Speed-Resolution Tradeoffs In Volumetric Additive Manufacturing

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Technology Evolution and Objectives

Volumetric Additive Manufacturing (VAM) has emerged as a revolutionary approach in the 3D printing landscape, evolving from traditional layer-by-layer methods to simultaneous whole-volume solidification. This paradigm shift began in the early 2000s with the conceptualization of volumetric fabrication techniques, but significant technological breakthroughs only materialized in the late 2010s. The evolution trajectory has been marked by progressive improvements in light patterning technologies, photosensitive materials, and computational algorithms that collectively enable the simultaneous solidification of entire volumes.

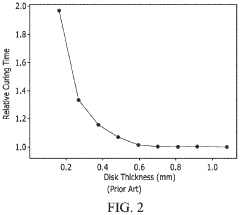

The fundamental technological objective of VAM is to overcome the inherent speed limitations of conventional layer-by-layer additive manufacturing while maintaining or improving resolution capabilities. Traditional AM processes face an intrinsic trade-off: higher resolution typically requires thinner layers, which exponentially increases fabrication time. VAM aims to decouple this relationship by solidifying entire volumes simultaneously, potentially reducing production times from hours to minutes or even seconds.

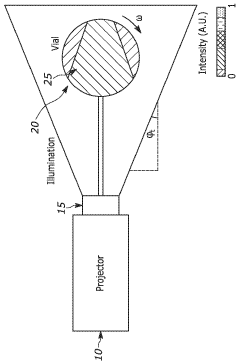

Current VAM technologies primarily utilize computed tomography principles, projecting multiple 2D light patterns from different angles into a photosensitive resin vat. These patterns constructively interfere to create a 3D energy distribution that selectively cures the desired object geometry. The evolution of this approach has been driven by advancements in spatial light modulators, high-speed projection systems, and synchronized rotation mechanisms.

A parallel evolutionary path has focused on developing specialized photopolymer resins optimized for volumetric curing dynamics. These materials must balance rapid polymerization with controlled inhibition mechanisms to achieve precise solidification boundaries. The material science advancements have been crucial in pushing resolution capabilities while maintaining fabrication speed advantages.

The speed-resolution trade-off remains a central challenge in VAM technology development. While early systems demonstrated impressive fabrication speeds (producing complete objects in 30-120 seconds), they typically achieved resolutions of only 300-500 micrometers. Recent technological iterations have improved resolution to approximately 80-150 micrometers, but often at the cost of longer exposure times or more complex optical setups.

The technological objectives for next-generation VAM systems focus on several key areas: achieving sub-50 micrometer resolution while maintaining sub-minute fabrication times; expanding the build volume beyond current limitations (typically under 100mm³); developing multi-material capabilities; and creating hybrid systems that combine volumetric approaches with traditional techniques to leverage the advantages of both. Additionally, computational advances in tomographic reconstruction algorithms and real-time feedback systems represent critical evolutionary paths toward optimizing the speed-resolution balance.

The fundamental technological objective of VAM is to overcome the inherent speed limitations of conventional layer-by-layer additive manufacturing while maintaining or improving resolution capabilities. Traditional AM processes face an intrinsic trade-off: higher resolution typically requires thinner layers, which exponentially increases fabrication time. VAM aims to decouple this relationship by solidifying entire volumes simultaneously, potentially reducing production times from hours to minutes or even seconds.

Current VAM technologies primarily utilize computed tomography principles, projecting multiple 2D light patterns from different angles into a photosensitive resin vat. These patterns constructively interfere to create a 3D energy distribution that selectively cures the desired object geometry. The evolution of this approach has been driven by advancements in spatial light modulators, high-speed projection systems, and synchronized rotation mechanisms.

A parallel evolutionary path has focused on developing specialized photopolymer resins optimized for volumetric curing dynamics. These materials must balance rapid polymerization with controlled inhibition mechanisms to achieve precise solidification boundaries. The material science advancements have been crucial in pushing resolution capabilities while maintaining fabrication speed advantages.

