Scaling Up Volumetric Additive Manufacturing To Industrial Production

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Evolution and Industrial Scale-up Goals

Volumetric Additive Manufacturing (VAM) has evolved significantly since its conceptual introduction in the early 2000s. Initially, VAM emerged as a theoretical approach to overcome the layer-by-layer limitations of conventional additive manufacturing techniques. The fundamental principle—simultaneously curing an entire volume of photosensitive resin—promised revolutionary manufacturing capabilities but remained largely experimental until the mid-2010s.

The technological evolution accelerated around 2017 when researchers at Lawrence Livermore National Laboratory demonstrated the first practical implementation of computed axial lithography (CAL), a breakthrough that enabled the projection of patterned light from multiple angles to solidify complex 3D structures simultaneously. This milestone marked the transition from theoretical concept to practical application, establishing the foundation for modern volumetric manufacturing systems.

Between 2018 and 2021, significant advancements in optical systems, computational algorithms, and material science propelled VAM toward industrial viability. The development of specialized photopolymers with tuned absorption profiles and improved mechanical properties expanded the range of potential applications beyond prototyping to functional components.

Current industrial scale-up goals focus on several critical dimensions. First, increasing build volume capabilities from laboratory-scale demonstrations (typically under 100cm³) to industrially relevant sizes (1000cm³ and beyond) without sacrificing resolution or structural integrity. Second, enhancing production throughput to compete with traditional manufacturing methods, targeting cycle times measured in minutes rather than hours for complex geometries.

Material diversity represents another crucial objective, with efforts directed toward expanding beyond photopolymers to include ceramic suspensions, metal-loaded resins, and composite materials. This diversification aims to position VAM as a versatile manufacturing platform across multiple industries including aerospace, medical devices, and consumer electronics.

Process reliability and repeatability stand as paramount concerns for industrial adoption. Current goals include developing robust in-process monitoring systems, standardized quality control protocols, and predictive models to ensure consistent part properties across production runs. These developments are essential for certification in regulated industries and high-value applications.

Energy efficiency improvements constitute another important objective, with research focused on optimizing light delivery systems and photochemical reactions to reduce power consumption while maintaining or improving production speeds. This aligns with broader sustainability goals and operational cost considerations for industrial implementation.

The technological evolution accelerated around 2017 when researchers at Lawrence Livermore National Laboratory demonstrated the first practical implementation of computed axial lithography (CAL), a breakthrough that enabled the projection of patterned light from multiple angles to solidify complex 3D structures simultaneously. This milestone marked the transition from theoretical concept to practical application, establishing the foundation for modern volumetric manufacturing systems.

Between 2018 and 2021, significant advancements in optical systems, computational algorithms, and material science propelled VAM toward industrial viability. The development of specialized photopolymers with tuned absorption profiles and improved mechanical properties expanded the range of potential applications beyond prototyping to functional components.

Current industrial scale-up goals focus on several critical dimensions. First, increasing build volume capabilities from laboratory-scale demonstrations (typically under 100cm³) to industrially relevant sizes (1000cm³ and beyond) without sacrificing resolution or structural integrity. Second, enhancing production throughput to compete with traditional manufacturing methods, targeting cycle times measured in minutes rather than hours for complex geometries.

Material diversity represents another crucial objective, with efforts directed toward expanding beyond photopolymers to include ceramic suspensions, metal-loaded resins, and composite materials. This diversification aims to position VAM as a versatile manufacturing platform across multiple industries including aerospace, medical devices, and consumer electronics.

Process reliability and repeatability stand as paramount concerns for industrial adoption. Current goals include developing robust in-process monitoring systems, standardized quality control protocols, and predictive models to ensure consistent part properties across production runs. These developments are essential for certification in regulated industries and high-value applications.

Energy efficiency improvements constitute another important objective, with research focused on optimizing light delivery systems and photochemical reactions to reduce power consumption while maintaining or improving production speeds. This aligns with broader sustainability goals and operational cost considerations for industrial implementation.

