Radiation Dose Control In Volumetric Additive Manufacturing

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radiation Dose Control Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, offering unprecedented speed and resolution capabilities compared to traditional layer-by-layer approaches. The evolution of radiation dose control within this domain has progressed significantly over the past decade, transitioning from rudimentary exposure techniques to sophisticated spatiotemporal control systems that enable precise material transformation.

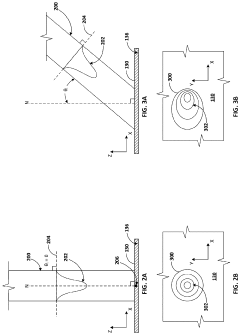

The fundamental principle behind VAM involves the projection of patterned radiation into a photosensitive resin volume, initiating polymerization at specific three-dimensional coordinates. This approach eliminates the mechanical constraints associated with conventional additive manufacturing methods, potentially reducing production times from hours to minutes or even seconds for complex structures.

Historical development of radiation dose control in VAM can be traced back to early computed axial lithography experiments in the 1990s, though significant breakthroughs only emerged after 2015 with the advent of digital light processing (DLP) technology and advanced computational methods. The convergence of high-resolution spatial light modulators, precise optical systems, and photochemistry innovations has accelerated progress in this field.

Current technical objectives in radiation dose control for VAM focus on several critical aspects: achieving sub-micron resolution across large build volumes, minimizing optical aberrations and scattering effects, developing multi-material capabilities through selective activation of different photopolymer systems, and implementing real-time feedback mechanisms to ensure dimensional accuracy and material property consistency.

The primary challenge lies in managing the complex light-matter interactions that occur during volumetric printing. Unlike layer-by-layer methods where exposure is limited to a single plane, VAM requires precise control of radiation throughout a three-dimensional volume, accounting for factors such as light attenuation, scattering, and the accumulation of dose contributions from multiple projections.

Looking forward, the field aims to establish standardized metrics for radiation dose quantification in volumetric printing environments, develop predictive models for photopolymerization kinetics under complex exposure conditions, and create adaptive control systems capable of compensating for material variations and environmental factors during the printing process.

The ultimate goal is to achieve deterministic control over material transformation at arbitrary points within a volume, enabling the fabrication of structures with spatially varying mechanical, optical, and chemical properties—a capability that would revolutionize applications ranging from biomedical devices to advanced optical components.

The fundamental principle behind VAM involves the projection of patterned radiation into a photosensitive resin volume, initiating polymerization at specific three-dimensional coordinates. This approach eliminates the mechanical constraints associated with conventional additive manufacturing methods, potentially reducing production times from hours to minutes or even seconds for complex structures.

Historical development of radiation dose control in VAM can be traced back to early computed axial lithography experiments in the 1990s, though significant breakthroughs only emerged after 2015 with the advent of digital light processing (DLP) technology and advanced computational methods. The convergence of high-resolution spatial light modulators, precise optical systems, and photochemistry innovations has accelerated progress in this field.

Current technical objectives in radiation dose control for VAM focus on several critical aspects: achieving sub-micron resolution across large build volumes, minimizing optical aberrations and scattering effects, developing multi-material capabilities through selective activation of different photopolymer systems, and implementing real-time feedback mechanisms to ensure dimensional accuracy and material property consistency.

The primary challenge lies in managing the complex light-matter interactions that occur during volumetric printing. Unlike layer-by-layer methods where exposure is limited to a single plane, VAM requires precise control of radiation throughout a three-dimensional volume, accounting for factors such as light attenuation, scattering, and the accumulation of dose contributions from multiple projections.

Looking forward, the field aims to establish standardized metrics for radiation dose quantification in volumetric printing environments, develop predictive models for photopolymerization kinetics under complex exposure conditions, and create adaptive control systems capable of compensating for material variations and environmental factors during the printing process.

The ultimate goal is to achieve deterministic control over material transformation at arbitrary points within a volume, enabling the fabrication of structures with spatially varying mechanical, optical, and chemical properties—a capability that would revolutionize applications ranging from biomedical devices to advanced optical components.

