Multi-Scale Printing Capabilities In Volumetric Additive Manufacturing

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric AM Multi-Scale Printing Background & Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in 3D printing technology, moving beyond traditional layer-by-layer approaches to simultaneous whole-volume solidification. The evolution of this technology began with early photopolymerization experiments in the 1990s but gained significant momentum only in the past decade with advancements in computational tomography and light projection systems. The trajectory of VAM development has been characterized by increasing precision, speed, and material versatility, with recent breakthroughs in multi-material capabilities.

Multi-scale printing within VAM refers to the ability to create structures with features spanning multiple size scales simultaneously—from nanometers to centimeters—within a single manufacturing process. This capability represents a critical frontier in additive manufacturing, as conventional techniques typically face a fundamental trade-off between resolution and build volume. The historical development of multi-scale capabilities has progressed from single-resolution systems to the current emerging technologies that can dynamically adjust feature resolution across different regions of a printed object.

The primary technical objective in advancing multi-scale VAM capabilities is to develop systems that can seamlessly transition between macro, micro, and nano-scale features without compromising structural integrity or manufacturing efficiency. This includes creating projection systems with variable resolution capabilities, developing computational algorithms that can optimize light patterns for multi-scale features, and formulating photopolymer resins that respond consistently across different energy densities and exposure times.

Current research aims to achieve feature sizes ranging from 10μm to 10cm within a single print, with positional accuracy maintained across all scales. Additional objectives include reducing the total volumetric manufacturing time to under 60 seconds for complex multi-scale objects and expanding the material palette to include functional materials with specific mechanical, electrical, or biological properties.

The long-term technological trajectory points toward integrated systems that combine multiple light sources operating at different wavelengths and intensities, synchronized through advanced computational models that account for light scattering, absorption, and polymerization kinetics across varying length scales. This development is expected to enable unprecedented capabilities in fields requiring complex hierarchical structures, such as tissue engineering, microfluidics, metamaterials, and next-generation electronics.

The ultimate goal of multi-scale VAM research is to establish a manufacturing platform that eliminates the traditional constraints of additive manufacturing, allowing designers and engineers to create objects where feature size is determined solely by functional requirements rather than technological limitations.

Multi-scale printing within VAM refers to the ability to create structures with features spanning multiple size scales simultaneously—from nanometers to centimeters—within a single manufacturing process. This capability represents a critical frontier in additive manufacturing, as conventional techniques typically face a fundamental trade-off between resolution and build volume. The historical development of multi-scale capabilities has progressed from single-resolution systems to the current emerging technologies that can dynamically adjust feature resolution across different regions of a printed object.

The primary technical objective in advancing multi-scale VAM capabilities is to develop systems that can seamlessly transition between macro, micro, and nano-scale features without compromising structural integrity or manufacturing efficiency. This includes creating projection systems with variable resolution capabilities, developing computational algorithms that can optimize light patterns for multi-scale features, and formulating photopolymer resins that respond consistently across different energy densities and exposure times.

Current research aims to achieve feature sizes ranging from 10μm to 10cm within a single print, with positional accuracy maintained across all scales. Additional objectives include reducing the total volumetric manufacturing time to under 60 seconds for complex multi-scale objects and expanding the material palette to include functional materials with specific mechanical, electrical, or biological properties.

The long-term technological trajectory points toward integrated systems that combine multiple light sources operating at different wavelengths and intensities, synchronized through advanced computational models that account for light scattering, absorption, and polymerization kinetics across varying length scales. This development is expected to enable unprecedented capabilities in fields requiring complex hierarchical structures, such as tissue engineering, microfluidics, metamaterials, and next-generation electronics.

The ultimate goal of multi-scale VAM research is to establish a manufacturing platform that eliminates the traditional constraints of additive manufacturing, allowing designers and engineers to create objects where feature size is determined solely by functional requirements rather than technological limitations.

Market Analysis for Multi-Scale Volumetric Manufacturing

The volumetric additive manufacturing (VAM) market is experiencing significant growth, driven by increasing demand for high-precision, multi-scale manufacturing capabilities across various industries. Current market projections indicate that the global VAM market is expected to grow at a compound annual growth rate of 25-30% over the next five years, potentially reaching a market value of several billion dollars by 2028.

