What Are The Future Trends In Volumetric Additive Manufacturing?

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Evolution and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of 3D printing, evolving from traditional layer-by-layer approaches to simultaneous whole-volume solidification. This revolutionary technology emerged from the convergence of advanced photopolymerization techniques and computational tomography principles in the early 2010s. The fundamental concept involves projecting patterned light into photosensitive resins from multiple angles simultaneously, creating complex three-dimensional structures in seconds rather than hours.

The evolution of VAM can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory demonstrated proof-of-concept systems using computed axial lithography (CAL) around 2017. This was followed by significant improvements in projection systems and resin chemistry, enabling higher resolution and faster production times. By 2020, commercial interest had grown substantially, with several startups and established manufacturers beginning to explore volumetric techniques.

Current technological objectives for VAM focus on overcoming several critical limitations. Resolution enhancement remains paramount, with researchers aiming to achieve sub-micron feature sizes while maintaining volumetric advantages. Material diversity presents another significant challenge, as most systems currently rely on specialized photopolymers with limited mechanical properties. Expanding the material palette to include ceramics, metals, and multi-material capabilities would dramatically increase application potential.

Scale-up capabilities represent another crucial objective, as current VAM systems typically operate at relatively small build volumes (typically under 100cm³). Researchers are exploring novel optical arrangements and resin formulations to enable larger build volumes without sacrificing speed or resolution. Additionally, process monitoring and quality control systems are being developed to ensure consistency and reliability in volumetric printing processes.

The long-term technological trajectory aims to position VAM as a mainstream manufacturing technology rather than merely a prototyping tool. This involves developing comprehensive design methodologies specifically optimized for volumetric fabrication, creating standardized material specifications, and establishing robust process parameters. Integration with existing digital manufacturing workflows and compatibility with industry standards will be essential for widespread adoption.

Looking forward, the convergence of VAM with other emerging technologies such as artificial intelligence for topology optimization, advanced functional materials, and high-performance computing for real-time simulation presents exciting possibilities for next-generation manufacturing systems capable of producing complex, functional parts with unprecedented speed and precision.

The evolution of VAM can be traced through several key developmental phases. Initially, researchers at Lawrence Livermore National Laboratory demonstrated proof-of-concept systems using computed axial lithography (CAL) around 2017. This was followed by significant improvements in projection systems and resin chemistry, enabling higher resolution and faster production times. By 2020, commercial interest had grown substantially, with several startups and established manufacturers beginning to explore volumetric techniques.

Current technological objectives for VAM focus on overcoming several critical limitations. Resolution enhancement remains paramount, with researchers aiming to achieve sub-micron feature sizes while maintaining volumetric advantages. Material diversity presents another significant challenge, as most systems currently rely on specialized photopolymers with limited mechanical properties. Expanding the material palette to include ceramics, metals, and multi-material capabilities would dramatically increase application potential.

Scale-up capabilities represent another crucial objective, as current VAM systems typically operate at relatively small build volumes (typically under 100cm³). Researchers are exploring novel optical arrangements and resin formulations to enable larger build volumes without sacrificing speed or resolution. Additionally, process monitoring and quality control systems are being developed to ensure consistency and reliability in volumetric printing processes.

The long-term technological trajectory aims to position VAM as a mainstream manufacturing technology rather than merely a prototyping tool. This involves developing comprehensive design methodologies specifically optimized for volumetric fabrication, creating standardized material specifications, and establishing robust process parameters. Integration with existing digital manufacturing workflows and compatibility with industry standards will be essential for widespread adoption.

Looking forward, the convergence of VAM with other emerging technologies such as artificial intelligence for topology optimization, advanced functional materials, and high-performance computing for real-time simulation presents exciting possibilities for next-generation manufacturing systems capable of producing complex, functional parts with unprecedented speed and precision.

Market Demand Analysis for Volumetric 3D Printing

The global market for volumetric 3D printing technology is experiencing significant growth, driven by increasing demand for faster, more efficient additive manufacturing solutions across multiple industries. Current market projections indicate that the volumetric additive manufacturing segment could reach substantial market value within the next five years, with a compound annual growth rate exceeding traditional layer-by-layer 3D printing methods.

