Surface Finish Optimization In Volumetric Additive Manufacturing

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VAM Surface Finish Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing, offering unprecedented speed and geometric freedom compared to traditional layer-by-layer approaches. The technology emerged in the mid-2010s as researchers sought to overcome the fundamental limitations of conventional additive manufacturing methods, particularly regarding production speed and surface quality. VAM utilizes photopolymerization throughout an entire volume simultaneously, rather than sequentially building layers, enabling the creation of complex structures in seconds rather than hours.

Surface finish quality remains one of the most significant challenges in VAM technology adoption across industries. While VAM offers remarkable speed advantages, the resulting surface characteristics often fail to meet the stringent requirements of end-use applications in aerospace, medical devices, and consumer products. Historical attempts to improve surface finish have primarily focused on post-processing techniques, which add time and cost to the manufacturing process, partially negating VAM's inherent speed advantages.

The evolution of VAM surface finish technology has progressed through several distinct phases. Initial systems produced parts with visible optical artifacts and surface roughness exceeding 50μm Ra. Subsequent iterations incorporated improved optical systems and resin formulations, reducing roughness to approximately 20-30μm Ra. Current state-of-the-art systems achieve surface finishes approaching 10μm Ra under optimal conditions, yet this remains insufficient for many high-value applications requiring finishes of 5μm Ra or better.

The primary objective of this technical research is to identify and evaluate novel approaches for optimizing surface finish in VAM processes without compromising the technology's fundamental speed advantage. Specifically, we aim to achieve surface roughness values below 5μm Ra directly from the printing process, eliminating or significantly reducing the need for post-processing operations.

Secondary objectives include understanding the fundamental relationships between light delivery parameters, resin chemistry, and resulting surface characteristics; developing predictive models for surface quality based on process parameters; and establishing standardized testing methodologies for consistent evaluation of VAM surface finish across different systems and materials.

This research is driven by market demands for high-quality, rapidly produced components across multiple industries. Success in this domain would significantly expand VAM's application potential, particularly in precision engineering fields where surface quality directly impacts functional performance. The findings will inform both hardware development strategies and material formulation approaches for next-generation VAM systems.

Surface finish quality remains one of the most significant challenges in VAM technology adoption across industries. While VAM offers remarkable speed advantages, the resulting surface characteristics often fail to meet the stringent requirements of end-use applications in aerospace, medical devices, and consumer products. Historical attempts to improve surface finish have primarily focused on post-processing techniques, which add time and cost to the manufacturing process, partially negating VAM's inherent speed advantages.

The evolution of VAM surface finish technology has progressed through several distinct phases. Initial systems produced parts with visible optical artifacts and surface roughness exceeding 50μm Ra. Subsequent iterations incorporated improved optical systems and resin formulations, reducing roughness to approximately 20-30μm Ra. Current state-of-the-art systems achieve surface finishes approaching 10μm Ra under optimal conditions, yet this remains insufficient for many high-value applications requiring finishes of 5μm Ra or better.

The primary objective of this technical research is to identify and evaluate novel approaches for optimizing surface finish in VAM processes without compromising the technology's fundamental speed advantage. Specifically, we aim to achieve surface roughness values below 5μm Ra directly from the printing process, eliminating or significantly reducing the need for post-processing operations.

Secondary objectives include understanding the fundamental relationships between light delivery parameters, resin chemistry, and resulting surface characteristics; developing predictive models for surface quality based on process parameters; and establishing standardized testing methodologies for consistent evaluation of VAM surface finish across different systems and materials.

This research is driven by market demands for high-quality, rapidly produced components across multiple industries. Success in this domain would significantly expand VAM's application potential, particularly in precision engineering fields where surface quality directly impacts functional performance. The findings will inform both hardware development strategies and material formulation approaches for next-generation VAM systems.

Market Analysis for High-Quality VAM Applications

The market for high-quality Volumetric Additive Manufacturing (VAM) applications is experiencing significant growth as industries increasingly recognize the potential of this advanced manufacturing technology. The global additive manufacturing market was valued at approximately $13.7 billion in 2021 and is projected to reach $51.0 billion by 2030, with VAM representing an emerging segment within this broader market.

