Optimization Of Light Modulators For Volumetric Additive Manufacturing

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Light Modulator Technology Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, enabling the simultaneous solidification of an entire volume rather than layer-by-layer fabrication. At the heart of this revolutionary approach lies the light modulator, a critical component that shapes and directs light patterns to achieve precise photopolymerization within a photosensitive resin. The evolution of light modulation technology can be traced back to the early 2000s, with significant advancements occurring in the past decade as digital light processing (DLP) and liquid crystal display (LCD) technologies matured.

The technological trajectory of light modulators has been characterized by increasing resolution, faster refresh rates, and enhanced contrast ratios. Early implementations utilized simple binary masks, while contemporary systems employ sophisticated spatial light modulators (SLMs) capable of generating complex three-dimensional light patterns. This progression has been driven by parallel developments in semiconductor manufacturing, optical engineering, and computational algorithms for light field manipulation.

Current light modulator technologies for VAM applications include Digital Micromirror Devices (DMDs), Liquid Crystal on Silicon (LCoS) displays, and Microelectromechanical Systems (MEMS). Each technology offers distinct advantages in terms of switching speed, contrast ratio, and spatial resolution, yet all face common challenges related to optical efficiency, heat management, and integration complexity within VAM systems.

The primary objective of light modulator optimization for VAM is to achieve unprecedented control over the spatial and temporal distribution of light energy within the printing volume. This entails developing modulators with higher pixel densities (exceeding 4K resolution), faster switching speeds (sub-millisecond response times), and improved optical throughput (>80% efficiency) to enable the fabrication of complex structures with micron-scale features.

Additionally, optimization efforts aim to address the fundamental physics challenges inherent to volumetric printing, such as light scattering, absorption gradients, and refractive index mismatches that can distort projected patterns. Advanced computational approaches, including wavefront shaping and holographic projection techniques, are being explored to compensate for these optical aberrations.

The long-term technological goal is to develop an integrated light modulation system capable of dynamically adjusting to changing material properties during the printing process, incorporating real-time feedback mechanisms, and supporting multi-material fabrication through wavelength-specific modulation. Such advancements would significantly expand the application scope of VAM technology across industries including medical device manufacturing, microfluidics, and advanced electronics packaging.

The technological trajectory of light modulators has been characterized by increasing resolution, faster refresh rates, and enhanced contrast ratios. Early implementations utilized simple binary masks, while contemporary systems employ sophisticated spatial light modulators (SLMs) capable of generating complex three-dimensional light patterns. This progression has been driven by parallel developments in semiconductor manufacturing, optical engineering, and computational algorithms for light field manipulation.

Current light modulator technologies for VAM applications include Digital Micromirror Devices (DMDs), Liquid Crystal on Silicon (LCoS) displays, and Microelectromechanical Systems (MEMS). Each technology offers distinct advantages in terms of switching speed, contrast ratio, and spatial resolution, yet all face common challenges related to optical efficiency, heat management, and integration complexity within VAM systems.

The primary objective of light modulator optimization for VAM is to achieve unprecedented control over the spatial and temporal distribution of light energy within the printing volume. This entails developing modulators with higher pixel densities (exceeding 4K resolution), faster switching speeds (sub-millisecond response times), and improved optical throughput (>80% efficiency) to enable the fabrication of complex structures with micron-scale features.

Additionally, optimization efforts aim to address the fundamental physics challenges inherent to volumetric printing, such as light scattering, absorption gradients, and refractive index mismatches that can distort projected patterns. Advanced computational approaches, including wavefront shaping and holographic projection techniques, are being explored to compensate for these optical aberrations.

The long-term technological goal is to develop an integrated light modulation system capable of dynamically adjusting to changing material properties during the printing process, incorporating real-time feedback mechanisms, and supporting multi-material fabrication through wavelength-specific modulation. Such advancements would significantly expand the application scope of VAM technology across industries including medical device manufacturing, microfluidics, and advanced electronics packaging.

