Volumetric Additive Manufacturing For Ceramic-Based Structures

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic VAM Technology Evolution and Objectives

Volumetric Additive Manufacturing (VAM) for ceramic materials represents a significant advancement in the field of additive manufacturing, evolving from traditional layer-by-layer approaches to more sophisticated volumetric techniques. The technology's roots can be traced back to the early 2000s when researchers began exploring alternatives to conventional AM methods that could overcome limitations in resolution, speed, and material compatibility.

The evolution of ceramic VAM technology has been marked by several key milestones. Initially, stereolithography (SLA) techniques were adapted for ceramic materials, utilizing photocurable resins loaded with ceramic particles. This approach, while groundbreaking, faced challenges related to resolution limitations and post-processing requirements. By the mid-2010s, researchers began exploring tomographic techniques that could cure entire volumes simultaneously, leading to the development of computed axial lithography (CAL) and holographic volumetric printing methods specifically optimized for ceramic materials.

Recent technological breakthroughs have focused on enhancing the precision and material properties of ceramic structures produced through VAM. Advanced photopolymerization chemistry has enabled higher ceramic loading in precursor resins, while innovations in light delivery systems have improved resolution capabilities down to the microscale. Parallel developments in computational algorithms for light pattern generation have further refined the ability to create complex internal geometries previously impossible with traditional manufacturing methods.

The primary objective of ceramic VAM technology is to enable the rapid fabrication of complex ceramic components with intricate internal features while maintaining the exceptional mechanical, thermal, and chemical properties inherent to ceramic materials. Specific technical goals include achieving sub-micron resolution, increasing build volumes beyond current limitations, and developing multi-material capabilities for functionally graded ceramic structures.

Another critical objective is reducing post-processing requirements, particularly addressing challenges related to debinding and sintering of ceramic parts without introducing defects or dimensional distortions. Researchers aim to develop in-situ monitoring and feedback systems to ensure consistent material properties throughout the fabricated volume, addressing current variability issues that limit industrial adoption.

Looking forward, the technology trajectory points toward integration with other manufacturing processes in hybrid systems, expansion of compatible ceramic material systems beyond alumina and zirconia to include technical ceramics like silicon nitride and silicon carbide, and scaling production capabilities to meet industrial demands while maintaining precision and material integrity.

The evolution of ceramic VAM technology has been marked by several key milestones. Initially, stereolithography (SLA) techniques were adapted for ceramic materials, utilizing photocurable resins loaded with ceramic particles. This approach, while groundbreaking, faced challenges related to resolution limitations and post-processing requirements. By the mid-2010s, researchers began exploring tomographic techniques that could cure entire volumes simultaneously, leading to the development of computed axial lithography (CAL) and holographic volumetric printing methods specifically optimized for ceramic materials.

Recent technological breakthroughs have focused on enhancing the precision and material properties of ceramic structures produced through VAM. Advanced photopolymerization chemistry has enabled higher ceramic loading in precursor resins, while innovations in light delivery systems have improved resolution capabilities down to the microscale. Parallel developments in computational algorithms for light pattern generation have further refined the ability to create complex internal geometries previously impossible with traditional manufacturing methods.

The primary objective of ceramic VAM technology is to enable the rapid fabrication of complex ceramic components with intricate internal features while maintaining the exceptional mechanical, thermal, and chemical properties inherent to ceramic materials. Specific technical goals include achieving sub-micron resolution, increasing build volumes beyond current limitations, and developing multi-material capabilities for functionally graded ceramic structures.

Another critical objective is reducing post-processing requirements, particularly addressing challenges related to debinding and sintering of ceramic parts without introducing defects or dimensional distortions. Researchers aim to develop in-situ monitoring and feedback systems to ensure consistent material properties throughout the fabricated volume, addressing current variability issues that limit industrial adoption.

Looking forward, the technology trajectory points toward integration with other manufacturing processes in hybrid systems, expansion of compatible ceramic material systems beyond alumina and zirconia to include technical ceramics like silicon nitride and silicon carbide, and scaling production capabilities to meet industrial demands while maintaining precision and material integrity.