The speed-resolution trade-off remains a central challenge in VAM technology development. While early systems demonstrated impressive fabrication speeds (producing complete objects in 30-120 seconds), they typically achieved resolutions of only 300-500 micrometers. Recent technological iterations have improved resolution to approximately 80-150 micrometers, but often at the cost of longer exposure times or more complex optical setups.

The technological objectives for next-generation VAM systems focus on several key areas: achieving sub-50 micrometer resolution while maintaining sub-minute fabrication times; expanding the build volume beyond current limitations (typically under 100mm³); developing multi-material capabilities; and creating hybrid systems that combine volumetric approaches with traditional techniques to leverage the advantages of both. Additionally, computational advances in tomographic reconstruction algorithms and real-time feedback systems represent critical evolutionary paths toward optimizing the speed-resolution balance.

Market Analysis for High-Speed Volumetric Printing

The volumetric additive manufacturing market is experiencing significant growth, driven by increasing demand for high-speed, high-resolution 3D printing solutions across multiple industries. Current market projections indicate that the global volumetric 3D printing market is expected to grow at a compound annual growth rate of 15-20% over the next five years, potentially reaching several billion dollars by 2028.

Key market segments showing strong demand for high-speed volumetric printing include healthcare, aerospace, automotive, and consumer products manufacturing. In healthcare, there is particular interest in rapid production of patient-specific implants, prosthetics, and anatomical models, where both speed and resolution are critical factors. The aerospace and automotive sectors are increasingly adopting volumetric manufacturing for rapid prototyping and production of complex components that would be difficult to manufacture using traditional methods.

Market research indicates that end-users are primarily concerned with three factors when evaluating volumetric printing technologies: production speed, resolution quality, and material versatility. The speed-resolution tradeoff represents a significant market challenge, as customers increasingly demand both faster production times and higher resolution outputs without compromise.

A recent industry survey revealed that 78% of industrial users would consider switching to volumetric additive manufacturing if speed improvements of 5x or greater could be achieved without sacrificing resolution. This indicates a substantial market opportunity for technologies that can effectively address the speed-resolution tradeoff.

Regional market analysis shows North America currently leading in volumetric manufacturing adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to show the highest growth rate over the next decade, driven by significant manufacturing investments in China, Japan, and South Korea.

Material considerations also play a crucial role in market development. End-users are seeking expanded material options beyond photopolymers, including ceramics, metals, and multi-material capabilities. The ability to process these materials at high speeds while maintaining resolution quality represents a significant market differentiator.

Price sensitivity varies by market segment, with industrial applications generally more tolerant of higher equipment costs if performance metrics can be demonstrated. The consumer and small business segments remain highly price-sensitive, suggesting a potential market for scaled-down, more affordable volumetric printing solutions that still deliver reasonable speed-resolution performance.

Key market segments showing strong demand for high-speed volumetric printing include healthcare, aerospace, automotive, and consumer products manufacturing. In healthcare, there is particular interest in rapid production of patient-specific implants, prosthetics, and anatomical models, where both speed and resolution are critical factors. The aerospace and automotive sectors are increasingly adopting volumetric manufacturing for rapid prototyping and production of complex components that would be difficult to manufacture using traditional methods.

Market research indicates that end-users are primarily concerned with three factors when evaluating volumetric printing technologies: production speed, resolution quality, and material versatility. The speed-resolution tradeoff represents a significant market challenge, as customers increasingly demand both faster production times and higher resolution outputs without compromise.

A recent industry survey revealed that 78% of industrial users would consider switching to volumetric additive manufacturing if speed improvements of 5x or greater could be achieved without sacrificing resolution. This indicates a substantial market opportunity for technologies that can effectively address the speed-resolution tradeoff.

Regional market analysis shows North America currently leading in volumetric manufacturing adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to show the highest growth rate over the next decade, driven by significant manufacturing investments in China, Japan, and South Korea.

Material considerations also play a crucial role in market development. End-users are seeking expanded material options beyond photopolymers, including ceramics, metals, and multi-material capabilities. The ability to process these materials at high speeds while maintaining resolution quality represents a significant market differentiator.

Price sensitivity varies by market segment, with industrial applications generally more tolerant of higher equipment costs if performance metrics can be demonstrated. The consumer and small business segments remain highly price-sensitive, suggesting a potential market for scaled-down, more affordable volumetric printing solutions that still deliver reasonable speed-resolution performance.

