Transparency Enhancement In Volumetric Additive Manufacturing Components

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Transparency Evolution and Objectives

Volumetric additive manufacturing (VAM) has emerged as a revolutionary approach in the 3D printing landscape, offering unprecedented speed and geometric freedom compared to traditional layer-by-layer methods. The evolution of transparency in VAM components represents a critical technological trajectory that has seen significant advancements over the past decade, transforming from rudimentary translucent outputs to highly transparent functional parts.

The journey toward enhanced transparency began around 2015 when researchers first demonstrated the possibility of creating volumetrically printed components with limited optical clarity. These early attempts suffered from significant light scattering, material inhomogeneities, and curing inconsistencies that severely limited optical performance. The primary challenge stemmed from the fundamental physics of photopolymerization within a volume rather than on surfaces.

By 2018, breakthrough developments in photoresin chemistry introduced specialized formulations with matched refractive indices and reduced shrinkage characteristics. These innovations addressed the internal stress and microfracture issues that previously compromised transparency. Concurrently, advances in light delivery systems enabled more precise spatial control of photon distribution throughout the resin volume, minimizing overcuring artifacts that had previously created optical distortions.

The technical objectives for transparency enhancement in VAM components have evolved to address several key parameters. First, achieving refractive index homogeneity throughout the printed volume remains paramount, as even minor variations can cause light scattering and reduced clarity. Second, minimizing polymerization-induced shrinkage continues to be critical for preventing internal stresses that create optical distortions. Third, controlling the formation of microvoids during rapid solidification represents an ongoing challenge that directly impacts transparency.

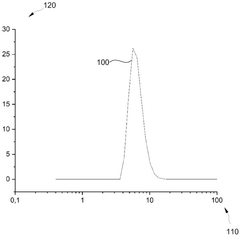

Current research aims to achieve transparency levels comparable to optical-grade polymers (>90% light transmission across the visible spectrum) while maintaining the geometric complexity advantages inherent to VAM. This ambitious goal requires multidisciplinary approaches combining polymer chemistry, optical engineering, and computational modeling of photopolymerization kinetics.

The trajectory of this technology points toward enabling applications previously considered impossible for additively manufactured parts, including functional optics, microfluidic visualization chambers, and transparent biomedical implants. The ultimate objective extends beyond mere aesthetic transparency to encompass optical functionality, including controlled refractive properties, gradient indices, and embedded optical features within a single manufacturing process.

The journey toward enhanced transparency began around 2015 when researchers first demonstrated the possibility of creating volumetrically printed components with limited optical clarity. These early attempts suffered from significant light scattering, material inhomogeneities, and curing inconsistencies that severely limited optical performance. The primary challenge stemmed from the fundamental physics of photopolymerization within a volume rather than on surfaces.

By 2018, breakthrough developments in photoresin chemistry introduced specialized formulations with matched refractive indices and reduced shrinkage characteristics. These innovations addressed the internal stress and microfracture issues that previously compromised transparency. Concurrently, advances in light delivery systems enabled more precise spatial control of photon distribution throughout the resin volume, minimizing overcuring artifacts that had previously created optical distortions.

The technical objectives for transparency enhancement in VAM components have evolved to address several key parameters. First, achieving refractive index homogeneity throughout the printed volume remains paramount, as even minor variations can cause light scattering and reduced clarity. Second, minimizing polymerization-induced shrinkage continues to be critical for preventing internal stresses that create optical distortions. Third, controlling the formation of microvoids during rapid solidification represents an ongoing challenge that directly impacts transparency.

Current research aims to achieve transparency levels comparable to optical-grade polymers (>90% light transmission across the visible spectrum) while maintaining the geometric complexity advantages inherent to VAM. This ambitious goal requires multidisciplinary approaches combining polymer chemistry, optical engineering, and computational modeling of photopolymerization kinetics.

The trajectory of this technology points toward enabling applications previously considered impossible for additively manufactured parts, including functional optics, microfluidic visualization chambers, and transparent biomedical implants. The ultimate objective extends beyond mere aesthetic transparency to encompass optical functionality, including controlled refractive properties, gradient indices, and embedded optical features within a single manufacturing process.