The healthcare sector represents the largest market segment for multi-scale volumetric manufacturing, accounting for approximately 40% of the total market share. This dominance is attributed to the growing need for customized medical implants, tissue engineering scaffolds, and drug delivery systems that require precise control at multiple scales. The ability to create structures with both macro and micro features simultaneously addresses critical needs in personalized medicine.

Industrial manufacturing constitutes the second-largest market segment at roughly 30%, with aerospace, automotive, and consumer electronics companies increasingly adopting multi-scale VAM technologies to produce complex components with enhanced functional properties. These industries value the technology's ability to create parts with optimized internal structures that would be impossible to manufacture using traditional methods.

Regional analysis reveals North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years due to substantial investments in advanced manufacturing technologies by countries like China, Japan, and South Korea.

Market adoption is primarily driven by several key factors: reduced production time compared to traditional layer-by-layer additive manufacturing, ability to create complex multi-material structures, and elimination of support structures during printing. These advantages translate to cost savings of 15-40% depending on application complexity and production volume.

Customer surveys indicate that key purchasing considerations include resolution capabilities across different scales, material compatibility, production speed, and total cost of ownership. End-users are particularly interested in systems that can seamlessly transition between macro, micro, and nano-scale features without compromising structural integrity or surface quality.

Market challenges include the high initial investment cost for multi-scale VAM systems, limited material selection compared to conventional manufacturing methods, and technical barriers related to process control and quality assurance. Despite these challenges, the market is expected to continue expanding as technological advancements address current limitations and new applications emerge across various industries.

The healthcare sector represents the largest market segment for multi-scale volumetric manufacturing, accounting for approximately 40% of the total market share. This dominance is attributed to the growing need for customized medical implants, tissue engineering scaffolds, and drug delivery systems that require precise control at multiple scales. The ability to create structures with both macro and micro features simultaneously addresses critical needs in personalized medicine.

Industrial manufacturing constitutes the second-largest market segment at roughly 30%, with aerospace, automotive, and consumer electronics companies increasingly adopting multi-scale VAM technologies to produce complex components with enhanced functional properties. These industries value the technology's ability to create parts with optimized internal structures that would be impossible to manufacture using traditional methods.

Regional analysis reveals North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years due to substantial investments in advanced manufacturing technologies by countries like China, Japan, and South Korea.

Market adoption is primarily driven by several key factors: reduced production time compared to traditional layer-by-layer additive manufacturing, ability to create complex multi-material structures, and elimination of support structures during printing. These advantages translate to cost savings of 15-40% depending on application complexity and production volume.

Customer surveys indicate that key purchasing considerations include resolution capabilities across different scales, material compatibility, production speed, and total cost of ownership. End-users are particularly interested in systems that can seamlessly transition between macro, micro, and nano-scale features without compromising structural integrity or surface quality.

Market challenges include the high initial investment cost for multi-scale VAM systems, limited material selection compared to conventional manufacturing methods, and technical barriers related to process control and quality assurance. Despite these challenges, the market is expected to continue expanding as technological advancements address current limitations and new applications emerge across various industries.

Technical Challenges in Multi-Scale Volumetric Printing

Volumetric Additive Manufacturing (VAM) faces significant technical challenges when implementing multi-scale printing capabilities. The fundamental issue stems from the inherent trade-off between resolution and build volume in current VAM systems. While conventional VAM can achieve rapid production speeds by simultaneously solidifying an entire volume of photopolymer resin, maintaining consistent resolution across different scales remains problematic.

The primary technical hurdle involves optical limitations in the projection systems. When attempting to print features at multiple scales simultaneously, diffraction limits and optical aberrations create inconsistencies in energy distribution. This results in varying degrees of polymerization across the build volume, leading to structural inconsistencies and dimensional inaccuracies in the final printed parts.

Material response heterogeneity presents another significant challenge. Photopolymer resins exhibit different curing behaviors depending on the energy dose received, which varies with feature size and location within the build volume. This variation becomes more pronounced when attempting to print both micro and macro features simultaneously, as the optimal exposure parameters differ substantially between these scales.