Healthcare and biomedical applications represent the largest market opportunity for volumetric 3D printing. The ability to rapidly produce complex biological structures with embedded vasculature addresses critical needs in tissue engineering and regenerative medicine. Hospitals and research institutions are increasingly investing in this technology for patient-specific implants, anatomical models, and eventually functional organ replacements.

The aerospace and automotive sectors demonstrate strong demand potential, particularly for lightweight components with complex internal geometries that are difficult to produce using conventional manufacturing methods. These industries value volumetric printing's ability to create parts with optimized weight-to-strength ratios and integrated functionality, potentially reducing assembly requirements and improving performance characteristics.

Consumer electronics manufacturers are exploring volumetric printing for rapid prototyping and customized component production. The technology's capacity to create complex electronic housings with integrated features in a single process offers significant advantages in product development cycles and design flexibility.

Market analysis reveals growing interest from dental and orthodontic practices, where the speed of volumetric printing could revolutionize chairside production of custom devices. The ability to produce dental restorations, aligners, and surgical guides in minutes rather than hours represents a compelling value proposition for these time-sensitive applications.

Material limitations currently constrain market expansion, with customers expressing strong demand for broader material compatibility. Market surveys indicate that expanding the range of printable materials, particularly high-performance polymers and multi-material capabilities, would significantly accelerate adoption across industries.

Regional market assessment shows North America leading in adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate as manufacturing hubs increasingly incorporate advanced additive manufacturing technologies into their production ecosystems.

Customer feedback indicates that key purchasing factors include production speed, resolution capabilities, build volume, and total cost of ownership. The market shows particular sensitivity to equipment costs, with mid-sized enterprises representing an underserved segment seeking more accessible volumetric printing solutions that balance performance with affordability.

Healthcare and biomedical applications represent the largest market opportunity for volumetric 3D printing. The ability to rapidly produce complex biological structures with embedded vasculature addresses critical needs in tissue engineering and regenerative medicine. Hospitals and research institutions are increasingly investing in this technology for patient-specific implants, anatomical models, and eventually functional organ replacements.

The aerospace and automotive sectors demonstrate strong demand potential, particularly for lightweight components with complex internal geometries that are difficult to produce using conventional manufacturing methods. These industries value volumetric printing's ability to create parts with optimized weight-to-strength ratios and integrated functionality, potentially reducing assembly requirements and improving performance characteristics.

Consumer electronics manufacturers are exploring volumetric printing for rapid prototyping and customized component production. The technology's capacity to create complex electronic housings with integrated features in a single process offers significant advantages in product development cycles and design flexibility.

Market analysis reveals growing interest from dental and orthodontic practices, where the speed of volumetric printing could revolutionize chairside production of custom devices. The ability to produce dental restorations, aligners, and surgical guides in minutes rather than hours represents a compelling value proposition for these time-sensitive applications.

Material limitations currently constrain market expansion, with customers expressing strong demand for broader material compatibility. Market surveys indicate that expanding the range of printable materials, particularly high-performance polymers and multi-material capabilities, would significantly accelerate adoption across industries.

Regional market assessment shows North America leading in adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate as manufacturing hubs increasingly incorporate advanced additive manufacturing technologies into their production ecosystems.

Customer feedback indicates that key purchasing factors include production speed, resolution capabilities, build volume, and total cost of ownership. The market shows particular sensitivity to equipment costs, with mid-sized enterprises representing an underserved segment seeking more accessible volumetric printing solutions that balance performance with affordability.

Current State and Technical Barriers in Volumetric AM

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, offering the potential to overcome many limitations of traditional layer-by-layer approaches. Currently, VAM exists in several primary forms, including computed axial lithography (CAL), holographic stereolithography, and tomographic volumetric printing. These methods share the fundamental principle of simultaneously solidifying an entire volume of photosensitive resin through controlled light projection from multiple angles.

Despite promising advances, VAM faces significant technical barriers that limit widespread industrial adoption. Resolution constraints remain a primary challenge, with most systems achieving feature sizes of 80-100 microns—adequate for many applications but insufficient for high-precision microstructures. The limited material compatibility represents another major hurdle, as current VAM processes work primarily with photopolymer resins with specific optical properties, restricting applications requiring diverse material properties.

Scaling difficulties present additional challenges. While VAM excels at producing small to medium-sized objects rapidly, creating larger components encounters issues with light penetration depth and optical distortion. The required computational resources also increase exponentially with object size and complexity, creating bottlenecks in the production pipeline.