Market Analysis for Ceramic-Based Volumetric Manufacturing

The global market for ceramic-based volumetric additive manufacturing is experiencing significant growth, driven by increasing demand for advanced ceramic components across multiple industries. Current market valuation stands at approximately 2.1 billion USD with projections indicating a compound annual growth rate of 18.7% through 2028, substantially outpacing traditional ceramic manufacturing methods.

Healthcare and biomedical applications represent the largest market segment, accounting for nearly 35% of the total market share. The demand for patient-specific implants, dental prosthetics, and bone scaffolds with complex internal structures has created a robust market opportunity that traditional manufacturing methods cannot adequately address. Particularly notable is the 27% year-over-year growth in custom dental ceramics produced through volumetric techniques.

The aerospace and defense sectors collectively constitute the second-largest market segment at 28%. These industries value the ability to produce lightweight, high-strength ceramic components with intricate internal cooling channels and complex geometries that significantly enhance performance while reducing weight. Market analysis indicates that fuel efficiency improvements of 3-5% have been achieved through the implementation of additively manufactured ceramic components in aerospace applications.

Electronics and semiconductor manufacturing represent a rapidly expanding market segment, currently at 17% but growing at 22% annually. The ability to produce ceramic substrates, packages, and insulators with precise dimensional control and customized properties is driving adoption in this sector. The miniaturization trend in electronics continues to push manufacturers toward more sophisticated ceramic manufacturing techniques.

Energy sector applications, including fuel cells, batteries, and solar technologies, comprise approximately 14% of the market. The remaining 6% is distributed across various industries including automotive, chemical processing, and consumer products.

Regionally, North America leads with 38% market share, followed by Europe (31%), Asia-Pacific (26%), and the rest of the world (5%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Market barriers include high equipment costs, limited material options, and technical challenges related to part size limitations and post-processing requirements. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address these limitations and expand the application scope of ceramic-based volumetric manufacturing.

Healthcare and biomedical applications represent the largest market segment, accounting for nearly 35% of the total market share. The demand for patient-specific implants, dental prosthetics, and bone scaffolds with complex internal structures has created a robust market opportunity that traditional manufacturing methods cannot adequately address. Particularly notable is the 27% year-over-year growth in custom dental ceramics produced through volumetric techniques.

The aerospace and defense sectors collectively constitute the second-largest market segment at 28%. These industries value the ability to produce lightweight, high-strength ceramic components with intricate internal cooling channels and complex geometries that significantly enhance performance while reducing weight. Market analysis indicates that fuel efficiency improvements of 3-5% have been achieved through the implementation of additively manufactured ceramic components in aerospace applications.

Electronics and semiconductor manufacturing represent a rapidly expanding market segment, currently at 17% but growing at 22% annually. The ability to produce ceramic substrates, packages, and insulators with precise dimensional control and customized properties is driving adoption in this sector. The miniaturization trend in electronics continues to push manufacturers toward more sophisticated ceramic manufacturing techniques.

Energy sector applications, including fuel cells, batteries, and solar technologies, comprise approximately 14% of the market. The remaining 6% is distributed across various industries including automotive, chemical processing, and consumer products.

Regionally, North America leads with 38% market share, followed by Europe (31%), Asia-Pacific (26%), and the rest of the world (5%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Market barriers include high equipment costs, limited material options, and technical challenges related to part size limitations and post-processing requirements. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address these limitations and expand the application scope of ceramic-based volumetric manufacturing.

Technical Barriers and Global Development Status

Volumetric Additive Manufacturing (VAM) for ceramic-based structures faces significant technical barriers despite its promising potential. The primary challenge lies in achieving precise control over the photopolymerization process when working with ceramic-loaded resins. These materials exhibit high light scattering and absorption properties, which limit penetration depth and resolution capabilities. Current systems struggle to maintain uniform curing throughout the volume, resulting in structural inconsistencies and compromised mechanical properties.

Material formulation presents another substantial hurdle. Creating ceramic slurries with appropriate viscosity, particle distribution, and photosensitivity remains complex. The ceramic particles must be uniformly dispersed while maintaining suitable rheological properties for the volumetric printing process. Post-processing challenges further complicate development, as green bodies require careful debinding and sintering protocols to remove polymer components without introducing defects or dimensional distortions.

