Decane's Integration in Bioinspired Material Production

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Bioinspiration Goals

The integration of decane in bioinspired material production represents a significant frontier in the field of biomimetics and sustainable materials engineering. This research direction aims to harness the unique properties of decane, a hydrocarbon compound, to develop innovative materials that mimic natural structures and functions. The primary goal is to create advanced materials with enhanced performance, sustainability, and adaptability by incorporating decane into bioinspired design processes.

One of the key objectives is to explore decane's potential in creating self-healing materials. By leveraging decane's molecular structure and behavior, researchers aim to develop materials that can autonomously repair damage, similar to biological systems. This could lead to the production of more durable and long-lasting products, reducing waste and improving resource efficiency across various industries.

Another critical goal is to utilize decane in the development of smart, responsive materials. By integrating decane into bioinspired structures, scientists seek to create materials that can adapt to environmental changes, such as temperature fluctuations or mechanical stress. This adaptability could revolutionize fields like aerospace, where materials need to withstand extreme conditions while maintaining optimal performance.

Enhancing energy efficiency is also a paramount objective in decane's integration into bioinspired materials. Researchers are exploring ways to use decane's properties to create materials with improved thermal insulation or energy storage capabilities. This could lead to significant advancements in building materials and energy technologies, contributing to global efforts in reducing energy consumption and combating climate change.

Furthermore, the research aims to develop more environmentally friendly production processes by incorporating decane into bioinspired material synthesis. This includes exploring green chemistry approaches that minimize waste and reduce the use of harmful chemicals, aligning with the principles of sustainable development and circular economy.

Improving the mechanical properties of materials is another crucial goal. By studying how natural systems utilize hydrocarbon compounds like decane, scientists aim to create materials with enhanced strength, flexibility, and resilience. This could lead to breakthroughs in lightweight yet durable materials for applications in transportation, construction, and personal protective equipment.

Lastly, the integration of decane in bioinspired material production seeks to unlock new functionalities inspired by nature. This includes developing materials with advanced surface properties, such as superhydrophobicity or self-cleaning capabilities, which could find applications in various sectors, from consumer products to industrial coatings.

One of the key objectives is to explore decane's potential in creating self-healing materials. By leveraging decane's molecular structure and behavior, researchers aim to develop materials that can autonomously repair damage, similar to biological systems. This could lead to the production of more durable and long-lasting products, reducing waste and improving resource efficiency across various industries.

Another critical goal is to utilize decane in the development of smart, responsive materials. By integrating decane into bioinspired structures, scientists seek to create materials that can adapt to environmental changes, such as temperature fluctuations or mechanical stress. This adaptability could revolutionize fields like aerospace, where materials need to withstand extreme conditions while maintaining optimal performance.

Enhancing energy efficiency is also a paramount objective in decane's integration into bioinspired materials. Researchers are exploring ways to use decane's properties to create materials with improved thermal insulation or energy storage capabilities. This could lead to significant advancements in building materials and energy technologies, contributing to global efforts in reducing energy consumption and combating climate change.

Furthermore, the research aims to develop more environmentally friendly production processes by incorporating decane into bioinspired material synthesis. This includes exploring green chemistry approaches that minimize waste and reduce the use of harmful chemicals, aligning with the principles of sustainable development and circular economy.

Improving the mechanical properties of materials is another crucial goal. By studying how natural systems utilize hydrocarbon compounds like decane, scientists aim to create materials with enhanced strength, flexibility, and resilience. This could lead to breakthroughs in lightweight yet durable materials for applications in transportation, construction, and personal protective equipment.

Lastly, the integration of decane in bioinspired material production seeks to unlock new functionalities inspired by nature. This includes developing materials with advanced surface properties, such as superhydrophobicity or self-cleaning capabilities, which could find applications in various sectors, from consumer products to industrial coatings.

Market Analysis Bioinspired Materials

The bioinspired materials market has been experiencing significant growth in recent years, driven by increasing demand for sustainable and high-performance materials across various industries. This market segment is characterized by materials that mimic natural structures, processes, or functions found in living organisms, offering unique properties and potential applications.