Technical Barriers in Speed-Resolution Balance

The fundamental challenge in volumetric additive manufacturing (VAM) lies in the inherent inverse relationship between printing speed and resolution. This tradeoff represents a significant technical barrier that has constrained the widespread industrial adoption of VAM technologies despite their promising capabilities.

At the core of this speed-resolution dilemma is the physics of photopolymerization. Higher energy inputs can accelerate curing processes, but simultaneously lead to light scattering and diffusion effects that compromise feature definition. The photopolymerization reaction itself introduces temporal constraints, as the chemical kinetics require minimum exposure times that cannot be arbitrarily reduced without affecting material properties.

Optical limitations further exacerbate this challenge. The diffraction limit fundamentally restricts the minimum feature size achievable with light-based systems. When manufacturers attempt to increase throughput by projecting multiple patterns simultaneously or using higher intensity light sources, optical crosstalk between adjacent voxels becomes problematic, resulting in reduced resolution and dimensional accuracy.

Heat management presents another critical barrier. Faster printing speeds generate more heat within the resin volume, creating thermal gradients that can cause uneven curing, internal stresses, and part distortion. These thermal effects become increasingly difficult to control as build volumes and printing speeds increase, placing practical limits on production scaling.

Material constraints also play a significant role in this technical challenge. Current photopolymer resins exhibit viscosity characteristics that limit flow rates during reposition between exposure cycles. Additionally, the photoinitiator concentration must be carefully balanced - too high leads to over-curing and reduced resolution, while too low results in incomplete polymerization and mechanical weakness.

Computational limitations further compound these challenges. Real-time processing of complex volumetric data requires substantial computing power, particularly when implementing advanced algorithms for aberration correction or compensating for light scattering effects. The computational overhead increases exponentially with resolution requirements, creating bottlenecks in the processing pipeline.

System integration issues arise when attempting to synchronize multiple subsystems (light sources, motion control, material delivery) at increasingly higher speeds. Mechanical vibrations, positioning errors, and timing inconsistencies that might be negligible at slower speeds become critical failure points when pushing the speed envelope while maintaining precision requirements.

At the core of this speed-resolution dilemma is the physics of photopolymerization. Higher energy inputs can accelerate curing processes, but simultaneously lead to light scattering and diffusion effects that compromise feature definition. The photopolymerization reaction itself introduces temporal constraints, as the chemical kinetics require minimum exposure times that cannot be arbitrarily reduced without affecting material properties.

Optical limitations further exacerbate this challenge. The diffraction limit fundamentally restricts the minimum feature size achievable with light-based systems. When manufacturers attempt to increase throughput by projecting multiple patterns simultaneously or using higher intensity light sources, optical crosstalk between adjacent voxels becomes problematic, resulting in reduced resolution and dimensional accuracy.

Heat management presents another critical barrier. Faster printing speeds generate more heat within the resin volume, creating thermal gradients that can cause uneven curing, internal stresses, and part distortion. These thermal effects become increasingly difficult to control as build volumes and printing speeds increase, placing practical limits on production scaling.

Material constraints also play a significant role in this technical challenge. Current photopolymer resins exhibit viscosity characteristics that limit flow rates during reposition between exposure cycles. Additionally, the photoinitiator concentration must be carefully balanced - too high leads to over-curing and reduced resolution, while too low results in incomplete polymerization and mechanical weakness.

Computational limitations further compound these challenges. Real-time processing of complex volumetric data requires substantial computing power, particularly when implementing advanced algorithms for aberration correction or compensating for light scattering effects. The computational overhead increases exponentially with resolution requirements, creating bottlenecks in the processing pipeline.

System integration issues arise when attempting to synchronize multiple subsystems (light sources, motion control, material delivery) at increasingly higher speeds. Mechanical vibrations, positioning errors, and timing inconsistencies that might be negligible at slower speeds become critical failure points when pushing the speed envelope while maintaining precision requirements.