Computational complexity exponentially increases with multi-scale capabilities. The algorithms required to generate appropriate light patterns must account for varying feature sizes, material properties, and optical effects throughout the volume. Current computational methods struggle to efficiently process the massive datasets needed for high-resolution multi-scale volumetric printing, creating bottlenecks in the workflow.

Heat management during the printing process presents additional complications. The exothermic nature of photopolymerization reactions can lead to thermal gradients within the resin volume, particularly when printing features of vastly different sizes. These thermal variations affect curing kinetics and can cause warping, internal stresses, or even part failure in multi-scale prints.

Calibration and validation methodologies for multi-scale VAM systems remain underdeveloped. Traditional metrology techniques are often insufficient for simultaneously assessing both microscale and macroscale features within a single printed part. This makes quality control and process optimization particularly challenging for multi-scale applications.

The integration of multi-material capabilities with multi-scale printing compounds these challenges further. Different materials may require distinct processing parameters, and ensuring proper interface formation between materials at varying scales introduces additional complexity to an already demanding technical landscape.

The primary technical hurdle involves optical limitations in the projection systems. When attempting to print features at multiple scales simultaneously, diffraction limits and optical aberrations create inconsistencies in energy distribution. This results in varying degrees of polymerization across the build volume, leading to structural inconsistencies and dimensional inaccuracies in the final printed parts.

Material response heterogeneity presents another significant challenge. Photopolymer resins exhibit different curing behaviors depending on the energy dose received, which varies with feature size and location within the build volume. This variation becomes more pronounced when attempting to print both micro and macro features simultaneously, as the optimal exposure parameters differ substantially between these scales.

Computational complexity exponentially increases with multi-scale capabilities. The algorithms required to generate appropriate light patterns must account for varying feature sizes, material properties, and optical effects throughout the volume. Current computational methods struggle to efficiently process the massive datasets needed for high-resolution multi-scale volumetric printing, creating bottlenecks in the workflow.

Heat management during the printing process presents additional complications. The exothermic nature of photopolymerization reactions can lead to thermal gradients within the resin volume, particularly when printing features of vastly different sizes. These thermal variations affect curing kinetics and can cause warping, internal stresses, or even part failure in multi-scale prints.

Calibration and validation methodologies for multi-scale VAM systems remain underdeveloped. Traditional metrology techniques are often insufficient for simultaneously assessing both microscale and macroscale features within a single printed part. This makes quality control and process optimization particularly challenging for multi-scale applications.

The integration of multi-material capabilities with multi-scale printing compounds these challenges further. Different materials may require distinct processing parameters, and ensuring proper interface formation between materials at varying scales introduces additional complexity to an already demanding technical landscape.

Current Multi-Scale Printing Methodologies

01 Multi-scale printing techniques in volumetric additive manufacturing

Volumetric additive manufacturing technologies enable multi-scale printing capabilities by utilizing advanced optical systems and materials. These techniques allow for the simultaneous fabrication of features at different scales within a single build process, from microscale precision components to macroscale structures. The multi-scale approach combines high-resolution features with larger structural elements, enabling complex geometries that would be difficult to achieve with traditional layer-by-layer methods.- Multi-scale printing techniques in volumetric additive manufacturing: Volumetric additive manufacturing technologies enable multi-scale printing capabilities through advanced projection and material curing methods. These techniques allow for the creation of structures with features spanning multiple size scales, from nanometers to centimeters, in a single manufacturing process. By controlling light patterns and material properties, manufacturers can achieve precise control over structural details at different scales, enabling the production of complex hierarchical structures with tailored mechanical and functional properties.

