Light Scattering Challenges In Volumetric Additive Manufacturing Resins

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Light Scattering in VAM: Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, emerging as a revolutionary approach that transcends the layer-by-layer limitations of conventional additive manufacturing methods. The evolution of VAM can be traced back to early experiments with photopolymerization in the 1980s, but significant breakthroughs have only materialized in the past decade with advances in computational imaging and photochemistry.

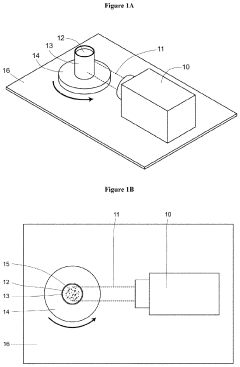

The fundamental principle of VAM involves the simultaneous projection of patterned light into a photosensitive resin volume, enabling the concurrent solidification of an entire three-dimensional object. This approach offers remarkable advantages in production speed, potentially reducing manufacturing times from hours to minutes or even seconds for complex geometries.

Light scattering, however, has emerged as a critical challenge impeding the widespread adoption and advancement of VAM technology. When light penetrates the photosensitive resin, it encounters particles, molecular structures, and density variations that cause deviation from its intended path. This scattering phenomenon results in unintended polymerization, dimensional inaccuracies, and compromised structural integrity of the final printed objects.

The technical evolution trajectory shows a progressive understanding of light-matter interactions in photopolymer systems. Initial VAM systems employed simple projection techniques with limited consideration for optical distortions. Contemporary approaches have evolved to incorporate sophisticated optical modeling and compensation algorithms, yet the fundamental physics of light scattering remains a significant barrier to achieving optimal resolution and accuracy.

The primary objective of addressing light scattering challenges in VAM resins is to enable precise control over the spatial distribution of light energy within the resin volume. This control is essential for achieving high-resolution features, consistent mechanical properties, and predictable printing outcomes across diverse geometries and material compositions.

Secondary objectives include developing standardized characterization methods for quantifying scattering properties of different resin formulations, establishing computational models that accurately predict light propagation through heterogeneous media, and creating adaptive optical systems capable of real-time compensation for scattering effects during the printing process.

The technological trajectory suggests that overcoming light scattering limitations will unlock new application domains for VAM, particularly in fields requiring microscale precision such as biomedical devices, microfluidics, and advanced optical components. The convergence of photochemistry, computational optics, and materials science represents the most promising pathway toward resolving these challenges and realizing the full potential of volumetric manufacturing technologies.

The fundamental principle of VAM involves the simultaneous projection of patterned light into a photosensitive resin volume, enabling the concurrent solidification of an entire three-dimensional object. This approach offers remarkable advantages in production speed, potentially reducing manufacturing times from hours to minutes or even seconds for complex geometries.

Light scattering, however, has emerged as a critical challenge impeding the widespread adoption and advancement of VAM technology. When light penetrates the photosensitive resin, it encounters particles, molecular structures, and density variations that cause deviation from its intended path. This scattering phenomenon results in unintended polymerization, dimensional inaccuracies, and compromised structural integrity of the final printed objects.

The technical evolution trajectory shows a progressive understanding of light-matter interactions in photopolymer systems. Initial VAM systems employed simple projection techniques with limited consideration for optical distortions. Contemporary approaches have evolved to incorporate sophisticated optical modeling and compensation algorithms, yet the fundamental physics of light scattering remains a significant barrier to achieving optimal resolution and accuracy.

The primary objective of addressing light scattering challenges in VAM resins is to enable precise control over the spatial distribution of light energy within the resin volume. This control is essential for achieving high-resolution features, consistent mechanical properties, and predictable printing outcomes across diverse geometries and material compositions.

Secondary objectives include developing standardized characterization methods for quantifying scattering properties of different resin formulations, establishing computational models that accurately predict light propagation through heterogeneous media, and creating adaptive optical systems capable of real-time compensation for scattering effects during the printing process.