Market Analysis for Radiation-Safe Additive Manufacturing

The global market for radiation-safe additive manufacturing is experiencing significant growth, driven by increasing applications in healthcare, aerospace, and industrial sectors. Current market valuation stands at approximately 2.1 billion USD, with projections indicating a compound annual growth rate of 18.7% through 2028. This robust growth trajectory reflects the expanding adoption of volumetric additive manufacturing technologies across diverse industries.

Healthcare represents the largest market segment, accounting for nearly 42% of the total market share. The demand for radiation-controlled manufacturing processes is particularly strong in medical device production, personalized implants, and radiotherapy equipment manufacturing. Hospitals and medical research institutions are increasingly investing in technologies that enable precise control of radiation exposure during the manufacturing process.

The aerospace and defense sectors collectively constitute the second-largest market segment at 27%. These industries require manufacturing processes that can produce complex components with minimal radiation signatures for sensitive electronic systems and equipment. The ability to control radiation doses during manufacturing directly impacts the longevity and reliability of critical aerospace components.

Regional analysis reveals North America as the dominant market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). The Asia-Pacific region, however, is expected to witness the fastest growth rate of 22.3% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, along with increasing healthcare infrastructure investments.

Consumer demand patterns indicate a growing preference for manufacturing technologies that offer enhanced safety profiles without compromising production efficiency. End-users are increasingly willing to pay premium prices for products manufactured under controlled radiation environments, particularly in medical and consumer electronics applications.

Market challenges include high implementation costs for radiation-controlled manufacturing systems and regulatory complexities across different regions. The average initial investment for a comprehensive radiation-safe volumetric additive manufacturing system ranges from 350,000 to 750,000 USD, creating significant entry barriers for small and medium enterprises.

Emerging market opportunities exist in developing economies where manufacturing sectors are expanding rapidly. Additionally, the growing focus on sustainable manufacturing practices is creating new market segments for radiation-safe technologies that minimize environmental impact while maintaining production quality and safety standards.

Healthcare represents the largest market segment, accounting for nearly 42% of the total market share. The demand for radiation-controlled manufacturing processes is particularly strong in medical device production, personalized implants, and radiotherapy equipment manufacturing. Hospitals and medical research institutions are increasingly investing in technologies that enable precise control of radiation exposure during the manufacturing process.

The aerospace and defense sectors collectively constitute the second-largest market segment at 27%. These industries require manufacturing processes that can produce complex components with minimal radiation signatures for sensitive electronic systems and equipment. The ability to control radiation doses during manufacturing directly impacts the longevity and reliability of critical aerospace components.

Regional analysis reveals North America as the dominant market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). The Asia-Pacific region, however, is expected to witness the fastest growth rate of 22.3% annually, primarily driven by rapid industrialization in China, Japan, and South Korea, along with increasing healthcare infrastructure investments.

Consumer demand patterns indicate a growing preference for manufacturing technologies that offer enhanced safety profiles without compromising production efficiency. End-users are increasingly willing to pay premium prices for products manufactured under controlled radiation environments, particularly in medical and consumer electronics applications.

Market challenges include high implementation costs for radiation-controlled manufacturing systems and regulatory complexities across different regions. The average initial investment for a comprehensive radiation-safe volumetric additive manufacturing system ranges from 350,000 to 750,000 USD, creating significant entry barriers for small and medium enterprises.

Emerging market opportunities exist in developing economies where manufacturing sectors are expanding rapidly. Additionally, the growing focus on sustainable manufacturing practices is creating new market segments for radiation-safe technologies that minimize environmental impact while maintaining production quality and safety standards.

Current Challenges in Volumetric Radiation Exposure

Volumetric Additive Manufacturing (VAM) faces significant challenges in controlling radiation exposure during the manufacturing process. The primary concern stems from the need to balance effective polymerization with minimizing harmful radiation effects on materials, equipment, and operators. Current VAM systems typically utilize high-energy light sources, including UV, visible spectrum, or X-rays, which present inherent safety risks when not properly controlled.