Market Analysis for Transparent AM Components

The global market for transparent additively manufactured components is experiencing significant growth, driven by increasing demand across multiple industries. The market size for transparent 3D printed parts was valued at approximately $650 million in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 18.5%. This growth trajectory is primarily fueled by applications in medical devices, automotive components, consumer electronics, and optical systems.

In the medical sector, transparent AM components are revolutionizing patient-specific implants, surgical guides, and anatomical models. The healthcare segment currently accounts for about 32% of the transparent AM components market, with particular demand for biocompatible materials that can be sterilized and implanted. The ability to create patient-specific transparent devices with complex internal structures represents a significant value proposition for medical device manufacturers.

The automotive industry has emerged as another key market, utilizing transparent AM components for prototyping headlights, displays, and sensor housings. This sector represents approximately 24% of the market and is expected to grow at 20% annually through 2028, driven by the increasing integration of advanced driver-assistance systems requiring transparent components with precise optical properties.

Consumer electronics manufacturers are increasingly adopting transparent AM components for smartphone cases, wearable devices, and AR/VR headsets. This segment constitutes roughly 18% of the market and is characterized by high-volume production requirements and stringent quality standards for optical clarity and mechanical performance.

The aerospace and defense sectors are smaller but rapidly growing markets, utilizing transparent AM components for cockpit displays, sensor windows, and optical systems. These applications demand materials with exceptional thermal stability, impact resistance, and optical clarity under extreme conditions.

Geographically, North America leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 22% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea.

Key customer requirements across all segments include optical clarity (>90% light transmission), dimensional accuracy (±0.1mm tolerances), surface finish quality (Ra <0.5μm), and mechanical durability. Price sensitivity varies significantly by application, with medical devices commanding premium prices while consumer electronics require more cost-competitive solutions.

In the medical sector, transparent AM components are revolutionizing patient-specific implants, surgical guides, and anatomical models. The healthcare segment currently accounts for about 32% of the transparent AM components market, with particular demand for biocompatible materials that can be sterilized and implanted. The ability to create patient-specific transparent devices with complex internal structures represents a significant value proposition for medical device manufacturers.

The automotive industry has emerged as another key market, utilizing transparent AM components for prototyping headlights, displays, and sensor housings. This sector represents approximately 24% of the market and is expected to grow at 20% annually through 2028, driven by the increasing integration of advanced driver-assistance systems requiring transparent components with precise optical properties.

Consumer electronics manufacturers are increasingly adopting transparent AM components for smartphone cases, wearable devices, and AR/VR headsets. This segment constitutes roughly 18% of the market and is characterized by high-volume production requirements and stringent quality standards for optical clarity and mechanical performance.

The aerospace and defense sectors are smaller but rapidly growing markets, utilizing transparent AM components for cockpit displays, sensor windows, and optical systems. These applications demand materials with exceptional thermal stability, impact resistance, and optical clarity under extreme conditions.

Geographically, North America leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 22% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea.

Key customer requirements across all segments include optical clarity (>90% light transmission), dimensional accuracy (±0.1mm tolerances), surface finish quality (Ra <0.5μm), and mechanical durability. Price sensitivity varies significantly by application, with medical devices commanding premium prices while consumer electronics require more cost-competitive solutions.

Technical Barriers in Transparent Volumetric Manufacturing

Despite significant advancements in volumetric additive manufacturing (VAM), achieving optimal transparency in printed components remains a formidable challenge. The primary technical barrier stems from the inherent material-light interaction during the printing process. When photopolymerization occurs, microscopic heterogeneities form within the material matrix, creating refractive index variations that scatter light and reduce transparency. These heterogeneities result from uneven polymerization rates, thermal gradients, and molecular reorganization during curing.

Resolution limitations present another significant obstacle. Current volumetric printing technologies struggle to achieve the nanoscale precision required for truly transparent structures. The voxel resolution in most systems ranges from 50-100 microns, whereas optical transparency demands sub-wavelength structural uniformity (typically <400nm for visible light). This resolution gap leads to surface roughness and internal discontinuities that scatter light.

