Volumetric Additive Manufacturing For Aerospace Fuel System Components

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace VAM Technology Evolution and Objectives

Volumetric Additive Manufacturing (VAM) for aerospace applications has evolved significantly over the past two decades, transforming from experimental laboratory techniques to viable manufacturing processes for critical components. The technology originated in the early 2000s when researchers began exploring the potential of creating three-dimensional structures through photopolymerization of entire volumes simultaneously, rather than layer-by-layer approaches used in conventional additive manufacturing.

The evolution of VAM technology has been marked by several key milestones. Initially limited to simple geometries and basic materials, advances in computational tomography reconstruction algorithms around 2010 enabled more complex internal structures. By 2015, the introduction of multi-wavelength light sources and tunable photoinhibitors significantly improved resolution capabilities, allowing for feature sizes below 100 microns while maintaining structural integrity across larger components.

For aerospace fuel system applications specifically, VAM technology development has focused on addressing the unique challenges of this domain. The ability to create complex internal flow channels, integrated sensors, and functionally graded materials has positioned VAM as a promising manufacturing approach for fuel system components that traditionally required assembly of multiple parts.

Current technological objectives for aerospace VAM implementation center on several critical areas. Material qualification remains paramount, with ongoing research focused on developing photopolymer resins that meet stringent aerospace requirements for chemical compatibility with aviation fuels, temperature resistance, and long-term durability. Resolution enhancement continues to be a priority, with the goal of achieving feature sizes below 50 microns while maintaining build volumes suitable for practical aerospace components.

Process reliability and repeatability represent another crucial objective, as aerospace applications demand consistent performance across production runs. This includes developing robust in-situ monitoring systems and closed-loop feedback mechanisms to ensure quality control during the manufacturing process. Computational modeling capabilities are being enhanced to accurately predict material behavior during photopolymerization and subsequent in-service conditions.

The integration of multi-material capabilities stands as perhaps the most ambitious objective, with research aimed at enabling single-build components that incorporate different material properties in specific regions. This would allow, for example, rigid structural sections alongside flexible sealing surfaces within fuel system components, potentially revolutionizing design approaches for these critical systems.

Looking forward, the technology roadmap for aerospace VAM focuses on certification pathways, scaling production capabilities, and developing specialized materials that address the unique requirements of next-generation aircraft fuel systems, including compatibility with sustainable aviation fuels and hydrogen propulsion systems.

The evolution of VAM technology has been marked by several key milestones. Initially limited to simple geometries and basic materials, advances in computational tomography reconstruction algorithms around 2010 enabled more complex internal structures. By 2015, the introduction of multi-wavelength light sources and tunable photoinhibitors significantly improved resolution capabilities, allowing for feature sizes below 100 microns while maintaining structural integrity across larger components.

For aerospace fuel system applications specifically, VAM technology development has focused on addressing the unique challenges of this domain. The ability to create complex internal flow channels, integrated sensors, and functionally graded materials has positioned VAM as a promising manufacturing approach for fuel system components that traditionally required assembly of multiple parts.

Current technological objectives for aerospace VAM implementation center on several critical areas. Material qualification remains paramount, with ongoing research focused on developing photopolymer resins that meet stringent aerospace requirements for chemical compatibility with aviation fuels, temperature resistance, and long-term durability. Resolution enhancement continues to be a priority, with the goal of achieving feature sizes below 50 microns while maintaining build volumes suitable for practical aerospace components.

Process reliability and repeatability represent another crucial objective, as aerospace applications demand consistent performance across production runs. This includes developing robust in-situ monitoring systems and closed-loop feedback mechanisms to ensure quality control during the manufacturing process. Computational modeling capabilities are being enhanced to accurately predict material behavior during photopolymerization and subsequent in-service conditions.

The integration of multi-material capabilities stands as perhaps the most ambitious objective, with research aimed at enabling single-build components that incorporate different material properties in specific regions. This would allow, for example, rigid structural sections alongside flexible sealing surfaces within fuel system components, potentially revolutionizing design approaches for these critical systems.

Looking forward, the technology roadmap for aerospace VAM focuses on certification pathways, scaling production capabilities, and developing specialized materials that address the unique requirements of next-generation aircraft fuel systems, including compatibility with sustainable aviation fuels and hydrogen propulsion systems.