Resolution limitations persist across the field, with most systems unable to achieve the micro-scale features necessary for advanced applications in electronics, biomedical devices, and aerospace components. The trade-off between build volume and resolution continues to constrain practical applications, particularly for complex geometries with internal features.

Globally, research institutions in North America, Europe, and East Asia lead VAM ceramic development. Lawrence Livermore National Laboratory (USA) has pioneered tomographic approaches, while ETH Zurich (Switzerland) has advanced holographic techniques for ceramic VAM. Chinese research institutions have made significant progress in high-temperature ceramic formulations, particularly for aerospace applications.

Commercial development remains predominantly at the early stage, with few systems specifically optimized for ceramic materials. Most existing solutions are adaptations of polymer-focused technologies, lacking the specialized capabilities required for high-performance ceramic components. The European market shows the highest concentration of specialized ceramic additive manufacturing companies, particularly in Germany and France.

Standardization represents another significant gap in the field. Unlike traditional ceramic manufacturing or even powder-bed fusion techniques, VAM for ceramics lacks established quality control metrics, testing protocols, and certification standards. This absence impedes industrial adoption despite the technology's potential advantages in production speed and geometric complexity.

Recent advancements in computational modeling have begun addressing some challenges through predictive simulation of light-material interactions and curing kinetics. These developments suggest pathways toward overcoming current limitations, though significant research investment remains necessary to bridge the gap between laboratory demonstrations and industrial implementation.

Material formulation presents another substantial hurdle. Creating ceramic slurries with appropriate viscosity, particle distribution, and photosensitivity remains complex. The ceramic particles must be uniformly dispersed while maintaining suitable rheological properties for the volumetric printing process. Post-processing challenges further complicate development, as green bodies require careful debinding and sintering protocols to remove polymer components without introducing defects or dimensional distortions.

Resolution limitations persist across the field, with most systems unable to achieve the micro-scale features necessary for advanced applications in electronics, biomedical devices, and aerospace components. The trade-off between build volume and resolution continues to constrain practical applications, particularly for complex geometries with internal features.

Globally, research institutions in North America, Europe, and East Asia lead VAM ceramic development. Lawrence Livermore National Laboratory (USA) has pioneered tomographic approaches, while ETH Zurich (Switzerland) has advanced holographic techniques for ceramic VAM. Chinese research institutions have made significant progress in high-temperature ceramic formulations, particularly for aerospace applications.

Commercial development remains predominantly at the early stage, with few systems specifically optimized for ceramic materials. Most existing solutions are adaptations of polymer-focused technologies, lacking the specialized capabilities required for high-performance ceramic components. The European market shows the highest concentration of specialized ceramic additive manufacturing companies, particularly in Germany and France.

Standardization represents another significant gap in the field. Unlike traditional ceramic manufacturing or even powder-bed fusion techniques, VAM for ceramics lacks established quality control metrics, testing protocols, and certification standards. This absence impedes industrial adoption despite the technology's potential advantages in production speed and geometric complexity.

Recent advancements in computational modeling have begun addressing some challenges through predictive simulation of light-material interactions and curing kinetics. These developments suggest pathways toward overcoming current limitations, though significant research investment remains necessary to bridge the gap between laboratory demonstrations and industrial implementation.

Current Volumetric Manufacturing Solutions for Ceramics

01 Volumetric additive manufacturing techniques

Volumetric additive manufacturing (VAM) involves creating 3D objects by solidifying material throughout a volume simultaneously, rather than layer-by-layer. These techniques include computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic approaches. VAM offers advantages such as faster build speeds, elimination of support structures, and the ability to create complex geometries that would be challenging with traditional layer-by-layer methods.- Volumetric additive manufacturing techniques: Volumetric additive manufacturing involves creating three-dimensional objects by solidifying material throughout a volume simultaneously, rather than layer by layer. This approach enables faster production times and can create complex geometries without the need for support structures. Various techniques include computed axial lithography, holographic stereolithography, and tomographic volumetric printing, which use controlled light patterns to cure photosensitive resins in specific volumetric patterns.