Surface finish quality represents a critical factor driving market adoption of VAM technologies across multiple sectors. In aerospace applications, components with superior surface finishes reduce drag and improve fuel efficiency, creating substantial cost savings over aircraft lifespans. The medical device industry demands exceptional surface quality for implants and prosthetics to ensure biocompatibility and reduce rejection risks, with the global medical 3D printing market growing at 16.3% annually.

Consumer electronics manufacturers are exploring VAM for producing complex internal components with minimal post-processing requirements. The automotive sector increasingly utilizes VAM for both prototyping and end-use parts production, with surface finish quality directly impacting aerodynamic performance and aesthetic appeal. Market research indicates that 67% of automotive manufacturers plan to increase their investment in advanced additive manufacturing technologies over the next five years.

The jewelry and luxury goods sector represents another promising market for high-quality VAM applications, where flawless surface finishes are essential for customer satisfaction. This segment values the ability to create intricate designs with minimal post-processing, reducing production costs while maintaining premium quality standards.

Market analysis reveals that companies achieving superior surface finishes in VAM can command premium pricing, with customers willing to pay 15-25% more for parts requiring minimal post-processing. This price premium directly impacts profit margins and return on investment for VAM equipment manufacturers and service providers.

Regional market distribution shows North America currently leading VAM adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade as manufacturing hubs in China, Japan, and South Korea increase investment in advanced manufacturing technologies.

Customer surveys indicate that surface finish quality ranks among the top three considerations for industrial VAM adoption, alongside dimensional accuracy and material properties. As the technology matures, market analysts predict a shift from early adopters focused on prototyping to mainstream manufacturing applications, with surface finish optimization being a key enabler for this transition.

Surface finish quality represents a critical factor driving market adoption of VAM technologies across multiple sectors. In aerospace applications, components with superior surface finishes reduce drag and improve fuel efficiency, creating substantial cost savings over aircraft lifespans. The medical device industry demands exceptional surface quality for implants and prosthetics to ensure biocompatibility and reduce rejection risks, with the global medical 3D printing market growing at 16.3% annually.

Consumer electronics manufacturers are exploring VAM for producing complex internal components with minimal post-processing requirements. The automotive sector increasingly utilizes VAM for both prototyping and end-use parts production, with surface finish quality directly impacting aerodynamic performance and aesthetic appeal. Market research indicates that 67% of automotive manufacturers plan to increase their investment in advanced additive manufacturing technologies over the next five years.

The jewelry and luxury goods sector represents another promising market for high-quality VAM applications, where flawless surface finishes are essential for customer satisfaction. This segment values the ability to create intricate designs with minimal post-processing, reducing production costs while maintaining premium quality standards.

Market analysis reveals that companies achieving superior surface finishes in VAM can command premium pricing, with customers willing to pay 15-25% more for parts requiring minimal post-processing. This price premium directly impacts profit margins and return on investment for VAM equipment manufacturers and service providers.

Regional market distribution shows North America currently leading VAM adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade as manufacturing hubs in China, Japan, and South Korea increase investment in advanced manufacturing technologies.

Customer surveys indicate that surface finish quality ranks among the top three considerations for industrial VAM adoption, alongside dimensional accuracy and material properties. As the technology matures, market analysts predict a shift from early adopters focused on prototyping to mainstream manufacturing applications, with surface finish optimization being a key enabler for this transition.