The technological trajectory suggests that overcoming light scattering limitations will unlock new application domains for VAM, particularly in fields requiring microscale precision such as biomedical devices, microfluidics, and advanced optical components. The convergence of photochemistry, computational optics, and materials science represents the most promising pathway toward resolving these challenges and realizing the full potential of volumetric manufacturing technologies.

Market Analysis for Advanced Additive Manufacturing Resins

The global market for advanced additive manufacturing resins is experiencing robust growth, driven by increasing adoption across multiple industries. The market size for photopolymer resins used in volumetric additive manufacturing was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate of 19.6%. This growth trajectory is particularly significant in sectors requiring high-precision components such as healthcare, aerospace, and automotive industries.

The healthcare segment currently dominates the market application landscape, accounting for nearly 35% of the total market share. This is primarily due to the expanding use of biocompatible resins in medical device manufacturing, dental applications, and personalized prosthetics. The aerospace sector follows closely, representing about 28% of market demand, where lightweight yet durable components manufactured using advanced resins are increasingly replacing traditional materials.

Regional analysis indicates that North America holds the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, driven by rapid industrialization in countries like China, Japan, and South Korea, along with increasing government initiatives to promote advanced manufacturing technologies.

A significant market trend is the growing demand for resins with enhanced optical clarity and reduced light scattering properties. This demand is particularly pronounced in applications requiring high resolution and dimensional accuracy, such as microfluidics, optical components, and precision engineering parts. Market research indicates that resins with optimized light scattering properties command a premium of 15-20% over standard formulations.

Customer preference is increasingly shifting toward environmentally sustainable resin formulations. Bio-based resins derived from renewable resources are gaining traction, with their market segment growing at 24.8% annually, outpacing the overall market growth rate. This shift is partly driven by stringent environmental regulations in key markets and corporate sustainability initiatives.

The competitive landscape features both established chemical companies and specialized additive manufacturing material developers. Key market players include 3D Systems, Stratasys, Formlabs, and BASF, collectively holding approximately 65% of the market share. However, the market is witnessing increased fragmentation with the entry of numerous startups focusing on niche applications and specialized resin formulations addressing specific technical challenges like light scattering in volumetric printing.

The healthcare segment currently dominates the market application landscape, accounting for nearly 35% of the total market share. This is primarily due to the expanding use of biocompatible resins in medical device manufacturing, dental applications, and personalized prosthetics. The aerospace sector follows closely, representing about 28% of market demand, where lightweight yet durable components manufactured using advanced resins are increasingly replacing traditional materials.

Regional analysis indicates that North America holds the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, driven by rapid industrialization in countries like China, Japan, and South Korea, along with increasing government initiatives to promote advanced manufacturing technologies.

A significant market trend is the growing demand for resins with enhanced optical clarity and reduced light scattering properties. This demand is particularly pronounced in applications requiring high resolution and dimensional accuracy, such as microfluidics, optical components, and precision engineering parts. Market research indicates that resins with optimized light scattering properties command a premium of 15-20% over standard formulations.

Customer preference is increasingly shifting toward environmentally sustainable resin formulations. Bio-based resins derived from renewable resources are gaining traction, with their market segment growing at 24.8% annually, outpacing the overall market growth rate. This shift is partly driven by stringent environmental regulations in key markets and corporate sustainability initiatives.

The competitive landscape features both established chemical companies and specialized additive manufacturing material developers. Key market players include 3D Systems, Stratasys, Formlabs, and BASF, collectively holding approximately 65% of the market share. However, the market is witnessing increased fragmentation with the entry of numerous startups focusing on niche applications and specialized resin formulations addressing specific technical challenges like light scattering in volumetric printing.

Current Limitations in Volumetric Printing Light Control

Volumetric additive manufacturing (VAM) represents a significant advancement in 3D printing technology, offering unprecedented speed and resolution. However, the control of light within volumetric printing resins presents substantial challenges that currently limit the full potential of this technology. The primary limitation stems from light scattering phenomena that occur when photons interact with resin components, causing unintended polymerization in areas outside the targeted voxels.

