What Limits The Scalability Of Volumetric Additive Manufacturing?

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Evolution and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing, evolving from traditional layer-by-layer approaches to simultaneous whole-volume solidification. This revolutionary technique emerged in the early 2010s as researchers sought to overcome the speed limitations inherent in conventional additive manufacturing methods. The fundamental concept of VAM involves projecting patterns of light into photosensitive resins to cure entire volumes simultaneously, dramatically reducing production times from hours to minutes or even seconds.

The evolution of VAM can be traced through several key developmental phases. Initially, researchers focused on proof-of-concept demonstrations using simple computed tomography principles. By 2017, significant breakthroughs occurred with the introduction of computed axial lithography (CAL), which utilized synchronized multi-angle light projections to create complex 3D structures. Subsequent advancements in 2019-2020 saw the integration of more sophisticated algorithms and optical systems, enabling higher resolution and more intricate geometries.

Recent developments have concentrated on expanding material compatibility beyond photopolymers to include ceramics, composites, and biomaterials, significantly broadening potential application domains. Parallel efforts have focused on scaling production volumes while maintaining precision, with notable progress in overcoming the resolution-volume tradeoff that has historically constrained the technology.

The primary objectives driving VAM research and development center around three interconnected goals. First, achieving industrial-scale production capabilities while preserving the exceptional speed advantages that distinguish VAM from conventional additive manufacturing. Second, enhancing resolution capabilities to compete with high-precision conventional 3D printing methods, particularly for applications requiring intricate microstructures. Third, expanding material versatility to accommodate a wider range of engineering requirements and application scenarios.

Technical objectives also include improving the uniformity of curing throughout volumes, especially for larger objects where light penetration and scattering effects become significant challenges. Additionally, researchers aim to develop more sophisticated computational models that can accurately predict and compensate for optical distortions, refractive effects, and other phenomena that impact printing fidelity.

The trajectory of VAM technology points toward integration with existing manufacturing ecosystems, requiring standardization efforts and compatibility with established workflows. As the technology matures, objectives increasingly focus on cost reduction and accessibility, potentially democratizing high-speed 3D printing capabilities across industries ranging from medical device manufacturing to consumer products.

The evolution of VAM can be traced through several key developmental phases. Initially, researchers focused on proof-of-concept demonstrations using simple computed tomography principles. By 2017, significant breakthroughs occurred with the introduction of computed axial lithography (CAL), which utilized synchronized multi-angle light projections to create complex 3D structures. Subsequent advancements in 2019-2020 saw the integration of more sophisticated algorithms and optical systems, enabling higher resolution and more intricate geometries.

Recent developments have concentrated on expanding material compatibility beyond photopolymers to include ceramics, composites, and biomaterials, significantly broadening potential application domains. Parallel efforts have focused on scaling production volumes while maintaining precision, with notable progress in overcoming the resolution-volume tradeoff that has historically constrained the technology.

The primary objectives driving VAM research and development center around three interconnected goals. First, achieving industrial-scale production capabilities while preserving the exceptional speed advantages that distinguish VAM from conventional additive manufacturing. Second, enhancing resolution capabilities to compete with high-precision conventional 3D printing methods, particularly for applications requiring intricate microstructures. Third, expanding material versatility to accommodate a wider range of engineering requirements and application scenarios.

Technical objectives also include improving the uniformity of curing throughout volumes, especially for larger objects where light penetration and scattering effects become significant challenges. Additionally, researchers aim to develop more sophisticated computational models that can accurately predict and compensate for optical distortions, refractive effects, and other phenomena that impact printing fidelity.

The trajectory of VAM technology points toward integration with existing manufacturing ecosystems, requiring standardization efforts and compatibility with established workflows. As the technology matures, objectives increasingly focus on cost reduction and accessibility, potentially democratizing high-speed 3D printing capabilities across industries ranging from medical device manufacturing to consumer products.

Market Analysis for Scalable Volumetric Manufacturing

The volumetric additive manufacturing (VAM) market is experiencing significant growth potential as industries seek faster, more efficient production methods. Current market analysis indicates that the global 3D printing market, valued at approximately $13.7 billion in 2021, is projected to reach $51 billion by 2030, with volumetric manufacturing representing an emerging high-growth segment within this broader market.