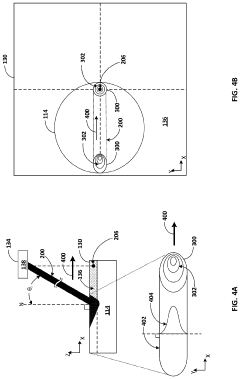

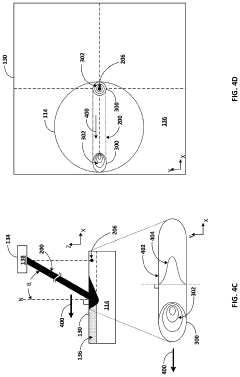

One major challenge is achieving uniform radiation distribution throughout the resin volume. Uneven exposure leads to inconsistent curing, resulting in structural weaknesses, dimensional inaccuracies, and potential part failure. This is particularly problematic in complex geometries where shadowing effects can create under-cured regions despite overall adequate exposure levels.

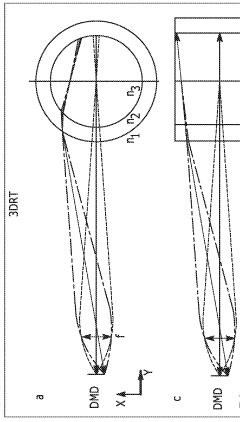

Radiation scattering and absorption phenomena further complicate dose control. As light penetrates the photopolymer resin, its intensity diminishes exponentially with depth due to absorption and scattering effects. This creates a fundamental trade-off between ensuring complete curing at maximum depths versus preventing over-curing at minimum depths. Current computational models struggle to accurately predict these complex light-material interactions across different resin formulations.

Temporal control presents another significant challenge. The dynamic nature of the polymerization process means that radiation requirements change as the material transitions from liquid to solid state. Most current systems lack real-time feedback mechanisms to adjust radiation parameters during printing, resulting in either excessive exposure or incomplete curing.

Heat management during radiation exposure represents a critical concern. High-energy radiation sources generate substantial thermal energy that can distort printed parts, alter material properties, or even damage equipment. Existing cooling systems often prove inadequate for maintaining optimal temperature profiles throughout the build volume, particularly in high-throughput manufacturing scenarios.

From a safety perspective, containing and shielding radiation presents ongoing challenges. While most commercial systems incorporate basic safety features, the increasing power of radiation sources used to accelerate production speeds necessitates more sophisticated containment solutions. Regulatory compliance adds another layer of complexity, with standards varying significantly across different regions and applications.

Material compatibility issues further complicate radiation control. Different photopolymer formulations exhibit varying sensitivity to radiation wavelengths and intensities. This variability makes it difficult to establish standardized exposure protocols, requiring extensive calibration for each new material. The industry currently lacks comprehensive databases correlating material properties with optimal radiation parameters.

One major challenge is achieving uniform radiation distribution throughout the resin volume. Uneven exposure leads to inconsistent curing, resulting in structural weaknesses, dimensional inaccuracies, and potential part failure. This is particularly problematic in complex geometries where shadowing effects can create under-cured regions despite overall adequate exposure levels.

Radiation scattering and absorption phenomena further complicate dose control. As light penetrates the photopolymer resin, its intensity diminishes exponentially with depth due to absorption and scattering effects. This creates a fundamental trade-off between ensuring complete curing at maximum depths versus preventing over-curing at minimum depths. Current computational models struggle to accurately predict these complex light-material interactions across different resin formulations.

Temporal control presents another significant challenge. The dynamic nature of the polymerization process means that radiation requirements change as the material transitions from liquid to solid state. Most current systems lack real-time feedback mechanisms to adjust radiation parameters during printing, resulting in either excessive exposure or incomplete curing.

Heat management during radiation exposure represents a critical concern. High-energy radiation sources generate substantial thermal energy that can distort printed parts, alter material properties, or even damage equipment. Existing cooling systems often prove inadequate for maintaining optimal temperature profiles throughout the build volume, particularly in high-throughput manufacturing scenarios.

From a safety perspective, containing and shielding radiation presents ongoing challenges. While most commercial systems incorporate basic safety features, the increasing power of radiation sources used to accelerate production speeds necessitates more sophisticated containment solutions. Regulatory compliance adds another layer of complexity, with standards varying significantly across different regions and applications.

Material compatibility issues further complicate radiation control. Different photopolymer formulations exhibit varying sensitivity to radiation wavelengths and intensities. This variability makes it difficult to establish standardized exposure protocols, requiring extensive calibration for each new material. The industry currently lacks comprehensive databases correlating material properties with optimal radiation parameters.

