Real-Time Monitoring In Volumetric Additive Manufacturing

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric Additive Manufacturing Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing technology, moving beyond traditional layer-by-layer approaches to enable the simultaneous solidification of an entire volume of material. This revolutionary technique emerged in the mid-2010s as researchers sought to overcome the speed limitations and mechanical anisotropy inherent in conventional additive manufacturing methods. The fundamental principle behind VAM involves projecting patterned light into a photosensitive resin from multiple angles simultaneously, creating a three-dimensional energy distribution that selectively cures the desired object geometry in a single step.

The evolution of VAM technology has been driven by advances in computational imaging, photochemistry, and high-speed projection systems. Early demonstrations relied on simple tomographic approaches, while more recent developments have incorporated sophisticated algorithms for dose control and optical field shaping. This progression has enabled increasingly complex geometries and improved material properties in fabricated parts, positioning VAM as a potentially transformative technology for rapid prototyping and production applications.

Real-time monitoring capabilities represent a critical frontier in the advancement of VAM technology. Unlike traditional layer-by-layer processes where each layer can be visually inspected during fabrication, the volumetric nature of VAM creates unique challenges for process observation and quality control. The ability to monitor curing dynamics, detect defects, and make real-time adjustments during the printing process is essential for ensuring consistent part quality and expanding the range of viable applications.

The primary technical objectives for real-time monitoring in VAM include: developing non-invasive sensing methodologies that can penetrate the resin volume without disrupting the curing process; creating computational frameworks for rapid data processing and anomaly detection; and establishing feedback mechanisms that enable adaptive control of the fabrication parameters. These capabilities would address current limitations in process reliability and repeatability, which have thus far restricted the industrial adoption of VAM technologies.

Looking forward, the integration of advanced monitoring systems with VAM is expected to enable closed-loop control of the manufacturing process, allowing for dynamic adjustment of exposure patterns based on real-time measurements of resin conversion and structural formation. This represents a significant step toward fully digital manufacturing workflows, where design specifications are seamlessly translated into physical objects with minimal human intervention and maximum quality assurance. The convergence of volumetric fabrication techniques with sophisticated monitoring capabilities promises to accelerate the maturation of VAM from a laboratory curiosity to a viable industrial production technology.

The evolution of VAM technology has been driven by advances in computational imaging, photochemistry, and high-speed projection systems. Early demonstrations relied on simple tomographic approaches, while more recent developments have incorporated sophisticated algorithms for dose control and optical field shaping. This progression has enabled increasingly complex geometries and improved material properties in fabricated parts, positioning VAM as a potentially transformative technology for rapid prototyping and production applications.

Real-time monitoring capabilities represent a critical frontier in the advancement of VAM technology. Unlike traditional layer-by-layer processes where each layer can be visually inspected during fabrication, the volumetric nature of VAM creates unique challenges for process observation and quality control. The ability to monitor curing dynamics, detect defects, and make real-time adjustments during the printing process is essential for ensuring consistent part quality and expanding the range of viable applications.

The primary technical objectives for real-time monitoring in VAM include: developing non-invasive sensing methodologies that can penetrate the resin volume without disrupting the curing process; creating computational frameworks for rapid data processing and anomaly detection; and establishing feedback mechanisms that enable adaptive control of the fabrication parameters. These capabilities would address current limitations in process reliability and repeatability, which have thus far restricted the industrial adoption of VAM technologies.

Looking forward, the integration of advanced monitoring systems with VAM is expected to enable closed-loop control of the manufacturing process, allowing for dynamic adjustment of exposure patterns based on real-time measurements of resin conversion and structural formation. This represents a significant step toward fully digital manufacturing workflows, where design specifications are seamlessly translated into physical objects with minimal human intervention and maximum quality assurance. The convergence of volumetric fabrication techniques with sophisticated monitoring capabilities promises to accelerate the maturation of VAM from a laboratory curiosity to a viable industrial production technology.

