Color Control In Volumetric Additive Manufacturing Systems

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Color Control Technology Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, enabling the simultaneous solidification of an entire volume rather than layer-by-layer fabrication. The evolution of color control within VAM systems traces back to early photopolymerization techniques developed in the 1980s, which laid the groundwork for modern volumetric printing methods. The field has experienced accelerated development over the past decade, with significant breakthroughs in multi-material and multi-color capabilities emerging since 2018.

The technological trajectory of color control in VAM has been shaped by advances in photochemistry, computational tomography, and optical engineering. Early systems were limited to monochromatic outputs, but recent innovations have expanded the chromatic range substantially. The convergence of digital light processing (DLP) technology with sophisticated photoinitiation systems has enabled more precise spectral control, allowing for increasingly complex color gradients and transitions within printed objects.

The primary objective of color control technology in VAM systems is to achieve accurate, consistent, and spatially resolved color reproduction throughout the printed volume. This encompasses several specific goals: developing photopolymer resins with predictable color response characteristics; creating precise optical delivery systems capable of projecting multiple wavelengths with spatial specificity; and establishing computational frameworks that can translate digital color information into appropriate light exposure patterns.

Another critical objective is the development of calibration methodologies that ensure color fidelity between digital designs and physical outputs. This includes addressing challenges related to light scattering, absorption depth variations across different wavelengths, and potential chemical interactions between multiple chromophores within the resin system.

The field aims to expand the color gamut achievable in VAM processes while maintaining the high resolution and structural integrity that make volumetric manufacturing advantageous. Current research focuses on overcoming the inherent trade-offs between printing speed, resolution, and color accuracy that have historically constrained the technology.

Looking forward, the technology roadmap includes objectives for real-time color adjustment capabilities, integration with advanced material property control, and development of standardized color management systems specific to volumetric manufacturing contexts. The ultimate goal is to establish VAM as a viable production method for full-color, functional parts with applications spanning medical visualization, consumer products, educational models, and artistic endeavors.

The technological trajectory of color control in VAM has been shaped by advances in photochemistry, computational tomography, and optical engineering. Early systems were limited to monochromatic outputs, but recent innovations have expanded the chromatic range substantially. The convergence of digital light processing (DLP) technology with sophisticated photoinitiation systems has enabled more precise spectral control, allowing for increasingly complex color gradients and transitions within printed objects.

The primary objective of color control technology in VAM systems is to achieve accurate, consistent, and spatially resolved color reproduction throughout the printed volume. This encompasses several specific goals: developing photopolymer resins with predictable color response characteristics; creating precise optical delivery systems capable of projecting multiple wavelengths with spatial specificity; and establishing computational frameworks that can translate digital color information into appropriate light exposure patterns.

Another critical objective is the development of calibration methodologies that ensure color fidelity between digital designs and physical outputs. This includes addressing challenges related to light scattering, absorption depth variations across different wavelengths, and potential chemical interactions between multiple chromophores within the resin system.

The field aims to expand the color gamut achievable in VAM processes while maintaining the high resolution and structural integrity that make volumetric manufacturing advantageous. Current research focuses on overcoming the inherent trade-offs between printing speed, resolution, and color accuracy that have historically constrained the technology.

Looking forward, the technology roadmap includes objectives for real-time color adjustment capabilities, integration with advanced material property control, and development of standardized color management systems specific to volumetric manufacturing contexts. The ultimate goal is to establish VAM as a viable production method for full-color, functional parts with applications spanning medical visualization, consumer products, educational models, and artistic endeavors.

Market Analysis for Colored Volumetric 3D Printing

The global market for colored volumetric 3D printing is experiencing significant growth, driven by increasing demand for customized, high-quality colored objects across various industries. The market size for volumetric additive manufacturing was valued at approximately $1.2 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 24.7%. The addition of color capabilities is expected to further accelerate this growth trajectory.