Key market drivers for scalable volumetric manufacturing include increasing demand for rapid prototyping across automotive, aerospace, healthcare, and consumer goods sectors. The healthcare segment shows particularly strong potential, with medical device manufacturing and bioprinting applications creating substantial market pull for volumetric technologies that can produce complex, customized structures in single operations.

Industrial manufacturing represents another significant market opportunity, with companies seeking to reduce production time and material waste while maintaining high precision. The ability of volumetric manufacturing to produce parts without support structures and with reduced post-processing requirements creates compelling value propositions for these sectors.

Regional market analysis reveals North America currently leads in volumetric manufacturing adoption, accounting for approximately 40% of the market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing industrial automation and manufacturing investments in China, Japan, and South Korea.

Market barriers include the high initial investment costs for volumetric systems, which currently range from $100,000 to $500,000 depending on build volume and resolution capabilities. This presents a significant adoption hurdle for small and medium enterprises, limiting market penetration in certain segments.

Customer demand patterns indicate growing interest in larger build volumes while maintaining high resolution, creating technical challenges that directly impact market growth. Current market offerings typically feature build volumes under 100mm³ for high-precision applications, with resolution decreasing significantly as build volumes increase.

Market forecasts suggest that as technical limitations are overcome, particularly in resin chemistry and optical control systems, the volumetric manufacturing market segment could grow at a CAGR of 25-30% through 2028, outpacing the broader additive manufacturing market. This growth trajectory depends heavily on successful scaling of the technology to meet industrial production requirements while maintaining cost-effectiveness.

Key market drivers for scalable volumetric manufacturing include increasing demand for rapid prototyping across automotive, aerospace, healthcare, and consumer goods sectors. The healthcare segment shows particularly strong potential, with medical device manufacturing and bioprinting applications creating substantial market pull for volumetric technologies that can produce complex, customized structures in single operations.

Industrial manufacturing represents another significant market opportunity, with companies seeking to reduce production time and material waste while maintaining high precision. The ability of volumetric manufacturing to produce parts without support structures and with reduced post-processing requirements creates compelling value propositions for these sectors.

Regional market analysis reveals North America currently leads in volumetric manufacturing adoption, accounting for approximately 40% of the market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing industrial automation and manufacturing investments in China, Japan, and South Korea.

Market barriers include the high initial investment costs for volumetric systems, which currently range from $100,000 to $500,000 depending on build volume and resolution capabilities. This presents a significant adoption hurdle for small and medium enterprises, limiting market penetration in certain segments.

Customer demand patterns indicate growing interest in larger build volumes while maintaining high resolution, creating technical challenges that directly impact market growth. Current market offerings typically feature build volumes under 100mm³ for high-precision applications, with resolution decreasing significantly as build volumes increase.

Market forecasts suggest that as technical limitations are overcome, particularly in resin chemistry and optical control systems, the volumetric manufacturing market segment could grow at a CAGR of 25-30% through 2028, outpacing the broader additive manufacturing market. This growth trajectory depends heavily on successful scaling of the technology to meet industrial production requirements while maintaining cost-effectiveness.

Technical Barriers in Volumetric AM Scalability

Volumetric Additive Manufacturing (VAM) faces significant technical barriers that limit its scalability despite its promising advantages over traditional layer-by-layer approaches. The fundamental challenge lies in the photochemical process itself, where the simultaneous projection of patterned light throughout a photosensitive resin volume creates complex constraints on energy delivery and material response.

One primary limitation is the optical penetration depth in photopolymer resins. As build volumes increase, light must travel through greater distances of material, leading to exponential attenuation according to the Beer-Lambert law. This physical constraint creates a trade-off between build size and resolution that becomes increasingly problematic at larger scales. Attempts to increase light intensity to overcome this limitation often result in uncontrolled polymerization and heat generation that degrades print quality.