Market Analysis for Volumetric Additive Manufacturing

The volumetric additive manufacturing (VAM) market is experiencing significant growth as industries seek faster, more efficient 3D printing solutions. Current market valuation stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 18-22% over the next five years. This growth trajectory is primarily driven by increasing demand for high-resolution, rapid prototyping capabilities across multiple sectors.

Healthcare represents the largest market segment, accounting for nearly 35% of the total VAM market. The ability to produce complex anatomical models, customized implants, and tissue scaffolds with high precision has positioned VAM as a transformative technology in medical applications. Dental applications alone constitute a rapidly expanding sub-segment, growing at 25% annually.

The industrial manufacturing sector follows closely, representing approximately 30% of market share. Automotive, aerospace, and consumer electronics manufacturers are increasingly adopting VAM technologies to reduce production time and material waste while enabling complex geometries that were previously unachievable through traditional manufacturing methods.

A key market driver is the significant reduction in production time offered by volumetric techniques compared to layer-by-layer approaches. VAM systems can produce complete objects in seconds or minutes rather than hours, representing productivity improvements of up to 100x for certain applications. This dramatic efficiency gain is creating strong pull from industries where rapid prototyping and small-batch production are critical.

Regional analysis shows North America leading with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in advanced manufacturing technologies in China, Japan, and South Korea.

Market barriers include the high initial investment costs for VAM systems, with industrial-grade equipment typically ranging from 100,000 to 500,000 USD. Additionally, material limitations and the need for specialized expertise present adoption challenges for smaller enterprises. The optimization of light modulators represents a critical factor in addressing these barriers, as improvements in this component directly impact system cost, resolution capabilities, and production speed.

Customer demand increasingly focuses on higher resolution capabilities (sub-10 micron features), larger build volumes, and expanded material compatibility. Market research indicates that advancements in light modulation technology that address these specific needs could potentially expand the addressable market by 30-40% within three years by enabling new applications in microfluidics, advanced electronics packaging, and precision consumer products.

Healthcare represents the largest market segment, accounting for nearly 35% of the total VAM market. The ability to produce complex anatomical models, customized implants, and tissue scaffolds with high precision has positioned VAM as a transformative technology in medical applications. Dental applications alone constitute a rapidly expanding sub-segment, growing at 25% annually.

The industrial manufacturing sector follows closely, representing approximately 30% of market share. Automotive, aerospace, and consumer electronics manufacturers are increasingly adopting VAM technologies to reduce production time and material waste while enabling complex geometries that were previously unachievable through traditional manufacturing methods.

A key market driver is the significant reduction in production time offered by volumetric techniques compared to layer-by-layer approaches. VAM systems can produce complete objects in seconds or minutes rather than hours, representing productivity improvements of up to 100x for certain applications. This dramatic efficiency gain is creating strong pull from industries where rapid prototyping and small-batch production are critical.

Regional analysis shows North America leading with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in advanced manufacturing technologies in China, Japan, and South Korea.

Market barriers include the high initial investment costs for VAM systems, with industrial-grade equipment typically ranging from 100,000 to 500,000 USD. Additionally, material limitations and the need for specialized expertise present adoption challenges for smaller enterprises. The optimization of light modulators represents a critical factor in addressing these barriers, as improvements in this component directly impact system cost, resolution capabilities, and production speed.

Customer demand increasingly focuses on higher resolution capabilities (sub-10 micron features), larger build volumes, and expanded material compatibility. Market research indicates that advancements in light modulation technology that address these specific needs could potentially expand the addressable market by 30-40% within three years by enabling new applications in microfluidics, advanced electronics packaging, and precision consumer products.

Current Light Modulator Limitations in VAM

Volumetric Additive Manufacturing (VAM) represents a significant advancement in 3D printing technology, offering unprecedented speed and resolution capabilities. However, current light modulator technologies present several critical limitations that impede the full realization of VAM's potential. Digital Micromirror Devices (DMDs) and Liquid Crystal Displays (LCDs), the two predominant light modulation technologies employed in VAM systems, each exhibit distinct constraints that affect manufacturing precision and efficiency.