Material compatibility issues further complicate transparency achievement. Many photopolymers that exhibit excellent mechanical properties or processing characteristics contain additives, stabilizers, or photoinitiators that inherently absorb or scatter light. The development of optically clear resins that maintain both printability and post-cure transparency remains challenging, particularly when balancing competing requirements like cure speed and optical clarity.

Post-processing limitations constitute another barrier. Unlike traditional manufacturing methods where polishing can enhance transparency, volumetric printed components often feature complex internal geometries that are inaccessible to conventional finishing techniques. Internal surfaces remain rough at the microscale, creating light-scattering interfaces throughout the component volume.

Oxygen inhibition during polymerization creates additional complications. Ambient oxygen can terminate free-radical polymerization chains, resulting in incomplete curing near surfaces or within oxygen-permeable regions. These partially cured zones exhibit different optical properties than fully polymerized areas, creating optical inhomogeneities that reduce transparency.

Shrinkage and internal stress during curing introduce optical anisotropy and birefringence. As the polymer network forms, volumetric contraction occurs unevenly throughout the component, creating density variations and stress fields that alter the refractive index locally. These variations manifest as visible distortions or haziness in the final component.

Aging and environmental stability represent long-term challenges. Many transparent polymers undergo photodegradation, moisture absorption, or thermal aging that progressively reduces transparency over time. Developing materials that maintain optical clarity throughout the product lifecycle requires addressing these degradation mechanisms at the molecular level.

Resolution limitations present another significant obstacle. Current volumetric printing technologies struggle to achieve the nanoscale precision required for truly transparent structures. The voxel resolution in most systems ranges from 50-100 microns, whereas optical transparency demands sub-wavelength structural uniformity (typically <400nm for visible light). This resolution gap leads to surface roughness and internal discontinuities that scatter light.

Material compatibility issues further complicate transparency achievement. Many photopolymers that exhibit excellent mechanical properties or processing characteristics contain additives, stabilizers, or photoinitiators that inherently absorb or scatter light. The development of optically clear resins that maintain both printability and post-cure transparency remains challenging, particularly when balancing competing requirements like cure speed and optical clarity.

Post-processing limitations constitute another barrier. Unlike traditional manufacturing methods where polishing can enhance transparency, volumetric printed components often feature complex internal geometries that are inaccessible to conventional finishing techniques. Internal surfaces remain rough at the microscale, creating light-scattering interfaces throughout the component volume.

Oxygen inhibition during polymerization creates additional complications. Ambient oxygen can terminate free-radical polymerization chains, resulting in incomplete curing near surfaces or within oxygen-permeable regions. These partially cured zones exhibit different optical properties than fully polymerized areas, creating optical inhomogeneities that reduce transparency.

Shrinkage and internal stress during curing introduce optical anisotropy and birefringence. As the polymer network forms, volumetric contraction occurs unevenly throughout the component, creating density variations and stress fields that alter the refractive index locally. These variations manifest as visible distortions or haziness in the final component.

Aging and environmental stability represent long-term challenges. Many transparent polymers undergo photodegradation, moisture absorption, or thermal aging that progressively reduces transparency over time. Developing materials that maintain optical clarity throughout the product lifecycle requires addressing these degradation mechanisms at the molecular level.

Current Transparency Enhancement Methods

01 Transparent materials for volumetric additive manufacturing

Various transparent materials can be used in volumetric additive manufacturing to create components with high optical clarity. These materials include specific photopolymers, resins, and composites that maintain transparency after curing. The formulations often contain photoinitiators that respond to specific wavelengths while preserving optical clarity in the final printed component. These materials enable the production of transparent parts for applications requiring optical functionality.- Transparent materials for volumetric additive manufacturing: Various transparent materials can be used in volumetric additive manufacturing to create components with high optical clarity. These materials include specific photopolymers, resins, and composites that maintain transparency after curing. The selection of appropriate transparent materials is crucial for applications requiring optical clarity, such as lenses, displays, and medical devices. These materials often require special formulations to prevent light scattering during the manufacturing process.