- Materials for volumetric additive manufacturing: Specialized materials are essential for volumetric additive manufacturing processes. These include photosensitive resins with specific curing properties, dual-initiator systems that enable precise spatial control of polymerization, and materials with tunable viscosity and optical properties. Advanced formulations may incorporate nanoparticles, functional additives, or biomaterials to enhance mechanical properties or add functionality to the printed structures.

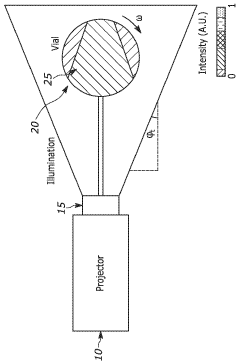

- Light projection and control systems: Sophisticated light projection and control systems are critical components of volumetric additive manufacturing. These systems include digital light processing (DLP) projectors, spatial light modulators, and specialized optics that shape and direct light patterns with high precision. Advanced algorithms control the temporal and spatial distribution of light energy to achieve desired curing patterns throughout the volume, enabling complex internal structures and gradient properties in the manufactured parts.

- Process optimization and control methods: Process optimization and control methods are essential for achieving high-quality results in volumetric additive manufacturing. These include real-time monitoring systems, feedback control mechanisms, and predictive algorithms that adjust manufacturing parameters during the printing process. Advanced computational models simulate light propagation, material curing kinetics, and thermal effects to optimize exposure patterns and timing sequences, resulting in improved dimensional accuracy and material properties.

- Applications and integration with other manufacturing processes: Volumetric additive manufacturing has diverse applications across industries including medical devices, microfluidics, optics, and consumer products. The technology can be integrated with other manufacturing processes to create hybrid production systems that combine the advantages of different fabrication methods. This integration enables the production of multi-material components, embedded electronics, and functionally graded structures with unique properties not achievable through conventional manufacturing techniques.

02 Materials for volumetric additive manufacturing

Various materials are used in volumetric additive manufacturing, including photopolymer resins, hydrogels, and composite materials. These materials are specially formulated to respond to specific light wavelengths or energy sources used in volumetric processes. The development of materials with appropriate viscosity, curing characteristics, and mechanical properties is crucial for successful volumetric printing. Advanced formulations may include additives to control light scattering, absorption, and reaction kinetics.Expand Specific Solutions03 Light projection and control systems

Volumetric additive manufacturing relies on sophisticated light projection and control systems to deliver patterned energy throughout a volume of photosensitive material. These systems may use digital light processing (DLP), spatial light modulators, or computed tomography approaches to project specific patterns from multiple angles. Advanced algorithms control the intensity, duration, and pattern of light exposure to achieve precise solidification at targeted locations within the volume, enabling the creation of complex 3D structures.Expand Specific Solutions04 Process optimization and control

Optimizing volumetric additive manufacturing processes involves controlling numerous parameters including exposure time, light intensity, material properties, and temperature. Advanced control systems use real-time monitoring and feedback mechanisms to adjust process parameters during fabrication. Computational models help predict material behavior and optimize fabrication strategies. These approaches improve print quality, dimensional accuracy, and mechanical properties of the final parts while reducing manufacturing time.Expand Specific Solutions05 Applications and specialized implementations

Volumetric additive manufacturing is applied across various fields including biomedical engineering, microfluidics, optics, and electronics. In biomedical applications, it enables the creation of tissue scaffolds with precisely controlled architectures. For industrial applications, specialized implementations focus on scaling up the technology for larger parts or integrating it with existing manufacturing processes. Recent developments include hybrid approaches combining volumetric techniques with traditional methods to leverage the advantages of both.Expand Specific Solutions