DMD-based systems, while offering high refresh rates (up to 32 kHz), struggle with limited contrast ratios typically ranging from 1000:1 to 2000:1. This limitation results in unwanted curing in non-target regions, particularly problematic when printing high-resolution microstructures. Additionally, DMDs exhibit wavelength-dependent diffraction effects that can cause spatial distortion of projected patterns, compromising dimensional accuracy in printed components.

LCD modulators present a different set of challenges. Their significantly lower refresh rates (60-240 Hz) substantially restrict printing speeds compared to DMD-based systems. Furthermore, LCDs suffer from lower light transmission efficiency (typically 3-5%), necessitating more powerful light sources that introduce thermal management complications and increase system complexity and cost.

Resolution limitations persist across both technologies. Current high-end DMDs offer pixel counts of approximately 4 million (2560×1600), while premium LCDs reach about 8 million pixels (4K resolution). These constraints directly limit the achievable feature resolution in VAM processes, particularly when projecting across larger build volumes where pixel density becomes increasingly diluted.

Thermal management represents another significant challenge. Both DMD and LCD technologies experience performance degradation under high-intensity illumination conditions necessary for rapid photopolymerization. DMDs can experience mechanical failures of mirror elements, while LCDs suffer from liquid crystal degradation and polarizer damage, leading to reduced contrast and pattern fidelity over time.

Spectral response limitations further complicate VAM implementation. Most commercial light modulators are optimized for visible light applications (400-700 nm), whereas many photopolymerization processes require specific wavelengths, particularly in the near-UV spectrum (365-405 nm). This spectral mismatch necessitates specialized optical components and reduces overall system efficiency.

Control precision presents additional challenges. Current modulator technologies typically offer 8-bit grayscale resolution (256 levels), which proves insufficient for precise control of photopolymerization in gradient structures or multi-material applications. This limitation restricts the ability to create components with spatially varying mechanical or optical properties, a key advantage that VAM theoretically offers over conventional layer-by-layer approaches.

DMD-based systems, while offering high refresh rates (up to 32 kHz), struggle with limited contrast ratios typically ranging from 1000:1 to 2000:1. This limitation results in unwanted curing in non-target regions, particularly problematic when printing high-resolution microstructures. Additionally, DMDs exhibit wavelength-dependent diffraction effects that can cause spatial distortion of projected patterns, compromising dimensional accuracy in printed components.

LCD modulators present a different set of challenges. Their significantly lower refresh rates (60-240 Hz) substantially restrict printing speeds compared to DMD-based systems. Furthermore, LCDs suffer from lower light transmission efficiency (typically 3-5%), necessitating more powerful light sources that introduce thermal management complications and increase system complexity and cost.

Resolution limitations persist across both technologies. Current high-end DMDs offer pixel counts of approximately 4 million (2560×1600), while premium LCDs reach about 8 million pixels (4K resolution). These constraints directly limit the achievable feature resolution in VAM processes, particularly when projecting across larger build volumes where pixel density becomes increasingly diluted.

Thermal management represents another significant challenge. Both DMD and LCD technologies experience performance degradation under high-intensity illumination conditions necessary for rapid photopolymerization. DMDs can experience mechanical failures of mirror elements, while LCDs suffer from liquid crystal degradation and polarizer damage, leading to reduced contrast and pattern fidelity over time.

Spectral response limitations further complicate VAM implementation. Most commercial light modulators are optimized for visible light applications (400-700 nm), whereas many photopolymerization processes require specific wavelengths, particularly in the near-UV spectrum (365-405 nm). This spectral mismatch necessitates specialized optical components and reduces overall system efficiency.

Control precision presents additional challenges. Current modulator technologies typically offer 8-bit grayscale resolution (256 levels), which proves insufficient for precise control of photopolymerization in gradient structures or multi-material applications. This limitation restricts the ability to create components with spatially varying mechanical or optical properties, a key advantage that VAM theoretically offers over conventional layer-by-layer approaches.