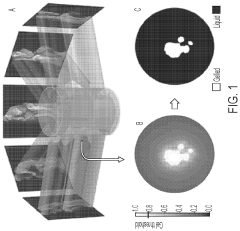

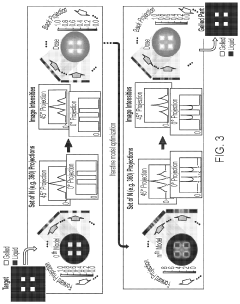

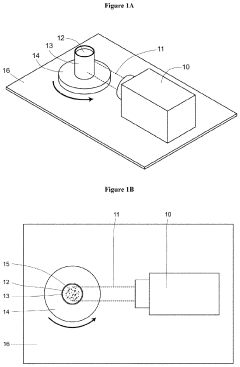

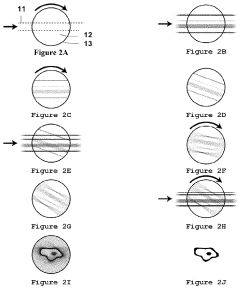

- Light-based volumetric printing systems: Advanced light-based systems for volumetric additive manufacturing utilize specialized optics and photosensitive materials to create three-dimensional objects through controlled photopolymerization. These systems employ techniques such as computed axial lithography, holographic projection, and tomographic reconstruction to cure entire volumes simultaneously rather than layer-by-layer. This approach enables significantly faster production times compared to traditional additive manufacturing methods while maintaining the ability to create complex internal structures and varying feature sizes within a single print.

- Materials and formulations for multi-scale volumetric printing: Specialized photopolymer formulations have been developed specifically for volumetric additive manufacturing with multi-scale capabilities. These materials incorporate photoinitiators with tailored absorption profiles, light-blocking agents for controlled depth penetration, and additives that enhance resolution across different feature sizes. Some formulations include nanoparticles or other functional materials that can be precisely positioned within the printed structure, enabling the creation of objects with spatially varying mechanical, optical, or electrical properties at multiple scales.

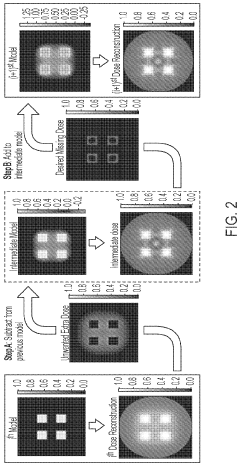

- Computational methods for multi-scale volumetric manufacturing: Advanced computational algorithms are essential for achieving multi-scale printing capabilities in volumetric additive manufacturing. These include specialized slicing algorithms, tomographic reconstruction methods, and physics-based simulations that account for light scattering, absorption, and material curing kinetics. Machine learning approaches have been integrated to optimize light patterns and exposure parameters for different feature sizes within the same build. These computational methods enable the translation of complex multi-scale digital designs into physical objects with high fidelity across all size scales.

- Applications and industrial implementation of multi-scale volumetric manufacturing: Multi-scale volumetric additive manufacturing has found applications across various industries including medical devices, microfluidics, optical components, and advanced materials. The ability to create hierarchical structures with features spanning multiple size scales enables the production of functional devices with optimized performance characteristics. Industrial implementations focus on scaling these technologies for higher throughput while maintaining precision across all feature sizes. Recent developments include hybrid systems that combine volumetric approaches with traditional manufacturing methods to leverage the advantages of each technique for specific applications.

02 Light-based volumetric printing systems

Advanced light-based systems for volumetric additive manufacturing utilize specialized light sources, projection techniques, and photosensitive materials to create three-dimensional objects. These systems employ technologies such as computed axial lithography, holographic projection, or multi-beam interference patterns to cure entire volumes of photopolymer resins simultaneously. This approach enables faster production speeds compared to traditional layer-by-layer methods while maintaining precision across multiple scales.Expand Specific Solutions03 Materials and formulations for multi-scale volumetric printing

Specialized materials and formulations have been developed specifically for volumetric additive manufacturing with multi-scale capabilities. These include photopolymer resins with tailored viscosity, curing kinetics, and optical properties that enable precise control over the solidification process throughout the volume. Advanced additives and nanoparticles can be incorporated to enhance mechanical properties, resolution capabilities, and functional characteristics of the printed structures across different scale ranges.Expand Specific Solutions04 Computational methods for volumetric manufacturing

Sophisticated computational methods are essential for volumetric additive manufacturing with multi-scale capabilities. These include advanced algorithms for tomographic reconstruction, holographic pattern generation, and multi-physics simulations that account for light propagation, material response, and thermal effects. Machine learning approaches optimize printing parameters and predict material behavior during the volumetric fabrication process, enabling precise control over features at different scales simultaneously.Expand Specific Solutions05 Applications and integration of multi-scale volumetric printing

Multi-scale volumetric additive manufacturing enables novel applications across various industries including medical devices, microfluidics, optical components, and advanced materials. The technology allows for the creation of hierarchical structures with functional features at different scales, such as microchannels within larger frameworks or gradient materials with varying properties. Integration with other manufacturing processes and digital workflows enhances the versatility and adoption of volumetric printing for complex, multi-functional components.Expand Specific Solutions