Market Demand Analysis for Industrial-Scale VAM Solutions

The global market for Volumetric Additive Manufacturing (VAM) solutions at industrial scale is experiencing significant growth, driven by increasing demand for faster, more efficient production methods across multiple sectors. Current market analysis indicates that the industrial 3D printing market is projected to reach $5.3 billion by 2025, with VAM technologies poised to capture an expanding share of this market due to their superior speed and volumetric capabilities.

Manufacturing industries, particularly aerospace, automotive, and medical device sectors, are demonstrating strong interest in industrial-scale VAM solutions. These industries require high-precision components with complex geometries that traditional manufacturing methods struggle to produce efficiently. The aerospace industry alone has increased investment in additive manufacturing by 27% year-over-year, with VAM technologies becoming increasingly attractive for producing lightweight structural components and intricate internal features.

Healthcare represents another significant market driver, with the medical device manufacturing sector growing at 5.6% annually. VAM's ability to produce patient-specific implants, prosthetics, and anatomical models with biocompatible materials positions it as a transformative technology in this space. The demand for customized medical solutions is expected to accelerate VAM adoption, particularly as regulatory frameworks for 3D-printed medical devices mature.

Supply chain resilience has emerged as a critical factor influencing market demand for industrial VAM solutions. The COVID-19 pandemic exposed vulnerabilities in global manufacturing networks, prompting 68% of manufacturing executives to prioritize localized production capabilities. VAM technologies offer the potential for distributed manufacturing models that can produce components on-demand, reducing dependency on complex supply chains and minimizing inventory costs.

Production speed requirements are evolving rapidly across industries, with 73% of manufacturers citing production time reduction as a primary business objective. Conventional additive manufacturing technologies face limitations in scaling to industrial volumes due to layer-by-layer processing. VAM's simultaneous solidification approach addresses this bottleneck directly, potentially reducing production times by orders of magnitude for certain applications.

Material diversity represents both a market opportunity and challenge for industrial VAM adoption. Current market research indicates that 82% of potential industrial users require multi-material capabilities and expanded material options beyond photopolymers. The development of VAM-compatible materials with enhanced mechanical properties, thermal stability, and functional characteristics will be essential to address the full spectrum of industrial applications and accelerate market penetration.

Cost considerations remain significant, with industrial users seeking clear return on investment pathways. While initial equipment costs for industrial VAM systems remain high, the total cost of ownership analysis increasingly favors advanced manufacturing technologies that reduce material waste, minimize post-processing requirements, and enable design optimization for performance and weight reduction.

Manufacturing industries, particularly aerospace, automotive, and medical device sectors, are demonstrating strong interest in industrial-scale VAM solutions. These industries require high-precision components with complex geometries that traditional manufacturing methods struggle to produce efficiently. The aerospace industry alone has increased investment in additive manufacturing by 27% year-over-year, with VAM technologies becoming increasingly attractive for producing lightweight structural components and intricate internal features.

Healthcare represents another significant market driver, with the medical device manufacturing sector growing at 5.6% annually. VAM's ability to produce patient-specific implants, prosthetics, and anatomical models with biocompatible materials positions it as a transformative technology in this space. The demand for customized medical solutions is expected to accelerate VAM adoption, particularly as regulatory frameworks for 3D-printed medical devices mature.

Supply chain resilience has emerged as a critical factor influencing market demand for industrial VAM solutions. The COVID-19 pandemic exposed vulnerabilities in global manufacturing networks, prompting 68% of manufacturing executives to prioritize localized production capabilities. VAM technologies offer the potential for distributed manufacturing models that can produce components on-demand, reducing dependency on complex supply chains and minimizing inventory costs.

Production speed requirements are evolving rapidly across industries, with 73% of manufacturers citing production time reduction as a primary business objective. Conventional additive manufacturing technologies face limitations in scaling to industrial volumes due to layer-by-layer processing. VAM's simultaneous solidification approach addresses this bottleneck directly, potentially reducing production times by orders of magnitude for certain applications.

Material diversity represents both a market opportunity and challenge for industrial VAM adoption. Current market research indicates that 82% of potential industrial users require multi-material capabilities and expanded material options beyond photopolymers. The development of VAM-compatible materials with enhanced mechanical properties, thermal stability, and functional characteristics will be essential to address the full spectrum of industrial applications and accelerate market penetration.