Current Optimization Approaches for VAM Light Modulators

01 Optimization of liquid crystal light modulators

Liquid crystal light modulators can be optimized through various techniques to improve performance characteristics such as response time, contrast ratio, and optical efficiency. These optimizations include specialized electrode configurations, temperature control systems, and advanced driving schemes. By carefully engineering the liquid crystal cell structure and implementing precise voltage control methods, manufacturers can achieve faster switching speeds and better image quality in display applications.- Optimization of spatial light modulators for display applications: Spatial light modulators can be optimized for display applications by improving pixel structure, addressing schemes, and response times. These optimizations enhance contrast ratio, brightness, and color reproduction in projection systems and flat panel displays. Advanced control algorithms and driver circuitry can further improve the performance of these modulators by reducing artifacts and increasing refresh rates.

- Optical configuration and alignment techniques for light modulators: Various optical configurations and alignment techniques can be employed to optimize light modulators. These include precision alignment of optical components, beam shaping elements, and specialized coatings to reduce unwanted reflections. Optimized optical paths can minimize light loss and maximize throughput, while careful alignment ensures uniform illumination and reduces distortion in the modulated output.

- Thermal management and stability improvements for light modulators: Thermal management is critical for optimizing light modulator performance. Techniques include heat sinks, active cooling systems, and thermally conductive materials to dissipate heat efficiently. Temperature stabilization circuits and compensation algorithms can be implemented to maintain consistent performance across varying operating conditions, preventing drift in optical properties and extending device lifetime.

- Advanced materials and fabrication techniques for light modulators: Novel materials and fabrication techniques can significantly improve light modulator performance. These include high-reflectivity coatings, specialized liquid crystal formulations, and MEMS-based structures with optimized mechanical properties. Advanced manufacturing processes such as precision lithography and atomic layer deposition enable finer feature sizes and more uniform optical surfaces, resulting in higher efficiency and better modulation characteristics.

- Control algorithms and driving schemes for light modulators: Sophisticated control algorithms and driving schemes can optimize the performance of light modulators. These include pulse width modulation techniques, adaptive voltage control, and predictive algorithms that compensate for device non-linearities. Digital signal processing methods can be employed to reduce artifacts, improve response times, and enhance the dynamic range of the modulation system, resulting in better overall image quality and system efficiency.

02 MEMS-based light modulation technologies

Micro-electromechanical systems (MEMS) offer innovative approaches to light modulation through the use of tiny movable structures that can reflect, diffract, or block light. These systems can be optimized by refining the mechanical design, improving actuation mechanisms, and enhancing control algorithms. MEMS-based light modulators provide advantages such as high speed operation, wavelength selectivity, and compact form factors, making them suitable for applications ranging from projectors to optical communications.Expand Specific Solutions03 Spatial light modulator performance enhancement

Spatial light modulators can be optimized through various techniques including improved pixel architectures, enhanced addressing schemes, and advanced manufacturing processes. By optimizing the fill factor, reducing pixel crosstalk, and implementing sophisticated control algorithms, the overall performance of spatial light modulators can be significantly enhanced. These optimizations lead to better contrast ratios, higher resolution, and improved optical efficiency in applications such as projection systems and holographic displays.Expand Specific Solutions04 Optical measurement and calibration systems for light modulators

Accurate measurement and calibration systems are essential for optimizing light modulator performance. These systems can include specialized optical sensors, precision alignment mechanisms, and advanced software algorithms for characterizing and adjusting modulator parameters. By implementing comprehensive testing protocols and feedback mechanisms, manufacturers can ensure consistent performance across devices and compensate for manufacturing variations or environmental factors that might affect light modulation quality.Expand Specific Solutions05 Advanced materials and fabrication techniques for light modulators

The development of advanced materials and fabrication techniques plays a crucial role in optimizing light modulators. Novel materials with enhanced optical properties, improved manufacturing processes for greater precision, and innovative structural designs can significantly improve modulator performance. These advancements enable higher efficiency, better reliability, and expanded functionality in applications ranging from telecommunications to display technologies, while potentially reducing production costs and energy consumption.Expand Specific Solutions

Key Industry Players in Optical Modulation Technology

The volumetric additive manufacturing light modulator optimization market is currently in its growth phase, with increasing adoption across industrial applications. The market is projected to expand significantly as 3D printing technologies mature, with an estimated value of $500-700 million by 2025. Technologically, the field is advancing rapidly but remains moderately mature, with key players developing proprietary solutions. Huawei and Intel are investing heavily in semiconductor-based modulators, while Nikon and SCREEN Holdings leverage their optical expertise for high-precision systems. Academic institutions like EPFL and University of Rochester are pioneering fundamental research, while specialized manufacturers such as Structo, 3D Fortify, and MTT Innovation focus on application-specific implementations. The ecosystem shows a balanced mix of established corporations and innovative startups competing to establish technical standards.