Leading Companies and Research Institutions in Ceramic VAM

Volumetric Additive Manufacturing for ceramic-based structures is currently in an early growth phase, with increasing market interest driven by applications in aerospace, electronics, and medical industries. The global market is expanding rapidly, projected to reach significant scale as manufacturing capabilities advance. Technologically, the field shows varied maturity levels across players: academic institutions like Huazhong University of Science & Technology, Central South University, and École Polytechnique Fédérale de Lausanne are pioneering fundamental research, while companies including Applied Materials, Siemens Energy, and Stratasys are developing commercial applications. Specialized firms like Readily3D are introducing innovative approaches such as tomographic bioprinting. Industry leaders RTX Corp., General Electric, and Corning are integrating these technologies into broader manufacturing ecosystems, indicating growing industrial adoption despite remaining technical challenges.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has developed a groundbreaking volumetric additive manufacturing technique called Computed Axial Lithography (CAL) specifically for ceramic materials. This approach uses projected light patterns from multiple angles to cure photosensitive ceramic resins in a volumetric manner, creating complex 3D ceramic structures without the need for layer-by-layer processing. Their technology enables the fabrication of ceramic components with intricate internal features that would be impossible with traditional manufacturing methods. The process involves suspending ceramic particles in photocurable resins, then using computed tomography principles in reverse to project calculated light patterns into the resin volume, solidifying the entire structure simultaneously rather than sequentially[1]. This results in significantly faster production times - minutes instead of hours or days compared to conventional methods. LLNL has also developed specialized ceramic-polymer composite materials that maintain structural integrity during the curing process and subsequent sintering stages, allowing for minimal shrinkage and high dimensional accuracy[3].

Strengths: Dramatically reduced production times (up to 100x faster than layer-based methods); ability to create previously impossible internal geometries; elimination of support structures; higher resolution than traditional ceramic manufacturing. Weaknesses: Limited to photosensitive ceramic materials; challenges in scaling to very large components; potential material property variations compared to traditionally manufactured ceramics.

The Regents of the University of California

Technical Solution: The University of California has pioneered a volumetric additive manufacturing approach for ceramics called Holographic Volumetric Additive Manufacturing (HVAM). This technique utilizes computer-generated holograms to create interference patterns of light within photosensitive ceramic suspensions, enabling the simultaneous solidification of entire 3D structures. Their research has focused on developing specialized ceramic nanocomposites that respond to specific light wavelengths while maintaining excellent post-processing properties. The UC system has demonstrated the ability to produce complex ceramic microstructures with feature sizes down to 10 microns and overall dimensions of several centimeters[2]. Their process incorporates real-time optical feedback systems that monitor and adjust the light patterns during fabrication to compensate for optical distortions and ensure dimensional accuracy. Additionally, they've developed post-processing protocols specifically for volumetrically manufactured ceramic parts that optimize sintering parameters to achieve near-theoretical density while preserving fine features[4]. The technology has been successfully applied to biomedical ceramics, electronic substrates, and high-temperature applications.

Strengths: Exceptional resolution capabilities for ceramic microstructures; rapid production of complex geometries; ability to create gradient material properties within a single part; excellent surface finish without layer lines. Weaknesses: Currently limited to relatively small overall dimensions; requires specialized photosensitive ceramic formulations; higher equipment costs compared to conventional ceramic manufacturing methods.

Key Patents and Technical Innovations in Ceramic VAM

Photocrosslinkable ceramic slip and method for the volumetric additive manufacturing of a ceramic component

PatentWO2025153525A1

Innovation

- A photocrosslinkable ceramic slip with a high ceramic particle content and controlled particle size distribution, allowing for light-induced crosslinking and sintering to form ceramic components with a predetermined three-dimensional structure.

Method of volumetric additive manufacturing

PatentWO2024069272A1

Innovation

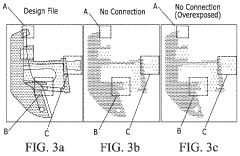

- The method involves rotating a vial of photocurable resin and projecting structured light images to cure only the shell and interior scaffolding of the object, using infilling and deconvolution to correct for diffusion effects, ensuring uniform curing of all features without over-exposure.

Material Science Considerations for Ceramic Photopolymers

The development of ceramic photopolymers for volumetric additive manufacturing requires careful consideration of material science principles to ensure successful fabrication of ceramic-based structures. Traditional ceramic processing methods often involve complex sintering steps, but photopolymer-based approaches offer unique advantages when properly formulated.

Ceramic photopolymers must balance several competing material properties to function effectively in volumetric additive manufacturing systems. The resin formulation typically consists of ceramic particles suspended in a photosensitive polymer matrix. The ceramic loading must be sufficiently high (typically 40-60% by volume) to achieve desired mechanical and functional properties after sintering, while maintaining appropriate rheological properties for the manufacturing process.