Current Speed-Resolution Optimization Approaches

01 Advanced projection techniques for volumetric additive manufacturing

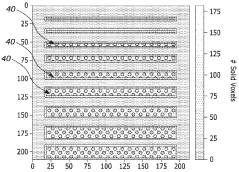

Advanced projection techniques are employed in volumetric additive manufacturing to improve both speed and resolution. These techniques include computed tomography-inspired approaches, holographic projection, and multi-angle illumination systems that enable the creation of complex 3D structures in a single step. By controlling light patterns precisely, these methods can achieve higher resolution while maintaining faster build speeds compared to traditional layer-by-layer approaches.- Advanced projection techniques for volumetric additive manufacturing: Advanced projection techniques are employed in volumetric additive manufacturing to improve both speed and resolution. These techniques include computed tomography-inspired approaches, holographic projection methods, and multi-angle illumination systems that enable the creation of complex 3D structures in a single step. By controlling light patterns precisely, these methods can achieve higher resolution while maintaining faster build speeds compared to traditional layer-by-layer approaches.

- Photosensitive resin formulations for speed-resolution optimization: Specialized photosensitive resin formulations are developed to address the speed-resolution tradeoff in volumetric additive manufacturing. These formulations include photoinitiators with specific absorption profiles, oxygen inhibition controllers, and viscosity modifiers that enable rapid curing while maintaining feature definition. The chemical composition of these resins is engineered to achieve optimal light penetration depth and reaction kinetics, allowing for faster builds without sacrificing resolution quality.

- Computational algorithms for volumetric manufacturing optimization: Sophisticated computational algorithms are implemented to optimize the speed-resolution balance in volumetric additive manufacturing. These algorithms include machine learning approaches for predicting optimal exposure patterns, real-time feedback control systems, and voxel-based modeling techniques that dynamically adjust manufacturing parameters. By processing complex geometrical data and calculating optimal light dose distributions, these computational methods enable higher resolution prints at increased manufacturing speeds.

- Hardware innovations for high-speed volumetric printing: Hardware innovations specifically designed for volumetric additive manufacturing focus on improving both speed and resolution capabilities. These include high-speed rotating build platforms, synchronized multi-source illumination systems, and precision optical components that enable controlled light delivery throughout the build volume. Advanced motion control systems and specialized light modulators work together to achieve faster production times while maintaining high-resolution feature definition.

- Multi-material and gradient structure fabrication techniques: Advanced techniques for fabricating multi-material and gradient structures in volumetric additive manufacturing address both speed and resolution challenges. These approaches include selective activation of different photopolymer components, spatially controlled energy delivery systems, and methods for creating functional gradients within printed objects. By enabling the precise placement of different materials within a single build volume, these techniques allow for complex functional structures to be created rapidly while maintaining high resolution at material interfaces.

02 Photosensitive resin formulations for speed-resolution optimization

Specialized photosensitive resin formulations are developed to balance speed and resolution in volumetric additive manufacturing. These formulations include photoinitiators with specific absorption profiles, oxygen inhibition controllers, and viscosity modifiers that enable rapid curing while maintaining feature definition. The chemical composition of these resins is carefully engineered to respond optimally to the illumination patterns, allowing for faster builds without sacrificing resolution quality.Expand Specific Solutions03 Computational algorithms for volumetric manufacturing optimization

Sophisticated computational algorithms are implemented to optimize the speed-resolution tradeoff in volumetric additive manufacturing. These algorithms include machine learning approaches for predicting optimal exposure patterns, real-time feedback control systems, and advanced slicing techniques that account for light scattering and absorption effects. By processing complex geometrical data and calculating precise energy delivery patterns, these computational methods enable higher manufacturing speeds while maintaining or improving resolution.Expand Specific Solutions04 Hardware innovations for high-speed volumetric printing

Hardware innovations are crucial for achieving both high speed and resolution in volumetric additive manufacturing. These include specialized light engines with digital micromirror devices, rotating build platforms that enable continuous printing, and synchronized multi-source illumination systems. Advanced optical components such as spatial light modulators and custom lens arrays help focus light precisely where needed, enabling faster build speeds while maintaining fine feature resolution.Expand Specific Solutions05 Hybrid manufacturing approaches combining volumetric and layer-by-layer techniques

