projected light patterns to cure photosensitive resins in specific three-dimensional patterns, allowing for the creation of complex structures without support materials.

- Materials and formulations for high-throughput VAM: Advanced photosensitive materials and resin formulations are crucial for high-throughput volumetric additive manufacturing. These materials are specifically designed to respond to light energy in a controlled manner, enabling rapid solidification while maintaining precision. Key developments include dual-initiator systems, oxygen-inhibition resistant formulations, and materials with tunable viscosity and curing properties. These specialized formulations allow for faster build speeds, improved resolution, and enhanced mechanical properties of the final printed objects.

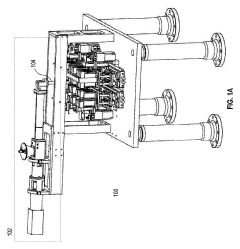

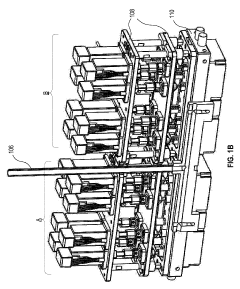

- Optical systems and light patterning for VAM: Advanced optical systems are essential components of high-throughput volumetric additive manufacturing. These systems include specialized light sources, spatial light modulators, and projection optics that enable precise control of light distribution throughout the build volume. Technologies such as digital light processing (DLP), digital micromirror devices (DMD), and holographic projectors are employed to create complex three-dimensional light patterns. The optimization of these optical systems allows for increased fabrication speed, improved resolution, and the ability to create intricate internal structures without support materials.

- Computational methods for volumetric fabrication: Sophisticated computational algorithms are critical for high-throughput volumetric additive manufacturing. These include advanced tomographic reconstruction techniques, real-time feedback control systems, and optimization algorithms that determine optimal light patterns for complex geometries. Machine learning approaches are increasingly being applied to predict and compensate for optical distortions and material behavior during the curing process. These computational methods enable precise control over the fabrication process, resulting in higher accuracy, improved surface quality, and reduced production time.

- Multi-material and functional volumetric printing: Recent advances in volumetric additive manufacturing have enabled multi-material and functional printing capabilities. These developments allow for the simultaneous fabrication of objects with varying material properties, embedded electronics, or gradient structures. Techniques include selective activation of different photosensitive materials, sequential printing with material exchange, and the incorporation of functional particles or compounds into the resin. These capabilities expand the application range of volumetric manufacturing to include functional prototypes, biomedical devices, and components with integrated sensing or actuation properties.

02 Advanced photopolymerization systems

Advanced photopolymerization systems for volumetric manufacturing utilize specialized photoinitiators and resins that respond to specific wavelengths of light. These systems employ precisely controlled light sources, such as lasers or digital light processing projectors, to achieve rapid curing while maintaining high resolution. The formulations are designed to prevent light scattering and ensure uniform curing throughout the volume, enabling the production of parts with consistent mechanical properties and surface finish at accelerated production rates.Expand Specific Solutions03 Tomographic projection approaches

Tomographic projection approaches in volumetric additive manufacturing involve rotating the photosensitive resin container while projecting synchronized light patterns from multiple angles. This technique uses computational algorithms to calculate the exact light dose needed at each point in the volume to achieve selective solidification. By optimizing the projection angles and intensity patterns, manufacturers can achieve higher resolution, faster build speeds, and improved material properties compared to conventional additive manufacturing methods.Expand Specific Solutions04 Multi-material volumetric fabrication

Multi-material volumetric fabrication techniques enable the creation of complex objects with varying material properties in a single manufacturing process. These systems utilize multiple resin reservoirs or gradient mixing approaches to introduce different materials or properties within the same build volume. By precisely controlling the spatial distribution of different photopolymer formulations and their curing parameters, manufacturers can create functionally graded materials, embedded structures, and components with region-specific mechanical, optical, or electrical properties.Expand Specific Solutions05 High-throughput process optimization

High-throughput process optimization for volumetric additive manufacturing involves advanced control systems that dynamically adjust fabrication parameters based on real-time feedback. These systems incorporate machine learning algorithms to predict and compensate for material behavior, thermal effects, and optical distortions during the manufacturing process. By optimizing light delivery patterns, resin formulations, and post-processing techniques, manufacturers can achieve significantly higher production rates while maintaining precision and quality across batches.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric AM