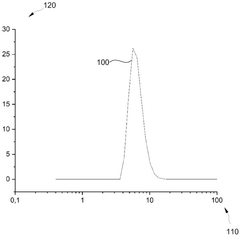

Light absorption and scattering characteristics present significant challenges in ceramic photopolymer development. Ceramic particles inherently scatter light, which can limit cure depth and resolution in volumetric printing. Particle size distribution must be carefully controlled, with optimal sizes typically ranging from 100nm to 5μm depending on the specific ceramic material and desired properties. Smaller particles reduce light scattering but increase viscosity, necessitating careful formulation balancing.

The interface between ceramic particles and the polymer matrix critically influences both green body strength and sintering behavior. Surface modification of ceramic particles with coupling agents such as silanes can significantly improve particle dispersion and polymer-particle adhesion. This enhances both the printing process and the mechanical integrity of the printed parts before sintering.

Rheological properties of ceramic photopolymers must be tailored for volumetric manufacturing. The suspension must maintain stability against particle sedimentation while exhibiting appropriate viscosity (typically 1-10 Pa·s) for the manufacturing process. Thixotropic additives may be incorporated to achieve shear-thinning behavior beneficial for certain volumetric printing approaches.

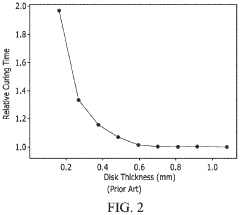

Post-processing considerations are equally important in ceramic photopolymer development. The polymer burnout process must be carefully designed to prevent defects such as cracking or warping. Typical burnout protocols involve slow heating rates (1-5°C/min) up to 600°C to allow for gradual polymer decomposition and gas escape. Subsequent sintering temperatures vary by ceramic type, ranging from 1200°C for some glass-ceramics to over 1600°C for materials like alumina or zirconia.

Recent advances in ceramic photopolymers include the development of hybrid organic-inorganic systems that form ceramic phases in-situ during thermal processing, reducing shrinkage and improving dimensional accuracy. Additionally, multi-functional monomers capable of both photopolymerization and subsequent ceramic network formation show promise for enhancing the properties of volumetrically manufactured ceramic structures.

Ceramic photopolymers must balance several competing material properties to function effectively in volumetric additive manufacturing systems. The resin formulation typically consists of ceramic particles suspended in a photosensitive polymer matrix. The ceramic loading must be sufficiently high (typically 40-60% by volume) to achieve desired mechanical and functional properties after sintering, while maintaining appropriate rheological properties for the manufacturing process.

Light absorption and scattering characteristics present significant challenges in ceramic photopolymer development. Ceramic particles inherently scatter light, which can limit cure depth and resolution in volumetric printing. Particle size distribution must be carefully controlled, with optimal sizes typically ranging from 100nm to 5μm depending on the specific ceramic material and desired properties. Smaller particles reduce light scattering but increase viscosity, necessitating careful formulation balancing.

The interface between ceramic particles and the polymer matrix critically influences both green body strength and sintering behavior. Surface modification of ceramic particles with coupling agents such as silanes can significantly improve particle dispersion and polymer-particle adhesion. This enhances both the printing process and the mechanical integrity of the printed parts before sintering.

Rheological properties of ceramic photopolymers must be tailored for volumetric manufacturing. The suspension must maintain stability against particle sedimentation while exhibiting appropriate viscosity (typically 1-10 Pa·s) for the manufacturing process. Thixotropic additives may be incorporated to achieve shear-thinning behavior beneficial for certain volumetric printing approaches.

Post-processing considerations are equally important in ceramic photopolymer development. The polymer burnout process must be carefully designed to prevent defects such as cracking or warping. Typical burnout protocols involve slow heating rates (1-5°C/min) up to 600°C to allow for gradual polymer decomposition and gas escape. Subsequent sintering temperatures vary by ceramic type, ranging from 1200°C for some glass-ceramics to over 1600°C for materials like alumina or zirconia.