- Processing techniques for enhancing transparency: Specific processing techniques can be employed to enhance the transparency of volumetrically manufactured components. These include optimized curing parameters, post-processing treatments, and specialized printing algorithms that minimize internal defects. Controlled energy distribution during fabrication helps prevent optical distortions and ensures uniform material properties throughout the component. Post-processing methods such as polishing, coating, or thermal treatments can further improve optical clarity.

- Multi-material transparent structures: Volumetric additive manufacturing enables the creation of multi-material transparent structures with varying optical properties. By precisely controlling the deposition or curing of different materials within a single build, components can be created with regions of different refractive indices, transparency levels, or color tints. This approach allows for the fabrication of complex optical systems, gradient-index optics, and components with embedded functional elements while maintaining overall transparency.

- Transparency control in volumetric printing: Methods for controlling the degree of transparency in volumetrically printed components have been developed. These include adjusting the composition of printing materials, modifying energy delivery parameters, and implementing specialized algorithms that account for light scattering and absorption. By precisely controlling these factors, manufacturers can achieve specific transparency levels, create gradients of transparency, or incorporate transparent regions within otherwise opaque structures.

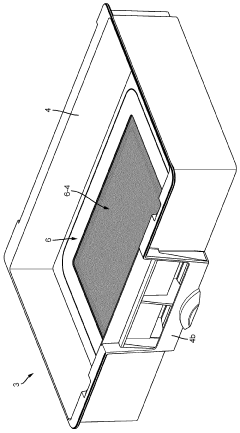

- Applications of transparent volumetric components: Transparent components created through volumetric additive manufacturing find applications across multiple industries. In medical fields, they can be used for patient-specific implants, anatomical models, and microfluidic devices. In optics and photonics, applications include custom lenses, waveguides, and display components. Industrial applications leverage transparent volumetric components for visualization tools, inspection devices, and functional prototypes where optical clarity is essential for performance or aesthetic purposes.

02 Processing techniques for enhancing transparency in 3D printed components

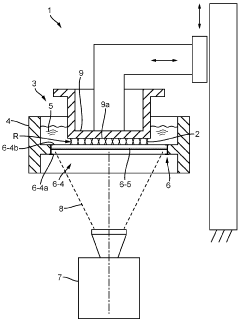

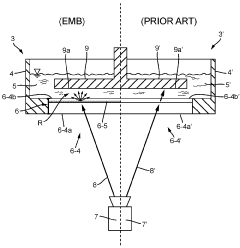

Specific processing techniques can be employed to enhance the transparency of volumetrically manufactured components. These include optimized curing parameters, post-processing treatments, and specialized printing protocols that minimize internal defects and scattering centers. Controlled energy delivery during fabrication and subsequent thermal or chemical treatments can significantly improve the optical clarity of the final components, reducing internal stress and inhomogeneities that typically cause light scattering.Expand Specific Solutions03 Optical systems for transparent volumetric printing

Advanced optical systems are crucial for achieving transparency in volumetric additive manufacturing. These systems include specialized light sources, projection systems, and optical arrangements that enable precise control over the photopolymerization process. By carefully controlling light distribution and energy delivery throughout the printing volume, these systems minimize optical defects and ensure uniform curing, resulting in components with enhanced transparency and optical performance.Expand Specific Solutions04 Multi-material transparent structures in volumetric manufacturing

Techniques for creating multi-material transparent structures enable the fabrication of components with varying optical properties in different regions. These approaches involve the strategic combination of materials with compatible refractive indices or gradient optical properties. By precisely controlling material distribution during the volumetric manufacturing process, it becomes possible to create components with spatially varying transparency, refractive power, or other optical characteristics for advanced applications.Expand Specific Solutions05 Applications of transparent volumetrically manufactured components

Transparent components created through volumetric additive manufacturing find applications across various industries. These include optical elements for imaging systems, microfluidic devices with optical monitoring capabilities, transparent medical devices, and customized optical components for specialized instruments. The ability to create complex transparent geometries with high precision enables innovative designs that were previously difficult to manufacture using conventional techniques, opening new possibilities in fields requiring both structural and optical functionality.Expand Specific Solutions