Market Analysis for Aerospace Fuel System Components

The aerospace fuel system components market is experiencing significant growth, driven by increasing aircraft production rates and the need for more efficient, lightweight components. The global market for these components was valued at approximately $4.2 billion in 2022 and is projected to reach $6.5 billion by 2028, representing a compound annual growth rate of 7.5%. This growth trajectory is supported by the expanding commercial aviation sector and increasing defense budgets worldwide.

Commercial aviation represents the largest market segment, accounting for roughly 60% of the total market share. Military applications follow at 30%, with the remaining 10% distributed across general aviation and space applications. Geographically, North America dominates with 40% market share, followed by Europe (30%), Asia-Pacific (20%), and the rest of the world (10%).

The demand for aerospace fuel system components is primarily driven by the need for fuel efficiency, weight reduction, and enhanced performance. Airlines are increasingly seeking components that can withstand extreme operating conditions while minimizing fuel consumption. Additionally, stringent safety regulations and environmental concerns are pushing manufacturers to develop components with improved reliability and reduced environmental impact.

Volumetric Additive Manufacturing (VAM) is emerging as a disruptive technology in this market, offering significant advantages over traditional manufacturing methods. The ability to produce complex geometries with internal channels and optimized flow paths is particularly valuable for fuel system components such as pumps, valves, and filters. Market analysis indicates that VAM-produced components can achieve weight reductions of 20-30% compared to conventionally manufactured parts, directly translating to fuel savings for aircraft operators.

The adoption of VAM for aerospace fuel system components is still in its early stages, with an estimated market penetration of less than 5%. However, this is expected to grow substantially, reaching 15-20% by 2030. Early adopters include major aerospace manufacturers such as GE Aviation, Rolls-Royce, and Safran, who are investing heavily in VAM capabilities.

Customer requirements in this market segment emphasize reliability, certification compliance, and cost-effectiveness. The total cost of ownership, including maintenance and operational efficiency, is becoming increasingly important in purchasing decisions. VAM-produced components must demonstrate clear advantages in these areas to achieve widespread market acceptance.

The competitive landscape is characterized by established aerospace component manufacturers expanding their additive manufacturing capabilities, alongside specialized AM service providers entering the aerospace supply chain. This dynamic is creating both collaborative opportunities and competitive pressures as the technology matures and gains industry acceptance.

Commercial aviation represents the largest market segment, accounting for roughly 60% of the total market share. Military applications follow at 30%, with the remaining 10% distributed across general aviation and space applications. Geographically, North America dominates with 40% market share, followed by Europe (30%), Asia-Pacific (20%), and the rest of the world (10%).

The demand for aerospace fuel system components is primarily driven by the need for fuel efficiency, weight reduction, and enhanced performance. Airlines are increasingly seeking components that can withstand extreme operating conditions while minimizing fuel consumption. Additionally, stringent safety regulations and environmental concerns are pushing manufacturers to develop components with improved reliability and reduced environmental impact.

Volumetric Additive Manufacturing (VAM) is emerging as a disruptive technology in this market, offering significant advantages over traditional manufacturing methods. The ability to produce complex geometries with internal channels and optimized flow paths is particularly valuable for fuel system components such as pumps, valves, and filters. Market analysis indicates that VAM-produced components can achieve weight reductions of 20-30% compared to conventionally manufactured parts, directly translating to fuel savings for aircraft operators.

The adoption of VAM for aerospace fuel system components is still in its early stages, with an estimated market penetration of less than 5%. However, this is expected to grow substantially, reaching 15-20% by 2030. Early adopters include major aerospace manufacturers such as GE Aviation, Rolls-Royce, and Safran, who are investing heavily in VAM capabilities.

Customer requirements in this market segment emphasize reliability, certification compliance, and cost-effectiveness. The total cost of ownership, including maintenance and operational efficiency, is becoming increasingly important in purchasing decisions. VAM-produced components must demonstrate clear advantages in these areas to achieve widespread market acceptance.

The competitive landscape is characterized by established aerospace component manufacturers expanding their additive manufacturing capabilities, alongside specialized AM service providers entering the aerospace supply chain. This dynamic is creating both collaborative opportunities and competitive pressures as the technology matures and gains industry acceptance.