The resin formulation presents another significant barrier. Current photopolymer systems optimized for volumetric printing require carefully balanced photoinitiator concentrations, oxygen inhibition characteristics, and viscosity profiles. These properties must maintain consistency throughout the entire volume during printing, which becomes exponentially more difficult as build sizes increase. Additionally, heat management during polymerization becomes critical at larger scales, as exothermic reactions can create thermal gradients that distort prints.

Computational challenges also impede scalability. The tomographic reconstruction algorithms used to generate the projection patterns become computationally intensive as resolution and volume increase. Real-time processing of these complex calculations requires substantial computing resources that scale non-linearly with build volume, creating practical limitations for industrial implementation.

Hardware constraints further complicate scaling efforts. Current optical systems struggle to maintain uniform light intensity and focus throughout larger volumes, leading to inconsistent curing and dimensional inaccuracies. The precision mechanical systems required for rotation and positioning also face increased challenges with larger resin containers, including vibration issues and alignment precision that deteriorates with scale.

Material removal and post-processing present additional barriers. As build volumes increase, the challenges of removing uncured resin from complex internal structures become more pronounced. The development of specialized washing techniques and support removal strategies that can effectively handle larger, more complex parts remains an active area of research but currently limits practical applications.

These technical barriers collectively create a complex optimization problem where improvements in one area often create new challenges in others. Overcoming these limitations requires interdisciplinary approaches spanning optics, materials science, computational methods, and mechanical engineering to develop truly scalable volumetric manufacturing solutions.

One primary limitation is the optical penetration depth in photopolymer resins. As build volumes increase, light must travel through greater distances of material, leading to exponential attenuation according to the Beer-Lambert law. This physical constraint creates a trade-off between build size and resolution that becomes increasingly problematic at larger scales. Attempts to increase light intensity to overcome this limitation often result in uncontrolled polymerization and heat generation that degrades print quality.

The resin formulation presents another significant barrier. Current photopolymer systems optimized for volumetric printing require carefully balanced photoinitiator concentrations, oxygen inhibition characteristics, and viscosity profiles. These properties must maintain consistency throughout the entire volume during printing, which becomes exponentially more difficult as build sizes increase. Additionally, heat management during polymerization becomes critical at larger scales, as exothermic reactions can create thermal gradients that distort prints.

Computational challenges also impede scalability. The tomographic reconstruction algorithms used to generate the projection patterns become computationally intensive as resolution and volume increase. Real-time processing of these complex calculations requires substantial computing resources that scale non-linearly with build volume, creating practical limitations for industrial implementation.

Hardware constraints further complicate scaling efforts. Current optical systems struggle to maintain uniform light intensity and focus throughout larger volumes, leading to inconsistent curing and dimensional inaccuracies. The precision mechanical systems required for rotation and positioning also face increased challenges with larger resin containers, including vibration issues and alignment precision that deteriorates with scale.

Material removal and post-processing present additional barriers. As build volumes increase, the challenges of removing uncured resin from complex internal structures become more pronounced. The development of specialized washing techniques and support removal strategies that can effectively handle larger, more complex parts remains an active area of research but currently limits practical applications.

These technical barriers collectively create a complex optimization problem where improvements in one area often create new challenges in others. Overcoming these limitations requires interdisciplinary approaches spanning optics, materials science, computational methods, and mechanical engineering to develop truly scalable volumetric manufacturing solutions.

Current Approaches to Volumetric AM Scaling

01 Continuous volumetric additive manufacturing techniques

Continuous volumetric additive manufacturing techniques enable scalable production by allowing for uninterrupted printing processes. These methods overcome traditional layer-by-layer limitations by solidifying entire volumes simultaneously or continuously, significantly reducing production time. Advanced technologies like computed axial lithography (CAL) and tomographic volumetric printing allow for rapid production of complex structures without the need for support structures, enhancing scalability for industrial applications.- Scaling volumetric additive manufacturing through process optimization: Process optimization techniques can significantly enhance the scalability of volumetric additive manufacturing. This includes optimizing light delivery systems, improving resin formulations for faster curing, and developing advanced algorithms for controlling the manufacturing process. These optimizations enable faster production rates, larger build volumes, and improved part quality, which are essential for industrial-scale applications.