Volumetric Additive Manufacturing (VAM) for high-throughput fabrication is currently in an early growth phase, with the market expanding rapidly as industries seek faster production methods. The global market is projected to reach significant scale as manufacturing sectors adopt these technologies for mass production. Technical maturity varies across players: research institutions like Lawrence Livermore National Laboratory, UT-Battelle, and MIT are pioneering fundamental breakthroughs, while companies such as Inkbit, HRL Laboratories, and Adaptive 3D Technologies are commercializing practical applications. Chinese institutions including Huazhong University and Beijing Institute of Technology are advancing parallel research tracks. The competitive landscape features collaboration between national laboratories, academic institutions, and commercial entities working to overcome speed, material, and scale limitations.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has pioneered Computed Axial Lithography (CAL), a revolutionary volumetric additive manufacturing technique that creates 3D objects simultaneously rather than layer-by-layer. Their approach uses synchronized rotation of a photosensitive resin container while projecting computed light patterns, enabling the creation of complex geometries in seconds instead of hours. LLNL's technology achieves printing speeds 100-1000 times faster than conventional methods[1], with resolution capabilities below 100 microns. Their system utilizes sophisticated algorithms for tomographic reconstruction and has demonstrated the ability to produce objects with complex internal features, overhangs, and encapsulated components without support structures. LLNL has also developed specialized resins optimized for volumetric printing that cure rapidly under specific light wavelengths while maintaining mechanical integrity.

Strengths: Dramatically reduced production times (minutes vs. hours); ability to create geometries impossible with traditional layer-by-layer methods; elimination of support structures; isotropic mechanical properties due to simultaneous curing. Weaknesses: Currently limited build volumes compared to some conventional systems; restricted material selection; challenges with extremely high-resolution features below certain thresholds; requires specialized photopolymer formulations.

Inkbit Corp.

Technical Solution: Inkbit has developed Vision-Controlled Jetting (VCJ), an advanced volumetric manufacturing platform that combines high-speed material jetting with real-time 3D scanning to enable unprecedented throughput and precision. Their proprietary system uses machine vision to scan each layer as it's printed, creating a closed-loop feedback system that automatically corrects errors and compensates for material shrinkage or deformation during the build process[4]. This approach allows for printing complex, multi-material objects with micron-level precision at speeds up to 10 times faster than conventional additive manufacturing methods. Inkbit's technology can process highly viscous materials that were previously unprintable, expanding the range of available mechanical properties. Their platform incorporates AI-driven process control that continuously optimizes printing parameters based on real-time data, ensuring consistent quality across production runs while maintaining high throughput rates of up to 2.5 liters per hour for industrial applications.

Strengths: Exceptional accuracy through real-time vision feedback; ability to print with previously unprintable materials including silicones and epoxies; scalable for mass production; multi-material capabilities with sharp interfaces between different materials. Weaknesses: Higher initial equipment investment compared to conventional systems; complex calibration requirements; limited to certain material classes despite expanded range; requires sophisticated software infrastructure and expertise to fully utilize capabilities.

Critical Patents and Innovations in Volumetric Fabrication

Photocrosslinkable ceramic slip and method for the volumetric additive manufacturing of a ceramic component

PatentWO2025153525A1

Innovation

- A photocrosslinkable ceramic slip with a high ceramic particle content and controlled particle size distribution, allowing for light-induced crosslinking and sintering to form ceramic components with a predetermined three-dimensional structure.

High-precision additive manufacturing equipment and high-throughput additive manufacturing system

PatentPendingJP2023534179A

Innovation

- The system employs a microscrew printhead with a threaded stem and conical head, combined with a drive module and actuator, to accurately control the ejection of printing material, utilizing a conical inner surface to seal the nozzle and prevent leakage, and a closed-loop control system for precise volumetric measurement.

Materials Science Advancements for Volumetric AM

The advancement of materials science has been pivotal in expanding the capabilities of Volumetric Additive Manufacturing (VAM). Traditional photopolymer resins used in early VAM systems had significant limitations in terms of mechanical properties, biocompatibility, and functional applications. Recent developments have focused on creating specialized photosensitive materials that can be precisely cured in three-dimensional space while maintaining desired physical and chemical characteristics.