Market Demand Analysis for Real-Time Monitoring Solutions

The global market for real-time monitoring solutions in Volumetric Additive Manufacturing (VAM) is experiencing significant growth, driven by increasing adoption of advanced manufacturing technologies across various industries. The demand for these monitoring systems stems primarily from the need to ensure quality control, reduce material waste, and optimize production efficiency in high-value manufacturing processes.

Manufacturing sectors such as aerospace, automotive, medical devices, and precision engineering represent the largest market segments for real-time monitoring in VAM. These industries require components with exceptional dimensional accuracy, structural integrity, and consistent material properties, making real-time process monitoring essential rather than optional.

Market research indicates that manufacturers are increasingly recognizing the value proposition of integrated monitoring systems. The ability to detect defects during the manufacturing process rather than post-production testing represents substantial cost savings. Studies show that early defect detection can reduce scrap rates by up to 30% and decrease quality control costs significantly in advanced manufacturing operations.

The healthcare sector demonstrates particularly strong demand growth for real-time monitoring in VAM applications. The production of patient-specific implants, prosthetics, and anatomical models requires exceptional precision and quality assurance. Real-time monitoring solutions that can verify biocompatibility parameters and structural integrity during fabrication are becoming critical requirements for medical device manufacturers.

From a geographical perspective, North America and Europe currently lead the market adoption of real-time monitoring solutions for VAM, with Asia-Pacific regions showing the fastest growth rate. This regional disparity reflects the varying stages of industrial digitalization and Industry 4.0 implementation across different markets.

A notable market trend is the increasing demand for monitoring systems that incorporate artificial intelligence and machine learning capabilities. End-users are seeking solutions that not only detect defects but can predict potential failures before they occur and automatically adjust process parameters to maintain optimal production conditions.

The market also shows strong preference for monitoring solutions that can be retrofitted to existing VAM equipment rather than requiring complete system replacement. This reflects the substantial capital investment already made in additive manufacturing infrastructure and the desire to extend equipment lifecycle while enhancing capabilities.

Overall, the market trajectory indicates a shift from optional monitoring capabilities to essential integrated systems, with customers increasingly valuing comprehensive data collection, real-time analysis, and closed-loop control features in their VAM operations.

Manufacturing sectors such as aerospace, automotive, medical devices, and precision engineering represent the largest market segments for real-time monitoring in VAM. These industries require components with exceptional dimensional accuracy, structural integrity, and consistent material properties, making real-time process monitoring essential rather than optional.

Market research indicates that manufacturers are increasingly recognizing the value proposition of integrated monitoring systems. The ability to detect defects during the manufacturing process rather than post-production testing represents substantial cost savings. Studies show that early defect detection can reduce scrap rates by up to 30% and decrease quality control costs significantly in advanced manufacturing operations.

The healthcare sector demonstrates particularly strong demand growth for real-time monitoring in VAM applications. The production of patient-specific implants, prosthetics, and anatomical models requires exceptional precision and quality assurance. Real-time monitoring solutions that can verify biocompatibility parameters and structural integrity during fabrication are becoming critical requirements for medical device manufacturers.

From a geographical perspective, North America and Europe currently lead the market adoption of real-time monitoring solutions for VAM, with Asia-Pacific regions showing the fastest growth rate. This regional disparity reflects the varying stages of industrial digitalization and Industry 4.0 implementation across different markets.

A notable market trend is the increasing demand for monitoring systems that incorporate artificial intelligence and machine learning capabilities. End-users are seeking solutions that not only detect defects but can predict potential failures before they occur and automatically adjust process parameters to maintain optimal production conditions.

The market also shows strong preference for monitoring solutions that can be retrofitted to existing VAM equipment rather than requiring complete system replacement. This reflects the substantial capital investment already made in additive manufacturing infrastructure and the desire to extend equipment lifecycle while enhancing capabilities.

Overall, the market trajectory indicates a shift from optional monitoring capabilities to essential integrated systems, with customers increasingly valuing comprehensive data collection, real-time analysis, and closed-loop control features in their VAM operations.