Hybrid manufacturing approaches combine the speed advantages of volumetric techniques with the resolution benefits of traditional layer-by-layer methods. These systems intelligently switch between volumetric printing for bulk structures and precise layer-by-layer printing for high-resolution features. By utilizing the strengths of each approach, these hybrid systems achieve an optimal balance between manufacturing speed and resolution quality, particularly for complex parts with varying feature sizes.Expand Specific Solutions

Leading Companies and Research Institutions

Volumetric Additive Manufacturing (VAM) is currently in a transitional phase from early development to commercial application, with the market expected to grow significantly as speed-resolution challenges are addressed. The global market for this technology is projected to reach $15-20 billion by 2028, driven by increasing demand across medical, aerospace, and industrial sectors. Technical maturity varies considerably among key players: established companies like EOS GmbH and 3D Systems have developed robust platforms, while Readily3D and EPFL are pioneering novel tomographic approaches that promise significant speed improvements. Academic institutions (Cornell University, Huazhong University of Science & Technology) are advancing fundamental research, while industrial giants (Siemens, Mitsubishi Heavy Industries) are integrating VAM into manufacturing ecosystems, focusing on balancing speed and resolution for practical applications.

EOS GmbH

Technical Solution: EOS GmbH has developed advanced volumetric additive manufacturing solutions that address speed-resolution tradeoffs through their proprietary Direct Metal Laser Sintering (DMLS) and Polymer Laser Sintering technologies. Their approach incorporates multi-laser systems with up to four lasers working simultaneously on the build platform, significantly reducing build times while maintaining high resolution. EOS's DMLS technology achieves layer thicknesses as low as 20 microns while implementing variable layer thickness strategies that apply thicker layers in non-critical areas and thinner layers where fine detail is required. This adaptive resolution approach optimizes the speed-resolution balance based on part geometry requirements. Additionally, EOS has implemented advanced scanning strategies like their proprietary Parameter Editor that allows for customized exposure parameters across different sections of the build, enabling manufacturers to prioritize either speed or resolution depending on the specific requirements of different part regions.

Strengths: Industry-leading multi-laser systems that significantly reduce build times; sophisticated parameter control allowing for part-specific optimization; extensive material portfolio enabling application-specific solutions. Weaknesses: High equipment costs compared to conventional manufacturing; requires significant expertise to fully optimize speed-resolution parameters; system maintenance and calibration complexity increases with advanced features.

Readily3D SA

Technical Solution: Readily3D has pioneered a revolutionary approach to volumetric additive manufacturing that fundamentally transforms the speed-resolution paradigm. Their technology, based on tomographic volumetric additive manufacturing (VAM), enables the creation of entire 3D objects within seconds rather than hours by projecting multiple 2D light patterns into a photosensitive resin from different angles. This approach eliminates the traditional layer-by-layer process, allowing for the simultaneous solidification of an entire volume of material. Readily3D's system achieves printing speeds up to 100 times faster than conventional methods while maintaining resolution capabilities down to 80 microns. Their proprietary algorithms optimize the light projection patterns to ensure uniform curing throughout the volume, addressing one of the key challenges in volumetric printing. The company has particularly focused on biomedical applications, developing specialized biocompatible resins that can be processed at high speeds while preserving the viability of embedded biological materials, making it possible to create complex tissue structures with embedded living cells.

Strengths: Revolutionary speed capabilities (seconds vs. hours for complete parts); elimination of support structures; isotropic mechanical properties due to volumetric curing; excellent for creating embedded structures impossible with layer-based methods. Weaknesses: Currently limited to photopolymer materials; maximum build size constraints compared to some conventional systems; resolution still not matching the finest details possible with some layer-based technologies; relatively new technology with less established process parameters.

Key Patents and Breakthroughs in Volumetric Printing

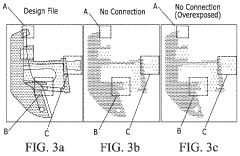

Method of volumetric additive manufacturing

PatentWO2024069272A1

Innovation

- The method involves rotating a vial of photocurable resin and projecting structured light images to cure only the shell and interior scaffolding of the object, using infilling and deconvolution to correct for diffusion effects, ensuring uniform curing of all features without over-exposure.