Healthcare and medical applications currently represent the largest market segment, accounting for nearly 35% of the total market share. The ability to produce anatomically accurate, color-differentiated medical models has revolutionized surgical planning and medical education. Dental applications, particularly for prosthetics and aligners, have shown remarkable adoption rates with a 32% year-over-year increase in 2022.

Consumer products and entertainment industries are rapidly emerging as significant market drivers, with demand for customized colored figurines, toys, and collectibles growing at 28% annually. The automotive and aerospace sectors are increasingly utilizing colored volumetric printing for prototyping and functional parts, with the automotive sector alone expected to grow at a CAGR of 22% through 2028.

Geographically, North America leads the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 29% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, and increasing adoption in manufacturing sectors.

Market analysis reveals several key customer demands driving adoption: reduced production time (cited by 78% of industrial users), improved color accuracy (65%), material versatility (61%), and cost-effectiveness (57%). The ability to produce multi-colored objects in a single print process represents a significant competitive advantage over traditional manufacturing methods.

Price sensitivity varies significantly by sector, with industrial applications demonstrating higher willingness to pay premium prices for quality and precision, while consumer markets remain more price-sensitive. The average price point for industrial-grade colored volumetric printing systems ranges from $75,000 to $350,000, with material costs averaging $180-$450 per kilogram for color-capable resins.

Market forecasts indicate that as technology matures and economies of scale are achieved, system prices are expected to decrease by 15-20% over the next five years, potentially expanding market penetration into small and medium enterprises. The development of more affordable desktop versions could potentially open significant new market segments in educational institutions, small businesses, and prosumer applications.

Healthcare and medical applications currently represent the largest market segment, accounting for nearly 35% of the total market share. The ability to produce anatomically accurate, color-differentiated medical models has revolutionized surgical planning and medical education. Dental applications, particularly for prosthetics and aligners, have shown remarkable adoption rates with a 32% year-over-year increase in 2022.

Consumer products and entertainment industries are rapidly emerging as significant market drivers, with demand for customized colored figurines, toys, and collectibles growing at 28% annually. The automotive and aerospace sectors are increasingly utilizing colored volumetric printing for prototyping and functional parts, with the automotive sector alone expected to grow at a CAGR of 22% through 2028.

Geographically, North America leads the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 29% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, and increasing adoption in manufacturing sectors.

Market analysis reveals several key customer demands driving adoption: reduced production time (cited by 78% of industrial users), improved color accuracy (65%), material versatility (61%), and cost-effectiveness (57%). The ability to produce multi-colored objects in a single print process represents a significant competitive advantage over traditional manufacturing methods.

Price sensitivity varies significantly by sector, with industrial applications demonstrating higher willingness to pay premium prices for quality and precision, while consumer markets remain more price-sensitive. The average price point for industrial-grade colored volumetric printing systems ranges from $75,000 to $350,000, with material costs averaging $180-$450 per kilogram for color-capable resins.

Market forecasts indicate that as technology matures and economies of scale are achieved, system prices are expected to decrease by 15-20% over the next five years, potentially expanding market penetration into small and medium enterprises. The development of more affordable desktop versions could potentially open significant new market segments in educational institutions, small businesses, and prosumer applications.

Technical Challenges in Multi-Color VAM Systems

Multi-color volumetric additive manufacturing (VAM) systems face several significant technical challenges that impede their widespread adoption and commercial viability. The primary challenge lies in achieving precise color control throughout the volumetric printing process. Unlike traditional layer-by-layer 3D printing, VAM creates objects by simultaneously curing an entire volume of photosensitive resin, making color integration substantially more complex.

Material compatibility presents a formidable obstacle, as photopolymer resins must simultaneously satisfy mechanical property requirements while incorporating color agents that respond appropriately to specific wavelengths of light. The interaction between different colored photoinitiators often leads to cross-activation issues, where light intended to cure one color inadvertently activates neighboring color agents, resulting in bleeding effects and reduced color fidelity.

Light scattering within the resin volume significantly complicates color precision. As projected light patterns penetrate the resin, they scatter and diffuse, causing unintended curing in adjacent regions. This phenomenon is particularly problematic for multi-color applications, as it creates gradient effects at color boundaries rather than sharp transitions, limiting the achievable color resolution and accuracy.