Current Challenges in VAM Surface Finish Technology

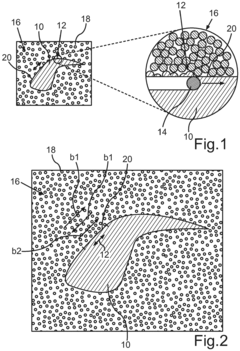

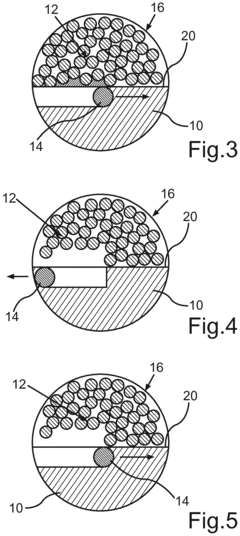

Volumetric Additive Manufacturing (VAM) represents a significant advancement in 3D printing technology, yet achieving optimal surface finish remains one of its most persistent challenges. Unlike traditional layer-by-layer approaches, VAM creates entire objects simultaneously through photopolymerization within a resin volume, which introduces unique surface quality issues. The primary challenge stems from the fundamental physics of light projection and interaction with photosensitive materials, resulting in surface irregularities that compromise both aesthetic appeal and functional performance.

One significant obstacle is the "projection boundary effect" where the interface between illuminated and non-illuminated regions creates micro-scale discontinuities. These manifest as visible lines or patterns on finished parts, particularly evident on curved or angled surfaces. The resolution limitations of current projection systems further exacerbate this issue, as the discrete nature of digital light processing creates pixelation effects that translate to surface roughness.

Resin chemistry presents another major hurdle in surface finish optimization. The complex interplay between photoinitiators, inhibitors, and light scattering agents affects curing uniformity. Oxygen inhibition at resin-air interfaces often leads to tacky or incompletely cured surface layers, while internal stress during polymerization can cause warping or micro-cracks that deteriorate surface quality. Additionally, the heat generated during rapid curing creates thermal gradients that may induce surface defects.

Light scattering and absorption phenomena within the resin volume significantly impact surface precision. As light penetrates deeper into the resin, scattering effects cause energy dispersion, leading to overcuring in some regions and undercuring in others. This non-uniform energy distribution results in dimensional inaccuracies and surface irregularities, particularly in geometrically complex parts with varying thicknesses.

Post-processing requirements represent another substantial challenge. Current VAM processes often necessitate extensive cleaning, additional curing, and manual finishing to achieve acceptable surface quality. These labor-intensive steps undermine the technology's speed advantages and introduce variability in final part quality. The development of automated post-processing techniques specifically tailored for VAM remains underdeveloped compared to traditional manufacturing methods.

Environmental factors such as ambient temperature, humidity, and dust particles also influence surface finish quality in VAM processes. These variables can affect resin viscosity, curing kinetics, and introduce contaminants that manifest as surface defects. Controlling these parameters requires sophisticated environmental management systems that add complexity and cost to VAM implementations.

One significant obstacle is the "projection boundary effect" where the interface between illuminated and non-illuminated regions creates micro-scale discontinuities. These manifest as visible lines or patterns on finished parts, particularly evident on curved or angled surfaces. The resolution limitations of current projection systems further exacerbate this issue, as the discrete nature of digital light processing creates pixelation effects that translate to surface roughness.

Resin chemistry presents another major hurdle in surface finish optimization. The complex interplay between photoinitiators, inhibitors, and light scattering agents affects curing uniformity. Oxygen inhibition at resin-air interfaces often leads to tacky or incompletely cured surface layers, while internal stress during polymerization can cause warping or micro-cracks that deteriorate surface quality. Additionally, the heat generated during rapid curing creates thermal gradients that may induce surface defects.

Light scattering and absorption phenomena within the resin volume significantly impact surface precision. As light penetrates deeper into the resin, scattering effects cause energy dispersion, leading to overcuring in some regions and undercuring in others. This non-uniform energy distribution results in dimensional inaccuracies and surface irregularities, particularly in geometrically complex parts with varying thicknesses.

Post-processing requirements represent another substantial challenge. Current VAM processes often necessitate extensive cleaning, additional curing, and manual finishing to achieve acceptable surface quality. These labor-intensive steps undermine the technology's speed advantages and introduce variability in final part quality. The development of automated post-processing techniques specifically tailored for VAM remains underdeveloped compared to traditional manufacturing methods.

Environmental factors such as ambient temperature, humidity, and dust particles also influence surface finish quality in VAM processes. These variables can affect resin viscosity, curing kinetics, and introduce contaminants that manifest as surface defects. Controlling these parameters requires sophisticated environmental management systems that add complexity and cost to VAM implementations.