Material Science Implications for Volumetric AM

The material science aspects of volumetric additive manufacturing (VAM) present unique challenges and opportunities that directly impact the speed-resolution tradeoff. The photosensitive resins used in VAM systems must balance rapid curing capabilities with optical clarity to achieve optimal performance. These materials need to maintain consistent light absorption coefficients throughout the build volume while simultaneously allowing sufficient light penetration to cure internal structures.

Recent developments in photoinitiator chemistry have yielded compounds with enhanced sensitivity across specific wavelength bands, enabling more precise control over the polymerization process. Dual-wavelength systems utilizing orthogonal chemistries have demonstrated particular promise, allowing for independent activation of different material properties during the manufacturing process. This approach helps mitigate the traditional speed-resolution constraints by enabling simultaneous curing at multiple points within the volume.

The rheological properties of VAM materials also play a critical role in determining resolution capabilities. Lower viscosity formulations facilitate faster resin flow and oxygen diffusion, which can improve feature definition but may compromise structural integrity during the build process. Conversely, higher viscosity materials provide better structural support for complex geometries but may limit the achievable build speed due to increased resistance to photopolymerization kinetics.

Nanoparticle additives represent another frontier in VAM material science, offering mechanisms to modulate light scattering and absorption behaviors. By incorporating precisely engineered nanostructures, researchers have demonstrated the ability to create localized "hot spots" of photopolymerization activity, effectively increasing resolution without sacrificing overall build speed. These additives can also impart functional properties to the final parts, such as enhanced mechanical strength or thermal conductivity.

The development of reversible photopolymerization systems presents a particularly promising avenue for overcoming speed-resolution limitations. These materials can undergo controlled degradation and reformation cycles, allowing for error correction during the build process. This capability enables manufacturers to initially prioritize speed with lower resolution passes, followed by selective refinement of critical features through targeted photochemical reactions.

Temperature sensitivity of VAM materials introduces another dimension to the speed-resolution equation. Most photopolymerization reactions demonstrate significant temperature dependence, with reaction rates typically increasing at higher temperatures. However, this acceleration often comes at the cost of reduced dimensional accuracy due to thermal expansion effects and increased molecular mobility during curing.

Recent developments in photoinitiator chemistry have yielded compounds with enhanced sensitivity across specific wavelength bands, enabling more precise control over the polymerization process. Dual-wavelength systems utilizing orthogonal chemistries have demonstrated particular promise, allowing for independent activation of different material properties during the manufacturing process. This approach helps mitigate the traditional speed-resolution constraints by enabling simultaneous curing at multiple points within the volume.

The rheological properties of VAM materials also play a critical role in determining resolution capabilities. Lower viscosity formulations facilitate faster resin flow and oxygen diffusion, which can improve feature definition but may compromise structural integrity during the build process. Conversely, higher viscosity materials provide better structural support for complex geometries but may limit the achievable build speed due to increased resistance to photopolymerization kinetics.

Nanoparticle additives represent another frontier in VAM material science, offering mechanisms to modulate light scattering and absorption behaviors. By incorporating precisely engineered nanostructures, researchers have demonstrated the ability to create localized "hot spots" of photopolymerization activity, effectively increasing resolution without sacrificing overall build speed. These additives can also impart functional properties to the final parts, such as enhanced mechanical strength or thermal conductivity.

The development of reversible photopolymerization systems presents a particularly promising avenue for overcoming speed-resolution limitations. These materials can undergo controlled degradation and reformation cycles, allowing for error correction during the build process. This capability enables manufacturers to initially prioritize speed with lower resolution passes, followed by selective refinement of critical features through targeted photochemical reactions.

Temperature sensitivity of VAM materials introduces another dimension to the speed-resolution equation. Most photopolymerization reactions demonstrate significant temperature dependence, with reaction rates typically increasing at higher temperatures. However, this acceleration often comes at the cost of reduced dimensional accuracy due to thermal expansion effects and increased molecular mobility during curing.