Existing Radiation Dose Mitigation Techniques

01 Radiation dose control in volumetric additive manufacturing

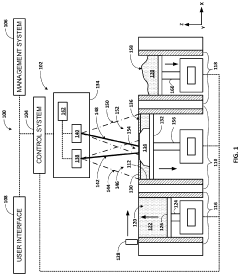

Controlling radiation dose is critical in volumetric additive manufacturing processes to ensure proper curing of materials while preventing overexposure. Advanced systems incorporate dose monitoring and adjustment mechanisms that can modulate radiation intensity based on material properties and desired structural outcomes. These systems often use feedback loops to maintain optimal exposure levels throughout the manufacturing process, resulting in improved part quality and consistency.- Radiation dose control in volumetric additive manufacturing: Controlling radiation dose is critical in volumetric additive manufacturing to ensure precise curing of photopolymers. Systems employ various methods to modulate radiation intensity, exposure time, and spatial distribution to achieve optimal curing while preventing overexposure. Advanced algorithms calculate and adjust radiation parameters based on material properties, desired structural characteristics, and manufacturing requirements, resulting in improved part quality and reduced manufacturing defects.

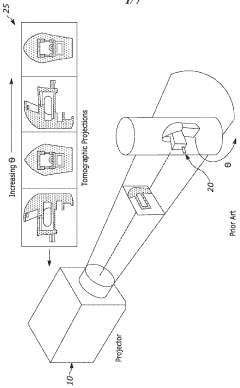

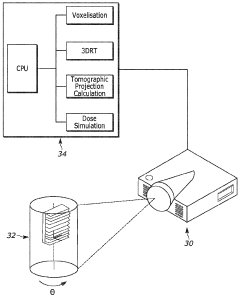

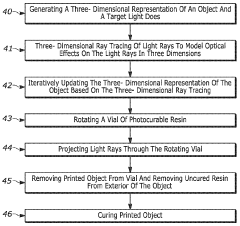

- Tomographic approaches for volumetric manufacturing: Tomographic techniques in volumetric additive manufacturing utilize controlled radiation doses from multiple angles to create three-dimensional structures. These methods project patterned light or other radiation sources into photosensitive resins, with each projection contributing to the overall dose distribution within the volume. By carefully calculating the cumulative radiation dose throughout the material, complex internal structures can be formed simultaneously rather than layer-by-layer, significantly increasing manufacturing speed while maintaining precision.

- Radiation monitoring and feedback systems: Advanced monitoring systems are implemented in volumetric additive manufacturing to measure and adjust radiation doses in real-time. These systems use sensors to detect actual radiation distribution within the build volume and compare it with target values. Feedback mechanisms automatically adjust radiation parameters to compensate for variations in material properties or environmental conditions. This closed-loop approach ensures consistent curing throughout the manufacturing process, improving part quality and reproducibility.

- Material formulations for radiation dose optimization: Specialized photopolymer formulations are developed to respond optimally to specific radiation dose profiles in volumetric manufacturing. These materials contain photoinitiators, inhibitors, and other additives that control the polymerization reaction based on received radiation dose. By engineering materials with precise dose thresholds and curing behaviors, manufacturers can achieve better resolution, mechanical properties, and manufacturing speed. Some formulations also incorporate radiation-absorbing compounds to help shape the dose distribution within the volume.

- Medical applications and radiation dose considerations: Volumetric additive manufacturing techniques are being adapted for medical applications with careful consideration of radiation dose. These applications include the production of patient-specific implants, tissue scaffolds, and anatomical models. When manufacturing medical devices, radiation dose must be precisely controlled to ensure biocompatibility, mechanical properties, and dimensional accuracy. Additionally, some approaches incorporate therapeutic radiation doses directly into the manufacturing process for specialized medical applications.