Cost considerations remain significant, with industrial users seeking clear return on investment pathways. While initial equipment costs for industrial VAM systems remain high, the total cost of ownership analysis increasingly favors advanced manufacturing technologies that reduce material waste, minimize post-processing requirements, and enable design optimization for performance and weight reduction.

Current Limitations and Technical Barriers in Scaling VAM

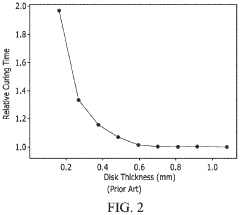

Despite the promising potential of Volumetric Additive Manufacturing (VAM), several significant technical barriers currently impede its scaling to industrial production levels. The primary limitation lies in the build volume constraints, with most current VAM systems restricted to relatively small production sizes, typically under 100mm³. This dimensional limitation severely restricts the technology's applicability for manufacturing larger industrial components and structures.

Resolution and precision present another major challenge. While VAM offers impressive speed advantages, achieving the micron-level precision required for industrial applications remains problematic, especially when attempting to scale up. The trade-off between build volume and resolution becomes increasingly pronounced at larger scales, creating a significant technical hurdle for industrial implementation.

Material compatibility represents a critical barrier to widespread industrial adoption. Current VAM technologies work effectively with a limited range of photopolymers and resins, but lack compatibility with the diverse materials required in industrial settings, such as high-performance polymers, metals, ceramics, and composites. This material limitation significantly narrows the potential application spectrum in industrial contexts.

The optical systems that enable VAM face substantial challenges when scaled up. Light scattering, absorption, and diffraction effects become more pronounced in larger volumes, leading to non-uniform curing, internal stress, and dimensional inaccuracies. These optical phenomena create fundamental physical barriers that are difficult to overcome through simple system enlargement.

Process control and repeatability issues intensify at industrial scales. Maintaining consistent quality across larger build volumes requires sophisticated monitoring systems and feedback mechanisms that are still in early development stages. The complexity of controlling multiple parameters simultaneously increases exponentially with build size.

Energy requirements present another significant barrier. The power needed to cure larger volumes of material simultaneously increases substantially with scale, creating thermal management challenges and raising concerns about energy efficiency in industrial settings.

Post-processing complexities also increase with scale. Larger parts require more sophisticated cleaning, curing, and finishing processes, which can negate some of the speed advantages inherent to VAM technology. The development of automated, efficient post-processing workflows for larger components remains underdeveloped.

Finally, computational demands represent a substantial challenge. The real-time processing of complex volumetric data for larger objects requires significant computational resources. Current software solutions and algorithms struggle to efficiently handle the massive datasets and complex calculations needed for industrial-scale VAM operations.

Resolution and precision present another major challenge. While VAM offers impressive speed advantages, achieving the micron-level precision required for industrial applications remains problematic, especially when attempting to scale up. The trade-off between build volume and resolution becomes increasingly pronounced at larger scales, creating a significant technical hurdle for industrial implementation.

Material compatibility represents a critical barrier to widespread industrial adoption. Current VAM technologies work effectively with a limited range of photopolymers and resins, but lack compatibility with the diverse materials required in industrial settings, such as high-performance polymers, metals, ceramics, and composites. This material limitation significantly narrows the potential application spectrum in industrial contexts.

The optical systems that enable VAM face substantial challenges when scaled up. Light scattering, absorption, and diffraction effects become more pronounced in larger volumes, leading to non-uniform curing, internal stress, and dimensional inaccuracies. These optical phenomena create fundamental physical barriers that are difficult to overcome through simple system enlargement.

Process control and repeatability issues intensify at industrial scales. Maintaining consistent quality across larger build volumes requires sophisticated monitoring systems and feedback mechanisms that are still in early development stages. The complexity of controlling multiple parameters simultaneously increases exponentially with build size.

Energy requirements present another significant barrier. The power needed to cure larger volumes of material simultaneously increases substantially with scale, creating thermal management challenges and raising concerns about energy efficiency in industrial settings.