The optical systems employed in VAM introduce their own constraints. Precise alignment of multiple light sources or projectors is critical yet technically demanding. Light scattering and absorption within the resin vat can compromise print quality, particularly for complex internal structures. These optical challenges become more pronounced as build volumes increase.

From a software perspective, the algorithms for computing optimal light dose distributions remain computationally intensive. Current approaches often require significant pre-processing time, negating some of the speed advantages inherent to volumetric techniques. Real-time feedback and correction mechanisms are still in early development stages.

Material development specifically tailored for VAM represents another frontier. Ideal resins must balance rapid curing kinetics with minimal light scattering properties—a combination that limits the available material palette. Additionally, achieving gradient materials or multi-material capabilities within a single print remains largely unsolved.

The integration of VAM into existing manufacturing workflows presents standardization challenges. Quality control methods, process monitoring, and certification protocols developed for layer-by-layer printing do not directly translate to volumetric approaches, creating barriers to industrial certification and adoption in regulated industries such as aerospace and medical device manufacturing.

Despite promising advances, VAM faces significant technical barriers that limit widespread industrial adoption. Resolution constraints remain a primary challenge, with most systems achieving feature sizes of 80-100 microns—adequate for many applications but insufficient for high-precision microstructures. The limited material compatibility represents another major hurdle, as current VAM processes work primarily with photopolymer resins with specific optical properties, restricting applications requiring diverse material properties.

Scaling difficulties present additional challenges. While VAM excels at producing small to medium-sized objects rapidly, creating larger components encounters issues with light penetration depth and optical distortion. The required computational resources also increase exponentially with object size and complexity, creating bottlenecks in the production pipeline.

The optical systems employed in VAM introduce their own constraints. Precise alignment of multiple light sources or projectors is critical yet technically demanding. Light scattering and absorption within the resin vat can compromise print quality, particularly for complex internal structures. These optical challenges become more pronounced as build volumes increase.

From a software perspective, the algorithms for computing optimal light dose distributions remain computationally intensive. Current approaches often require significant pre-processing time, negating some of the speed advantages inherent to volumetric techniques. Real-time feedback and correction mechanisms are still in early development stages.

Material development specifically tailored for VAM represents another frontier. Ideal resins must balance rapid curing kinetics with minimal light scattering properties—a combination that limits the available material palette. Additionally, achieving gradient materials or multi-material capabilities within a single print remains largely unsolved.

The integration of VAM into existing manufacturing workflows presents standardization challenges. Quality control methods, process monitoring, and certification protocols developed for layer-by-layer printing do not directly translate to volumetric approaches, creating barriers to industrial certification and adoption in regulated industries such as aerospace and medical device manufacturing.

Current Volumetric Fabrication Approaches

01 Volumetric additive manufacturing techniques

Volumetric additive manufacturing involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer by layer. This approach uses techniques such as computed axial lithography, tomographic volumetric printing, or holographic printing to project patterns of light into photosensitive resins. These techniques enable faster production times compared to traditional layer-by-layer methods and can create complex geometries without the need for support structures.- Volumetric additive manufacturing techniques: Volumetric additive manufacturing (VAM) involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer-by-layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic approaches that use projected light patterns to cure photosensitive resins. This approach enables faster production times compared to traditional layer-by-layer methods and can create complex geometries without support structures.

- Materials for volumetric printing: Specialized materials are essential for volumetric additive manufacturing, including photosensitive resins with specific curing properties, dual-initiator systems, and materials with tunable viscosity. These materials must respond appropriately to the volumetric energy delivery methods while maintaining desired mechanical properties in the final part. Advanced formulations may incorporate nanoparticles, functional additives, or biomaterials to enhance performance characteristics or enable specific applications in medical, aerospace, or electronics fields.

- Energy delivery systems for volumetric manufacturing: Energy delivery systems in volumetric additive manufacturing use sophisticated optical arrangements to project patterned light or other energy forms throughout a volume of photosensitive material. These systems may employ multiple light sources, spatial light modulators, digital micromirror devices, or holographic elements to control the distribution of energy. Advanced systems incorporate real-time feedback mechanisms to adjust energy delivery based on material response, ensuring precise control over the solidification process and resulting part quality.