The optical complexity of projecting multiple wavelengths simultaneously or in rapid sequence introduces synchronization challenges. Current systems struggle with temporal and spatial alignment of different color channels, resulting in registration errors that manifest as color misalignment in the final printed object. Additionally, the absorption characteristics of colored resins vary significantly, requiring sophisticated compensation algorithms to achieve uniform curing depths across different colored regions.

Color calibration and consistency represent another major hurdle. Environmental factors such as temperature fluctuations and resin aging can alter color outcomes between print sessions. The absence of standardized color management systems specifically designed for volumetric printing further complicates the achievement of predictable, reproducible results across different machines and material batches.

Resolution limitations also constrain multi-color VAM capabilities. While monochrome VAM systems have demonstrated impressive resolution metrics, introducing color significantly reduces the effective spatial resolution due to the need for multiple photoinitiators and the resulting optical interference effects. Current systems typically sacrifice either color gamut range or spatial resolution, creating a challenging engineering trade-off.

Material compatibility presents a formidable obstacle, as photopolymer resins must simultaneously satisfy mechanical property requirements while incorporating color agents that respond appropriately to specific wavelengths of light. The interaction between different colored photoinitiators often leads to cross-activation issues, where light intended to cure one color inadvertently activates neighboring color agents, resulting in bleeding effects and reduced color fidelity.

Light scattering within the resin volume significantly complicates color precision. As projected light patterns penetrate the resin, they scatter and diffuse, causing unintended curing in adjacent regions. This phenomenon is particularly problematic for multi-color applications, as it creates gradient effects at color boundaries rather than sharp transitions, limiting the achievable color resolution and accuracy.

The optical complexity of projecting multiple wavelengths simultaneously or in rapid sequence introduces synchronization challenges. Current systems struggle with temporal and spatial alignment of different color channels, resulting in registration errors that manifest as color misalignment in the final printed object. Additionally, the absorption characteristics of colored resins vary significantly, requiring sophisticated compensation algorithms to achieve uniform curing depths across different colored regions.

Color calibration and consistency represent another major hurdle. Environmental factors such as temperature fluctuations and resin aging can alter color outcomes between print sessions. The absence of standardized color management systems specifically designed for volumetric printing further complicates the achievement of predictable, reproducible results across different machines and material batches.

Resolution limitations also constrain multi-color VAM capabilities. While monochrome VAM systems have demonstrated impressive resolution metrics, introducing color significantly reduces the effective spatial resolution due to the need for multiple photoinitiators and the resulting optical interference effects. Current systems typically sacrifice either color gamut range or spatial resolution, creating a challenging engineering trade-off.

Current Color Control Methodologies in VAM

01 Multi-material color control systems

Volumetric additive manufacturing systems can achieve color control through the use of multiple materials with different colorants. These systems incorporate specialized dispensing mechanisms that can precisely deposit different colored materials at specific locations within the build volume. By controlling the ratio and distribution of these materials, manufacturers can create objects with complex color patterns and gradients. Advanced algorithms determine the optimal material combinations to achieve desired color specifications while maintaining structural integrity.- Color mixing and control systems in volumetric additive manufacturing: Advanced color mixing and control systems are implemented in volumetric additive manufacturing to achieve precise color reproduction. These systems utilize multiple colorants or pigments that can be selectively activated or mixed to produce a wide gamut of colors. The control systems often include software algorithms that determine optimal colorant combinations based on desired output specifications, allowing for consistent color reproduction across different manufacturing runs.

- Multi-material printing for color control: Volumetric additive manufacturing systems achieve color control through multi-material printing techniques. By precisely depositing different colored materials in specific patterns or layers, these systems can create complex color gradients and transitions. The technology often involves multiple print heads or material delivery systems that can switch between different colored resins or polymers during the manufacturing process, enabling the creation of objects with detailed color specifications.