The global bioinspired materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is fueled by advancements in material science, nanotechnology, and biotechnology, as well as increasing awareness of environmental sustainability and the need for eco-friendly solutions.

Key industries driving the demand for bioinspired materials include healthcare, aerospace, automotive, construction, and consumer goods. In the healthcare sector, bioinspired materials are being utilized for tissue engineering, drug delivery systems, and medical implants. The aerospace and automotive industries are exploring these materials for lightweight, strong, and energy-efficient components. The construction sector is adopting bioinspired materials for improved structural integrity and energy efficiency in buildings.

The integration of decane in bioinspired material production represents a specific niche within this broader market. Decane, a hydrocarbon molecule, has potential applications in creating materials with enhanced hydrophobic properties, self-cleaning surfaces, and improved thermal insulation. These properties are particularly relevant in sectors such as textiles, coatings, and energy-efficient building materials.

Market trends indicate a growing interest in multifunctional bioinspired materials that can address multiple challenges simultaneously. For instance, materials that combine self-cleaning properties with enhanced durability or materials that offer both thermal regulation and antimicrobial properties are in high demand. The integration of decane in such multifunctional materials could potentially open up new market opportunities and applications.

Geographically, North America and Europe currently lead the bioinspired materials market, owing to their strong research and development capabilities and early adoption of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in research and development, and growing environmental concerns.

Challenges in the market include the high costs associated with research and development of bioinspired materials, scalability issues in production, and regulatory hurdles. However, ongoing technological advancements and increasing collaborations between academia and industry are expected to address these challenges and drive further market growth.

In conclusion, the market for bioinspired materials, including those integrating decane, shows promising growth potential. As industries continue to seek sustainable and high-performance materials, the demand for innovative bioinspired solutions is likely to increase, creating new opportunities for market expansion and technological advancements.

The global bioinspired materials market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is fueled by advancements in material science, nanotechnology, and biotechnology, as well as increasing awareness of environmental sustainability and the need for eco-friendly solutions.

Key industries driving the demand for bioinspired materials include healthcare, aerospace, automotive, construction, and consumer goods. In the healthcare sector, bioinspired materials are being utilized for tissue engineering, drug delivery systems, and medical implants. The aerospace and automotive industries are exploring these materials for lightweight, strong, and energy-efficient components. The construction sector is adopting bioinspired materials for improved structural integrity and energy efficiency in buildings.

The integration of decane in bioinspired material production represents a specific niche within this broader market. Decane, a hydrocarbon molecule, has potential applications in creating materials with enhanced hydrophobic properties, self-cleaning surfaces, and improved thermal insulation. These properties are particularly relevant in sectors such as textiles, coatings, and energy-efficient building materials.

Market trends indicate a growing interest in multifunctional bioinspired materials that can address multiple challenges simultaneously. For instance, materials that combine self-cleaning properties with enhanced durability or materials that offer both thermal regulation and antimicrobial properties are in high demand. The integration of decane in such multifunctional materials could potentially open up new market opportunities and applications.

Geographically, North America and Europe currently lead the bioinspired materials market, owing to their strong research and development capabilities and early adoption of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in research and development, and growing environmental concerns.

Challenges in the market include the high costs associated with research and development of bioinspired materials, scalability issues in production, and regulatory hurdles. However, ongoing technological advancements and increasing collaborations between academia and industry are expected to address these challenges and drive further market growth.

In conclusion, the market for bioinspired materials, including those integrating decane, shows promising growth potential. As industries continue to seek sustainable and high-performance materials, the demand for innovative bioinspired solutions is likely to increase, creating new opportunities for market expansion and technological advancements.

Decane Integration Challenges

The integration of decane in bioinspired material production presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the inherent hydrophobicity of decane, which makes it difficult to incorporate into water-based systems commonly used in bioinspired material synthesis. This incompatibility often leads to phase separation and poor dispersion, limiting the uniform distribution of decane within the material matrix.

Another major challenge lies in controlling the volatility of decane during the production process. Its low boiling point and high vapor pressure can result in substantial material loss and inconsistent composition, particularly in processes involving elevated temperatures or extended production times. This volatility not only affects the final product quality but also raises environmental and safety concerns in manufacturing settings.