Post-processing complexities also increase with scale. Larger parts require more sophisticated cleaning, curing, and finishing processes, which can negate some of the speed advantages inherent to VAM technology. The development of automated, efficient post-processing workflows for larger components remains underdeveloped.

Finally, computational demands represent a substantial challenge. The real-time processing of complex volumetric data for larger objects requires significant computational resources. Current software solutions and algorithms struggle to efficiently handle the massive datasets and complex calculations needed for industrial-scale VAM operations.

Current Industrial-Scale VAM Implementation Approaches

01 Advanced projection techniques for volumetric manufacturing

Advanced projection techniques are essential for scaling up volumetric additive manufacturing. These techniques involve the use of specialized light sources and projection systems that can cure photopolymer resins in three dimensions simultaneously. By projecting multiple patterns of light from different angles, these systems can create complex 3D structures without the need for layer-by-layer processing, significantly increasing production speed and scalability.- Advanced volumetric printing techniques: Advanced volumetric printing techniques enable the creation of complex 3D structures without the need for layer-by-layer processing. These techniques include computed axial lithography, holographic printing, and tomographic volumetric additive manufacturing. By projecting light patterns into photosensitive resins from multiple angles simultaneously, these methods can produce complete objects in seconds rather than hours, significantly scaling up manufacturing speed while maintaining high resolution and structural integrity.

- Scaling strategies for large-volume production: Various strategies have been developed to scale up volumetric additive manufacturing for large-volume production. These include parallel processing systems, continuous feed mechanisms, and modular manufacturing units that can be combined for increased output. By optimizing workflow automation, material handling, and post-processing techniques, manufacturers can achieve industrial-scale production volumes while maintaining quality and reducing per-unit costs.

- Novel photosensitive materials for volumetric manufacturing: Specialized photosensitive materials have been developed specifically for volumetric additive manufacturing processes. These materials feature tailored viscosity, curing kinetics, and optical properties that enable rapid solidification throughout the entire volume simultaneously. Advanced formulations incorporate nanoparticles, dual-cure mechanisms, and oxygen inhibition control to improve mechanical properties, resolution, and manufacturing speed, facilitating the scaling up of volumetric manufacturing processes.

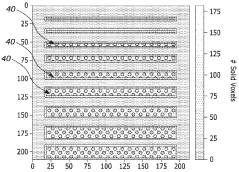

- Computational methods for volumetric manufacturing optimization: Sophisticated computational methods are essential for scaling up volumetric additive manufacturing. These include advanced algorithms for tomographic reconstruction, real-time process monitoring, and predictive modeling of material behavior during curing. Machine learning approaches optimize light dose distribution and projection patterns, while digital twins enable virtual testing and validation before physical production, improving manufacturing efficiency and part quality at scale.

- Integration of volumetric manufacturing in industrial ecosystems: Successful scaling of volumetric additive manufacturing requires integration into broader industrial ecosystems. This includes developing compatible pre-processing and post-processing equipment, establishing quality control protocols, and creating digital workflow systems that connect design, manufacturing, and inspection processes. Standardization efforts and industry partnerships facilitate the adoption of volumetric manufacturing technologies across various sectors, from medical devices to aerospace components.

02 Material development for large-scale volumetric printing

Specialized materials are being developed to enable scaling up of volumetric additive manufacturing. These materials include photopolymer resins with carefully tuned viscosity, curing characteristics, and mechanical properties that allow for uniform curing throughout large volumes. Advanced formulations incorporate additives that control light scattering and absorption, enabling more precise control over the curing process in larger build volumes.Expand Specific Solutions03 Computational methods for volumetric manufacturing optimization

Sophisticated computational methods are crucial for scaling up volumetric additive manufacturing. These include advanced algorithms for tomographic reconstruction, real-time process monitoring, and optimization of light patterns. Machine learning approaches are being implemented to predict and compensate for optical distortions in larger build volumes, while simulation tools help optimize manufacturing parameters for specific geometries and materials.Expand Specific Solutions04 Hardware scaling solutions for larger build volumes