Current Surface Finish Enhancement Methods

01 Post-processing techniques for surface finish improvement

Various post-processing techniques can be applied to improve the surface finish of parts manufactured using volumetric additive manufacturing. These techniques include mechanical polishing, chemical treatments, thermal processing, and hybrid approaches that combine multiple methods. Post-processing helps to reduce surface roughness, remove layer lines, and achieve smoother surfaces on additively manufactured components.- Post-processing techniques for surface finish improvement: Various post-processing techniques can be applied to improve the surface finish of parts manufactured using volumetric additive manufacturing. These techniques include mechanical polishing, chemical treatments, thermal processing, and hybrid approaches that combine multiple methods. Post-processing helps to reduce surface roughness, remove layer lines, and achieve smoother surfaces on the additively manufactured parts.

- Material formulation for enhanced surface quality: The composition and formulation of materials used in volumetric additive manufacturing significantly impact the surface finish of the final product. Advanced photopolymers, composite materials with specialized fillers, and materials with optimized rheological properties can be engineered to minimize surface defects and improve overall surface quality during the manufacturing process.

- Process parameter optimization for surface finish control: Optimizing process parameters such as light intensity, exposure time, build orientation, and layer thickness can significantly improve surface finish in volumetric additive manufacturing. Advanced algorithms and machine learning techniques can be employed to determine optimal parameter combinations that minimize surface roughness while maintaining dimensional accuracy and mechanical properties.

- In-situ monitoring and real-time correction systems: Implementation of in-situ monitoring systems that use sensors, cameras, and advanced imaging techniques to detect surface defects during the manufacturing process allows for real-time corrections. These systems can adjust process parameters on-the-fly to address potential surface finish issues before they become permanent in the final part, resulting in improved overall surface quality.

- Hybrid manufacturing approaches for superior surface finish: Combining volumetric additive manufacturing with other manufacturing techniques in hybrid approaches can achieve superior surface finish. These methods may integrate subtractive processes like CNC machining, laser polishing, or traditional finishing techniques with the additive process, either sequentially or simultaneously, to leverage the advantages of each method and produce parts with excellent surface quality.

02 Material formulations for enhanced surface quality

Specialized material formulations can significantly impact the surface finish of volumetrically printed parts. By incorporating specific additives, modifying resin compositions, or using nanoparticles, manufacturers can achieve improved surface characteristics directly during the printing process. These formulations can reduce the need for extensive post-processing while delivering parts with superior surface quality and dimensional accuracy.Expand Specific Solutions03 Process parameter optimization for surface finish control

The optimization of process parameters plays a crucial role in controlling surface finish in volumetric additive manufacturing. Parameters such as light intensity, exposure time, build orientation, layer thickness, and printing speed can be fine-tuned to minimize surface defects. Advanced algorithms and machine learning approaches can help identify optimal parameter combinations for specific geometries and materials.Expand Specific Solutions04 In-situ monitoring and real-time correction systems

In-situ monitoring systems can detect surface irregularities during the volumetric additive manufacturing process, allowing for real-time corrections. These systems use various sensing technologies such as optical cameras, laser scanning, or spectroscopic methods to analyze the part as it's being built. When deviations from the desired surface quality are detected, the process parameters can be automatically adjusted to maintain consistent surface finish.Expand Specific Solutions05 Hybrid manufacturing approaches for superior surface finish

Hybrid manufacturing approaches combine volumetric additive manufacturing with other fabrication techniques to achieve superior surface finish. These approaches may integrate subtractive methods like CNC machining, laser ablation, or micro-milling with the additive process. By leveraging the strengths of multiple manufacturing methods, complex parts with excellent surface quality can be produced efficiently, particularly for high-precision applications.Expand Specific Solutions