- Light-based color activation in photopolymer systems: Color control in volumetric additive manufacturing can be achieved through light-based activation of photopolymers containing color-changing compounds. By precisely controlling the wavelength, intensity, and duration of light exposure, specific colors can be developed within the printing material. These systems often utilize multiple light sources or spatial light modulators to selectively activate different color-forming reactions throughout the volume of the printed object.

- Real-time color monitoring and feedback systems: Advanced volumetric additive manufacturing systems incorporate real-time color monitoring and feedback mechanisms to ensure color accuracy. These systems use optical sensors, spectrophotometers, or machine vision technologies to analyze the color properties of the printed object during the manufacturing process. The collected data is then used to make dynamic adjustments to the printing parameters, ensuring that the final product matches the intended color specifications.

- Post-processing techniques for color enhancement: Various post-processing techniques are employed in volumetric additive manufacturing to enhance or modify the color properties of printed objects. These techniques include surface treatments, coating applications, or secondary curing processes that can alter the appearance, saturation, or durability of colors. Some systems integrate these post-processing steps directly into the manufacturing workflow to streamline production and ensure consistent color results.

02 Light-based color manipulation techniques

Color control in volumetric additive manufacturing can be achieved through sophisticated light-based techniques. These methods use specific wavelengths of light to selectively cure photopolymers containing various chromophores or color-changing compounds. By precisely controlling the intensity, duration, and spectral characteristics of the light source, manufacturers can induce different color formations within the printed object. This approach enables the creation of complex color patterns without requiring multiple material feedstocks.Expand Specific Solutions03 Real-time color monitoring and feedback systems

Advanced volumetric additive manufacturing systems incorporate real-time color monitoring and feedback mechanisms. These systems use optical sensors, spectrophotometers, or machine vision technology to continuously analyze the color properties of the object during the manufacturing process. When deviations from the desired color specifications are detected, the system automatically adjusts manufacturing parameters such as material flow rates, curing conditions, or light exposure to correct the color. This closed-loop approach ensures consistent color quality throughout the build process.Expand Specific Solutions04 Color calibration and standardization methods

Effective color control in volumetric additive manufacturing requires sophisticated calibration and standardization methods. These approaches involve creating reference color samples under controlled conditions and developing mathematical models that map between digital color specifications and physical outputs. The systems account for material-specific properties, environmental factors, and equipment variations that can affect color reproduction. Regular calibration procedures ensure that the manufacturing system consistently produces the intended colors across different production runs.Expand Specific Solutions05 Post-processing techniques for color enhancement

Various post-processing techniques can be employed to enhance or modify the color properties of objects produced through volumetric additive manufacturing. These methods include surface treatments, infiltration with colored resins, controlled exposure to specific chemicals or light sources, and application of specialized coatings. Post-processing approaches can be used to achieve colors that are difficult to produce during the initial manufacturing process, increase color durability, or create special effects such as iridescence or color-changing properties.Expand Specific Solutions

Leading Companies in Colored VAM Technology

The color control landscape in Volumetric Additive Manufacturing (VAM) is currently in its growth phase, with the market expanding rapidly as the technology matures from experimental to commercial applications. Key players represent diverse sectors, with research institutions like Lawrence Livermore National Laboratory, Cornell University, and EPFL driving fundamental innovations, while established manufacturing companies such as EOS GmbH, Siemens Energy, and General Electric are commercializing solutions. Specialized additive manufacturing firms like Readily3D and Nano Dimension are developing proprietary color control technologies for specific applications. The technology is approaching maturity in monochromatic applications but remains in development for full-color volumetric printing, with significant R&D investments focused on photosensitive materials, light projection systems, and color calibration algorithms.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has developed an advanced volumetric additive manufacturing color control system utilizing their proprietary Computed Axial Lithography (CAL) technology. Their approach revolves around projecting computed tomographic patterns of light into photosensitive resins containing multiple photoinitiators with different spectral sensitivities. By precisely controlling the wavelength, intensity, and spatial distribution of light patterns from multiple angles, they can selectively cure specific regions with predetermined color properties throughout the entire volume simultaneously. The system incorporates sophisticated algorithms that calculate optimal light dose distributions to achieve desired color gradients and transitions within complex 3D geometries. LLNL's technology includes a multi-wavelength optical system with specialized light sources and filters to achieve precise spectral control. Their research has demonstrated the ability to create intricate colored objects with embedded functional features in a fraction of the time required by traditional layer-by-layer approaches. The system also features in-situ monitoring capabilities that analyze light transmission patterns to verify proper color formation during the printing process.