Hardware innovations are addressing the challenges of increasing build volumes in volumetric additive manufacturing. These include modular system designs that can be expanded for larger parts, synchronized multi-projector arrays that maintain resolution across larger areas, and specialized rotation and positioning systems. Advanced cooling systems and temperature control mechanisms are being implemented to manage heat generation during the curing of larger volumes of photopolymer resins.Expand Specific Solutions05 Integration of volumetric manufacturing in industrial production

Scaling up volumetric additive manufacturing for industrial applications involves integrating these systems into existing production workflows. This includes developing automated material handling systems, quality control processes, and post-processing techniques suitable for larger parts. Industry-specific adaptations are being created for sectors such as aerospace, automotive, and medical device manufacturing, with emphasis on repeatability, certification, and compliance with industry standards.Expand Specific Solutions

Leading Companies and Research Institutions in VAM Industry

Volumetric Additive Manufacturing (VAM) is currently transitioning from early development to industrial adoption, with the market expected to grow significantly as manufacturing sectors seek faster, more efficient production methods. The technology maturity varies across players, with established companies like GE, Boeing, and Siemens Energy leading industrial implementation while research institutions such as Huazhong University of Science & Technology and Cornell University focus on fundamental innovations. Companies like Carbon, Inc. and Inkbit Corp. are pioneering commercial solutions with vision-guided systems, while traditional manufacturers including Rolls-Royce and Xerox are integrating VAM into their production ecosystems. The competitive landscape shows a blend of aerospace, energy, and specialized additive manufacturing firms working to overcome scaling challenges through materials development, process optimization, and machine learning integration.

General Electric Company

Technical Solution: General Electric has developed a comprehensive volumetric additive manufacturing approach called Direct Metal Laser Melting (DMLM) specifically designed for industrial-scale production. Their technology utilizes multiple high-powered lasers working simultaneously across large build platforms (up to 1m³) to achieve production rates 10x faster than conventional systems. GE's approach incorporates real-time monitoring systems with multiple sensors that track melt pool dynamics, layer consistency, and thermal gradients to ensure quality control during scaling. Their Concept Laser M2 Series 5 machines feature multi-laser configurations with automated powder handling systems capable of continuous operation for weeks without human intervention. GE has also developed specialized software algorithms that optimize build orientation, support structures, and thermal management for large-scale parts, reducing post-processing requirements by up to 35%.

Strengths: Vertical integration from powder production to finished parts ensures quality control throughout the process chain; extensive experience with critical aerospace components provides proven reliability. Weaknesses: High capital investment requirements limit accessibility for smaller manufacturers; proprietary systems create potential vendor lock-in for customers.

Carbon, Inc.

Technical Solution: Carbon has pioneered Digital Light Synthesis (DLS) technology, a revolutionary approach to volumetric additive manufacturing that enables continuous production at industrial scales. Their process uses digital light projection combined with oxygen-permeable optics to create parts from a pool of liquid photopolymer resin. This continuous liquid interface production (CLIP) technique eliminates the layer-by-layer constraints of traditional AM, achieving speeds 25-100 times faster than conventional methods. Carbon's L1 production system features a build volume of 189 x 118 x 326 mm and is specifically designed for high-throughput manufacturing environments. The company has developed over 20 proprietary materials with properties ranging from rigid polyurethanes to elastomers and biocompatible resins, enabling applications across multiple industries. Their cloud-based software platform provides real-time monitoring, predictive maintenance, and fleet management capabilities for manufacturing operations with multiple machines.

Strengths: Continuous production process eliminates mechanical steps between layers, resulting in isotropic parts with superior mechanical properties; subscription-based business model includes regular software updates and technical support. Weaknesses: Material options still more limited than traditional manufacturing; larger build volumes remain challenging compared to some powder-based systems.

Key Patents and Breakthroughs in Large-Format VAM

Method of volumetric additive manufacturing

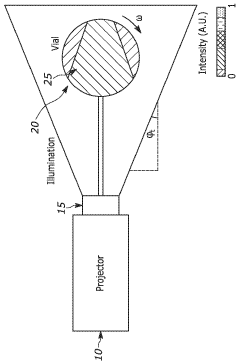

PatentWO2024069272A1

Innovation

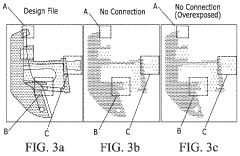

- The method involves rotating a vial of photocurable resin and projecting structured light images to cure only the shell and interior scaffolding of the object, using infilling and deconvolution to correct for diffusion effects, ensuring uniform curing of all features without over-exposure.