- Process control and optimization in volumetric manufacturing: Process control in volumetric additive manufacturing involves sophisticated algorithms and feedback systems to ensure precise material transformation. This includes computational methods for determining optimal energy dose distributions, real-time monitoring of resin curing, and adaptive control strategies. Machine learning approaches may be employed to optimize process parameters based on desired part characteristics, material properties, and production requirements, resulting in improved part quality, reduced production time, and enhanced repeatability.

- Applications and integration of volumetric manufacturing: Volumetric additive manufacturing enables applications across various industries including medical devices, microfluidics, optics, and aerospace components. The technology is particularly valuable for producing complex internal structures, embedded components, and functionally graded materials. Integration with existing manufacturing workflows may involve hybrid approaches combining volumetric techniques with traditional methods, automated post-processing, and quality control systems. This integration facilitates the production of parts with unique geometries and functional properties not achievable through conventional manufacturing methods.

02 Materials for volumetric 3D printing

Various materials are used in volumetric additive manufacturing, including photopolymer resins, hydrogels, and composite materials. These materials are specially formulated to respond to specific light wavelengths and energy thresholds, allowing for controlled solidification within a volume. Advanced formulations may incorporate nanoparticles, functional additives, or multiple components to achieve desired mechanical properties, biocompatibility, or other functional characteristics in the final printed object.Expand Specific Solutions03 Light projection and control systems

Sophisticated light projection and control systems are essential for volumetric additive manufacturing. These systems may use digital light processing (DLP), spatial light modulators, or multiple synchronized light sources to project patterned light into the printing volume. Advanced optical setups, including specialized lenses, mirrors, and beam splitters, help achieve precise control over light distribution. Computational algorithms optimize the light patterns to ensure uniform curing throughout the volume and to compensate for optical distortions.Expand Specific Solutions04 Process optimization and control

Process optimization in volumetric additive manufacturing involves controlling various parameters such as exposure time, light intensity, resin composition, and temperature. Real-time monitoring systems may be employed to track the solidification process and make adjustments as needed. Machine learning algorithms can optimize printing parameters based on desired object properties and historical printing data. These control systems help ensure consistent quality, dimensional accuracy, and mechanical properties in the printed parts.Expand Specific Solutions05 Applications and integration with other manufacturing processes

Volumetric additive manufacturing has diverse applications across industries including medical devices, microfluidics, optics, and consumer products. The technology is particularly valuable for producing complex internal structures, customized components, and biocompatible parts. It can be integrated with other manufacturing processes in hybrid production systems, combining the speed and complexity advantages of volumetric printing with the precision of traditional manufacturing methods. This integration enables new production workflows and expands the range of achievable part geometries and material properties.Expand Specific Solutions

Leading Companies and Research Institutions in Volumetric AM

Volumetric Additive Manufacturing is currently in an early growth phase, with the market expected to expand significantly as the technology matures. The global market size is projected to reach substantial value in the coming years, driven by increasing applications in medical, aerospace, and industrial sectors. From a technological maturity perspective, research institutions like Lawrence Livermore National Security, Huazhong University of Science & Technology, and École Polytechnique Fédérale de Lausanne are leading fundamental research, while companies such as 3D Systems, Xerox, and Readily3D are commercializing solutions. Academic-industrial partnerships are accelerating development, with significant contributions from Tsinghua University, National Research Council of Canada, and Agency for Science, Technology & Research. The competitive landscape shows a balanced distribution between established manufacturers, specialized startups, and research institutions working on overcoming current limitations in speed, resolution, and material compatibility.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has pioneered volumetric additive manufacturing through their Computed Axial Lithography (CAL) technology. This approach creates entire 3D structures simultaneously rather than layer-by-layer, by projecting computed patterns of light into photosensitive resin. Their proprietary Direct Ink Write (DIW) technology enables printing of viscoelastic materials with controlled rheology for complex structures. LLNL has also developed high-area-rate projection micro-stereolithography (μSL) systems capable of producing parts with microscale features at unprecedented speeds[1]. Their recent innovations include multi-material volumetric printing capabilities and integration of real-time tomographic feedback systems that allow for in-process quality control and adaptive manufacturing parameters[3]. The laboratory continues to advance high-resolution volumetric techniques that can achieve feature sizes below 100 microns while maintaining build volumes suitable for practical applications.