Strengths: Rapid production of complex colored volumetric structures; elimination of layer lines common in traditional AM; ability to create seamless color transitions throughout objects. Weaknesses: Currently limited to specific photopolymer materials; challenges with achieving certain color combinations in highly absorptive materials; resolution constraints based on optical system limitations.

EOS GmbH

Technical Solution: EOS has developed a sophisticated color control system for volumetric additive manufacturing that integrates with their Direct Metal Laser Sintering (DMLS) and polymer-based technologies. Their approach utilizes a proprietary voxel-based color assignment methodology where each volumetric pixel in the build can be assigned specific material properties including color attributes. The system employs multiple laser sources with varying wavelengths to selectively activate different photosensitive materials containing color-specific properties. EOS's technology incorporates advanced color mapping algorithms that translate CAD model color data into machine-specific build instructions, accounting for material behavior during sintering or fusion processes. Their system includes in-process monitoring using high-resolution cameras and spectral analysis tools to verify color accuracy throughout the build volume. EOS has also developed specialized post-processing techniques that enhance color vibrancy and durability while maintaining dimensional accuracy of the printed components.

Strengths: Exceptional color consistency throughout complex geometries; integration with established industrial-grade AM platforms; advanced material development specifically for color applications. Weaknesses: Higher cost compared to monochrome systems; limited color gamut in certain materials; requires specialized expertise for optimal color calibration and maintenance.

Key Patents and Research in VAM Color Technology

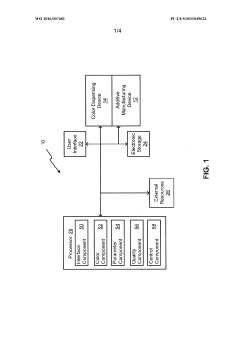

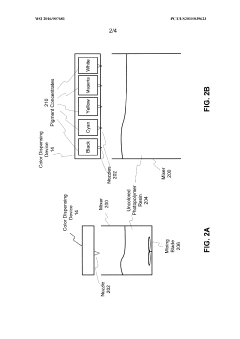

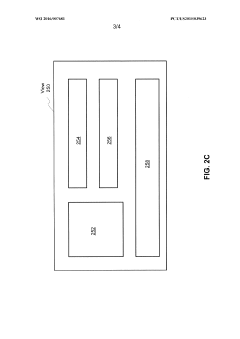

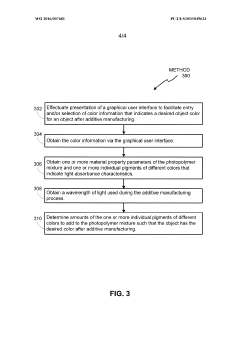

Color determination for photopolymer mixtures in additive manufacturing

PatentWO2016007681A1

Innovation

- A system comprising an additive manufacturing device, color dispensing device, and a processor that controls the dispensing of individual pigments based on light absorbance characteristics and material properties to achieve the desired color, ensuring the final object matches the target color by calculating and dispensing precise amounts of pigments and dyes.

System and method for in situ volumetric sensing of 3D cure state of resin being used in an additive manufacturing system

PatentActiveUS20210146628A1

Innovation

- Incorporating an in situ cure monitoring control system that uses optical Computed Tomographic (CT) images to generate real-time feedback on the curing state of the resist, allowing for the modification of the curing beam to optimize the curing process.