VAM Technology Status and Barriers in Aerospace Applications

Volumetric Additive Manufacturing (VAM) in aerospace applications currently faces several significant technological barriers despite its promising potential. The primary challenge lies in achieving the high precision and material properties required for aerospace fuel system components, where tolerances are exceptionally tight and safety standards are stringent. Current VAM technologies struggle to consistently produce parts with the necessary dimensional accuracy at the microscale level required for fuel delivery systems.

Material compatibility presents another substantial hurdle. Aerospace fuel systems require components resistant to various fuels, hydraulic fluids, and extreme temperature variations. Existing photopolymer resins used in VAM often lack the chemical resistance, thermal stability, and mechanical strength needed for these demanding applications. While research into high-performance resins is ongoing, few commercially available materials meet aerospace qualification standards.

Process repeatability and quality assurance remain problematic for VAM implementation in aerospace. The industry demands 100% reliability for critical components, yet current volumetric printing technologies show variations between builds that would be unacceptable for certified flight hardware. The lack of standardized in-process monitoring tools specifically designed for volumetric techniques further complicates quality control efforts.

Certification and regulatory compliance represent perhaps the most significant barrier to adoption. The aerospace industry operates under rigorous certification frameworks such as AS9100 and specific FAA/EASA requirements. VAM processes have not yet established the necessary qualification pathways for aerospace fuel system components, creating uncertainty around approval timelines and requirements.

Scale limitations also restrict VAM applications in aerospace fuel systems. While the technology excels at producing complex internal geometries, the build volume of most current systems remains relatively small compared to the size requirements of many fuel system components. This constraint forces designers to segment larger parts, introducing potential weak points at joining interfaces.

Post-processing requirements further complicate implementation. Many VAM parts require extensive cleaning, curing, and surface finishing to meet aerospace specifications. These additional steps reduce the efficiency advantages of the technology and introduce variability that can affect final part performance in critical fuel system applications.

The integration of VAM into existing aerospace manufacturing workflows presents organizational challenges. Current production systems are optimized around traditional manufacturing methods, and the introduction of volumetric techniques requires significant changes to design approaches, quality systems, and supply chain management practices.

Material compatibility presents another substantial hurdle. Aerospace fuel systems require components resistant to various fuels, hydraulic fluids, and extreme temperature variations. Existing photopolymer resins used in VAM often lack the chemical resistance, thermal stability, and mechanical strength needed for these demanding applications. While research into high-performance resins is ongoing, few commercially available materials meet aerospace qualification standards.

Process repeatability and quality assurance remain problematic for VAM implementation in aerospace. The industry demands 100% reliability for critical components, yet current volumetric printing technologies show variations between builds that would be unacceptable for certified flight hardware. The lack of standardized in-process monitoring tools specifically designed for volumetric techniques further complicates quality control efforts.

Certification and regulatory compliance represent perhaps the most significant barrier to adoption. The aerospace industry operates under rigorous certification frameworks such as AS9100 and specific FAA/EASA requirements. VAM processes have not yet established the necessary qualification pathways for aerospace fuel system components, creating uncertainty around approval timelines and requirements.

Scale limitations also restrict VAM applications in aerospace fuel systems. While the technology excels at producing complex internal geometries, the build volume of most current systems remains relatively small compared to the size requirements of many fuel system components. This constraint forces designers to segment larger parts, introducing potential weak points at joining interfaces.

Post-processing requirements further complicate implementation. Many VAM parts require extensive cleaning, curing, and surface finishing to meet aerospace specifications. These additional steps reduce the efficiency advantages of the technology and introduce variability that can affect final part performance in critical fuel system applications.

The integration of VAM into existing aerospace manufacturing workflows presents organizational challenges. Current production systems are optimized around traditional manufacturing methods, and the introduction of volumetric techniques requires significant changes to design approaches, quality systems, and supply chain management practices.

Current VAM Solutions for Fuel System Components

01 Volumetric additive manufacturing techniques

Volumetric additive manufacturing involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer by layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic approaches. This method enables faster production times compared to traditional layer-by-layer processes and can create complex geometries without the need for support structures.- Volumetric additive manufacturing techniques: Volumetric additive manufacturing involves creating three-dimensional objects by solidifying material throughout a volume simultaneously, rather than layer by layer. These techniques include computed axial lithography, tomographic volumetric additive manufacturing, and holographic approaches that use light patterns to cure photosensitive resins. This approach enables faster production times compared to traditional layer-by-layer methods and can create complex geometries without the need for support structures.