Leading Companies in VAM Surface Optimization

The surface finish optimization in volumetric additive manufacturing market is currently in its growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The global market size is estimated to reach $15-20 billion by 2025, driven by demand for high-precision components. Leading players include established industrial giants like Siemens Energy and Rolls-Royce, who leverage their manufacturing expertise, alongside specialized additive manufacturing companies such as Stratasys and Carbon, Inc. who focus on innovative materials and processes. Academic institutions like EPFL and Beihang University collaborate with Fraunhofer-Gesellschaft to advance technical capabilities. The technology is approaching maturity in certain applications, with companies like Boeing and PostProcess Technologies developing post-processing solutions to achieve superior surface quality, though challenges remain in standardization and material optimization.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed multiple advanced approaches to surface finish optimization in volumetric additive manufacturing. Their research institutes have pioneered hybrid manufacturing systems that integrate additive processes with in-situ surface treatment technologies. One notable innovation is their Selective Laser Melting (SLM) process enhancement that incorporates real-time surface monitoring and laser remelting for targeted surface improvement. Fraunhofer's AMELI 4.0 project specifically addresses surface quality through machine learning algorithms that predict and compensate for surface defects during the build process. Their volumetric AM research includes development of specialized parameter sets that optimize energy distribution to minimize surface roughness at boundaries and overhangs. Additionally, Fraunhofer has created novel post-processing techniques including selective chemical etching and plasma treatment methods specifically calibrated for different AM materials and geometries, achieving surface roughness reductions of up to 80% compared to untreated parts.

Strengths: Comprehensive research approach combining hardware, software, and material innovations; strong focus on industrial applicability and technology transfer; extensive experience across multiple AM technologies. Weaknesses: Solutions often require integration of multiple technologies rather than single-system approaches; some technologies still at research stage rather than commercial implementation; complex parameter optimization requires significant expertise.

Stratasys, Inc.

Technical Solution: Stratasys has developed a comprehensive approach to surface finish optimization in volumetric additive manufacturing through their PolyJet technology. This system utilizes multi-material jetting with microscopic layer thicknesses (as small as 16 microns) to achieve superior surface quality. Their proprietary Digital ABS Plus material specifically addresses surface finish challenges by minimizing the stair-stepping effect common in additive manufacturing. Stratasys has implemented adaptive slicing algorithms that automatically adjust layer thickness based on geometry complexity, optimizing both build time and surface quality. Their GrabCAD software incorporates surface analysis tools that predict and compensate for potential finish issues before printing begins. Recent innovations include their SUP706B soluble support material, which enables complex geometries while ensuring clean removal without damaging delicate surfaces.

Strengths: Industry-leading resolution capabilities with multi-material options allowing for gradient finishes; proprietary support removal systems that preserve surface integrity. Weaknesses: Higher material costs compared to competitors; system requires significant expertise to fully optimize surface parameters; limited compatibility with third-party materials.

Key Patents in VAM Surface Quality Control

Methods, systems, and apparatuses for improving surface finish of additively manufactured parts

PatentActiveEP3482874A1

Innovation

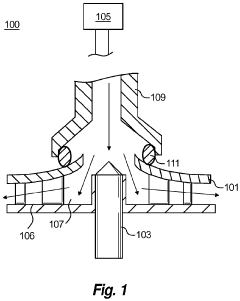

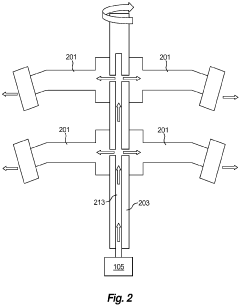

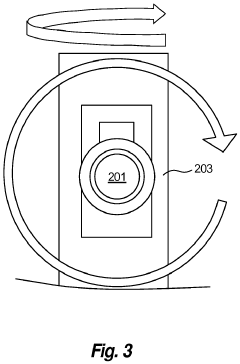

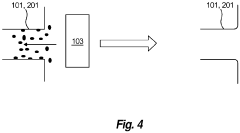

- A method involving rotating an additively manufactured part around a central axis to induce abrasive media flow through its internal channels using centrifugal force, improving surface finish by impinging abrasive particles on the surface, which can include using a rotatable element and a conduit with a rotational seal for fluid communication with an abrasive media source.

Method and apparatus for additive manufacture of at least one component area of a component

PatentInactiveEP3248719A1

Innovation

- A method involving selective exposure of component layers to a high-energy beam, where the contour sections are first heated slightly to push away powder particles without melting, followed by full melting to prevent re-deposition, ensuring a smooth surface finish during the manufacturing process.