Leading Companies in Multi-Scale Volumetric Printing

Volumetric Additive Manufacturing (VAM) with multi-scale printing capabilities is currently in an early growth phase, with the market expected to expand significantly as the technology matures. The global market is projected to reach substantial value as industries recognize VAM's potential for creating complex structures with varying feature sizes. Leading research institutions like École Polytechnique Fédérale de Lausanne and Lawrence Livermore National Laboratory are pioneering fundamental research, while companies such as Readily3D, OPT Industries, and Divergent Technologies are commercializing applications. Established manufacturers including HP, Stratasys, and GE are integrating multi-scale capabilities into their portfolios. Universities in China (Huazhong University of Science & Technology, Wuhan University) are rapidly advancing research, suggesting a competitive global landscape emerging across academic and industrial sectors.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed advanced volumetric additive manufacturing (VAM) technology that enables multi-scale printing capabilities through their tomographic volumetric additive manufacturing approach. Their system uses synchronized illumination from multiple angles to create complex 3D structures in photosensitive resins within seconds. The technology achieves multi-scale printing by employing digital light processing (DLP) projectors with variable focal lengths and resolution settings, allowing for the creation of structures with features ranging from micrometers to centimeters in a single build. EPFL researchers have demonstrated the ability to print objects with internal features as small as 80 micrometers while maintaining overall structural dimensions of several centimeters. Their approach incorporates computational optimization of light dose distribution to ensure uniform curing throughout the volume, addressing one of the key challenges in volumetric printing across different scales.

Strengths: Extremely fast printing speeds (seconds vs. hours for traditional methods); ability to create complex internal structures without support materials; excellent resolution across varying feature sizes. Weaknesses: Limited material compatibility compared to conventional methods; challenges in achieving consistent mechanical properties across multi-scale features; relatively small build volumes compared to some industrial systems.

Lawrence Livermore National Security LLC

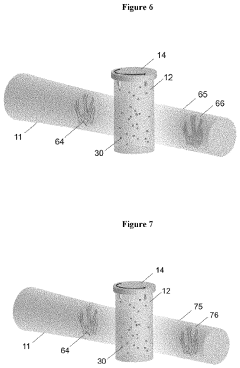

Technical Solution: Lawrence Livermore National Laboratory (LLNL) has pioneered Computed Axial Lithography (CAL) for volumetric additive manufacturing with multi-scale capabilities. Their approach uses synchronized rotation of photosensitive resin while projecting calculated light patterns to solidify specific regions within the volume simultaneously. LLNL's technology achieves multi-scale printing through sophisticated algorithms that optimize light delivery based on the desired feature resolution, enabling the creation of structures with both macro and micro features in a single process. The system incorporates advanced optics with variable focal lengths and projection patterns that can be dynamically adjusted during the printing process. This allows for precise control over feature resolution ranging from 100 micrometers to several centimeters. LLNL has demonstrated the ability to print complex biomedical devices, microfluidic systems, and engineering components with varying feature sizes and mechanical properties within a single build volume.

Strengths: Exceptional speed (printing entire volumes in under a minute); ability to create objects with complex internal geometries impossible with layer-by-layer methods; excellent resolution control across different feature scales. Weaknesses: Current material limitations primarily focused on photopolymers; challenges in scaling to very large build volumes; potential issues with optical distortion affecting precision at extreme size differences.

Key Patents in Multi-Scale Volumetric Manufacturing

Systems and methods for improved volumetric additive manufacturing

PatentPendingUS20240217180A1

Innovation

- An algebraic object-space optimization algorithm that directly optimizes image computation for VAM, allowing for improved reconstruction fidelity, simplicity, and flexibility, and enabling new printing geometries and materials like Grayscale VAM, which controls polymeric conversion throughout a printed part.

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentPendingUS20220274326A1

Innovation

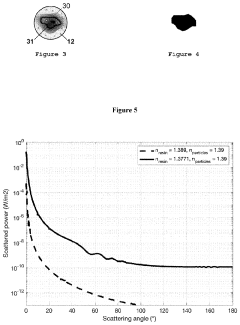

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1000 nm, to reduce light scattering and improve the accuracy of three-dimensional object formation by creating a controlled three-dimensional dose distribution.