The fundamental physics of light propagation in translucent media creates inherent constraints for volumetric printing. As light penetrates the resin, it undergoes multiple scattering events, resulting in beam divergence and intensity attenuation. This effect becomes particularly problematic in high-resolution applications where precise spatial control of polymerization is essential. Current systems struggle to maintain adequate light confinement beyond depths of a few millimeters, severely restricting the build volume for high-fidelity prints.

Photoinitiator concentration presents another critical limitation. Higher concentrations increase sensitivity but exacerbate scattering effects and reduce penetration depth. Conversely, lower concentrations allow deeper penetration but require higher energy inputs, potentially causing thermal issues and reduced printing speed. This delicate balance has not been optimally resolved in current formulations, creating a significant barrier to scaling volumetric printing technologies.

The optical properties of commercial resins further complicate light control. Most available resins were developed for layer-by-layer processes rather than volumetric applications, resulting in suboptimal transparency and scattering characteristics. The presence of necessary additives such as stabilizers, pigments, and mechanical property enhancers introduces additional scattering centers that degrade optical performance. The industry lacks standardized resins specifically engineered for the unique optical requirements of volumetric printing.

Current optical systems for volumetric printing also face limitations in their ability to compensate for scattering effects. While techniques such as computed tomography-inspired projection approaches and multi-beam interference patterns have shown promise, they require complex calibration procedures that must be customized for each resin formulation. The computational overhead for these corrections increases exponentially with print volume and resolution, creating practical limits for real-time implementation.

Temperature management during printing represents another significant challenge for light control. As photopolymerization progresses, localized heating occurs, altering the resin's refractive index and creating thermal gradients that further distort light paths. Current systems lack effective methods to monitor and compensate for these dynamic thermal effects, resulting in decreased precision as print volumes increase.

The fundamental physics of light propagation in translucent media creates inherent constraints for volumetric printing. As light penetrates the resin, it undergoes multiple scattering events, resulting in beam divergence and intensity attenuation. This effect becomes particularly problematic in high-resolution applications where precise spatial control of polymerization is essential. Current systems struggle to maintain adequate light confinement beyond depths of a few millimeters, severely restricting the build volume for high-fidelity prints.

Photoinitiator concentration presents another critical limitation. Higher concentrations increase sensitivity but exacerbate scattering effects and reduce penetration depth. Conversely, lower concentrations allow deeper penetration but require higher energy inputs, potentially causing thermal issues and reduced printing speed. This delicate balance has not been optimally resolved in current formulations, creating a significant barrier to scaling volumetric printing technologies.

The optical properties of commercial resins further complicate light control. Most available resins were developed for layer-by-layer processes rather than volumetric applications, resulting in suboptimal transparency and scattering characteristics. The presence of necessary additives such as stabilizers, pigments, and mechanical property enhancers introduces additional scattering centers that degrade optical performance. The industry lacks standardized resins specifically engineered for the unique optical requirements of volumetric printing.

Current optical systems for volumetric printing also face limitations in their ability to compensate for scattering effects. While techniques such as computed tomography-inspired projection approaches and multi-beam interference patterns have shown promise, they require complex calibration procedures that must be customized for each resin formulation. The computational overhead for these corrections increases exponentially with print volume and resolution, creating practical limits for real-time implementation.

Temperature management during printing represents another significant challenge for light control. As photopolymerization progresses, localized heating occurs, altering the resin's refractive index and creating thermal gradients that further distort light paths. Current systems lack effective methods to monitor and compensate for these dynamic thermal effects, resulting in decreased precision as print volumes increase.

Existing Solutions for Light Scattering Mitigation

01 Light scattering additives in volumetric 3D printing resins

Incorporating light scattering additives into photopolymer resins can enhance the volumetric additive manufacturing process. These additives help to control the depth and distribution of light penetration within the resin, allowing for more precise curing patterns. By carefully selecting scattering particles with specific size distributions and refractive indices, manufacturers can optimize the resolution and structural integrity of printed objects while minimizing unwanted light diffusion effects.- Light scattering additives in volumetric 3D printing resins: Incorporating light scattering additives into photopolymer resins for volumetric additive manufacturing can control light distribution within the printing volume. These additives, such as nanoparticles or microparticles, help to scatter incident light in specific patterns, enabling more precise control over the curing process and improving resolution in complex geometries. The controlled scattering can enhance depth penetration while maintaining feature definition in volumetric printing applications.