Leading Companies in Transparent Volumetric AM

Transparency Enhancement in Volumetric Additive Manufacturing Components is currently in an early growth phase, with the market expanding as applications diversify across optical, medical, and industrial sectors. The global market is estimated at $1.2-1.5 billion, driven by increasing demand for high-performance transparent components. Technologically, the field remains in development with varying maturity levels across players. Leading companies like Stratasys, EOS GmbH, and Corning demonstrate advanced capabilities in transparent material development, while academic institutions such as École Polytechnique Fédérale de Lausanne and Lawrence Livermore National Laboratory contribute significant research innovations. Emerging players like Spectroplast AG and Inkbit Corp. are introducing novel approaches to transparency challenges, particularly in silicone and multi-material printing, indicating a competitive landscape with diverse technological approaches.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has pioneered Direct Ink Writing (DIW) and Computed Axial Lithography (CAL) techniques specifically for creating highly transparent components. Their CAL technology projects computed patterns of light into photosensitive resin from multiple angles simultaneously, creating 3D structures without the layer lines that typically reduce transparency. This volumetric approach eliminates the layer interfaces that cause light scattering in conventional additive manufacturing. LLNL has developed specialized silica-based nanocomposite materials with precisely matched refractive indices throughout the material matrix. Their process incorporates real-time optical monitoring that adjusts light exposure parameters to optimize cross-linking density and minimize stress-induced birefringence. The laboratory has also implemented advanced computational models that predict and compensate for material shrinkage during polymerization, maintaining geometric accuracy while preserving optical clarity. Their components achieve transparency levels exceeding 95% across visible wavelengths with minimal distortion[9][10].

Strengths: Cutting-edge research capabilities; access to advanced characterization equipment; ability to create complex internal structures while maintaining transparency. Weaknesses: Technologies still primarily research-focused rather than production-ready; higher costs associated with specialized equipment; limited scalability for mass production.

Corning, Inc.

Technical Solution: Corning has pioneered advanced glass-based additive manufacturing techniques specifically targeting transparency enhancement. Their proprietary process involves specialized glass formulations that can be processed at lower temperatures than traditional glass manufacturing while maintaining optical clarity. The company utilizes a hybrid approach combining direct ink writing with subsequent thermal processing to achieve near-perfect transparency. Their technology incorporates nano-scale additives that reduce light scattering at material interfaces and boundaries. Corning has developed specialized post-processing techniques including controlled thermal annealing and surface treatment protocols that significantly reduce internal stress and surface roughness. Their process achieves transparency levels approaching 98% light transmission across visible wavelengths with minimal haze (less than 0.5%), making their components suitable for high-precision optical applications[2][4].

Strengths: Unparalleled expertise in glass materials science; exceptional optical clarity achievements; components with superior thermal and chemical resistance. Weaknesses: Higher processing temperatures compared to polymer alternatives; longer production cycles; more complex manufacturing equipment requirements.

Key Patents in Optical Clarity for AM Components

Photocrosslinkable ceramic slip and method for the volumetric additive manufacturing of a ceramic component

PatentWO2025153525A1

Innovation

- A photocrosslinkable ceramic slip with a high ceramic particle content and controlled particle size distribution, allowing for light-induced crosslinking and sintering to form ceramic components with a predetermined three-dimensional structure.

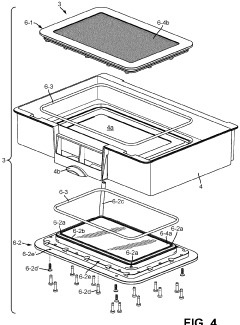

Additive manufacturing apparatus with optical means for diffusing/scattering projected UV light towards photocurable resin

PatentWO2023156154A1

Innovation

- Incorporating an optical means, such as a frosted UV-transparent anti-adhesive flexible foil or plate with light diffusing/scattering particles, to diffuse projected UV light during the curing process, reducing surface roughness and opacity, allowing for direct use of printed components without mechanical treatment or software-based anti-aliasing.