Materials Compatibility and Development Roadmap

The compatibility of materials with volumetric additive manufacturing (VAM) processes represents a critical factor in the technology's widespread adoption and application versatility. Currently, VAM primarily utilizes photopolymerizable resins that can be selectively cured through light-based processes. These materials must possess specific optical properties to enable controlled solidification at precise spatial coordinates within the volume.

The existing material palette for VAM includes acrylate-based resins, thiol-ene systems, and specialized formulations containing photoinitiators sensitive to specific wavelengths. However, this limited range presents significant constraints for industrial applications requiring diverse material properties. The development of new compatible materials necessitates a systematic approach addressing both photochemical reactivity and final mechanical properties.

A strategic materials development roadmap for multi-scale VAM should focus on expanding the material library while maintaining compatibility with volumetric printing processes. Short-term goals (1-2 years) include optimizing existing photopolymer formulations to improve resolution at different scales and enhancing mechanical properties through additives and reinforcement strategies. This phase should also explore hybrid materials that combine organic photopolymers with inorganic components to expand the functional property range.

Mid-term objectives (3-5 years) should target the development of multi-material capabilities, enabling the simultaneous printing of different materials with varying properties within a single build volume. This advancement would significantly enhance the technology's application scope, particularly for complex functional devices requiring gradient properties or distinct material domains at different scales.

Long-term research directions (5+ years) should focus on developing completely new material classes compatible with VAM processes. These include stimuli-responsive materials that can change properties post-printing, biodegradable formulations for medical applications, and high-performance engineering materials that can rival traditional manufacturing materials in strength and durability while maintaining printability across multiple scales.

The materials development roadmap must also address characterization and standardization challenges. As new materials emerge, comprehensive testing protocols must be established to evaluate their performance across different scale regimes within the VAM process. This includes developing methods to assess resolution capabilities, mechanical properties, and long-term stability at both macro and micro scales within the same printed structure.

Collaborative efforts between material scientists, chemical engineers, and manufacturing specialists will be essential to accelerate this development timeline. Industry-academic partnerships should be fostered to combine fundamental research with practical application requirements, ensuring that material innovations directly address market needs while enabling the full potential of multi-scale volumetric manufacturing.

The existing material palette for VAM includes acrylate-based resins, thiol-ene systems, and specialized formulations containing photoinitiators sensitive to specific wavelengths. However, this limited range presents significant constraints for industrial applications requiring diverse material properties. The development of new compatible materials necessitates a systematic approach addressing both photochemical reactivity and final mechanical properties.

A strategic materials development roadmap for multi-scale VAM should focus on expanding the material library while maintaining compatibility with volumetric printing processes. Short-term goals (1-2 years) include optimizing existing photopolymer formulations to improve resolution at different scales and enhancing mechanical properties through additives and reinforcement strategies. This phase should also explore hybrid materials that combine organic photopolymers with inorganic components to expand the functional property range.

Mid-term objectives (3-5 years) should target the development of multi-material capabilities, enabling the simultaneous printing of different materials with varying properties within a single build volume. This advancement would significantly enhance the technology's application scope, particularly for complex functional devices requiring gradient properties or distinct material domains at different scales.

Long-term research directions (5+ years) should focus on developing completely new material classes compatible with VAM processes. These include stimuli-responsive materials that can change properties post-printing, biodegradable formulations for medical applications, and high-performance engineering materials that can rival traditional manufacturing materials in strength and durability while maintaining printability across multiple scales.

The materials development roadmap must also address characterization and standardization challenges. As new materials emerge, comprehensive testing protocols must be established to evaluate their performance across different scale regimes within the VAM process. This includes developing methods to assess resolution capabilities, mechanical properties, and long-term stability at both macro and micro scales within the same printed structure.

Collaborative efforts between material scientists, chemical engineers, and manufacturing specialists will be essential to accelerate this development timeline. Industry-academic partnerships should be fostered to combine fundamental research with practical application requirements, ensuring that material innovations directly address market needs while enabling the full potential of multi-scale volumetric manufacturing.