Lawrence Livermore National Security LLC

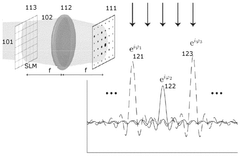

Technical Solution: Lawrence Livermore has pioneered volumetric additive manufacturing through their Computed Axial Lithography (CAL) technology. Their approach uses synchronized projection of patterned light from multiple angles into a photosensitive resin, creating complex 3D structures without layer-by-layer printing. They've optimized spatial light modulators (SLMs) to achieve precise control over light patterns, implementing advanced algorithms that correct for optical aberrations and scattering effects in the resin. Their system incorporates real-time feedback mechanisms to adjust light modulation parameters during printing, significantly enhancing resolution and accuracy. Recent developments include multi-wavelength light modulation techniques that enable simultaneous curing of different materials with varying properties within the same build volume, expanding the range of achievable structures and material compositions.

Strengths: Superior resolution capabilities (achieving features below 100 microns) and significantly faster production times compared to traditional layer-by-layer methods. Weaknesses: System complexity requires sophisticated calibration procedures and specialized expertise to operate effectively.

Structo Pte Ltd.

Technical Solution: Structo has developed a proprietary Mask Stereolithography (MSLA) technology that incorporates advanced light modulation techniques for volumetric manufacturing. Their system utilizes a custom-designed digital light processing engine with specialized optical components that enable rapid, large-area exposure while maintaining high resolution. Structo has implemented innovative light modulation algorithms that dynamically adjust exposure patterns based on part geometry and material properties, optimizing curing parameters throughout the build volume. Their technology incorporates a unique optical train design that minimizes light scattering and improves energy distribution uniformity across the projection area. Structo has also developed specialized calibration techniques that compensate for optical distortions and ensure consistent performance across the entire build platform. Their latest developments include multi-zone exposure capabilities that allow for variable resolution and curing characteristics within different regions of the same part.

Strengths: Exceptionally fast print speeds (up to 10x faster than conventional SLA systems) while maintaining high resolution and surface quality. Weaknesses: Current technology optimization focuses primarily on specific dental and medical applications, potentially limiting versatility in other industrial applications.

Critical Patents in Light Modulation for 3D Printing

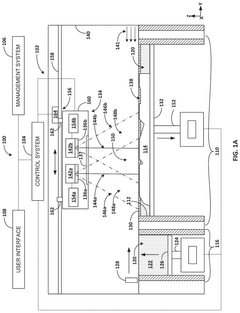

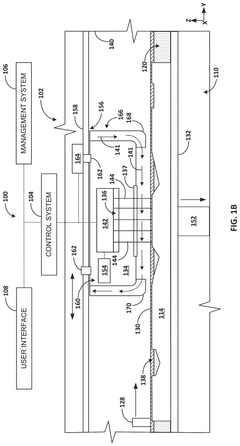

Irradiation devices with optical modulators for additively manufacturing three-dimensional objects

PatentPendingUS20250229358A1

Innovation

- The use of an optical modulator with a micromirror array and focusing lens assembly to manipulate energy beams, allowing for a conduction irradiation regime with lower intensity and power density, enabling increased resolution and improved temperature control, resulting in finer features and better material properties of three-dimensional objects.