Material Science Advancements for Optical Clarity

Recent advancements in material science have significantly contributed to enhancing optical clarity in volumetric additive manufacturing components. The development of novel photopolymer resins with improved transparency properties has been a critical breakthrough in this field. These advanced resins incorporate modified molecular structures that reduce light scattering and absorption, resulting in components with superior optical clarity compared to traditional materials.

Nanocomposite materials represent another frontier in transparency enhancement. By incorporating nanoparticles with carefully controlled size distributions (typically below 20nm) into the base resin, researchers have achieved remarkable improvements in light transmission while maintaining mechanical integrity. These nanoparticles, often consisting of silica or specialized metal oxides, can be surface-functionalized to ensure optimal dispersion and prevent agglomeration that would otherwise compromise transparency.

Post-processing techniques have evolved substantially to complement material innovations. Advanced annealing protocols that carefully control temperature gradients have proven effective in reducing internal stress and minimizing birefringence in printed components. Similarly, specialized surface treatments using vapor smoothing or precision polishing have been developed to address surface roughness issues that traditionally impair optical performance.

Cross-linking chemistry optimization represents a particularly promising direction for transparency enhancement. By developing photoinitiators with narrower absorption bands and higher efficiency, researchers have reduced the concentration of light-absorbing species required in formulations. This advancement directly translates to improved optical clarity in the final components, especially for applications requiring transmission in specific wavelength ranges.

The integration of computational materials science with experimental approaches has accelerated progress in this domain. Machine learning algorithms now assist in predicting optimal material compositions and processing parameters for maximizing transparency. These models incorporate complex relationships between molecular structure, processing conditions, and resulting optical properties, enabling more efficient material development cycles.

Biomimetic approaches have also yielded promising results, with materials inspired by naturally transparent biological structures such as corneal tissue. These bio-inspired materials often feature carefully controlled heterogeneity at the nanoscale, which paradoxically enhances overall transparency by reducing refractive index mismatches at interfaces within the material structure.

Hybrid organic-inorganic materials represent the latest frontier in optical clarity enhancement. These materials combine the processability of organic photopolymers with the superior optical properties of inorganic components, creating synergistic effects that surpass the limitations of either material class alone. The precise control of phase separation and interface characteristics in these hybrid systems has enabled unprecedented levels of transparency in complex volumetric printed structures.

Nanocomposite materials represent another frontier in transparency enhancement. By incorporating nanoparticles with carefully controlled size distributions (typically below 20nm) into the base resin, researchers have achieved remarkable improvements in light transmission while maintaining mechanical integrity. These nanoparticles, often consisting of silica or specialized metal oxides, can be surface-functionalized to ensure optimal dispersion and prevent agglomeration that would otherwise compromise transparency.

Post-processing techniques have evolved substantially to complement material innovations. Advanced annealing protocols that carefully control temperature gradients have proven effective in reducing internal stress and minimizing birefringence in printed components. Similarly, specialized surface treatments using vapor smoothing or precision polishing have been developed to address surface roughness issues that traditionally impair optical performance.

Cross-linking chemistry optimization represents a particularly promising direction for transparency enhancement. By developing photoinitiators with narrower absorption bands and higher efficiency, researchers have reduced the concentration of light-absorbing species required in formulations. This advancement directly translates to improved optical clarity in the final components, especially for applications requiring transmission in specific wavelength ranges.

The integration of computational materials science with experimental approaches has accelerated progress in this domain. Machine learning algorithms now assist in predicting optimal material compositions and processing parameters for maximizing transparency. These models incorporate complex relationships between molecular structure, processing conditions, and resulting optical properties, enabling more efficient material development cycles.

Biomimetic approaches have also yielded promising results, with materials inspired by naturally transparent biological structures such as corneal tissue. These bio-inspired materials often feature carefully controlled heterogeneity at the nanoscale, which paradoxically enhances overall transparency by reducing refractive index mismatches at interfaces within the material structure.