- Materials for volumetric 3D printing: Specialized materials are essential for volumetric additive manufacturing processes. These include photosensitive resins with specific curing properties, composite materials that can be solidified throughout a volume, and materials with tailored optical and mechanical characteristics. The development of these materials focuses on achieving rapid solidification, high resolution, and desired physical properties in the final printed objects while maintaining compatibility with volumetric printing techniques.

- Light-based volumetric manufacturing systems: Light-based systems for volumetric manufacturing utilize controlled light patterns to selectively cure photosensitive materials throughout a volume. These systems employ various light sources, projection techniques, and optical arrangements to achieve precise spatial control of the solidification process. Advanced systems may incorporate multiple light sources, dynamic pattern generation, and sophisticated algorithms to optimize the curing process and achieve high-resolution prints with minimal distortion.

- Process control and optimization in volumetric printing: Process control and optimization are critical aspects of volumetric additive manufacturing. This includes developing algorithms for calculating optimal light patterns, methods for monitoring and adjusting the curing process in real-time, and techniques for ensuring uniform material properties throughout the printed object. Advanced control systems may incorporate feedback mechanisms, machine learning approaches, and simulation tools to predict and compensate for potential issues during the printing process.

- Applications and innovations in volumetric manufacturing: Volumetric additive manufacturing enables novel applications across various industries. In the medical field, it allows for the rapid production of customized implants, prosthetics, and tissue scaffolds. In engineering, it facilitates the creation of complex components with internal features that would be difficult to produce using traditional methods. Recent innovations include multi-material volumetric printing, integration with other manufacturing processes, and scaling techniques for producing larger objects while maintaining high resolution.

02 Materials for volumetric additive manufacturing

Various materials can be used in volumetric additive manufacturing processes, including photopolymer resins, hydrogels, and composite materials. These materials are formulated to respond to specific light wavelengths or energy sources to achieve rapid solidification throughout a volume. The development of specialized materials with appropriate viscosity, curing characteristics, and mechanical properties is crucial for successful volumetric manufacturing applications.Expand Specific Solutions03 Light projection and control systems

Advanced light projection and control systems are essential components of volumetric additive manufacturing. These systems include digital light processing (DLP) projectors, spatial light modulators, and specialized optics that deliver patterned light energy to specific regions within the build volume. Precise control of light intensity, wavelength, and spatial distribution enables the creation of complex three-dimensional structures with high resolution.Expand Specific Solutions04 Computational methods for volumetric manufacturing

Sophisticated computational methods are employed in volumetric additive manufacturing to calculate optimal light patterns and energy distributions. These include tomographic reconstruction algorithms, computational optimization techniques, and machine learning approaches that determine the precise light patterns needed to create desired 3D geometries. Advanced software tools process 3D models to generate the necessary control signals for the manufacturing system.Expand Specific Solutions05 Applications and industrial implementation

Volumetric additive manufacturing has diverse applications across multiple industries including medical devices, microfluidics, and precision engineering. The technology enables rapid production of complex parts with features that would be difficult to achieve using conventional manufacturing methods. Industrial implementations focus on scaling the technology for higher throughput, larger build volumes, and integration with existing manufacturing workflows.Expand Specific Solutions