02 Radiation sources and delivery systems for volumetric manufacturing

Various radiation sources and delivery systems are employed in volumetric additive manufacturing, including UV light, X-rays, and electron beams. These systems are designed to precisely direct radiation to specific volumes within the build material, enabling complex three-dimensional structures to be created. Advanced delivery systems incorporate beam shaping technologies, multi-angle exposure capabilities, and synchronized radiation patterns to achieve desired curing profiles throughout the volume of the material.Expand Specific Solutions03 Photosensitive materials and radiation dose requirements

Specialized photosensitive materials have been developed for volumetric additive manufacturing with specific radiation dose requirements. These materials are formulated to respond to particular wavelengths and intensities of radiation, with carefully calibrated photoinitiators and inhibitors that control the polymerization process. The relationship between radiation dose and material response is critical, with different materials requiring specific exposure parameters to achieve optimal mechanical properties and dimensional accuracy.Expand Specific Solutions04 Computational modeling of radiation dose distribution

Advanced computational models are used to predict and optimize radiation dose distribution in volumetric additive manufacturing. These models account for factors such as light scattering, absorption, and attenuation through the build material, enabling precise control of the curing process. Simulation tools help engineers design optimal exposure strategies that ensure uniform curing throughout complex geometries while minimizing residual stress and maximizing resolution.Expand Specific Solutions05 Medical applications and safety considerations for radiation dose

Volumetric additive manufacturing techniques are increasingly applied in medical contexts, where radiation dose must be carefully managed for both product safety and operator protection. Systems designed for medical applications incorporate additional safeguards to prevent unintended radiation exposure while maintaining precise control over the manufacturing process. Regulatory frameworks govern the acceptable radiation levels for both the manufacturing environment and the final medical products, ensuring patient safety and compliance with healthcare standards.Expand Specific Solutions

Leading Companies in Radiation-Safe Manufacturing

Radiation Dose Control in Volumetric Additive Manufacturing is currently in an early growth phase, with the market expanding as industries recognize its critical importance for safety and quality. The global market is estimated to reach $1.2 billion by 2027, driven by increasing adoption in medical, aerospace, and industrial applications. Technologically, the field shows varying maturity levels across different sectors. Leading players like Siemens Healthineers, Philips, and GE have established advanced radiation control systems for medical applications, while companies such as Stratasys, EOS GmbH, and Concept Laser are integrating sophisticated dose monitoring in industrial additive manufacturing. Research institutions including EPFL and Lawrence Livermore National Laboratory are pioneering next-generation technologies, focusing on real-time monitoring and AI-based optimization systems.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced radiation dose control systems for volumetric additive manufacturing that integrate real-time monitoring with adaptive exposure control. Their technology utilizes proprietary algorithms to dynamically adjust radiation parameters based on material properties and geometry complexity. The system employs a multi-sensor array that continuously monitors radiation distribution across the build volume, enabling precise dose modulation. Philips' solution incorporates predictive modeling that anticipates how different materials respond to radiation exposure, allowing for optimized curing profiles that minimize overall dose while maintaining structural integrity. Their approach includes a closed-loop feedback system that automatically adjusts radiation parameters in response to detected variations, ensuring consistent quality across complex geometries while minimizing unnecessary exposure to sensitive components and operators.

Strengths: Superior integration with medical imaging systems allows for precise radiation control in medical applications. Their extensive experience in healthcare radiation management translates well to manufacturing contexts. Weaknesses: Solutions tend to be premium-priced and may require significant infrastructure investment for full implementation.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has pioneered a comprehensive radiation dose control framework for volumetric additive manufacturing that leverages their extensive expertise in nuclear science and high-energy physics. Their approach utilizes high-precision radiation mapping technology that creates three-dimensional models of radiation distribution throughout the build chamber. The system incorporates specialized shielding designs that selectively direct radiation only where needed, significantly reducing scatter and unnecessary exposure. LLNS has developed proprietary algorithms that optimize radiation delivery patterns based on material properties, geometry complexity, and desired mechanical characteristics. Their technology includes adaptive power modulation that continuously adjusts radiation intensity based on real-time feedback from multiple sensor arrays, ensuring precise energy delivery while minimizing waste and potential damage to surrounding materials or components.

Strengths: Unparalleled expertise in radiation physics and materials science enables highly sophisticated control systems. Their solutions offer exceptional precision for critical applications requiring strict radiation management. Weaknesses: Technologies often require specialized knowledge to implement effectively and may have higher initial costs compared to commercial alternatives.

Key Patents in Radiation Shielding Technology

Method of volumetric additive manufacturing via 3D ray-tracing dose optimization

PatentWO2024069276A1

Innovation

- A method utilizing three-dimensional ray-tracing to compute and optimize light doses by accounting for refraction, absorption, etendue, and non-telecentricity, allowing for accurate modeling of light rays in all dimensions, enabling improved print fidelity without additional hardware costs.