- Multi-material and multi-scale manufacturing capabilities: Advanced volumetric additive manufacturing systems can be scaled to handle multiple materials simultaneously and operate across different dimensional scales. These systems incorporate specialized material delivery mechanisms, switchable material reservoirs, and precise control systems that allow for the creation of complex, multi-material structures. This capability enables the production of functionally graded materials and hierarchical structures with tailored properties.

- Integration with industrial production systems: Scaling volumetric additive manufacturing for industrial applications involves integrating these systems with existing production lines and workflows. This includes developing standardized interfaces, automated material handling systems, and quality control mechanisms. Such integration enables continuous production, reduces human intervention, and ensures consistent part quality across manufacturing batches.

- Advanced control systems and computational methods: Sophisticated control systems and computational methods are crucial for scaling volumetric additive manufacturing. These include real-time monitoring systems, machine learning algorithms for process optimization, and advanced simulation tools that predict and compensate for manufacturing variations. These technologies enable precise control over the manufacturing process, resulting in improved part quality and manufacturing reliability at scale.

- Novel energy delivery systems for large-scale manufacturing: Innovative energy delivery systems are being developed to enable large-scale volumetric additive manufacturing. These systems include advanced optical setups, synchronized multiple light sources, and specialized energy distribution mechanisms that can cure larger volumes of material simultaneously. By increasing the effective build volume and reducing production time, these systems make volumetric additive manufacturing viable for producing larger components and higher production volumes.

02 Multi-material and multi-scale manufacturing capabilities

Scalable volumetric additive manufacturing systems incorporate multi-material and multi-scale capabilities to address diverse industrial requirements. These systems can process various materials simultaneously, from polymers to composites, and produce components with features spanning from micro to macro scales. This versatility enables the production of functionally graded materials and complex geometries with varying properties throughout the structure, expanding the application range and production scalability of volumetric manufacturing.Expand Specific Solutions03 Parallel processing and distributed manufacturing systems

Parallel processing and distributed manufacturing approaches significantly enhance the scalability of volumetric additive manufacturing. By employing multiple projection sources or printing units operating simultaneously, these systems can dramatically increase production throughput. Distributed manufacturing networks allow for coordinated production across multiple locations, optimizing resource utilization and reducing logistical constraints. These approaches enable efficient scaling from prototype to mass production while maintaining consistent quality across manufacturing sites.Expand Specific Solutions04 Advanced resin formulations and curing mechanisms

Specialized resin formulations and innovative curing mechanisms are critical for scaling volumetric additive manufacturing. These advanced materials feature optimized viscosity, photoinitiator systems, and thermal properties that enable faster curing times while maintaining structural integrity. Novel curing approaches, including two-photon polymerization and oxygen inhibition control, allow for precise solidification within volumes rather than surfaces, facilitating higher production speeds and larger build volumes without compromising resolution or mechanical properties.Expand Specific Solutions05 Computational optimization and digital workflow integration

Computational optimization and integrated digital workflows are essential for scaling volumetric additive manufacturing to industrial levels. Advanced algorithms optimize light dose distribution, material parameters, and manufacturing sequences to maximize build volume while maintaining precision. Machine learning approaches predict and compensate for material behavior during processing, reducing defects in scaled production. Seamless integration with design software, simulation tools, and quality control systems creates end-to-end digital workflows that enhance repeatability and facilitate the transition from prototype to mass production.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric AM

Volumetric Additive Manufacturing (VAM) is currently in an early growth phase, with the market expected to expand significantly as technical limitations are addressed. The global market size is estimated at $2-3 billion but growing rapidly at 20-25% annually. Technical scalability remains constrained by several factors including light penetration depth, resin viscosity, and resolution-speed tradeoffs. Leading players like 3D Systems and MIT are advancing solutions through novel photopolymerization techniques, while industrial giants such as Siemens and Align Technology are developing application-specific implementations. Academic institutions (Carnegie Mellon, EPFL) are pioneering fundamental research in material science and process optimization, while specialized firms like HRL Laboratories and coobx AG focus on proprietary light-based curing technologies to overcome current volumetric limitations.