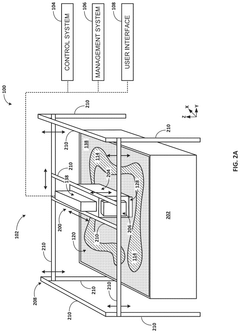

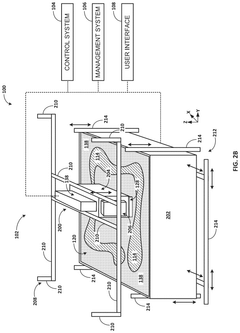

Holographic volumetric additive manufacturing (holovam)

PatentWO2025088142A1

Innovation

- The method employs holographic volumetric additive manufacturing (HoloVAM) by generating a composite hologram that modulates a coherent input beam to create a pixelated projection in a reconstruction space, allowing for improved resolution, speed, and light efficiency through phase-only holographic projections.

Material Compatibility Considerations

The compatibility between light modulators and photosensitive materials represents a critical consideration in volumetric additive manufacturing (VAM) systems. Different photopolymer resins exhibit varying responses to specific wavelengths and light intensities, necessitating careful matching between modulator specifications and material properties. For instance, digital light processing (DLP) modulators typically operate in the 385-405nm wavelength range, which must align with the photoinitiator absorption spectrum of the target resin to achieve optimal curing efficiency.

Material viscosity significantly impacts the performance of light modulation systems in VAM. Higher viscosity materials may require increased exposure times or light intensity, potentially exceeding the operational parameters of certain modulators. This relationship becomes particularly important when considering the heat generated by prolonged modulator operation, as excessive heat can alter material properties during the manufacturing process, leading to dimensional inaccuracies or structural weaknesses in the final product.

The refractive index of photosensitive materials presents another crucial compatibility factor. Materials with higher refractive indices can cause light scattering and diffraction effects that distort the projected patterns from spatial light modulators (SLMs). This optical phenomenon necessitates compensation algorithms or specialized optical configurations to maintain pattern fidelity throughout the build volume, especially for high-resolution applications requiring precise feature control.

Chemical compatibility between photopolymer constituents and modulator components must also be evaluated. Volatile organic compounds (VOCs) released during the curing process may damage sensitive electronic or optical elements in certain modulator designs. Similarly, the long-term exposure of modulator optical surfaces to reactive photopolymer components can lead to degradation of anti-reflective coatings or other optical treatments, reducing system performance over time.

The thermal characteristics of both materials and modulators create another interdependency. Some high-performance photopolymers require precise temperature control during curing to achieve optimal mechanical properties. Light modulators that generate significant heat during operation may necessitate additional cooling systems to maintain material temperature within the specified processing window, adding complexity to the overall system design.

For multi-material VAM applications, the modulator technology must accommodate the potentially diverse optical and chemical requirements of different materials used within the same build. This may involve specialized multi-wavelength modulation systems or rapid switching capabilities to address the unique curing parameters of each material without cross-contamination or unwanted interactions between adjacent material volumes.

Material viscosity significantly impacts the performance of light modulation systems in VAM. Higher viscosity materials may require increased exposure times or light intensity, potentially exceeding the operational parameters of certain modulators. This relationship becomes particularly important when considering the heat generated by prolonged modulator operation, as excessive heat can alter material properties during the manufacturing process, leading to dimensional inaccuracies or structural weaknesses in the final product.

The refractive index of photosensitive materials presents another crucial compatibility factor. Materials with higher refractive indices can cause light scattering and diffraction effects that distort the projected patterns from spatial light modulators (SLMs). This optical phenomenon necessitates compensation algorithms or specialized optical configurations to maintain pattern fidelity throughout the build volume, especially for high-resolution applications requiring precise feature control.

Chemical compatibility between photopolymer constituents and modulator components must also be evaluated. Volatile organic compounds (VOCs) released during the curing process may damage sensitive electronic or optical elements in certain modulator designs. Similarly, the long-term exposure of modulator optical surfaces to reactive photopolymer components can lead to degradation of anti-reflective coatings or other optical treatments, reducing system performance over time.

The thermal characteristics of both materials and modulators create another interdependency. Some high-performance photopolymers require precise temperature control during curing to achieve optimal mechanical properties. Light modulators that generate significant heat during operation may necessitate additional cooling systems to maintain material temperature within the specified processing window, adding complexity to the overall system design.