Controlling irradiation parameters of an additive manufacturing machine

PatentActiveUS20220080662A1

Innovation

- The implementation of an irradiation control model that determines optimal irradiation settings based on power density factors and irradiation vector factors, allowing for precise control of energy beam parameters like beam power, spot size, and scanning velocity to improve the melting and sintering behavior of the powder bed.

Safety Standards and Regulatory Compliance

Volumetric Additive Manufacturing (VAM) operates within a complex regulatory landscape that requires strict adherence to radiation safety standards. The International Commission on Radiological Protection (ICRP) provides foundational guidelines for radiation protection, establishing the principles of justification, optimization, and dose limitation that govern VAM operations. These principles ensure that radiation exposure is kept As Low As Reasonably Achievable (ALARA), a concept central to radiation safety management in manufacturing environments.

The International Atomic Energy Agency (IAEA) further codifies these principles through its Basic Safety Standards, which have been adopted by numerous countries for national regulatory frameworks. In the United States, the Nuclear Regulatory Commission (NRC) and Occupational Safety and Health Administration (OSHA) jointly oversee radiation safety in industrial applications, including VAM. OSHA standard 29 CFR 1910.1096 specifically addresses occupational radiation exposure limits, requiring comprehensive monitoring programs and protective measures.

European regulations, particularly EU Directive 2013/59/Euratom, establish harmonized safety standards for protection against ionizing radiation, with specific provisions for industrial applications. These regulations mandate regular equipment calibration, worker training, and environmental monitoring to prevent radiation leakage beyond controlled areas.

Industry-specific standards such as ISO 15609 for radiation protection in manufacturing environments provide detailed technical specifications for shielding design, interlocking safety systems, and emergency protocols. The American Society for Testing and Materials (ASTM) has developed F3303, a standard specifically addressing radiation safety in additive manufacturing processes, which outlines requirements for equipment design, operation procedures, and quality assurance.

Compliance verification involves regular third-party inspections, dosimetry monitoring, and documentation of radiation exposure records. Manufacturers must implement Radiation Protection Programs (RPPs) that include risk assessments, standard operating procedures, and emergency response plans. These programs must be regularly updated to reflect technological advancements and regulatory changes.

Emerging trends in regulatory compliance include the development of real-time monitoring systems that provide immediate feedback on radiation levels, allowing for dynamic adjustment of manufacturing parameters to maintain safety thresholds. Additionally, international harmonization efforts are underway to standardize radiation safety requirements across different jurisdictions, facilitating global adoption of VAM technologies while ensuring consistent safety standards.

The integration of radiation safety management systems with overall quality management frameworks represents another significant development, enabling manufacturers to address radiation safety as part of their comprehensive risk management approach rather than as an isolated compliance requirement.

The International Atomic Energy Agency (IAEA) further codifies these principles through its Basic Safety Standards, which have been adopted by numerous countries for national regulatory frameworks. In the United States, the Nuclear Regulatory Commission (NRC) and Occupational Safety and Health Administration (OSHA) jointly oversee radiation safety in industrial applications, including VAM. OSHA standard 29 CFR 1910.1096 specifically addresses occupational radiation exposure limits, requiring comprehensive monitoring programs and protective measures.

European regulations, particularly EU Directive 2013/59/Euratom, establish harmonized safety standards for protection against ionizing radiation, with specific provisions for industrial applications. These regulations mandate regular equipment calibration, worker training, and environmental monitoring to prevent radiation leakage beyond controlled areas.

Industry-specific standards such as ISO 15609 for radiation protection in manufacturing environments provide detailed technical specifications for shielding design, interlocking safety systems, and emergency protocols. The American Society for Testing and Materials (ASTM) has developed F3303, a standard specifically addressing radiation safety in additive manufacturing processes, which outlines requirements for equipment design, operation procedures, and quality assurance.

Compliance verification involves regular third-party inspections, dosimetry monitoring, and documentation of radiation exposure records. Manufacturers must implement Radiation Protection Programs (RPPs) that include risk assessments, standard operating procedures, and emergency response plans. These programs must be regularly updated to reflect technological advancements and regulatory changes.