- Resin formulations with tunable optical properties: Specialized resin formulations with tunable optical properties are essential for volumetric additive manufacturing. These formulations contain components that can be adjusted to control light absorption, scattering, and transmission characteristics. By carefully balancing photoinitiators, inhibitors, and other additives, manufacturers can create resins that respond optimally to specific wavelengths and intensities of light, allowing for controlled solidification throughout the entire volume rather than just at surfaces.

- Light management systems for volumetric printing: Advanced light management systems are critical for controlling light scattering in volumetric additive manufacturing. These systems incorporate specialized optics, beam shapers, and projection technologies to deliver precisely controlled light patterns throughout the resin volume. By managing how light interacts with the resin at different depths and angles, these systems can compensate for scattering effects and achieve more uniform curing throughout complex three-dimensional structures.

- Nanoparticle-enhanced resins for improved resolution: Incorporating specific nanoparticles into printing resins can enhance resolution in volumetric additive manufacturing by controlling light scattering behavior. These nanoparticles can be engineered to scatter light in beneficial ways, reducing unwanted curing in adjacent areas while enhancing curing efficiency in target regions. The size, concentration, and surface properties of these nanoparticles can be optimized to achieve specific light scattering profiles that improve feature definition and enable finer details in printed structures.

- Computational modeling of light scattering in resins: Computational modeling techniques are employed to predict and optimize light scattering behavior in volumetric printing resins. These models simulate how light interacts with resin components at different concentrations and under various printing conditions. By understanding the complex physics of light propagation, absorption, and scattering within photopolymer systems, manufacturers can formulate resins with precisely engineered optical properties tailored for specific volumetric printing applications, resulting in improved print quality and process reliability.

02 Resin formulations with controlled optical properties

Specialized resin formulations with tailored optical properties are essential for volumetric additive manufacturing. These formulations balance light absorption, scattering, and transmission characteristics to achieve desired curing patterns throughout the volume. By incorporating specific photoinitiators, inhibitors, and modifiers, manufacturers can control the polymerization kinetics and light interaction behavior. This enables the creation of complex internal structures and improves the overall quality and functionality of 3D printed components.Expand Specific Solutions03 Light delivery systems for volumetric manufacturing

Advanced light delivery systems play a crucial role in managing light scattering during volumetric additive manufacturing. These systems utilize specialized optics, beam shaping technologies, and projection methods to control how light interacts with the photosensitive resin. By precisely directing light patterns and managing intensity distributions, these systems can compensate for scattering effects and achieve higher resolution prints with improved feature definition and dimensional accuracy.Expand Specific Solutions04 Nanoparticle additives for enhanced printing performance

Nanoparticle additives incorporated into volumetric printing resins can significantly influence light scattering behavior and improve manufacturing outcomes. These nanoparticles, which may include silica, titanium dioxide, or specialized polymeric materials, can be engineered to provide specific optical properties. When properly dispersed within the resin matrix, they help control curing depth, enhance mechanical properties, and enable the creation of gradient structures or materials with spatially varying properties.Expand Specific Solutions05 Computational modeling of light scattering in resins

Computational modeling techniques are essential for predicting and optimizing light scattering behavior in volumetric additive manufacturing resins. These models simulate how light interacts with the resin components, accounting for absorption, scattering, and refraction phenomena. By applying advanced algorithms and physics-based simulations, researchers can develop resin formulations with precisely controlled curing characteristics. This computational approach enables the design of manufacturing processes that achieve desired resolution, speed, and material properties while minimizing trial-and-error experimentation.Expand Specific Solutions