Current Monitoring Technologies and Technical Barriers

Volumetric Additive Manufacturing (VAM) currently employs several monitoring technologies to ensure process quality and consistency. Optical monitoring systems, including high-speed cameras and machine vision setups, represent the most widely adopted approach. These systems capture real-time images of the fabrication volume, allowing for detection of anomalies in light distribution patterns and material polymerization. However, they face significant limitations in penetrating optically dense materials and providing information about internal structures during the manufacturing process.

Spectroscopic monitoring techniques, particularly Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR), have emerged as valuable tools for tracking chemical reactions during photopolymerization. These methods can detect the conversion rate of monomers to polymers in real-time, offering insights into curing dynamics. The major technical barrier remains their limited spatial resolution and difficulty in obtaining volumetric data from within the fabrication chamber without interfering with the printing process.

Thermal monitoring using infrared cameras and thermocouples provides critical data on temperature distribution throughout the build volume. This is essential for processes involving temperature-sensitive materials or exothermic reactions. However, current thermal imaging technologies struggle with spatial resolution limitations and cannot effectively penetrate beyond surface layers in most VAM setups.

Acoustic monitoring represents a promising but underdeveloped approach. Techniques such as ultrasonic testing and acoustic emission analysis can potentially detect internal defects and material property changes. The primary technical barriers include signal interpretation complexity and the need for sophisticated algorithms to translate acoustic data into meaningful process information.

The integration of these monitoring technologies with control systems presents perhaps the most significant technical challenge. While data collection capabilities have advanced considerably, the development of closed-loop control systems that can interpret multi-modal sensor data and make real-time adjustments to printing parameters remains limited. Current systems typically operate in an open-loop configuration, where monitoring data is collected but not automatically fed back to adjust process parameters.

Computational barriers further complicate real-time monitoring. The massive data streams generated by multiple sensors require substantial processing power and sophisticated algorithms for meaningful interpretation. Current image processing and machine learning approaches struggle with the speed requirements of real-time decision-making in VAM processes, particularly when dealing with complex geometries or multi-material prints.

Spectroscopic monitoring techniques, particularly Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR), have emerged as valuable tools for tracking chemical reactions during photopolymerization. These methods can detect the conversion rate of monomers to polymers in real-time, offering insights into curing dynamics. The major technical barrier remains their limited spatial resolution and difficulty in obtaining volumetric data from within the fabrication chamber without interfering with the printing process.

Thermal monitoring using infrared cameras and thermocouples provides critical data on temperature distribution throughout the build volume. This is essential for processes involving temperature-sensitive materials or exothermic reactions. However, current thermal imaging technologies struggle with spatial resolution limitations and cannot effectively penetrate beyond surface layers in most VAM setups.

Acoustic monitoring represents a promising but underdeveloped approach. Techniques such as ultrasonic testing and acoustic emission analysis can potentially detect internal defects and material property changes. The primary technical barriers include signal interpretation complexity and the need for sophisticated algorithms to translate acoustic data into meaningful process information.

The integration of these monitoring technologies with control systems presents perhaps the most significant technical challenge. While data collection capabilities have advanced considerably, the development of closed-loop control systems that can interpret multi-modal sensor data and make real-time adjustments to printing parameters remains limited. Current systems typically operate in an open-loop configuration, where monitoring data is collected but not automatically fed back to adjust process parameters.

Computational barriers further complicate real-time monitoring. The massive data streams generated by multiple sensors require substantial processing power and sophisticated algorithms for meaningful interpretation. Current image processing and machine learning approaches struggle with the speed requirements of real-time decision-making in VAM processes, particularly when dealing with complex geometries or multi-material prints.