Material-Process Interaction Effects on Surface Quality

The intricate relationship between material properties and processing parameters in volumetric additive manufacturing (VAM) significantly impacts surface quality outcomes. When photosensitive resins interact with spatially controlled light patterns, complex photochemical reactions occur that determine the final surface characteristics of printed objects. The viscosity, optical clarity, and photoinitiator concentration of the resin directly influence how light energy is absorbed and distributed throughout the volume, affecting surface resolution and smoothness.

Processing parameters such as light intensity, exposure time, and wavelength must be precisely calibrated to match specific material formulations. Excessive light energy can cause over-curing that extends beyond intended boundaries, creating rough surfaces with protrusions. Conversely, insufficient energy results in incomplete polymerization, leading to tacky or poorly defined surfaces. The thermal properties of materials also play a crucial role, as heat generated during photopolymerization can cause localized expansion and contraction, potentially introducing surface defects.

Oxygen inhibition represents another critical material-process interaction affecting surface quality. Atmospheric oxygen can quench excited photoinitiator molecules at resin-air interfaces, creating partially cured boundary layers that manifest as surface irregularities. Various approaches to mitigate this effect include oxygen scavenging additives, inert gas environments, or modified exposure strategies that account for inhibition zones.

The refractive index mismatch between cured and uncured resin creates light scattering effects that can distort projected light patterns, particularly at interfaces and boundaries. This optical phenomenon becomes increasingly significant when printing complex geometries with internal features, as light paths may be unpredictably altered, affecting surface definition and dimensional accuracy at critical transitions.

Material aging and storage conditions prior to processing also influence surface quality outcomes. Resins exposed to ambient light or improper temperature conditions may undergo partial polymerization or degradation of photoinitiators, resulting in inconsistent curing responses during the manufacturing process. These variations can manifest as surface defects, including pitting, waviness, or regions of varying gloss.

Recent research has demonstrated that incorporating nanoparticles or specialized additives can modify the rheological and optical properties of photopolymer resins, enabling enhanced control over surface characteristics. These additives can function as light absorbers, scattering agents, or polymerization modifiers that, when properly formulated, allow for more precise boundary definition and smoother surface transitions in volumetrically printed parts.

Processing parameters such as light intensity, exposure time, and wavelength must be precisely calibrated to match specific material formulations. Excessive light energy can cause over-curing that extends beyond intended boundaries, creating rough surfaces with protrusions. Conversely, insufficient energy results in incomplete polymerization, leading to tacky or poorly defined surfaces. The thermal properties of materials also play a crucial role, as heat generated during photopolymerization can cause localized expansion and contraction, potentially introducing surface defects.

Oxygen inhibition represents another critical material-process interaction affecting surface quality. Atmospheric oxygen can quench excited photoinitiator molecules at resin-air interfaces, creating partially cured boundary layers that manifest as surface irregularities. Various approaches to mitigate this effect include oxygen scavenging additives, inert gas environments, or modified exposure strategies that account for inhibition zones.

The refractive index mismatch between cured and uncured resin creates light scattering effects that can distort projected light patterns, particularly at interfaces and boundaries. This optical phenomenon becomes increasingly significant when printing complex geometries with internal features, as light paths may be unpredictably altered, affecting surface definition and dimensional accuracy at critical transitions.

Material aging and storage conditions prior to processing also influence surface quality outcomes. Resins exposed to ambient light or improper temperature conditions may undergo partial polymerization or degradation of photoinitiators, resulting in inconsistent curing responses during the manufacturing process. These variations can manifest as surface defects, including pitting, waviness, or regions of varying gloss.

Recent research has demonstrated that incorporating nanoparticles or specialized additives can modify the rheological and optical properties of photopolymer resins, enabling enhanced control over surface characteristics. These additives can function as light absorbers, scattering agents, or polymerization modifiers that, when properly formulated, allow for more precise boundary definition and smoother surface transitions in volumetrically printed parts.