Leading Companies in Volumetric Additive Manufacturing

The volumetric additive manufacturing resin market is currently in a growth phase, with light scattering challenges representing a critical technical barrier to advancement. The global market is projected to expand significantly as industries adopt this technology for high-precision applications. Technical maturity varies considerably among key players, with research institutions like École Polytechnique Fédérale de Lausanne and National Research Council of Canada driving fundamental innovations, while established corporations including Formlabs, FUJIFILM, and Sumitomo Chemical focus on commercial applications. Chemical specialists such as JSR Corp., Daicel, and LG Chem are developing advanced formulations to mitigate light scattering effects. The competitive landscape features a mix of traditional chemical manufacturers and specialized 3D printing companies, with Asian corporations particularly well-represented in materials development for next-generation resins with improved optical properties.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has pioneered volumetric additive manufacturing techniques that specifically address light scattering challenges through their Tomographic Volumetric Additive Manufacturing (Tomographic VAM) approach. This technology uses computed tomography principles to project multiple 2D light patterns from different angles simultaneously into a photopolymer resin. Their innovation includes developing algorithms that pre-compensate for light scattering effects by calculating the optical path through the resin and adjusting light intensity and pattern accordingly. EPFL researchers have created specialized photoinitiator systems with controlled absorption profiles that minimize scattering while maintaining high polymerization efficiency. They've also developed resin formulations with matched refractive indices between components to reduce internal scattering boundaries. Their system can produce complex 3D structures in seconds rather than hours by addressing the fundamental limitations of layer-by-layer approaches.

Strengths: Extremely fast production speeds (seconds vs. hours) for complete 3D objects. Their approach eliminates the need for support structures and enables the creation of geometries impossible with traditional methods. Weaknesses: Currently limited to smaller build volumes compared to conventional systems, and requires highly specialized equipment that may be cost-prohibitive for widespread adoption.

Nikon Corp.

Technical Solution: Nikon has leveraged its extensive optical expertise to develop advanced solutions for light scattering challenges in volumetric additive manufacturing resins. Their approach combines specialized optical systems with computational modeling to achieve precise control over light distribution within resin volumes. Nikon's technology incorporates adaptive optics that dynamically adjust based on feedback from in-situ monitoring systems that detect and measure scattering effects in real-time during the printing process. They've developed proprietary algorithms that pre-distort projection patterns to compensate for anticipated scattering, similar to how astronomical telescopes correct for atmospheric distortion. Nikon has also created specialized optical components including custom-designed spatial light modulators and beam-shaping elements that help maintain light path integrity through the resin. Additionally, they've partnered with material scientists to develop resin formulations with optimized optical properties specifically designed to work with their optical systems.

Strengths: Unparalleled optical engineering expertise allows for exceptional precision in light delivery and control. Their integrated approach combining hardware, software, and materials science provides comprehensive solutions to complex scattering problems. Weaknesses: Their systems tend to be high-end and expensive, potentially limiting accessibility for smaller organizations or educational institutions.

Key Innovations in Photopolymer Resin Technology

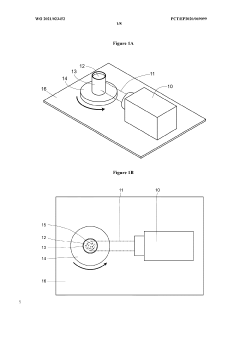

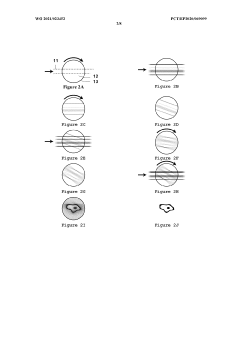

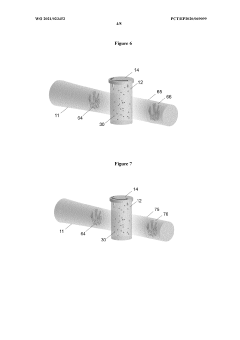

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentPendingUS20220274326A1

Innovation

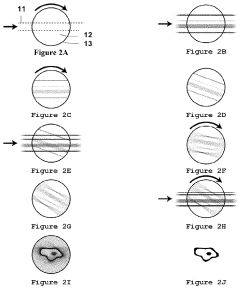

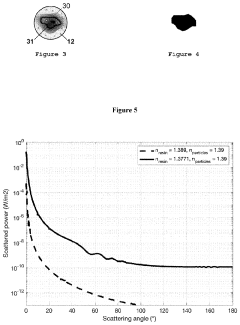

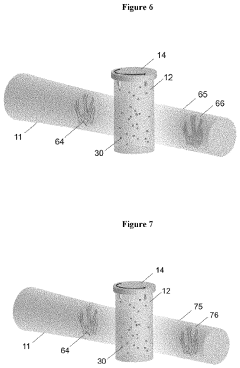

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1000 nm, to reduce light scattering and improve the accuracy of three-dimensional object formation by creating a controlled three-dimensional dose distribution.