Existing Real-Time Monitoring Methodologies for VAM

01 Optical monitoring systems for volumetric additive manufacturing

Optical monitoring systems are employed in volumetric additive manufacturing to observe the printing process in real-time. These systems typically include cameras, sensors, and imaging devices that capture visual data of the build volume during fabrication. Advanced optical techniques such as high-speed imaging and spectroscopy allow for the detection of defects, dimensional accuracy, and material properties as the part is being formed. These monitoring systems enable immediate quality control and can be integrated with feedback mechanisms to adjust printing parameters on-the-fly.- Optical monitoring systems for volumetric additive manufacturing: Optical monitoring systems are employed in volumetric additive manufacturing to provide real-time feedback on the printing process. These systems use cameras, sensors, and imaging technologies to capture and analyze the build process as it occurs. By monitoring parameters such as light intensity, curing patterns, and material deposition, these optical systems can detect defects, ensure dimensional accuracy, and maintain quality control throughout the manufacturing process. Advanced image processing algorithms help in interpreting the collected data for immediate process adjustments.

- In-situ process monitoring with integrated sensors: Volumetric additive manufacturing systems incorporate integrated sensors that provide in-situ monitoring capabilities. These sensors are embedded within the manufacturing equipment to collect real-time data on various process parameters including temperature, pressure, material flow, and curing rates. The integration of multiple sensor types creates a comprehensive monitoring network that enables precise control over the manufacturing process. This approach allows for immediate detection of anomalies and facilitates automated adjustments to maintain optimal printing conditions throughout the build process.

- Machine learning and AI for real-time process optimization: Machine learning and artificial intelligence technologies are being implemented in volumetric additive manufacturing monitoring systems to enhance real-time process optimization. These intelligent systems analyze data streams from various sensors to identify patterns, predict potential issues, and make autonomous adjustments to printing parameters. By continuously learning from historical and current manufacturing data, these systems can optimize print quality, reduce material waste, and increase production efficiency. The AI-driven approach enables adaptive manufacturing processes that improve over time through experience.

- Multi-modal data fusion for comprehensive monitoring: Multi-modal data fusion techniques combine information from various monitoring sources to create a comprehensive understanding of the volumetric additive manufacturing process. By integrating data from optical systems, thermal sensors, acoustic monitors, and mechanical feedback, these systems provide a holistic view of the printing process. The synchronized data streams enable correlation between different process parameters and manufacturing outcomes. This approach enhances defect detection capabilities and provides deeper insights into the complex relationships between manufacturing variables, resulting in improved process control and product quality.

- Closed-loop feedback control systems: Closed-loop feedback control systems in volumetric additive manufacturing utilize real-time monitoring data to automatically adjust process parameters during production. These systems compare actual manufacturing conditions against desired specifications and make immediate corrections when deviations occur. The feedback mechanisms can control various aspects of the process including light intensity, exposure time, material feed rates, and platform positioning. By continuously optimizing the manufacturing parameters based on real-time data, these systems ensure consistent quality, reduce the need for post-processing, and enable the production of complex geometries with high precision.

02 Machine learning and AI-based monitoring solutions

Machine learning and artificial intelligence algorithms are increasingly being integrated into volumetric additive manufacturing monitoring systems. These computational approaches analyze real-time data streams from various sensors to detect anomalies, predict defects, and optimize printing parameters. Deep learning models can be trained to recognize patterns associated with successful prints versus failures, enabling predictive quality control. AI systems can also automate decision-making processes during manufacturing, adjusting parameters based on historical data and current conditions to maintain consistent quality.Expand Specific Solutions03 Multi-sensor fusion for comprehensive process monitoring

Multi-sensor fusion approaches combine data from various monitoring technologies to provide comprehensive oversight of volumetric additive manufacturing processes. By integrating information from thermal cameras, acoustic sensors, optical systems, and mechanical sensors, these systems create a more complete picture of the printing process. The synchronized data allows for correlation between different physical phenomena occurring during fabrication, enabling more accurate detection of defects and process anomalies. This holistic monitoring approach improves quality control and provides richer datasets for process optimization.Expand Specific Solutions04 In-situ metrology for dimensional accuracy verification