Emerging trends in regulatory compliance include the development of real-time monitoring systems that provide immediate feedback on radiation levels, allowing for dynamic adjustment of manufacturing parameters to maintain safety thresholds. Additionally, international harmonization efforts are underway to standardize radiation safety requirements across different jurisdictions, facilitating global adoption of VAM technologies while ensuring consistent safety standards.

The integration of radiation safety management systems with overall quality management frameworks represents another significant development, enabling manufacturers to address radiation safety as part of their comprehensive risk management approach rather than as an isolated compliance requirement.

Material Science Advancements for Radiation Control

Recent advancements in material science have significantly contributed to radiation dose control in volumetric additive manufacturing. The development of novel photopolymers with tailored photoinitiator systems has enabled more precise control over the polymerization process, allowing manufacturers to achieve desired mechanical properties while minimizing radiation exposure. These materials incorporate specialized additives that can modulate light absorption and scattering properties, effectively controlling the depth and lateral spread of radiation during the manufacturing process.

Radiation-responsive smart materials represent another breakthrough in this field. These materials change their physical or chemical properties in response to specific radiation doses, creating a self-regulating mechanism that can prevent overexposure. For instance, some photopolymers incorporate chromophores that undergo reversible or irreversible color changes at predetermined radiation thresholds, providing visual indicators of cumulative exposure levels during the manufacturing process.

Nanocomposite materials have emerged as particularly promising for radiation control applications. By incorporating nanoparticles with specific radiation-absorbing or radiation-shielding properties into the base resin, researchers have created materials that can selectively attenuate certain wavelengths while allowing others to pass through. This wavelength-specific control enables more precise energy deposition patterns and reduces scattered radiation that could affect adjacent volumes.

The integration of quantum dots and rare earth elements into photocurable resins has opened new possibilities for radiation management. These elements can convert harmful high-energy radiation into more benign forms or redirect energy through processes like up-conversion or down-conversion. This not only protects surrounding materials but also improves energy efficiency in the manufacturing process by utilizing wavelengths that would otherwise be wasted.

Biomimetic approaches have also influenced material design for radiation control. Materials inspired by natural radiation-resistant organisms incorporate structural and chemical features that dissipate or neutralize radiation effects. For example, melanin-inspired polymers demonstrate exceptional radiation-absorbing properties while maintaining structural integrity under exposure conditions that would degrade conventional materials.

Multi-functional materials that combine radiation control with other desirable properties represent the cutting edge of current research. These materials simultaneously address radiation dose management while enhancing mechanical strength, thermal stability, or post-processing capabilities. The development of such materials requires sophisticated molecular engineering approaches but offers significant advantages in terms of manufacturing efficiency and product performance.

Radiation-responsive smart materials represent another breakthrough in this field. These materials change their physical or chemical properties in response to specific radiation doses, creating a self-regulating mechanism that can prevent overexposure. For instance, some photopolymers incorporate chromophores that undergo reversible or irreversible color changes at predetermined radiation thresholds, providing visual indicators of cumulative exposure levels during the manufacturing process.

Nanocomposite materials have emerged as particularly promising for radiation control applications. By incorporating nanoparticles with specific radiation-absorbing or radiation-shielding properties into the base resin, researchers have created materials that can selectively attenuate certain wavelengths while allowing others to pass through. This wavelength-specific control enables more precise energy deposition patterns and reduces scattered radiation that could affect adjacent volumes.

The integration of quantum dots and rare earth elements into photocurable resins has opened new possibilities for radiation management. These elements can convert harmful high-energy radiation into more benign forms or redirect energy through processes like up-conversion or down-conversion. This not only protects surrounding materials but also improves energy efficiency in the manufacturing process by utilizing wavelengths that would otherwise be wasted.

Biomimetic approaches have also influenced material design for radiation control. Materials inspired by natural radiation-resistant organisms incorporate structural and chemical features that dissipate or neutralize radiation effects. For example, melanin-inspired polymers demonstrate exceptional radiation-absorbing properties while maintaining structural integrity under exposure conditions that would degrade conventional materials.

Multi-functional materials that combine radiation control with other desirable properties represent the cutting edge of current research. These materials simultaneously address radiation dose management while enhancing mechanical strength, thermal stability, or post-processing capabilities. The development of such materials requires sophisticated molecular engineering approaches but offers significant advantages in terms of manufacturing efficiency and product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!