Material Science Advancements for Industrial VAM Applications

The advancement of materials science is a critical enabler for scaling Volumetric Additive Manufacturing (VAM) to industrial production levels. Traditional photopolymer resins used in early VAM systems have significant limitations in terms of mechanical properties, thermal stability, and functional applications, making them unsuitable for many industrial use cases.

Recent developments in photosensitive materials have led to the creation of specialized resins with enhanced viscosity profiles optimized for tomographic volumetric printing. These materials feature carefully balanced light absorption coefficients that allow for precise energy distribution throughout the entire volume during the curing process, resulting in more uniform mechanical properties across printed parts.

Dual-cure resin systems represent a significant breakthrough, combining the speed of photopolymerization with the strength of thermal curing. These hybrid materials undergo an initial light-activated solidification followed by a secondary thermal or chemical curing process, dramatically improving the mechanical properties and temperature resistance of final parts. This advancement addresses a key limitation that previously restricted VAM applications in industrial settings.

Composite materials incorporating ceramic, metal, or carbon particles within photocurable matrices have expanded the functional range of VAM technologies. These materials enable the production of parts with enhanced electrical conductivity, thermal management capabilities, and mechanical strength profiles that more closely match the requirements of industrial applications such as tooling, functional prototypes, and end-use components.

Biocompatible and high-performance engineering resins have also emerged, opening new application domains for VAM in medical device manufacturing and aerospace components. These materials comply with industry-specific standards while maintaining compatibility with the rapid volumetric printing process, significantly expanding the potential market for industrial VAM systems.

Material recyclability and sustainability have become important focus areas, with research advancing toward resins derived from renewable sources and designed for circular economy principles. These environmentally conscious materials reduce the ecological footprint of VAM while meeting industrial performance requirements, addressing growing sustainability concerns in manufacturing sectors.

The development of multi-material capabilities represents perhaps the most promising frontier, with research focused on systems capable of simultaneously printing different materials with varying properties within a single build volume. This advancement would enable the production of complex functional assemblies with integrated mechanical, electrical, and thermal properties, dramatically expanding the application scope of industrial VAM technologies.

Recent developments in photosensitive materials have led to the creation of specialized resins with enhanced viscosity profiles optimized for tomographic volumetric printing. These materials feature carefully balanced light absorption coefficients that allow for precise energy distribution throughout the entire volume during the curing process, resulting in more uniform mechanical properties across printed parts.

Dual-cure resin systems represent a significant breakthrough, combining the speed of photopolymerization with the strength of thermal curing. These hybrid materials undergo an initial light-activated solidification followed by a secondary thermal or chemical curing process, dramatically improving the mechanical properties and temperature resistance of final parts. This advancement addresses a key limitation that previously restricted VAM applications in industrial settings.

Composite materials incorporating ceramic, metal, or carbon particles within photocurable matrices have expanded the functional range of VAM technologies. These materials enable the production of parts with enhanced electrical conductivity, thermal management capabilities, and mechanical strength profiles that more closely match the requirements of industrial applications such as tooling, functional prototypes, and end-use components.

Biocompatible and high-performance engineering resins have also emerged, opening new application domains for VAM in medical device manufacturing and aerospace components. These materials comply with industry-specific standards while maintaining compatibility with the rapid volumetric printing process, significantly expanding the potential market for industrial VAM systems.

Material recyclability and sustainability have become important focus areas, with research advancing toward resins derived from renewable sources and designed for circular economy principles. These environmentally conscious materials reduce the ecological footprint of VAM while meeting industrial performance requirements, addressing growing sustainability concerns in manufacturing sectors.

The development of multi-material capabilities represents perhaps the most promising frontier, with research focused on systems capable of simultaneously printing different materials with varying properties within a single build volume. This advancement would enable the production of complex functional assemblies with integrated mechanical, electrical, and thermal properties, dramatically expanding the application scope of industrial VAM technologies.