In-situ metrology systems enable real-time verification of dimensional accuracy during volumetric additive manufacturing. These systems employ various measurement technologies such as laser scanning, structured light projection, and photogrammetry to create digital representations of the part as it's being built. By comparing the actual geometry with the intended design, these systems can detect deviations and dimensional errors during the manufacturing process. This capability allows for immediate corrective actions and ensures that the final product meets specified tolerances without waiting for post-process inspection.Expand Specific Solutions05 Closed-loop control systems for process parameter adjustment

Closed-loop control systems in volumetric additive manufacturing utilize real-time monitoring data to automatically adjust process parameters during fabrication. These systems continuously analyze feedback from various sensors and compare actual conditions with desired specifications. When deviations are detected, the control system makes immediate adjustments to parameters such as energy input, material feed rate, or build platform positioning. This adaptive approach maintains optimal printing conditions throughout the build process, compensating for environmental variations and material inconsistencies to ensure consistent part quality.Expand Specific Solutions

Leading Companies and Research Institutions in VAM Monitoring

Real-time monitoring in Volumetric Additive Manufacturing is evolving rapidly, currently transitioning from early development to commercial implementation. The market is projected to grow significantly as industries recognize the value of real-time quality control in reducing waste and ensuring part integrity. Technologically, the field shows varying maturity levels across players: established industrial giants like General Electric, Rolls-Royce, and Siemens Energy are integrating monitoring systems into their manufacturing processes, while academic institutions such as Tsinghua University and Northwestern Polytechnical University are advancing fundamental research. Specialized companies like EOS GmbH and Interspectral AB are developing dedicated monitoring solutions, with the latter's AI-powered analytics platform representing the cutting edge. The competitive landscape features collaboration between industry and academia, with increasing focus on AI-enhanced monitoring capabilities.

General Electric Company

Technical Solution: General Electric has developed an advanced real-time monitoring system for volumetric additive manufacturing that integrates multiple sensor technologies including thermal imaging cameras, acoustic sensors, and high-speed cameras. Their approach utilizes machine learning algorithms to process the multi-modal sensor data streams simultaneously, enabling detection of defects and anomalies during the build process. GE's system incorporates Digital Twin technology that creates a virtual replica of the part being manufactured, allowing for real-time comparison between the intended design and the actual build progress[1]. The company has implemented this technology in their Direct Metal Laser Melting (DMLM) machines, where thermal sensors monitor melt pool dynamics and detect variations that could indicate potential defects. GE's monitoring system also features closed-loop control capabilities that can automatically adjust process parameters based on real-time feedback, ensuring consistent part quality even under varying conditions[3].

Strengths: Comprehensive multi-sensor integration provides redundant verification methods; advanced AI algorithms enable predictive quality control rather than just reactive measures; seamless integration with GE's existing manufacturing systems. Weaknesses: High implementation cost; requires significant computational resources; system complexity may necessitate specialized training for operators.

EOS GmbH

Technical Solution: EOS has developed EOSTATE, a comprehensive real-time monitoring suite for volumetric additive manufacturing that consists of multiple integrated modules. Their system includes EOSTATE MeltPool, which uses photodiodes and high-speed cameras to monitor the melt pool dynamics during the laser melting process, capturing data at rates exceeding 100 kHz to detect anomalies in real-time[9]. The EOSTATE Exposure OT module employs optical tomography to capture layer-wise images of the powder bed after each laser exposure, enabling immediate detection of irregularities in powder deposition and fusion. EOS has also implemented EOSTATE System, which continuously monitors machine parameters including oxygen levels, gas flow, and laser power to ensure process stability. Their PowderBed module uses cameras to detect irregularities in powder spreading that could lead to defects. The entire EOSTATE ecosystem is integrated through EOS's EOSPRINT software, which provides a unified interface for monitoring data analysis and visualization. The system employs machine learning algorithms that have been trained on extensive datasets from EOS's decades of experience in additive manufacturing, enabling highly accurate defect prediction and classification[10]. Recent enhancements include cloud connectivity for remote monitoring capabilities and integration with EOS's Digital Factory solutions for comprehensive production management.