3D Systems, Inc.

Technical Solution: 3D Systems has developed Figure 4 technology, a non-contact membrane-based approach that addresses volumetric manufacturing scalability. Their solution utilizes continuous Digital Light Processing (cDLP) with a light-permeable membrane that enables continuous part movement during printing, significantly reducing separation forces. This technology overcomes traditional layer-by-layer limitations by implementing a continuous vertical build process with oxygen-inhibited chemistry. Their proprietary materials portfolio includes photopolymers specifically engineered to overcome resin viscosity challenges that typically limit build volume. The company has also implemented parallel processing capabilities where multiple parts can be produced simultaneously within the build volume, effectively increasing throughput without expanding physical dimensions. Their software ecosystem incorporates advanced slicing algorithms that optimize light distribution throughout the volume to ensure consistent curing and minimize optical distortion effects that typically limit scalability.

Strengths: Proprietary membrane technology reduces separation forces, enabling faster production speeds and larger build volumes. Their extensive materials science expertise allows for custom formulations that maintain consistent properties throughout large volumes. Weaknesses: System still faces fundamental physics constraints related to light penetration depth in larger volumes, and heat dissipation remains challenging in scaled-up implementations.

Massachusetts Institute of Technology

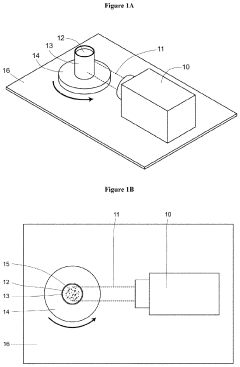

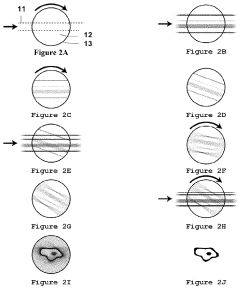

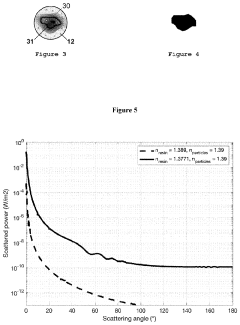

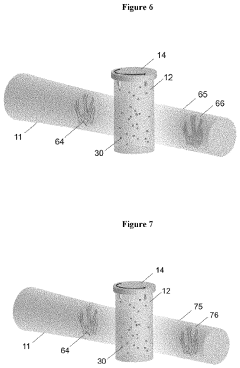

Technical Solution: MIT researchers have pioneered Computed Axial Lithography (CAL) to address volumetric additive manufacturing scalability limitations. This revolutionary approach projects synchronized 2D light patterns from multiple angles into a photosensitive resin, creating 3D structures without the need for layering. MIT's implementation uses sophisticated tomographic reconstruction algorithms that calculate precise light dose distributions throughout the entire volume, enabling simultaneous solidification of the complete object. Their research has demonstrated the ability to create complex internal geometries impossible with traditional layer-based methods. MIT has also developed specialized photoinitiator systems with carefully tuned absorption coefficients that allow light to penetrate deeper into the resin while maintaining resolution. Their work includes computational models that account for light scattering and absorption effects, which typically limit build volume. Recent advancements incorporate real-time feedback systems using optical sensors to monitor and adjust light patterns during printing, compensating for material variations that would otherwise constrain scalability.

Strengths: Eliminates mechanical constraints of layer-based approaches, enabling significantly faster production times (30-120 seconds vs. hours). Their tomographic approach allows for complex internal structures without support materials. Weaknesses: Current implementations face resolution limitations at larger volumes due to light scattering effects, and material options remain limited compared to conventional additive manufacturing techniques.

Critical Patents and Breakthroughs in Volumetric Printing

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentPendingUS20220274326A1

Innovation

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1000 nm, to reduce light scattering and improve the accuracy of three-dimensional object formation by creating a controlled three-dimensional dose distribution.