Hybrid organic-inorganic materials represent the latest frontier in optical clarity enhancement. These materials combine the processability of organic photopolymers with the superior optical properties of inorganic components, creating synergistic effects that surpass the limitations of either material class alone. The precise control of phase separation and interface characteristics in these hybrid systems has enabled unprecedented levels of transparency in complex volumetric printed structures.

Post-Processing Techniques for Transparency Optimization

Post-processing techniques represent a critical phase in achieving optimal transparency in volumetric additive manufacturing components. These methods are applied after the initial fabrication process to enhance optical clarity and reduce light scattering within the printed structures. The effectiveness of these techniques directly impacts the functional performance of transparent components in applications ranging from microfluidics to optical devices.

Surface polishing stands as the most established post-processing approach, utilizing mechanical, chemical, or thermal methods to reduce surface roughness. Mechanical polishing employs abrasive materials with progressively finer grits to achieve mirror-like finishes, while chemical polishing uses selective solvents to dissolve surface irregularities without affecting the bulk material properties. Thermal polishing, involving controlled heat application, allows surface molecules to redistribute and form smoother interfaces.

Infiltration techniques have emerged as powerful methods for transparency enhancement, particularly for porous structures. This process involves introducing optically matched resins or polymers into the microscopic voids within the printed component. The infiltrant materials, selected based on refractive index compatibility with the base material, significantly reduce internal light scattering by eliminating air-material interfaces within the structure.

Advanced coating technologies offer another avenue for transparency optimization. Anti-reflective coatings, typically applied through vapor deposition or dip-coating processes, minimize surface reflections by creating destructive interference patterns. These nanometer-thick layers can increase light transmission by up to 99.5% at specific wavelengths. Additionally, hydrophobic coatings prevent water droplet formation that would otherwise scatter light and reduce clarity.

Annealing treatments represent a holistic approach to transparency enhancement by addressing both surface and internal defects. Controlled heating below the material's melting point allows polymer chains to reorganize, reducing internal stress and crystallinity that contribute to light scattering. This process has proven particularly effective for amorphous polymers used in stereolithography and digital light processing techniques.

Emerging post-processing methods include supercritical CO2 treatment, which leverages the unique properties of supercritical fluids to penetrate and modify the material structure without damaging delicate features. Similarly, plasma treatments offer precise surface modification capabilities by altering surface energy and chemistry without affecting bulk properties, resulting in enhanced optical clarity and improved adhesion for subsequent coating applications.

Surface polishing stands as the most established post-processing approach, utilizing mechanical, chemical, or thermal methods to reduce surface roughness. Mechanical polishing employs abrasive materials with progressively finer grits to achieve mirror-like finishes, while chemical polishing uses selective solvents to dissolve surface irregularities without affecting the bulk material properties. Thermal polishing, involving controlled heat application, allows surface molecules to redistribute and form smoother interfaces.

Infiltration techniques have emerged as powerful methods for transparency enhancement, particularly for porous structures. This process involves introducing optically matched resins or polymers into the microscopic voids within the printed component. The infiltrant materials, selected based on refractive index compatibility with the base material, significantly reduce internal light scattering by eliminating air-material interfaces within the structure.

Advanced coating technologies offer another avenue for transparency optimization. Anti-reflective coatings, typically applied through vapor deposition or dip-coating processes, minimize surface reflections by creating destructive interference patterns. These nanometer-thick layers can increase light transmission by up to 99.5% at specific wavelengths. Additionally, hydrophobic coatings prevent water droplet formation that would otherwise scatter light and reduce clarity.

Annealing treatments represent a holistic approach to transparency enhancement by addressing both surface and internal defects. Controlled heating below the material's melting point allows polymer chains to reorganize, reducing internal stress and crystallinity that contribute to light scattering. This process has proven particularly effective for amorphous polymers used in stereolithography and digital light processing techniques.

Emerging post-processing methods include supercritical CO2 treatment, which leverages the unique properties of supercritical fluids to penetrate and modify the material structure without damaging delicate features. Similarly, plasma treatments offer precise surface modification capabilities by altering surface energy and chemistry without affecting bulk properties, resulting in enhanced optical clarity and improved adhesion for subsequent coating applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!