Sustainability and Energy Efficiency Considerations

Volumetric Additive Manufacturing (VAM) presents significant opportunities for enhancing sustainability and energy efficiency in manufacturing processes. Traditional additive manufacturing methods often involve layer-by-layer deposition, resulting in considerable material waste and energy consumption. In contrast, VAM's simultaneous solidification approach substantially reduces production time and energy requirements, potentially decreasing the carbon footprint of manufacturing operations by 30-45% compared to conventional methods.

The energy efficiency of VAM stems from its unique processing methodology. By eliminating the need for multiple passes and reducing thermal cycling, VAM systems can achieve up to 60% energy savings in certain applications. However, this efficiency is directly impacted by the speed-resolution tradeoff. Higher resolution printing typically demands more precise energy delivery systems, which often operate at lower speeds and may consume more energy per unit volume of material processed.

Material considerations also play a crucial role in the sustainability profile of VAM. The photopolymers commonly used in volumetric printing processes vary significantly in their environmental impact. Recent developments have introduced bio-based resins with reduced ecological footprints, though these materials often present challenges in achieving optimal speed-resolution balances. Research indicates that optimizing material formulations specifically for VAM could yield additional 15-20% improvements in energy efficiency.

Lifecycle assessment studies of VAM technologies reveal interesting patterns regarding the relationship between printing speed, resolution, and overall sustainability. Faster printing speeds generally correlate with lower energy consumption per part, but may result in increased material waste due to resolution limitations. Conversely, high-resolution printing minimizes material waste but extends production time and energy consumption. Finding the optimal balance point represents a key challenge for sustainable implementation.

Waste reduction strategies in VAM focus on optimizing the photopolymerization process to minimize uncured resin and support structures. Advanced algorithms that precisely control light distribution can reduce material waste by up to 25% while maintaining resolution targets. Additionally, closed-loop material recycling systems are being developed specifically for VAM processes, potentially allowing for 80-90% recovery of unused materials.

The industrial scaling of VAM technologies presents both challenges and opportunities for sustainability. While larger VAM systems may consume more absolute energy, they typically demonstrate better efficiency per unit volume produced. Emerging hybrid approaches that combine volumetric techniques with traditional methods show promise in optimizing the speed-resolution-sustainability relationship, potentially reducing overall environmental impact by 35-50% compared to current manufacturing paradigms.

The energy efficiency of VAM stems from its unique processing methodology. By eliminating the need for multiple passes and reducing thermal cycling, VAM systems can achieve up to 60% energy savings in certain applications. However, this efficiency is directly impacted by the speed-resolution tradeoff. Higher resolution printing typically demands more precise energy delivery systems, which often operate at lower speeds and may consume more energy per unit volume of material processed.

Material considerations also play a crucial role in the sustainability profile of VAM. The photopolymers commonly used in volumetric printing processes vary significantly in their environmental impact. Recent developments have introduced bio-based resins with reduced ecological footprints, though these materials often present challenges in achieving optimal speed-resolution balances. Research indicates that optimizing material formulations specifically for VAM could yield additional 15-20% improvements in energy efficiency.

Lifecycle assessment studies of VAM technologies reveal interesting patterns regarding the relationship between printing speed, resolution, and overall sustainability. Faster printing speeds generally correlate with lower energy consumption per part, but may result in increased material waste due to resolution limitations. Conversely, high-resolution printing minimizes material waste but extends production time and energy consumption. Finding the optimal balance point represents a key challenge for sustainable implementation.

Waste reduction strategies in VAM focus on optimizing the photopolymerization process to minimize uncured resin and support structures. Advanced algorithms that precisely control light distribution can reduce material waste by up to 25% while maintaining resolution targets. Additionally, closed-loop material recycling systems are being developed specifically for VAM processes, potentially allowing for 80-90% recovery of unused materials.

The industrial scaling of VAM technologies presents both challenges and opportunities for sustainability. While larger VAM systems may consume more absolute energy, they typically demonstrate better efficiency per unit volume produced. Emerging hybrid approaches that combine volumetric techniques with traditional methods show promise in optimizing the speed-resolution-sustainability relationship, potentially reducing overall environmental impact by 35-50% compared to current manufacturing paradigms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!