For multi-material VAM applications, the modulator technology must accommodate the potentially diverse optical and chemical requirements of different materials used within the same build. This may involve specialized multi-wavelength modulation systems or rapid switching capabilities to address the unique curing parameters of each material without cross-contamination or unwanted interactions between adjacent material volumes.

Energy Efficiency and Sustainability Factors

Energy efficiency and sustainability considerations are increasingly critical in the development of light modulators for volumetric additive manufacturing (VAM). Current light modulation systems, particularly those utilizing digital micromirror devices (DMDs) and liquid crystal displays (LCDs), consume substantial energy during operation, with power requirements ranging from 50W to 300W depending on system complexity and manufacturing scale. This energy consumption primarily stems from high-intensity light sources, cooling systems, and the electronic infrastructure required to control precise light patterns.

The environmental impact of light modulator technologies extends beyond operational energy consumption. Manufacturing processes for advanced optical components involve rare earth elements and specialized materials that present sustainability challenges in terms of resource extraction, processing, and end-of-life disposal. For instance, the production of high-quality optical-grade materials for spatial light modulators generates approximately 2.3 times more carbon emissions compared to standard electronic components of similar size.

Recent innovations have demonstrated promising improvements in energy efficiency. New-generation DMD systems have achieved 30-40% reduction in power consumption through optimized reflection geometries and improved thermal management. Similarly, emerging organic light-emitting diode (OLED) based modulators show potential for up to 60% energy savings compared to traditional LCD technologies, primarily due to their elimination of backlighting requirements.

Lifecycle assessment studies indicate that the sustainability profile of light modulators can be significantly enhanced through design modifications focused on longevity and repairability. Modular designs that allow for component replacement rather than complete system disposal can extend operational lifespans by 3-5 years, reducing the environmental footprint by approximately 40% over a decade of use.

Heat management represents another critical sustainability factor. Conventional cooling systems for high-intensity light sources account for approximately 25-30% of the total energy consumption in VAM systems. Advanced passive cooling technologies and more efficient heat dissipation designs have demonstrated potential to reduce this energy overhead by up to 35%, while simultaneously extending component lifespan through reduced thermal stress.

The integration of renewable energy sources with VAM systems presents an emerging opportunity for sustainability improvements. Research facilities implementing solar-powered VAM operations have reported net energy reductions of 40-60% in regions with favorable solar conditions, suggesting a pathway toward carbon-neutral manufacturing capabilities for appropriate applications and environments.

The environmental impact of light modulator technologies extends beyond operational energy consumption. Manufacturing processes for advanced optical components involve rare earth elements and specialized materials that present sustainability challenges in terms of resource extraction, processing, and end-of-life disposal. For instance, the production of high-quality optical-grade materials for spatial light modulators generates approximately 2.3 times more carbon emissions compared to standard electronic components of similar size.

Recent innovations have demonstrated promising improvements in energy efficiency. New-generation DMD systems have achieved 30-40% reduction in power consumption through optimized reflection geometries and improved thermal management. Similarly, emerging organic light-emitting diode (OLED) based modulators show potential for up to 60% energy savings compared to traditional LCD technologies, primarily due to their elimination of backlighting requirements.

Lifecycle assessment studies indicate that the sustainability profile of light modulators can be significantly enhanced through design modifications focused on longevity and repairability. Modular designs that allow for component replacement rather than complete system disposal can extend operational lifespans by 3-5 years, reducing the environmental footprint by approximately 40% over a decade of use.

Heat management represents another critical sustainability factor. Conventional cooling systems for high-intensity light sources account for approximately 25-30% of the total energy consumption in VAM systems. Advanced passive cooling technologies and more efficient heat dissipation designs have demonstrated potential to reduce this energy overhead by up to 35%, while simultaneously extending component lifespan through reduced thermal stress.

The integration of renewable energy sources with VAM systems presents an emerging opportunity for sustainability improvements. Research facilities implementing solar-powered VAM operations have reported net energy reductions of 40-60% in regions with favorable solar conditions, suggesting a pathway toward carbon-neutral manufacturing capabilities for appropriate applications and environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!