Leading Companies in Aerospace VAM Technology

Volumetric Additive Manufacturing (VAM) for aerospace fuel system components is currently in an early growth phase, with the market expanding as technology matures. The global market is estimated to reach significant scale as aerospace manufacturers seek lightweight, complex components with improved performance characteristics. Leading players represent diverse technological approaches: Lawrence Livermore National Security brings advanced research capabilities; RTX Corp. and Safran SA leverage their aerospace systems integration expertise; while Airbus Operations GmbH and MTU Aero Engines focus on implementation in critical engine components. Specialized additive manufacturing companies like Renishaw Plc provide enabling technologies. The technology is approaching commercial maturity with key players demonstrating functional prototypes, though widespread certification for flight-critical fuel system components remains a challenge requiring further development and regulatory approval.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has developed a revolutionary approach to volumetric additive manufacturing (VAM) for aerospace fuel system components called Computed Axial Lithography (CAL). This technology creates 3D objects by projecting computed patterns of light into photosensitive resin, allowing for the simultaneous curing of the entire volume rather than layer-by-layer fabrication. For aerospace fuel systems, they've engineered specialized photopolymer resins with chemical resistance to aviation fuels and thermal stability for extreme operating conditions. Their process enables the creation of complex internal flow channels and integrated fuel filtration systems that would be impossible with traditional manufacturing. The technology achieves micron-level precision critical for fuel metering components and can produce parts with embedded sensors for real-time monitoring of fuel system performance. Their VAM approach significantly reduces production time from days to hours while maintaining aerospace-grade quality standards.

Strengths: Enables creation of complex internal geometries impossible with traditional manufacturing; produces parts with superior surface finish reducing post-processing requirements; allows for embedding sensors during manufacturing process. Weaknesses: Limited material selection compared to traditional manufacturing; scaling challenges for larger aerospace components; requires specialized equipment and expertise.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed an advanced volumetric additive manufacturing platform specifically for aerospace fuel system components called SMART (Synchronized Multi-Axis Resin Transfer) technology. This system utilizes holographic projection techniques to cure specialized photopolymer resins in three dimensions simultaneously, rather than layer-by-layer. For aerospace fuel applications, RTX has engineered proprietary materials that offer exceptional chemical resistance to aviation fuels while maintaining structural integrity at extreme operating temperatures (-65°F to 350°F). Their manufacturing process incorporates in-situ metrology that continuously monitors dimensional accuracy during production, achieving tolerances of ±0.001 inches critical for fuel metering components. The technology enables the creation of complex internal geometries such as integrated check valves, pressure regulators, and filtration systems within a single component, reducing assembly requirements by up to 70%. RTX has successfully implemented this technology to produce fuel manifolds with optimized flow paths that reduce pressure drops by 25% compared to conventionally manufactured components, directly improving engine efficiency.

Strengths: Produces components with significantly reduced assembly requirements; achieves exceptional dimensional accuracy critical for fuel system performance; enables rapid design iterations and customization. Weaknesses: Limited production volume capabilities compared to traditional manufacturing; higher material costs; requires specialized expertise for design optimization.

Critical Patents and Innovations in Aerospace VAM

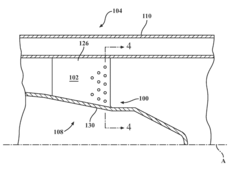

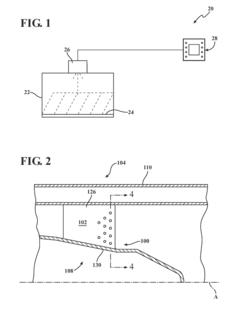

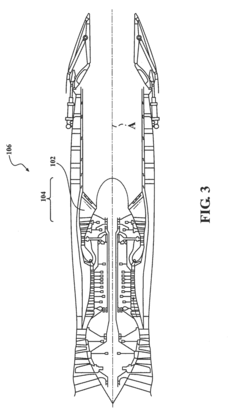

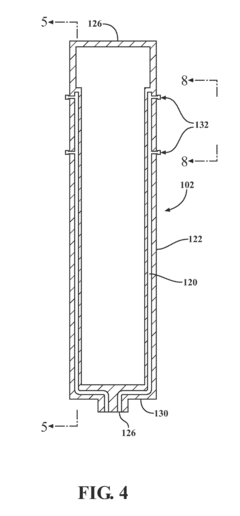

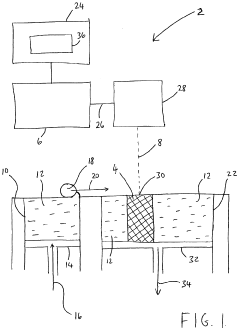

Additively Manufactured Component With Integral Fuel Lines Passage

PatentActiveUS20180030842A1

Innovation

- An aerospace component with an additively manufactured augmentor vane that integrates a fuel line within the vane, eliminating the need for separate fuel tubes and seals by using internal passages and exit apertures to manage thermal growth and reduce assembly complexity.