Strengths: Modular approach allows customers to implement only the monitoring capabilities they need; extensive validation across thousands of production builds; seamless integration with EOS machines. Weaknesses: Full functionality limited to EOS equipment ecosystem; significant cost for complete implementation of all modules; requires substantial data storage infrastructure for long-term monitoring data retention.

Key Patents and Technical Literature in VAM Monitoring

Real-time monitoring of additive manufacturing

PatentActiveUS12325190B2

Innovation

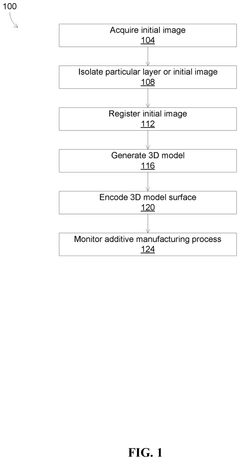

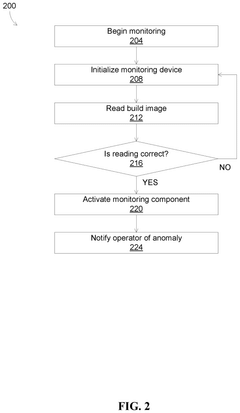

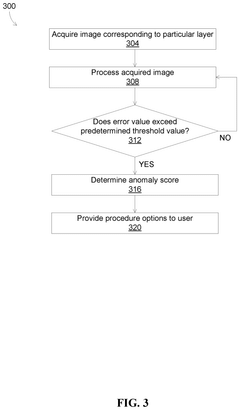

- A method for real-time monitoring of additive manufacturing that involves acquiring images of the object being constructed, isolating and registering layers, generating 3D models, comparing them to an object model, and providing notifications of discrepancies, allowing for immediate decision-making regarding the construction process.

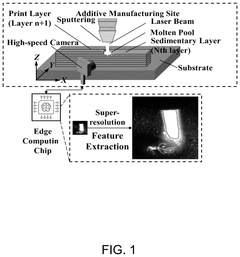

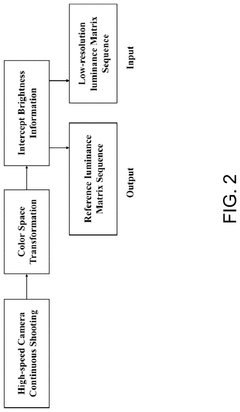

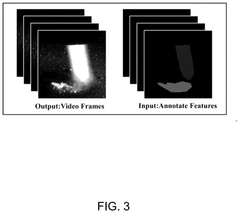

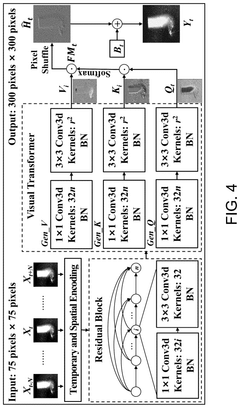

Edge computing-based additive manufacturing real-time monitoring method and system

PatentActiveUS12406504B2

Innovation

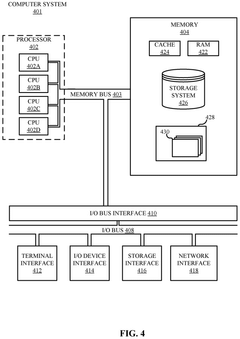

- Integration of edge computing technology for real-time monitoring in additive manufacturing, enabling on-site data processing without reliance on cloud infrastructure.

- Development of a specialized online monitoring model trained on additive manufacturing datasets that can be deployed directly on edge devices for immediate process analysis.

- Use of high-speed camera systems connected to edge devices for capturing and analyzing manufacturing footage in real-time, enabling immediate detection of process anomalies.

Quality Control Standards and Certification Requirements

The establishment of robust quality control standards and certification requirements is paramount for the widespread adoption of real-time monitoring systems in volumetric additive manufacturing (VAM). Currently, the industry faces significant challenges due to the lack of standardized protocols for evaluating the performance and reliability of monitoring technologies across different VAM platforms.