Strengths: Superior speed (100x faster than conventional methods); elimination of support structures; isotropic mechanical properties; ability to print around pre-existing objects; exceptional surface finish. Weaknesses: Limited material compatibility compared to traditional methods; challenges in scaling to very large build volumes; higher computational requirements for pattern generation; current resolution limitations for certain high-precision applications.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology (HUST) has pioneered a novel approach to volumetric additive manufacturing through their Integral Volumetric Projection (IVP) technology. This system utilizes synchronized multi-directional light projections to create complex 3D structures within photosensitive resins without the need for layering. Their proprietary algorithms calculate precise light intensity distributions to achieve controlled polymerization throughout the entire volume simultaneously[9]. HUST researchers have developed specialized high-speed cameras and projection systems that enable real-time monitoring and adjustment during the printing process, significantly improving accuracy and reliability. Their recent innovations include multi-material volumetric printing capabilities through selective wavelength activation of different photopolymers within the same resin bath. The university has also made significant advances in developing ceramic-loaded and metal-loaded photopolymers compatible with volumetric techniques, expanding the technology's application to functional components[10]. Their system can produce complex structures with internal features at resolutions down to 50 micrometers across build volumes of several cubic centimeters in under one minute.

Strengths: Exceptional printing speed (up to 100x faster than conventional methods); ability to create complex internal geometries without support structures; excellent material isotropy; minimal residual stress in printed parts. Weaknesses: Current limitations in build volume compared to traditional manufacturing; restricted material selection primarily to photopolymers and their composites; challenges with optical clarity requirements for larger objects; higher computational requirements for pattern generation.

Key Patents and Innovations in Volumetric Manufacturing

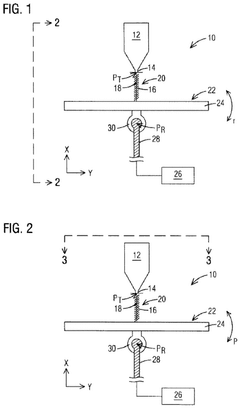

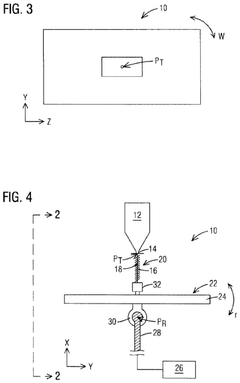

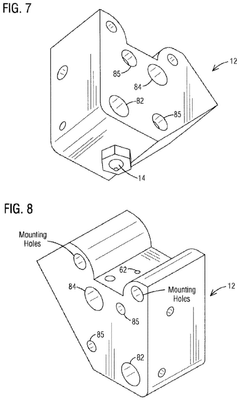

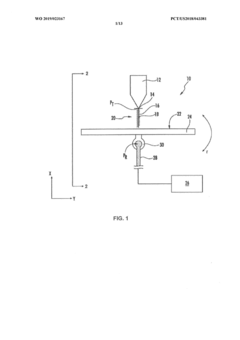

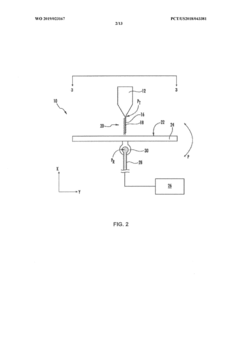

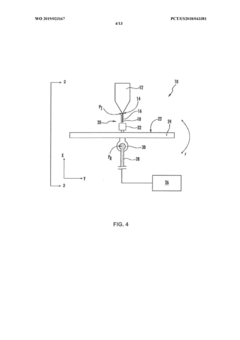

3D printing system nozzle assembly for printing of fiber reinforced parts

PatentActiveUS12122097B2

Innovation

- An integrated robotic 3D printing system with a nozzle assembly that allows for controlled deposition of composite materials by encasing continuous fibers with polymers, minimizing fiber tension, and enabling movement in multiple degrees of freedom to achieve precise fiber placement and orientation.

3D printing system nozzle assembly for printing of fiber reinforced parts

PatentWO2019023167A1

Innovation

- A 3D printing system with a nozzle assembly that allows controlled deposition of composite materials with continuous fibers, utilizing a liquefier assembly to encase fibers with polymer, and a robotic armature with six degrees of freedom for precise fiber placement and orientation, enabling the creation of high-performance fiber/polymer composites with enhanced mechanical and thermal properties.