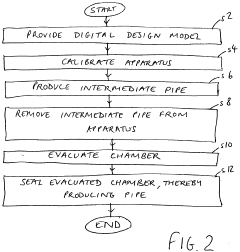

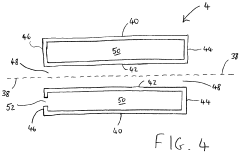

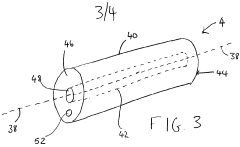

Object production

PatentInactiveGB2519411A

Innovation

- An Additive Manufacturing process forms a thermally insulated pipe by attaching an inner tube within an outer tube, creating a chamber between them that is evacuated and sealed, reducing thermal conductivity and weight, and allowing fluid flow through the inner tube with minimal supporting structures, thereby enhancing insulation and safety.

Material Qualification and Certification Processes

Material qualification and certification for aerospace fuel system components manufactured through Volumetric Additive Manufacturing (VAM) presents unique challenges due to the critical nature of these parts. The aerospace industry operates under stringent regulatory frameworks established by authorities such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international bodies. These frameworks demand comprehensive testing and validation protocols that traditionally were not designed with additive manufacturing in mind.

The qualification process for VAM-produced aerospace fuel system components typically follows a multi-tiered approach. Initially, the base materials undergo extensive characterization to establish baseline properties. This includes chemical composition analysis, microstructural evaluation, and mechanical property testing under various environmental conditions relevant to aerospace applications. For fuel system components specifically, additional testing for fuel compatibility, chemical resistance, and permeability characteristics is mandatory.

Process qualification represents the second major hurdle, where the VAM manufacturing process itself must be validated to ensure consistency and repeatability. This involves establishing process parameter windows, developing in-process monitoring techniques, and creating statistical process control methodologies. For aerospace fuel systems, the process must demonstrate capability to produce parts with consistent internal channels, uniform wall thickness, and predictable surface finish characteristics that won't introduce contaminants into the fuel system.

Part qualification follows, requiring extensive non-destructive and destructive testing of representative components. This includes dimensional accuracy verification, surface roughness measurements, internal feature validation, pressure testing, and accelerated life testing. Particularly challenging for fuel system components is the verification of internal geometries that may be inaccessible to conventional inspection methods, necessitating advanced techniques such as computed tomography scanning.

Certification pathways for VAM aerospace components are still evolving, with organizations like America Makes and the Aerospace Industries Association working to develop standardized approaches. Currently, most certifications follow a "building block" approach as outlined in documents such as the FAA's Advisory Circular AC 20-107B, progressing from coupon-level testing to sub-component validation and finally full-component qualification.

The timeline for qualification and certification remains a significant barrier, typically requiring 2-5 years for new materials and processes. This extended timeline presents challenges for technology adoption, particularly for smaller suppliers looking to enter the aerospace supply chain with innovative VAM solutions for fuel system components.

The qualification process for VAM-produced aerospace fuel system components typically follows a multi-tiered approach. Initially, the base materials undergo extensive characterization to establish baseline properties. This includes chemical composition analysis, microstructural evaluation, and mechanical property testing under various environmental conditions relevant to aerospace applications. For fuel system components specifically, additional testing for fuel compatibility, chemical resistance, and permeability characteristics is mandatory.

Process qualification represents the second major hurdle, where the VAM manufacturing process itself must be validated to ensure consistency and repeatability. This involves establishing process parameter windows, developing in-process monitoring techniques, and creating statistical process control methodologies. For aerospace fuel systems, the process must demonstrate capability to produce parts with consistent internal channels, uniform wall thickness, and predictable surface finish characteristics that won't introduce contaminants into the fuel system.

Part qualification follows, requiring extensive non-destructive and destructive testing of representative components. This includes dimensional accuracy verification, surface roughness measurements, internal feature validation, pressure testing, and accelerated life testing. Particularly challenging for fuel system components is the verification of internal geometries that may be inaccessible to conventional inspection methods, necessitating advanced techniques such as computed tomography scanning.

Certification pathways for VAM aerospace components are still evolving, with organizations like America Makes and the Aerospace Industries Association working to develop standardized approaches. Currently, most certifications follow a "building block" approach as outlined in documents such as the FAA's Advisory Circular AC 20-107B, progressing from coupon-level testing to sub-component validation and finally full-component qualification.