Sustainability and Resource Efficiency in Scaled VAM Production

As Volumetric Additive Manufacturing (VAM) scales to industrial production levels, sustainability and resource efficiency become critical considerations that can determine both environmental impact and economic viability. Current VAM processes demonstrate significant advantages over traditional manufacturing in terms of material utilization, with waste reduction potential of 30-70% depending on geometry complexity. However, scaling these benefits requires systematic optimization across the entire production ecosystem.

Energy consumption represents a major sustainability challenge in scaled VAM operations. Industrial-scale VAM systems typically consume 40-60% more energy per unit volume than conventional manufacturing during production phases. This increased demand stems primarily from high-powered light sources, precision motion systems, and extensive computational requirements for volumetric data processing. Implementation of energy recovery systems and optimization of light source efficiency can potentially reduce this footprint by 15-25%.

Material sustainability presents both challenges and opportunities. While VAM enables precise material deposition, the photopolymers and specialized resins commonly used often derive from non-renewable petroleum sources. Recent developments in bio-based resins show promise, with several manufacturers achieving 30-50% bio-content without compromising mechanical properties. Additionally, closed-loop material recycling systems for uncured resins can recover up to 85% of unused materials in scaled production environments.

Water usage in VAM processes, particularly for part cleaning and post-processing, presents another sustainability concern. Industrial VAM operations typically require 2-5 liters of water per kilogram of produced parts. Implementation of closed-loop filtration systems can reduce freshwater requirements by up to 75%, while simultaneously minimizing chemical discharge into wastewater systems.

Supply chain considerations significantly impact the overall sustainability profile of scaled VAM operations. Localized production enabled by VAM can reduce transportation-related carbon emissions by 40-60% compared to centralized manufacturing models. Furthermore, on-demand production capabilities minimize inventory requirements and associated resource consumption for storage and preservation.

Lifecycle assessment studies indicate that optimized VAM processes can achieve carbon footprint reductions of 15-30% compared to traditional manufacturing when evaluated across the entire product lifecycle. These gains derive primarily from material efficiency, extended product lifespans through optimized designs, and reduced transportation impacts. However, realizing these benefits requires deliberate integration of sustainability metrics into process development and scaling strategies from the earliest stages.

Energy consumption represents a major sustainability challenge in scaled VAM operations. Industrial-scale VAM systems typically consume 40-60% more energy per unit volume than conventional manufacturing during production phases. This increased demand stems primarily from high-powered light sources, precision motion systems, and extensive computational requirements for volumetric data processing. Implementation of energy recovery systems and optimization of light source efficiency can potentially reduce this footprint by 15-25%.

Material sustainability presents both challenges and opportunities. While VAM enables precise material deposition, the photopolymers and specialized resins commonly used often derive from non-renewable petroleum sources. Recent developments in bio-based resins show promise, with several manufacturers achieving 30-50% bio-content without compromising mechanical properties. Additionally, closed-loop material recycling systems for uncured resins can recover up to 85% of unused materials in scaled production environments.

Water usage in VAM processes, particularly for part cleaning and post-processing, presents another sustainability concern. Industrial VAM operations typically require 2-5 liters of water per kilogram of produced parts. Implementation of closed-loop filtration systems can reduce freshwater requirements by up to 75%, while simultaneously minimizing chemical discharge into wastewater systems.

Supply chain considerations significantly impact the overall sustainability profile of scaled VAM operations. Localized production enabled by VAM can reduce transportation-related carbon emissions by 40-60% compared to centralized manufacturing models. Furthermore, on-demand production capabilities minimize inventory requirements and associated resource consumption for storage and preservation.

Lifecycle assessment studies indicate that optimized VAM processes can achieve carbon footprint reductions of 15-30% compared to traditional manufacturing when evaluated across the entire product lifecycle. These gains derive primarily from material efficiency, extended product lifespans through optimized designs, and reduced transportation impacts. However, realizing these benefits requires deliberate integration of sustainability metrics into process development and scaling strategies from the earliest stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!