Material Science Advancements for Color Stability

Recent advancements in material science have significantly contributed to improving color stability in volumetric additive manufacturing systems. Photopolymer chemistry has evolved to incorporate color-stable chromophores that resist degradation under various environmental conditions. These specialized formulations maintain their vibrancy and hue accuracy throughout the printing process and product lifecycle, addressing one of the major challenges in colored volumetric printing.

Nanoparticle technology has emerged as a crucial innovation for color stability. By incorporating precisely engineered nanoparticles into printing materials, manufacturers can achieve more consistent color distribution and enhanced resistance to UV degradation. These particles, ranging from 10-100nm in size, provide superior color properties while maintaining the mechanical integrity of the printed objects. Research indicates that silica-coated quantum dots and core-shell nanostructures offer particularly promising results for long-term color stability.

Cross-linking chemistry improvements have led to more robust color fixation within polymer matrices. Advanced cross-linking agents now enable stronger bonds between colorants and base materials, preventing color migration and leaching that previously plagued volumetric color printing. These chemical innovations ensure that colors remain fixed in their intended positions throughout the complex volumetric printing process, even when multiple colors are introduced simultaneously.

Stabilizing additives represent another significant advancement in the field. Anti-oxidants, UV absorbers, and hindered amine light stabilizers (HALS) are now routinely incorporated into volumetric printing materials to prevent color fading and yellowing. These additives effectively neutralize free radicals and absorb harmful radiation that would otherwise degrade chromophores over time. Studies show that synergistic combinations of these stabilizers can extend color life by up to 300% compared to unprotected formulations.

Surface treatment technologies have also evolved to enhance color protection in finished volumetric prints. Post-processing techniques such as plasma treatment and specialized coating applications create protective barriers that shield colorants from environmental stressors. These treatments maintain optical clarity while providing a defensive layer against moisture, oxygen, and UV radiation – the primary culprits behind color degradation.

Biomimetic approaches are gaining traction in material science research for color stability. By studying natural systems with exceptional color properties, such as butterfly wings and beetle exoskeletons, researchers have developed structural coloration techniques that rely on physical nanostructures rather than traditional pigments. These structural colors demonstrate remarkable stability as they do not fade through chemical degradation, potentially revolutionizing long-term color performance in volumetric manufacturing.

Nanoparticle technology has emerged as a crucial innovation for color stability. By incorporating precisely engineered nanoparticles into printing materials, manufacturers can achieve more consistent color distribution and enhanced resistance to UV degradation. These particles, ranging from 10-100nm in size, provide superior color properties while maintaining the mechanical integrity of the printed objects. Research indicates that silica-coated quantum dots and core-shell nanostructures offer particularly promising results for long-term color stability.

Cross-linking chemistry improvements have led to more robust color fixation within polymer matrices. Advanced cross-linking agents now enable stronger bonds between colorants and base materials, preventing color migration and leaching that previously plagued volumetric color printing. These chemical innovations ensure that colors remain fixed in their intended positions throughout the complex volumetric printing process, even when multiple colors are introduced simultaneously.

Stabilizing additives represent another significant advancement in the field. Anti-oxidants, UV absorbers, and hindered amine light stabilizers (HALS) are now routinely incorporated into volumetric printing materials to prevent color fading and yellowing. These additives effectively neutralize free radicals and absorb harmful radiation that would otherwise degrade chromophores over time. Studies show that synergistic combinations of these stabilizers can extend color life by up to 300% compared to unprotected formulations.

Surface treatment technologies have also evolved to enhance color protection in finished volumetric prints. Post-processing techniques such as plasma treatment and specialized coating applications create protective barriers that shield colorants from environmental stressors. These treatments maintain optical clarity while providing a defensive layer against moisture, oxygen, and UV radiation – the primary culprits behind color degradation.

Biomimetic approaches are gaining traction in material science research for color stability. By studying natural systems with exceptional color properties, such as butterfly wings and beetle exoskeletons, researchers have developed structural coloration techniques that rely on physical nanostructures rather than traditional pigments. These structural colors demonstrate remarkable stability as they do not fade through chemical degradation, potentially revolutionizing long-term color performance in volumetric manufacturing.