Multi-material compatibility represents one of the most significant breakthroughs in VAM materials science. Researchers have developed dual-initiator systems that allow for selective curing of different material compositions within the same volume, enabling the creation of objects with regionally varied properties. These systems utilize wavelength-specific photoinitiators that respond to different light frequencies, allowing for precise spatial control of material properties.

Nanocomposite photopolymers have emerged as another critical advancement, incorporating nanoscale additives such as carbon nanotubes, graphene, and ceramic nanoparticles into the resin matrix. These additives significantly enhance mechanical strength, thermal stability, and electrical conductivity without compromising the optical transparency required for volumetric curing processes. For instance, silica nanoparticle-reinforced resins have demonstrated up to 300% improvement in tensile strength compared to conventional photopolymers.

Biocompatible and biodegradable materials represent a particularly promising direction for VAM applications in medical fields. Modified polyethylene glycol (PEG) based hydrogels and gelatin methacrylate (GelMA) formulations have been optimized for volumetric printing, enabling the fabrication of complex tissue scaffolds with precisely controlled porosity and mechanical gradients. These materials support cell adhesion and proliferation while maintaining the optical properties necessary for volumetric fabrication.

Thermo-responsive and self-healing materials are expanding the functional capabilities of volumetrically printed objects. These smart materials can change their properties in response to environmental stimuli or repair damage autonomously. For example, incorporating dynamic covalent bonds into photopolymer networks has produced materials that can heal microcracks through thermal activation, significantly extending component lifespan.

The development of low-shrinkage formulations addresses one of the persistent challenges in photopolymerization processes. Novel oligomers with reduced polymerization-induced shrinkage have been synthesized, minimizing internal stresses and improving dimensional accuracy. These materials typically incorporate ring-opening polymerization mechanisms or utilize thiol-ene chemistry to achieve volumetric stability during curing.

Future materials development for VAM is focusing on multi-functional composites that combine structural performance with active properties such as sensing capabilities, energy storage, or programmable response mechanisms. These developments will further expand the application space for high-throughput volumetric manufacturing across industries ranging from aerospace to healthcare.

Multi-material compatibility represents one of the most significant breakthroughs in VAM materials science. Researchers have developed dual-initiator systems that allow for selective curing of different material compositions within the same volume, enabling the creation of objects with regionally varied properties. These systems utilize wavelength-specific photoinitiators that respond to different light frequencies, allowing for precise spatial control of material properties.

Nanocomposite photopolymers have emerged as another critical advancement, incorporating nanoscale additives such as carbon nanotubes, graphene, and ceramic nanoparticles into the resin matrix. These additives significantly enhance mechanical strength, thermal stability, and electrical conductivity without compromising the optical transparency required for volumetric curing processes. For instance, silica nanoparticle-reinforced resins have demonstrated up to 300% improvement in tensile strength compared to conventional photopolymers.

Biocompatible and biodegradable materials represent a particularly promising direction for VAM applications in medical fields. Modified polyethylene glycol (PEG) based hydrogels and gelatin methacrylate (GelMA) formulations have been optimized for volumetric printing, enabling the fabrication of complex tissue scaffolds with precisely controlled porosity and mechanical gradients. These materials support cell adhesion and proliferation while maintaining the optical properties necessary for volumetric fabrication.

Thermo-responsive and self-healing materials are expanding the functional capabilities of volumetrically printed objects. These smart materials can change their properties in response to environmental stimuli or repair damage autonomously. For example, incorporating dynamic covalent bonds into photopolymer networks has produced materials that can heal microcracks through thermal activation, significantly extending component lifespan.

The development of low-shrinkage formulations addresses one of the persistent challenges in photopolymerization processes. Novel oligomers with reduced polymerization-induced shrinkage have been synthesized, minimizing internal stresses and improving dimensional accuracy. These materials typically incorporate ring-opening polymerization mechanisms or utilize thiol-ene chemistry to achieve volumetric stability during curing.