Recent advances in ceramic photopolymers include the development of hybrid organic-inorganic systems that form ceramic phases in-situ during thermal processing, reducing shrinkage and improving dimensional accuracy. Additionally, multi-functional monomers capable of both photopolymerization and subsequent ceramic network formation show promise for enhancing the properties of volumetrically manufactured ceramic structures.

Sustainability and Energy Efficiency in Ceramic VAM Processes

The sustainability and energy efficiency aspects of Volumetric Additive Manufacturing (VAM) for ceramic-based structures represent critical considerations in the broader adoption of this technology. Traditional ceramic manufacturing processes typically require high-temperature firing and extensive energy consumption, contributing significantly to carbon emissions and resource depletion. In contrast, VAM offers promising pathways toward more sustainable ceramic production.

Energy consumption in ceramic VAM processes is substantially lower than conventional methods due to the targeted application of energy. Unlike traditional kilns that heat entire volumes uniformly, VAM systems direct energy precisely where needed through photopolymerization or other curing mechanisms. Recent studies indicate energy savings of 30-45% compared to traditional ceramic manufacturing, with particularly notable efficiency gains in complex geometries that would otherwise require extensive machining.

Material utilization represents another significant sustainability advantage of ceramic VAM. The process generates minimal waste as it builds structures additively rather than subtractively. Quantitative analyses demonstrate that VAM techniques typically utilize 85-95% of input materials, compared to 40-60% material utilization rates in conventional ceramic manufacturing processes where substantial material is lost during grinding and finishing operations.

Water consumption in ceramic VAM processes also demonstrates environmental benefits. Traditional ceramic slurry preparation and processing can require 5-7 liters of water per kilogram of finished product. Advanced VAM systems have reduced this requirement by up to 70% through closed-loop material handling systems and precise resin formulations that minimize water content while maintaining appropriate rheological properties.

The lifecycle assessment of ceramic components produced via VAM reveals additional sustainability benefits. The ability to create lightweight, optimized structures with internal lattices or channels reduces material requirements while maintaining functional performance. This translates to downstream energy savings in transportation and operation of ceramic components, particularly in aerospace and automotive applications where weight directly correlates with fuel consumption.

Emerging research focuses on developing bio-based and recyclable ceramic precursors specifically designed for VAM processes. These materials aim to replace petroleum-derived components in photocurable ceramic resins with sustainable alternatives derived from agricultural waste or other renewable sources. Though still in early development stages, initial results suggest viable pathways toward fully sustainable ceramic VAM material systems with minimal environmental impact throughout their lifecycle.

Energy consumption in ceramic VAM processes is substantially lower than conventional methods due to the targeted application of energy. Unlike traditional kilns that heat entire volumes uniformly, VAM systems direct energy precisely where needed through photopolymerization or other curing mechanisms. Recent studies indicate energy savings of 30-45% compared to traditional ceramic manufacturing, with particularly notable efficiency gains in complex geometries that would otherwise require extensive machining.

Material utilization represents another significant sustainability advantage of ceramic VAM. The process generates minimal waste as it builds structures additively rather than subtractively. Quantitative analyses demonstrate that VAM techniques typically utilize 85-95% of input materials, compared to 40-60% material utilization rates in conventional ceramic manufacturing processes where substantial material is lost during grinding and finishing operations.

Water consumption in ceramic VAM processes also demonstrates environmental benefits. Traditional ceramic slurry preparation and processing can require 5-7 liters of water per kilogram of finished product. Advanced VAM systems have reduced this requirement by up to 70% through closed-loop material handling systems and precise resin formulations that minimize water content while maintaining appropriate rheological properties.

The lifecycle assessment of ceramic components produced via VAM reveals additional sustainability benefits. The ability to create lightweight, optimized structures with internal lattices or channels reduces material requirements while maintaining functional performance. This translates to downstream energy savings in transportation and operation of ceramic components, particularly in aerospace and automotive applications where weight directly correlates with fuel consumption.

Emerging research focuses on developing bio-based and recyclable ceramic precursors specifically designed for VAM processes. These materials aim to replace petroleum-derived components in photocurable ceramic resins with sustainable alternatives derived from agricultural waste or other renewable sources. Though still in early development stages, initial results suggest viable pathways toward fully sustainable ceramic VAM material systems with minimal environmental impact throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!