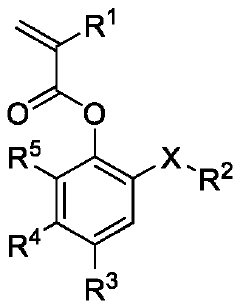

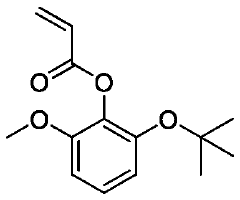

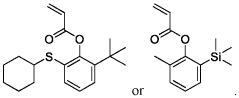

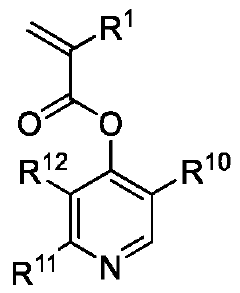

Monomeric and polymeric compositions and methods of producing and using the same

PatentWO2022226416A1

Innovation

- Development of photo-curable resins with polymerizable monomers having low vapor pressure and high boiling points, which act as viscosity modifiers and cross-linkers, enabling the creation of polymeric materials with improved thermomechanical properties suitable for medical devices like orthodontic appliances.

Material Science Challenges in Large-Scale Volumetric Printing

Volumetric additive manufacturing (VAM) faces significant material science challenges when scaling to larger dimensions. The photosensitive resins used in VAM must maintain consistent optical properties throughout the entire volume, which becomes increasingly difficult as build sizes increase. Light scattering and absorption effects intensify with distance, creating non-uniform curing patterns that compromise structural integrity in larger prints.

The rheological properties of printing materials present another major obstacle. As build volumes increase, the viscosity and flow characteristics of resins become critical factors. Higher viscosity materials resist movement during the printing process, potentially creating internal stresses and defects, while lower viscosity materials may not maintain their position during curing, leading to dimensional inaccuracies in larger structures.

Thermal management emerges as a paramount concern in large-scale VAM. The exothermic polymerization reactions generate substantial heat during curing, which dissipates inefficiently in larger volumes. This can lead to thermal gradients, causing differential curing rates, warping, and internal stress accumulation. These thermal issues become exponentially more problematic as print dimensions increase.

Material homogeneity across large volumes presents significant challenges. Ensuring uniform distribution of photoinitiators, monomers, and other additives becomes increasingly difficult in larger resin baths. Sedimentation, phase separation, and concentration gradients can develop over time, particularly in materials formulated for high-resolution printing, resulting in inconsistent mechanical properties throughout the printed object.

The development of advanced composite materials for large-scale VAM introduces additional complexities. Incorporating reinforcement particles or fibers to enhance mechanical properties often increases light scattering and absorption, limiting penetration depth. Finding the optimal balance between mechanical performance and optical properties remains a significant research challenge for scaling volumetric printing technologies.

Shelf-life and stability considerations become more critical with larger material volumes. Photosensitive resins may undergo premature polymerization or degradation when stored in large quantities, particularly under varying environmental conditions. Developing stabilization strategies that maintain consistent material properties throughout extended printing processes represents a substantial material science challenge for industrial-scale implementation of volumetric manufacturing technologies.

The rheological properties of printing materials present another major obstacle. As build volumes increase, the viscosity and flow characteristics of resins become critical factors. Higher viscosity materials resist movement during the printing process, potentially creating internal stresses and defects, while lower viscosity materials may not maintain their position during curing, leading to dimensional inaccuracies in larger structures.

Thermal management emerges as a paramount concern in large-scale VAM. The exothermic polymerization reactions generate substantial heat during curing, which dissipates inefficiently in larger volumes. This can lead to thermal gradients, causing differential curing rates, warping, and internal stress accumulation. These thermal issues become exponentially more problematic as print dimensions increase.

Material homogeneity across large volumes presents significant challenges. Ensuring uniform distribution of photoinitiators, monomers, and other additives becomes increasingly difficult in larger resin baths. Sedimentation, phase separation, and concentration gradients can develop over time, particularly in materials formulated for high-resolution printing, resulting in inconsistent mechanical properties throughout the printed object.

The development of advanced composite materials for large-scale VAM introduces additional complexities. Incorporating reinforcement particles or fibers to enhance mechanical properties often increases light scattering and absorption, limiting penetration depth. Finding the optimal balance between mechanical performance and optical properties remains a significant research challenge for scaling volumetric printing technologies.