Quality Assurance Standards for Colored VAM Products

The establishment of quality assurance standards for colored Volumetric Additive Manufacturing (VAM) products represents a critical framework for ensuring consistency, reliability, and market acceptance of these advanced manufacturing outputs. Currently, the industry faces significant challenges due to the absence of unified standards specifically addressing color fidelity and consistency in volumetric printing processes.

Leading standardization bodies including ASTM International, ISO, and the 3MF Consortium have begun developing preliminary guidelines that incorporate color quality metrics into broader additive manufacturing standards. These emerging frameworks typically address color gamut verification, color accuracy measurement protocols, and minimum acceptable color consistency across production batches.

Color calibration procedures form a cornerstone of these standards, with requirements for regular calibration cycles, reference color targets, and spectrophotometric verification methods. Most standards mandate documentation of calibration history and traceability to ensure manufacturing process transparency and repeatability.

Tolerance specifications represent another crucial component, with standards typically defining acceptable Delta-E values (color difference measurements) for various application categories. Medical applications generally require the strictest tolerances (Delta-E < 2.0), while consumer products may permit wider variances (Delta-E < 5.0) depending on functional requirements and visual significance.

Testing methodologies prescribed by these standards commonly include accelerated aging protocols to evaluate color stability under various environmental conditions, including UV exposure, temperature cycling, and humidity variations. These tests aim to predict long-term color performance and establish minimum stability requirements for different product classifications.

Documentation requirements constitute a significant aspect of quality assurance standards, with manufacturers typically required to maintain comprehensive color management plans, material-specific color characterization data, and batch-specific color verification reports. This documentation serves both regulatory compliance and customer assurance purposes.

Industry-specific adaptations of these standards have emerged, with medical device manufacturers implementing particularly rigorous color verification protocols for anatomical models and surgical guides. Similarly, consumer product manufacturers have developed streamlined testing procedures focused on visual consistency rather than absolute color accuracy.

The evolution of these standards continues to accelerate as VAM technology matures, with increasing emphasis on spectral color representation rather than traditional RGB/CMYK approaches. This shift acknowledges the unique capabilities and challenges of volumetric manufacturing processes in achieving accurate color throughout complex three-dimensional structures.

Leading standardization bodies including ASTM International, ISO, and the 3MF Consortium have begun developing preliminary guidelines that incorporate color quality metrics into broader additive manufacturing standards. These emerging frameworks typically address color gamut verification, color accuracy measurement protocols, and minimum acceptable color consistency across production batches.

Color calibration procedures form a cornerstone of these standards, with requirements for regular calibration cycles, reference color targets, and spectrophotometric verification methods. Most standards mandate documentation of calibration history and traceability to ensure manufacturing process transparency and repeatability.

Tolerance specifications represent another crucial component, with standards typically defining acceptable Delta-E values (color difference measurements) for various application categories. Medical applications generally require the strictest tolerances (Delta-E < 2.0), while consumer products may permit wider variances (Delta-E < 5.0) depending on functional requirements and visual significance.

Testing methodologies prescribed by these standards commonly include accelerated aging protocols to evaluate color stability under various environmental conditions, including UV exposure, temperature cycling, and humidity variations. These tests aim to predict long-term color performance and establish minimum stability requirements for different product classifications.

Documentation requirements constitute a significant aspect of quality assurance standards, with manufacturers typically required to maintain comprehensive color management plans, material-specific color characterization data, and batch-specific color verification reports. This documentation serves both regulatory compliance and customer assurance purposes.

Industry-specific adaptations of these standards have emerged, with medical device manufacturers implementing particularly rigorous color verification protocols for anatomical models and surgical guides. Similarly, consumer product manufacturers have developed streamlined testing procedures focused on visual consistency rather than absolute color accuracy.

The evolution of these standards continues to accelerate as VAM technology matures, with increasing emphasis on spectral color representation rather than traditional RGB/CMYK approaches. This shift acknowledges the unique capabilities and challenges of volumetric manufacturing processes in achieving accurate color throughout complex three-dimensional structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!