Materials Science Developments for Volumetric AM

The evolution of materials science is fundamentally reshaping the landscape of Volumetric Additive Manufacturing (VAM). Recent breakthroughs in photopolymer chemistry have yielded resins with significantly improved optical properties, enabling deeper light penetration and more uniform curing throughout the volume. These advanced formulations incorporate specialized photoinitiators that respond to specific wavelengths, allowing for precise spatial control during the solidification process.

Dual-cure resin systems represent another promising development, combining photopolymerization with secondary curing mechanisms such as thermal or chemical processes. This approach addresses one of VAM's persistent challenges: achieving both rapid fabrication and robust mechanical properties in the final parts. Early research indicates that these hybrid materials can deliver up to 300% improvement in tensile strength compared to conventional single-cure resins.

Nanocomposite materials are emerging as critical enablers for functional VAM applications. By incorporating nanoparticles such as carbon nanotubes, graphene, or ceramic nanostructures into photocurable resins, researchers have demonstrated enhanced electrical conductivity, thermal stability, and mechanical performance. These advancements are particularly relevant for electronic applications, where volumetrically printed components must meet stringent performance requirements.

Bio-compatible and bio-degradable materials represent another frontier in VAM materials science. Medical-grade resins that meet ISO 10993 standards for biocompatibility are being developed specifically for volumetric printing, enabling applications in personalized medical devices and tissue engineering scaffolds. These materials feature carefully controlled degradation profiles and reduced cytotoxicity compared to conventional photopolymers.

Multi-material capabilities are advancing through the development of orthogonal chemistry approaches. By utilizing different photoinitiator systems that respond to distinct wavelengths, researchers have demonstrated the ability to selectively cure different materials within the same volume. This breakthrough enables the creation of objects with spatially varying properties, such as rigid structures with flexible joints or components with embedded electrical pathways.

Sustainability considerations are driving innovation in environmentally friendly VAM materials. Water-based resins with reduced volatile organic compound (VOC) content are being developed as alternatives to traditional solvent-based systems. Additionally, bio-derived monomers sourced from renewable feedstocks are showing promise as sustainable building blocks for next-generation VAM materials, potentially reducing the carbon footprint of volumetric manufacturing processes by up to 40%.

Dual-cure resin systems represent another promising development, combining photopolymerization with secondary curing mechanisms such as thermal or chemical processes. This approach addresses one of VAM's persistent challenges: achieving both rapid fabrication and robust mechanical properties in the final parts. Early research indicates that these hybrid materials can deliver up to 300% improvement in tensile strength compared to conventional single-cure resins.

Nanocomposite materials are emerging as critical enablers for functional VAM applications. By incorporating nanoparticles such as carbon nanotubes, graphene, or ceramic nanostructures into photocurable resins, researchers have demonstrated enhanced electrical conductivity, thermal stability, and mechanical performance. These advancements are particularly relevant for electronic applications, where volumetrically printed components must meet stringent performance requirements.

Bio-compatible and bio-degradable materials represent another frontier in VAM materials science. Medical-grade resins that meet ISO 10993 standards for biocompatibility are being developed specifically for volumetric printing, enabling applications in personalized medical devices and tissue engineering scaffolds. These materials feature carefully controlled degradation profiles and reduced cytotoxicity compared to conventional photopolymers.

Multi-material capabilities are advancing through the development of orthogonal chemistry approaches. By utilizing different photoinitiator systems that respond to distinct wavelengths, researchers have demonstrated the ability to selectively cure different materials within the same volume. This breakthrough enables the creation of objects with spatially varying properties, such as rigid structures with flexible joints or components with embedded electrical pathways.

Sustainability considerations are driving innovation in environmentally friendly VAM materials. Water-based resins with reduced volatile organic compound (VOC) content are being developed as alternatives to traditional solvent-based systems. Additionally, bio-derived monomers sourced from renewable feedstocks are showing promise as sustainable building blocks for next-generation VAM materials, potentially reducing the carbon footprint of volumetric manufacturing processes by up to 40%.