Shelf-life and stability considerations become more critical with larger material volumes. Photosensitive resins may undergo premature polymerization or degradation when stored in large quantities, particularly under varying environmental conditions. Developing stabilization strategies that maintain consistent material properties throughout extended printing processes represents a substantial material science challenge for industrial-scale implementation of volumetric manufacturing technologies.

Energy Efficiency and Sustainability Considerations

Volumetric Additive Manufacturing (VAM) faces significant challenges in energy efficiency and sustainability that directly impact its scalability potential. The energy consumption of VAM systems is considerably higher than traditional manufacturing methods, primarily due to the high-powered light sources required for photopolymerization processes. Current VAM technologies utilize powerful lasers or projector systems that operate continuously during production, resulting in substantial electricity consumption that increases proportionally with manufacturing volume and complexity.

Material efficiency represents another critical sustainability concern. While VAM offers advantages in reducing material waste compared to subtractive manufacturing, the photopolymer resins commonly used are petroleum-based and non-biodegradable. These materials present environmental challenges throughout their lifecycle, from production to disposal. Additionally, the chemical additives required for optimal photopolymerization performance often include photoinitiators and stabilizers that may have negative environmental impacts.

Thermal management during the VAM process contributes significantly to energy inefficiency. The conversion of light energy to chemical energy during photopolymerization generates substantial heat that must be dissipated to maintain process stability and product quality. As manufacturing volumes increase, cooling systems consume additional energy, creating a compounding effect on overall energy requirements.

The carbon footprint of VAM extends beyond direct energy consumption to include the embodied energy in specialized equipment and materials. The production of precision optical components, high-powered light sources, and specialized photopolymers involves energy-intensive processes and rare materials with their own environmental implications. This upstream environmental impact is often overlooked in scalability assessments.

Recycling and end-of-life considerations present further sustainability challenges. Unlike some traditional manufacturing materials, cured photopolymers used in VAM are difficult to recycle or repurpose, contributing to long-term waste accumulation. As production scales up, this waste stream becomes increasingly significant, potentially offsetting the material efficiency benefits of the additive approach.

Recent research has begun addressing these limitations through the development of bio-based resins, energy-efficient light sources, and optimized process parameters. Some promising approaches include pulsed illumination strategies that reduce continuous energy requirements, and the integration of renewable energy sources to power VAM systems. However, these solutions remain in early development stages and have yet to demonstrate viability at industrial scales.

Material efficiency represents another critical sustainability concern. While VAM offers advantages in reducing material waste compared to subtractive manufacturing, the photopolymer resins commonly used are petroleum-based and non-biodegradable. These materials present environmental challenges throughout their lifecycle, from production to disposal. Additionally, the chemical additives required for optimal photopolymerization performance often include photoinitiators and stabilizers that may have negative environmental impacts.

Thermal management during the VAM process contributes significantly to energy inefficiency. The conversion of light energy to chemical energy during photopolymerization generates substantial heat that must be dissipated to maintain process stability and product quality. As manufacturing volumes increase, cooling systems consume additional energy, creating a compounding effect on overall energy requirements.

The carbon footprint of VAM extends beyond direct energy consumption to include the embodied energy in specialized equipment and materials. The production of precision optical components, high-powered light sources, and specialized photopolymers involves energy-intensive processes and rare materials with their own environmental implications. This upstream environmental impact is often overlooked in scalability assessments.

Recycling and end-of-life considerations present further sustainability challenges. Unlike some traditional manufacturing materials, cured photopolymers used in VAM are difficult to recycle or repurpose, contributing to long-term waste accumulation. As production scales up, this waste stream becomes increasingly significant, potentially offsetting the material efficiency benefits of the additive approach.

Recent research has begun addressing these limitations through the development of bio-based resins, energy-efficient light sources, and optimized process parameters. Some promising approaches include pulsed illumination strategies that reduce continuous energy requirements, and the integration of renewable energy sources to power VAM systems. However, these solutions remain in early development stages and have yet to demonstrate viability at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!