The timeline for qualification and certification remains a significant barrier, typically requiring 2-5 years for new materials and processes. This extended timeline presents challenges for technology adoption, particularly for smaller suppliers looking to enter the aerospace supply chain with innovative VAM solutions for fuel system components.

Supply Chain Integration and Manufacturing Scalability

The integration of Volumetric Additive Manufacturing (VAM) into aerospace fuel system component production necessitates a comprehensive supply chain transformation. Traditional aerospace manufacturing relies on complex, multi-tier supplier networks with long lead times and significant inventory requirements. VAM technology offers the potential to dramatically compress these supply chains by enabling on-demand, localized production of complex fuel system components that previously required multiple suppliers and manufacturing processes.

Current aerospace supply chains typically involve specialized material suppliers, component manufacturers, system integrators, and OEMs, with components traveling thousands of miles before final assembly. VAM implementation can reduce this complexity by consolidating multiple manufacturing steps into a single process, potentially eliminating 30-50% of traditional supply chain nodes for specific components.

Material supply represents a critical consideration in VAM supply chain integration. The specialized photopolymers and composite materials required for aerospace-grade fuel system components demand new supplier relationships and quality assurance protocols. Leading material suppliers like Henkel, BASF, and Carbon are developing aerospace-certified materials specifically optimized for volumetric printing processes, though certification timelines remain a challenge.

Scaling VAM for aerospace production presents unique challenges. Current volumetric printing systems demonstrate excellent precision but limited build volumes, typically under 100mm³. Industry projections suggest scaling to 500mm³ build volumes within 3-5 years will be necessary to accommodate larger fuel system components. Additionally, production speed must increase from current rates of approximately 1-2 components per hour to 10-15 components per hour to meet aerospace manufacturing demands.

Digital inventory management represents a significant opportunity within VAM implementation. By maintaining digital part files rather than physical inventory, aerospace manufacturers can reduce warehousing costs by up to 15-20% while improving part availability. Companies like Moog Aircraft Group have already demonstrated successful digital inventory programs for non-critical components, providing a framework for fuel system implementation.

Quality assurance integration within the VAM supply chain requires development of new in-process monitoring systems and post-production verification protocols. Current aerospace standards require 100% inspection of fuel system components, necessitating advanced CT scanning and material verification technologies compatible with volumetrically printed parts. Industry consortia including America Makes and the Aerospace Technology Institute are actively developing these standards and protocols.

Current aerospace supply chains typically involve specialized material suppliers, component manufacturers, system integrators, and OEMs, with components traveling thousands of miles before final assembly. VAM implementation can reduce this complexity by consolidating multiple manufacturing steps into a single process, potentially eliminating 30-50% of traditional supply chain nodes for specific components.

Material supply represents a critical consideration in VAM supply chain integration. The specialized photopolymers and composite materials required for aerospace-grade fuel system components demand new supplier relationships and quality assurance protocols. Leading material suppliers like Henkel, BASF, and Carbon are developing aerospace-certified materials specifically optimized for volumetric printing processes, though certification timelines remain a challenge.

Scaling VAM for aerospace production presents unique challenges. Current volumetric printing systems demonstrate excellent precision but limited build volumes, typically under 100mm³. Industry projections suggest scaling to 500mm³ build volumes within 3-5 years will be necessary to accommodate larger fuel system components. Additionally, production speed must increase from current rates of approximately 1-2 components per hour to 10-15 components per hour to meet aerospace manufacturing demands.

Digital inventory management represents a significant opportunity within VAM implementation. By maintaining digital part files rather than physical inventory, aerospace manufacturers can reduce warehousing costs by up to 15-20% while improving part availability. Companies like Moog Aircraft Group have already demonstrated successful digital inventory programs for non-critical components, providing a framework for fuel system implementation.

Quality assurance integration within the VAM supply chain requires development of new in-process monitoring systems and post-production verification protocols. Current aerospace standards require 100% inspection of fuel system components, necessitating advanced CT scanning and material verification technologies compatible with volumetrically printed parts. Industry consortia including America Makes and the Aerospace Technology Institute are actively developing these standards and protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!