Future materials development for VAM is focusing on multi-functional composites that combine structural performance with active properties such as sensing capabilities, energy storage, or programmable response mechanisms. These developments will further expand the application space for high-throughput volumetric manufacturing across industries ranging from aerospace to healthcare.

Sustainability Impact of High-Throughput Volumetric Manufacturing

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in sustainable manufacturing practices, offering significant environmental benefits compared to traditional manufacturing methods. The high-throughput nature of VAM substantially reduces material waste through its additive approach, utilizing only the necessary materials for object creation rather than subtractive techniques that generate considerable scrap. This efficiency translates to approximately 30-70% reduction in raw material consumption depending on geometry complexity.

Energy efficiency constitutes another critical sustainability advantage of high-throughput VAM. The volumetric approach enables simultaneous solidification of entire object volumes, dramatically reducing production time from hours to minutes or even seconds. This time compression correlates directly with energy savings, with some studies indicating up to 60% reduction in energy consumption compared to layer-by-layer additive manufacturing and up to 85% compared to traditional manufacturing for certain applications.

The carbon footprint reduction potential of high-throughput VAM extends beyond direct manufacturing processes. By enabling on-demand, localized production, VAM can significantly reduce transportation emissions associated with global supply chains. Analysis suggests potential reductions of 25-40% in transportation-related carbon emissions when implementing distributed manufacturing models enabled by VAM technologies.

Water conservation represents an often-overlooked sustainability benefit of VAM systems. Unlike traditional manufacturing processes requiring substantial cooling and cleaning operations, most VAM systems operate with minimal water requirements. This characteristic is particularly valuable in water-stressed regions where manufacturing operations face increasing scrutiny regarding water consumption patterns.

The extended lifecycle impact of VAM-produced components further enhances sustainability metrics. The design freedom inherent in volumetric manufacturing enables topology optimization and lightweighting strategies that reduce material requirements while maintaining functional performance. These optimized designs can reduce operational energy consumption in applications ranging from automotive to aerospace, with lifecycle assessments indicating potential 15-30% improvements in overall environmental impact.

Chemical sustainability also improves with advanced VAM systems. Many contemporary volumetric manufacturing approaches utilize photopolymers with significantly lower toxicity profiles than materials employed in conventional manufacturing. The continued development of bio-based and biodegradable resins compatible with VAM processes promises further improvements in this domain, potentially reducing end-of-life environmental impacts by 40-60% compared to petroleum-based alternatives.

Energy efficiency constitutes another critical sustainability advantage of high-throughput VAM. The volumetric approach enables simultaneous solidification of entire object volumes, dramatically reducing production time from hours to minutes or even seconds. This time compression correlates directly with energy savings, with some studies indicating up to 60% reduction in energy consumption compared to layer-by-layer additive manufacturing and up to 85% compared to traditional manufacturing for certain applications.

The carbon footprint reduction potential of high-throughput VAM extends beyond direct manufacturing processes. By enabling on-demand, localized production, VAM can significantly reduce transportation emissions associated with global supply chains. Analysis suggests potential reductions of 25-40% in transportation-related carbon emissions when implementing distributed manufacturing models enabled by VAM technologies.

Water conservation represents an often-overlooked sustainability benefit of VAM systems. Unlike traditional manufacturing processes requiring substantial cooling and cleaning operations, most VAM systems operate with minimal water requirements. This characteristic is particularly valuable in water-stressed regions where manufacturing operations face increasing scrutiny regarding water consumption patterns.

The extended lifecycle impact of VAM-produced components further enhances sustainability metrics. The design freedom inherent in volumetric manufacturing enables topology optimization and lightweighting strategies that reduce material requirements while maintaining functional performance. These optimized designs can reduce operational energy consumption in applications ranging from automotive to aerospace, with lifecycle assessments indicating potential 15-30% improvements in overall environmental impact.

Chemical sustainability also improves with advanced VAM systems. Many contemporary volumetric manufacturing approaches utilize photopolymers with significantly lower toxicity profiles than materials employed in conventional manufacturing. The continued development of bio-based and biodegradable resins compatible with VAM processes promises further improvements in this domain, potentially reducing end-of-life environmental impacts by 40-60% compared to petroleum-based alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!