Post-Processing Technologies for VAM Parts

Post-processing technologies play a critical role in enhancing the surface finish quality of Volumetric Additive Manufacturing (VAM) parts. Unlike traditional layer-by-layer additive manufacturing, VAM creates entire objects simultaneously, presenting unique challenges and opportunities for surface optimization through post-processing methods.

Chemical post-processing techniques have shown significant promise for VAM parts. Chemical polishing using solvents specific to the photopolymer resin can selectively dissolve surface irregularities while preserving the overall geometry. Recent developments include specialized chemical baths with controlled exposure times that can reduce surface roughness by up to 85% without compromising structural integrity.

Mechanical finishing methods adapted specifically for VAM geometries include micro-abrasive blasting and precision vibratory finishing. These techniques have been optimized to address the unique surface characteristics of volumetrically printed parts, which differ fundamentally from layer-based prints. Automated robotic polishing systems with adaptive pressure control have demonstrated particular effectiveness for complex internal features that are common in VAM parts.

Thermal post-processing represents another frontier in VAM surface enhancement. Controlled heat treatment protocols can promote molecular reorganization at the surface level, reducing microscopic irregularities. Research indicates that precision-controlled infrared treatment can decrease surface roughness values from Ra 15μm to below 2μm while maintaining dimensional accuracy within ±0.05mm.

Hybrid approaches combining multiple post-processing technologies have emerged as particularly effective for VAM applications. Sequential application of chemical treatment followed by precision mechanical polishing has demonstrated superior results compared to single-method approaches. These hybrid protocols typically reduce processing time by 40-60% while achieving surface quality comparable to injection-molded parts.

Emerging technologies specifically designed for VAM post-processing include plasma surface treatment and supercritical CO2 polishing. These advanced methods address the unique challenges of simultaneously cured volumes, particularly in regions with complex internal geometries that are inaccessible to traditional finishing tools. Early studies indicate that plasma treatment can reduce surface roughness by up to 70% while simultaneously improving surface energy characteristics for subsequent coating applications.

The development of automated post-processing workflows tailored to VAM production represents a significant advancement in commercialization efforts. These systems integrate multiple finishing technologies with machine learning algorithms that optimize parameters based on part geometry, material properties, and desired surface specifications.

Chemical post-processing techniques have shown significant promise for VAM parts. Chemical polishing using solvents specific to the photopolymer resin can selectively dissolve surface irregularities while preserving the overall geometry. Recent developments include specialized chemical baths with controlled exposure times that can reduce surface roughness by up to 85% without compromising structural integrity.

Mechanical finishing methods adapted specifically for VAM geometries include micro-abrasive blasting and precision vibratory finishing. These techniques have been optimized to address the unique surface characteristics of volumetrically printed parts, which differ fundamentally from layer-based prints. Automated robotic polishing systems with adaptive pressure control have demonstrated particular effectiveness for complex internal features that are common in VAM parts.

Thermal post-processing represents another frontier in VAM surface enhancement. Controlled heat treatment protocols can promote molecular reorganization at the surface level, reducing microscopic irregularities. Research indicates that precision-controlled infrared treatment can decrease surface roughness values from Ra 15μm to below 2μm while maintaining dimensional accuracy within ±0.05mm.

Hybrid approaches combining multiple post-processing technologies have emerged as particularly effective for VAM applications. Sequential application of chemical treatment followed by precision mechanical polishing has demonstrated superior results compared to single-method approaches. These hybrid protocols typically reduce processing time by 40-60% while achieving surface quality comparable to injection-molded parts.

Emerging technologies specifically designed for VAM post-processing include plasma surface treatment and supercritical CO2 polishing. These advanced methods address the unique challenges of simultaneously cured volumes, particularly in regions with complex internal geometries that are inaccessible to traditional finishing tools. Early studies indicate that plasma treatment can reduce surface roughness by up to 70% while simultaneously improving surface energy characteristics for subsequent coating applications.

The development of automated post-processing workflows tailored to VAM production represents a significant advancement in commercialization efforts. These systems integrate multiple finishing technologies with machine learning algorithms that optimize parameters based on part geometry, material properties, and desired surface specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!