International standards organizations, including ISO, ASTM, and IEEE, have begun developing preliminary frameworks specifically addressing real-time monitoring in advanced manufacturing processes. The ASTM F42 committee has recently published guidelines focusing on data acquisition parameters and minimum detection thresholds for common defects in volumetric printing. These standards emphasize the importance of temporal resolution, spatial accuracy, and defect classification capabilities.

Certification requirements for real-time monitoring systems typically encompass three critical domains: hardware validation, software verification, and process integration. Hardware certification focuses on sensor calibration, measurement accuracy, and environmental resilience. Software certification addresses algorithm reliability, data processing capabilities, and cybersecurity measures. Process integration certification evaluates how effectively monitoring systems interface with manufacturing equipment without compromising production efficiency.

Regulatory bodies in major manufacturing regions have established different approaches to certification. The European Union, through its CE marking requirements, demands comprehensive documentation of monitoring system capabilities and validation testing. The FDA in the United States has implemented specific guidelines for medical applications of VAM, requiring extensive validation of real-time quality assurance systems, particularly for implantable devices.

Industry consortia have also developed sector-specific certification programs. The Additive Manufacturing Consortium (AMC) has created a tiered certification system for monitoring technologies, categorizing them based on detection capabilities, response times, and integration flexibility. Similarly, the Aerospace Additive Manufacturing Consortium requires monitoring systems to demonstrate 99.9% detection rates for critical defects in aerospace components.

The economic implications of these standards are substantial. Research indicates that manufacturers implementing certified monitoring systems experience a 30-45% reduction in post-production inspection costs and a 25% decrease in material waste. However, the certification process itself represents a significant investment, with testing and documentation costs averaging $50,000-$100,000 per system configuration.

Future developments in standardization will likely focus on harmonizing international requirements and establishing performance-based certification rather than prescriptive approaches. This shift would accelerate innovation while maintaining quality assurance, creating a more flexible framework that can adapt to rapidly evolving volumetric manufacturing technologies.

International standards organizations, including ISO, ASTM, and IEEE, have begun developing preliminary frameworks specifically addressing real-time monitoring in advanced manufacturing processes. The ASTM F42 committee has recently published guidelines focusing on data acquisition parameters and minimum detection thresholds for common defects in volumetric printing. These standards emphasize the importance of temporal resolution, spatial accuracy, and defect classification capabilities.

Certification requirements for real-time monitoring systems typically encompass three critical domains: hardware validation, software verification, and process integration. Hardware certification focuses on sensor calibration, measurement accuracy, and environmental resilience. Software certification addresses algorithm reliability, data processing capabilities, and cybersecurity measures. Process integration certification evaluates how effectively monitoring systems interface with manufacturing equipment without compromising production efficiency.

Regulatory bodies in major manufacturing regions have established different approaches to certification. The European Union, through its CE marking requirements, demands comprehensive documentation of monitoring system capabilities and validation testing. The FDA in the United States has implemented specific guidelines for medical applications of VAM, requiring extensive validation of real-time quality assurance systems, particularly for implantable devices.

Industry consortia have also developed sector-specific certification programs. The Additive Manufacturing Consortium (AMC) has created a tiered certification system for monitoring technologies, categorizing them based on detection capabilities, response times, and integration flexibility. Similarly, the Aerospace Additive Manufacturing Consortium requires monitoring systems to demonstrate 99.9% detection rates for critical defects in aerospace components.

The economic implications of these standards are substantial. Research indicates that manufacturers implementing certified monitoring systems experience a 30-45% reduction in post-production inspection costs and a 25% decrease in material waste. However, the certification process itself represents a significant investment, with testing and documentation costs averaging $50,000-$100,000 per system configuration.

Future developments in standardization will likely focus on harmonizing international requirements and establishing performance-based certification rather than prescriptive approaches. This shift would accelerate innovation while maintaining quality assurance, creating a more flexible framework that can adapt to rapidly evolving volumetric manufacturing technologies.