Sustainability Aspects of Volumetric Manufacturing

Volumetric Additive Manufacturing (VAM) represents a significant advancement in sustainable manufacturing practices compared to traditional manufacturing methods and conventional layer-by-layer 3D printing. The sustainability advantages of VAM stem primarily from its material efficiency, energy consumption patterns, and production workflow optimization.

Material utilization in VAM demonstrates remarkable efficiency, with significantly reduced waste compared to subtractive manufacturing techniques. Unlike traditional methods that can waste up to 90% of raw materials through cutting and machining, VAM's volumetric approach enables near-complete material utilization, with minimal support structures required and substantially reduced post-processing waste. This efficiency extends to multi-scale printing capabilities, where precise material deposition across varying scales minimizes excess material usage.

Energy consumption represents another critical sustainability dimension where VAM excels. The simultaneous solidification process employed in volumetric manufacturing requires substantially less energy than layer-by-layer approaches that demand repeated heating and cooling cycles. Studies indicate energy savings of 30-50% compared to conventional additive manufacturing techniques, with multi-scale capabilities further optimizing energy usage by enabling appropriately scaled energy application based on feature requirements.

Production lifecycle considerations also favor VAM from a sustainability perspective. The technology enables significant reductions in production time—often by factors of 10-100x compared to traditional additive manufacturing—resulting in lower overall energy consumption per part. Additionally, the simplified workflow reduces the need for environmentally harmful cleaning agents and post-processing chemicals often required in conventional manufacturing.

The environmental footprint of VAM is further reduced through its compatibility with bio-based and recyclable resins. Recent research demonstrates successful implementation of biodegradable polymers in volumetric manufacturing processes, creating pathways for more environmentally responsible end-of-life scenarios for manufactured parts. Multi-scale printing capabilities enhance this advantage by enabling optimized material distribution and structural designs that maintain performance while reducing overall material requirements.

Looking forward, the sustainability potential of VAM appears promising as the technology continues to mature. Current research focuses on expanding material compatibility to include more eco-friendly options, developing closed-loop material recycling systems specifically for volumetric manufacturing, and optimizing energy delivery systems to further reduce consumption. The integration of multi-scale printing capabilities within these sustainability initiatives represents a particularly promising direction, potentially enabling unprecedented resource efficiency across diverse manufacturing applications.

Material utilization in VAM demonstrates remarkable efficiency, with significantly reduced waste compared to subtractive manufacturing techniques. Unlike traditional methods that can waste up to 90% of raw materials through cutting and machining, VAM's volumetric approach enables near-complete material utilization, with minimal support structures required and substantially reduced post-processing waste. This efficiency extends to multi-scale printing capabilities, where precise material deposition across varying scales minimizes excess material usage.

Energy consumption represents another critical sustainability dimension where VAM excels. The simultaneous solidification process employed in volumetric manufacturing requires substantially less energy than layer-by-layer approaches that demand repeated heating and cooling cycles. Studies indicate energy savings of 30-50% compared to conventional additive manufacturing techniques, with multi-scale capabilities further optimizing energy usage by enabling appropriately scaled energy application based on feature requirements.

Production lifecycle considerations also favor VAM from a sustainability perspective. The technology enables significant reductions in production time—often by factors of 10-100x compared to traditional additive manufacturing—resulting in lower overall energy consumption per part. Additionally, the simplified workflow reduces the need for environmentally harmful cleaning agents and post-processing chemicals often required in conventional manufacturing.

The environmental footprint of VAM is further reduced through its compatibility with bio-based and recyclable resins. Recent research demonstrates successful implementation of biodegradable polymers in volumetric manufacturing processes, creating pathways for more environmentally responsible end-of-life scenarios for manufactured parts. Multi-scale printing capabilities enhance this advantage by enabling optimized material distribution and structural designs that maintain performance while reducing overall material requirements.

Looking forward, the sustainability potential of VAM appears promising as the technology continues to mature. Current research focuses on expanding material compatibility to include more eco-friendly options, developing closed-loop material recycling systems specifically for volumetric manufacturing, and optimizing energy delivery systems to further reduce consumption. The integration of multi-scale printing capabilities within these sustainability initiatives represents a particularly promising direction, potentially enabling unprecedented resource efficiency across diverse manufacturing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!