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentWO2021023452A1

Innovation

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1050 nm, to reduce light scattering and achieve optimal print accuracy and resolution.

Material Characterization Methods for VAM Resins

Effective characterization of resins used in Volumetric Additive Manufacturing (VAM) is essential for addressing light scattering challenges. Spectrophotometric analysis serves as a primary method for quantifying light absorption and scattering properties across different wavelengths. This technique enables researchers to determine the critical photoinitiator absorption bands and identify wavelength regions where scattering effects are most pronounced, providing fundamental data for optimizing resin formulations.

Rheological characterization complements optical analysis by measuring viscosity profiles under varying shear rates and temperatures. These measurements are crucial as viscosity directly impacts the mobility of suspended particles and dissolved components, affecting both light scattering behavior and the resolution of printed structures. Advanced rheometers equipped with photo-curing capabilities can simulate in-situ polymerization conditions, offering insights into how material properties evolve during the printing process.

Particle size analysis using dynamic light scattering (DLS) or laser diffraction techniques provides detailed information about the size distribution of suspended particles in VAM resins. This data is particularly valuable since particle size directly correlates with Mie scattering effects that can compromise printing precision. Modern DLS instruments can detect particles in the nanometer range, helping formulators understand how even sub-micron particles contribute to overall scattering phenomena.

Refractive index matching techniques represent another sophisticated approach to characterization. By carefully adjusting the refractive index of the liquid resin matrix to match that of suspended particles or fillers, researchers can minimize scattering effects. Precise refractometry measurements across temperature ranges relevant to the VAM process are essential for implementing this strategy effectively.

Time-resolved spectroscopy offers dynamic insights into how light-matter interactions evolve during the curing process. This method captures the changing optical properties as the resin transitions from liquid to solid state, revealing how scattering behavior changes throughout polymerization. Such temporal data helps identify critical stages where scattering effects might compromise dimensional accuracy or structural integrity.

Computational modeling based on empirical characterization data has emerged as a powerful predictive tool. Monte Carlo simulations of photon transport through resin volumes can predict light distribution patterns and identify potential "hot spots" or shadowing effects. These models require accurate input parameters derived from the aforementioned characterization methods to generate reliable predictions for optimizing both resin formulations and exposure strategies.

Rheological characterization complements optical analysis by measuring viscosity profiles under varying shear rates and temperatures. These measurements are crucial as viscosity directly impacts the mobility of suspended particles and dissolved components, affecting both light scattering behavior and the resolution of printed structures. Advanced rheometers equipped with photo-curing capabilities can simulate in-situ polymerization conditions, offering insights into how material properties evolve during the printing process.

Particle size analysis using dynamic light scattering (DLS) or laser diffraction techniques provides detailed information about the size distribution of suspended particles in VAM resins. This data is particularly valuable since particle size directly correlates with Mie scattering effects that can compromise printing precision. Modern DLS instruments can detect particles in the nanometer range, helping formulators understand how even sub-micron particles contribute to overall scattering phenomena.

Refractive index matching techniques represent another sophisticated approach to characterization. By carefully adjusting the refractive index of the liquid resin matrix to match that of suspended particles or fillers, researchers can minimize scattering effects. Precise refractometry measurements across temperature ranges relevant to the VAM process are essential for implementing this strategy effectively.

Time-resolved spectroscopy offers dynamic insights into how light-matter interactions evolve during the curing process. This method captures the changing optical properties as the resin transitions from liquid to solid state, revealing how scattering behavior changes throughout polymerization. Such temporal data helps identify critical stages where scattering effects might compromise dimensional accuracy or structural integrity.