Data Processing and AI Integration in VAM Monitoring

The integration of advanced data processing techniques and artificial intelligence (AI) has become a critical component in the evolution of Volumetric Additive Manufacturing (VAM) monitoring systems. These technologies enable the transformation of raw sensor data into actionable insights, significantly enhancing the quality control and process optimization capabilities of VAM systems.

Real-time data processing in VAM monitoring involves multiple stages, beginning with data acquisition from various sensors including high-speed cameras, thermal imaging devices, and spectroscopic instruments. This multi-modal data undergoes preprocessing to reduce noise, normalize values, and align temporal sequences, creating a coherent dataset that accurately represents the manufacturing process state.

Machine learning algorithms, particularly deep learning models, have demonstrated remarkable effectiveness in analyzing the complex patterns within VAM processes. Convolutional Neural Networks (CNNs) excel at identifying spatial defects in layer formation, while Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks capture temporal dependencies in the manufacturing sequence. These AI models can detect anomalies that would be imperceptible to traditional rule-based systems.

Edge computing architectures are increasingly being deployed to process VAM monitoring data directly at the manufacturing site, reducing latency and enabling truly real-time decision making. This distributed approach allows for immediate process adjustments without the bandwidth limitations associated with cloud-based processing, while still maintaining connectivity to centralized systems for comprehensive analytics.

Digital twin technology represents another frontier in VAM monitoring, creating virtual replicas of physical manufacturing processes that evolve in parallel with their real-world counterparts. These digital twins, powered by physics-informed neural networks, enable predictive capabilities that anticipate potential defects before they manifest, allowing for preemptive adjustments to process parameters.

The integration of natural language processing (NLP) with VAM monitoring systems is facilitating more intuitive human-machine interfaces, enabling operators to query system status and receive recommendations using conversational language. This democratizes access to complex manufacturing analytics and reduces the technical expertise required for system operation.

Federated learning approaches are emerging as a solution to the proprietary nature of manufacturing data, allowing multiple organizations to collectively train robust AI models without sharing sensitive process data. This collaborative framework accelerates the development of more accurate monitoring systems while preserving intellectual property and competitive advantages.

Real-time data processing in VAM monitoring involves multiple stages, beginning with data acquisition from various sensors including high-speed cameras, thermal imaging devices, and spectroscopic instruments. This multi-modal data undergoes preprocessing to reduce noise, normalize values, and align temporal sequences, creating a coherent dataset that accurately represents the manufacturing process state.

Machine learning algorithms, particularly deep learning models, have demonstrated remarkable effectiveness in analyzing the complex patterns within VAM processes. Convolutional Neural Networks (CNNs) excel at identifying spatial defects in layer formation, while Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks capture temporal dependencies in the manufacturing sequence. These AI models can detect anomalies that would be imperceptible to traditional rule-based systems.

Edge computing architectures are increasingly being deployed to process VAM monitoring data directly at the manufacturing site, reducing latency and enabling truly real-time decision making. This distributed approach allows for immediate process adjustments without the bandwidth limitations associated with cloud-based processing, while still maintaining connectivity to centralized systems for comprehensive analytics.

Digital twin technology represents another frontier in VAM monitoring, creating virtual replicas of physical manufacturing processes that evolve in parallel with their real-world counterparts. These digital twins, powered by physics-informed neural networks, enable predictive capabilities that anticipate potential defects before they manifest, allowing for preemptive adjustments to process parameters.

The integration of natural language processing (NLP) with VAM monitoring systems is facilitating more intuitive human-machine interfaces, enabling operators to query system status and receive recommendations using conversational language. This democratizes access to complex manufacturing analytics and reduces the technical expertise required for system operation.

Federated learning approaches are emerging as a solution to the proprietary nature of manufacturing data, allowing multiple organizations to collectively train robust AI models without sharing sensitive process data. This collaborative framework accelerates the development of more accurate monitoring systems while preserving intellectual property and competitive advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!