Sustainability and Environmental Impact of Volumetric Technologies

Volumetric Additive Manufacturing (VAM) technologies are increasingly being scrutinized for their environmental impact and sustainability credentials. As industries worldwide face mounting pressure to reduce carbon footprints, VAM offers promising advantages over traditional manufacturing methods. The elimination of support structures in volumetric printing significantly reduces material waste, addressing a critical sustainability challenge in conventional additive manufacturing processes.

Energy consumption patterns in volumetric technologies demonstrate notable efficiency improvements compared to layer-by-layer approaches. Recent studies indicate that volumetric methods can achieve energy reductions of 30-45% for comparable build volumes, primarily due to faster production speeds and elimination of repetitive mechanical movements. This efficiency translates directly to reduced carbon emissions in production environments, particularly when scaled to industrial applications.

Material sustainability represents another frontier where volumetric technologies are making significant advances. The development of bio-based and biodegradable photopolymers specifically formulated for volumetric processes has accelerated in recent years. These materials not only reduce dependence on petroleum-based inputs but also offer improved end-of-life scenarios through composting or chemical recycling pathways.

Lifecycle assessment (LCA) studies comparing volumetric manufacturing to both traditional manufacturing and conventional additive approaches reveal complex sustainability profiles. While volumetric methods generally demonstrate advantages in production-phase impacts, challenges remain in raw material sourcing and end-of-life management. Emerging research focuses on closing these loops through circular economy principles applied specifically to volumetric manufacturing ecosystems.

Water usage represents an often-overlooked environmental dimension where volumetric technologies offer substantial benefits. Unlike many conventional manufacturing processes requiring significant water for cooling or material processing, volumetric approaches typically operate with minimal water requirements. This advantage becomes particularly relevant in water-stressed regions where manufacturing sustainability increasingly depends on reduced hydrological impacts.

Regulatory frameworks worldwide are beginning to acknowledge and incentivize the sustainability advantages of advanced manufacturing technologies like VAM. The European Union's Circular Economy Action Plan and similar initiatives in North America and Asia are creating policy environments that may accelerate adoption of more sustainable volumetric approaches. These frameworks increasingly incorporate lifecycle thinking that favors the material efficiency inherent in volumetric technologies.

Looking forward, the sustainability trajectory of volumetric manufacturing will likely depend on continued innovations in renewable energy integration, closed-loop material systems, and design approaches that maximize the unique capabilities of volumetric production while minimizing environmental footprints.

Energy consumption patterns in volumetric technologies demonstrate notable efficiency improvements compared to layer-by-layer approaches. Recent studies indicate that volumetric methods can achieve energy reductions of 30-45% for comparable build volumes, primarily due to faster production speeds and elimination of repetitive mechanical movements. This efficiency translates directly to reduced carbon emissions in production environments, particularly when scaled to industrial applications.

Material sustainability represents another frontier where volumetric technologies are making significant advances. The development of bio-based and biodegradable photopolymers specifically formulated for volumetric processes has accelerated in recent years. These materials not only reduce dependence on petroleum-based inputs but also offer improved end-of-life scenarios through composting or chemical recycling pathways.

Lifecycle assessment (LCA) studies comparing volumetric manufacturing to both traditional manufacturing and conventional additive approaches reveal complex sustainability profiles. While volumetric methods generally demonstrate advantages in production-phase impacts, challenges remain in raw material sourcing and end-of-life management. Emerging research focuses on closing these loops through circular economy principles applied specifically to volumetric manufacturing ecosystems.

Water usage represents an often-overlooked environmental dimension where volumetric technologies offer substantial benefits. Unlike many conventional manufacturing processes requiring significant water for cooling or material processing, volumetric approaches typically operate with minimal water requirements. This advantage becomes particularly relevant in water-stressed regions where manufacturing sustainability increasingly depends on reduced hydrological impacts.

Regulatory frameworks worldwide are beginning to acknowledge and incentivize the sustainability advantages of advanced manufacturing technologies like VAM. The European Union's Circular Economy Action Plan and similar initiatives in North America and Asia are creating policy environments that may accelerate adoption of more sustainable volumetric approaches. These frameworks increasingly incorporate lifecycle thinking that favors the material efficiency inherent in volumetric technologies.

Looking forward, the sustainability trajectory of volumetric manufacturing will likely depend on continued innovations in renewable energy integration, closed-loop material systems, and design approaches that maximize the unique capabilities of volumetric production while minimizing environmental footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!