Computational modeling based on empirical characterization data has emerged as a powerful predictive tool. Monte Carlo simulations of photon transport through resin volumes can predict light distribution patterns and identify potential "hot spots" or shadowing effects. These models require accurate input parameters derived from the aforementioned characterization methods to generate reliable predictions for optimizing both resin formulations and exposure strategies.

Environmental Impact of Advanced Printing Resins

The environmental implications of advanced resins used in volumetric additive manufacturing are becoming increasingly significant as this technology gains wider adoption. Light scattering challenges in these resins not only affect print quality but also have substantial environmental consequences. The chemical composition of photopolymer resins typically includes photoinitiators, monomers, and various additives that can be potentially harmful to ecosystems when improperly disposed of or when they leach into water systems.

Manufacturing processes for these specialized resins often require energy-intensive procedures and utilize petroleum-based raw materials, contributing to carbon emissions and resource depletion. The light scattering properties that manufacturers aim to control often necessitate the inclusion of additional chemicals and nanoparticles, some of which have unknown long-term environmental impacts. These additives can persist in the environment long after the printed object's useful life has ended.

Waste management presents another critical environmental concern. Failed prints due to light scattering issues result in material waste that cannot be easily recycled due to the crosslinked nature of cured photopolymers. Additionally, uncured resin residues require special handling as hazardous waste, creating disposal challenges for both industrial and consumer users. The cleaning solvents used to remove excess resin from printed parts often contain volatile organic compounds (VOCs) that contribute to air pollution.

Recent research has begun exploring more sustainable alternatives, including bio-based resins derived from renewable resources such as soybean oil, lignin, and cellulose. These materials show promise in reducing the environmental footprint while potentially offering improved light scattering characteristics. Some manufacturers have also developed closed-loop recycling systems for resin containers and filtration methods to extend resin life, reducing overall waste generation.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of these materials. The European Union's REACH regulations and similar initiatives in other regions are placing greater scrutiny on potentially harmful chemicals in manufacturing processes. This regulatory pressure is driving innovation toward greener formulations that maintain the optical properties necessary for successful volumetric printing while reducing environmental impact.

Life cycle assessment studies indicate that optimizing light scattering properties can indirectly benefit environmental sustainability by reducing print failures and associated waste. However, these benefits must be balanced against the potential introduction of environmentally persistent additives. The industry faces the challenge of developing resins that offer optimal printing performance while minimizing ecological harm throughout their entire life cycle.

Manufacturing processes for these specialized resins often require energy-intensive procedures and utilize petroleum-based raw materials, contributing to carbon emissions and resource depletion. The light scattering properties that manufacturers aim to control often necessitate the inclusion of additional chemicals and nanoparticles, some of which have unknown long-term environmental impacts. These additives can persist in the environment long after the printed object's useful life has ended.

Waste management presents another critical environmental concern. Failed prints due to light scattering issues result in material waste that cannot be easily recycled due to the crosslinked nature of cured photopolymers. Additionally, uncured resin residues require special handling as hazardous waste, creating disposal challenges for both industrial and consumer users. The cleaning solvents used to remove excess resin from printed parts often contain volatile organic compounds (VOCs) that contribute to air pollution.

Recent research has begun exploring more sustainable alternatives, including bio-based resins derived from renewable resources such as soybean oil, lignin, and cellulose. These materials show promise in reducing the environmental footprint while potentially offering improved light scattering characteristics. Some manufacturers have also developed closed-loop recycling systems for resin containers and filtration methods to extend resin life, reducing overall waste generation.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of these materials. The European Union's REACH regulations and similar initiatives in other regions are placing greater scrutiny on potentially harmful chemicals in manufacturing processes. This regulatory pressure is driving innovation toward greener formulations that maintain the optical properties necessary for successful volumetric printing while reducing environmental impact.

Life cycle assessment studies indicate that optimizing light scattering properties can indirectly benefit environmental sustainability by reducing print failures and associated waste. However, these benefits must be balanced against the potential introduction of environmentally persistent additives. The industry faces the challenge of developing resins that offer optimal printing performance while minimizing ecological harm throughout their entire life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!