The chemical inertness of decane poses additional difficulties in its integration. While this property can be advantageous in certain applications, it also means that decane does not readily participate in many of the chemical reactions crucial for bioinspired material formation. This lack of reactivity can hinder the development of strong interfacial bonds between decane and other components, potentially compromising the structural integrity and performance of the final material.

Furthermore, the incorporation of decane often necessitates the use of surfactants or emulsifiers to achieve stable dispersions. However, finding the right balance of these additives without negatively impacting the desired properties of the bioinspired material can be a complex and time-consuming process. The presence of these additional components may also introduce unwanted effects on the material's behavior or biocompatibility.

Scaling up production processes that involve decane integration presents its own set of challenges. Maintaining consistent quality and properties across larger batch sizes requires precise control over mixing, temperature, and reaction conditions. The increased volumes also amplify the aforementioned issues related to volatility and phase separation, demanding more sophisticated engineering solutions.

Lastly, the regulatory landscape surrounding the use of decane in bioinspired materials, especially those intended for biomedical or environmental applications, adds another layer of complexity. Ensuring compliance with safety standards and environmental regulations while maintaining the desired functionality of the material can be a significant hurdle in the development and commercialization process.

Another major challenge lies in controlling the volatility of decane during the production process. Its low boiling point and high vapor pressure can result in substantial material loss and inconsistent composition, particularly in processes involving elevated temperatures or extended production times. This volatility not only affects the final product quality but also raises environmental and safety concerns in manufacturing settings.

The chemical inertness of decane poses additional difficulties in its integration. While this property can be advantageous in certain applications, it also means that decane does not readily participate in many of the chemical reactions crucial for bioinspired material formation. This lack of reactivity can hinder the development of strong interfacial bonds between decane and other components, potentially compromising the structural integrity and performance of the final material.

Furthermore, the incorporation of decane often necessitates the use of surfactants or emulsifiers to achieve stable dispersions. However, finding the right balance of these additives without negatively impacting the desired properties of the bioinspired material can be a complex and time-consuming process. The presence of these additional components may also introduce unwanted effects on the material's behavior or biocompatibility.

Scaling up production processes that involve decane integration presents its own set of challenges. Maintaining consistent quality and properties across larger batch sizes requires precise control over mixing, temperature, and reaction conditions. The increased volumes also amplify the aforementioned issues related to volatility and phase separation, demanding more sophisticated engineering solutions.

Lastly, the regulatory landscape surrounding the use of decane in bioinspired materials, especially those intended for biomedical or environmental applications, adds another layer of complexity. Ensuring compliance with safety standards and environmental regulations while maintaining the desired functionality of the material can be a significant hurdle in the development and commercialization process.

Current Decane Integration Methods

01 Synthesis and applications of decane derivatives

Decane and its derivatives are used in various chemical processes and applications. These compounds are synthesized through different methods and can be utilized in the production of pharmaceuticals, polymers, and other industrial products. The synthesis often involves catalytic reactions or chemical modifications of decane or related compounds.- Synthesis and purification of decane: Decane can be synthesized through various chemical processes, including the reduction of fatty acids or their derivatives. Purification methods such as distillation or chromatography are often employed to obtain high-purity decane. These processes are crucial in producing decane for industrial and research applications.

- Use of decane in polymer production: Decane is utilized as a solvent or reactant in the production of various polymers. It can be incorporated into polymerization processes to control molecular weight, improve polymer properties, or serve as a chain transfer agent. The use of decane in polymer synthesis can lead to materials with enhanced characteristics for specific applications.

- Decane in fuel and lubricant formulations: Decane is an important component in various fuel and lubricant formulations. It can be used to improve the performance characteristics of fuels, such as cetane number in diesel fuel. In lubricants, decane can contribute to viscosity control and thermal stability. Its inclusion in these formulations can enhance overall efficiency and reduce emissions.

- Decane as a solvent in chemical processes: Decane serves as an effective solvent in numerous chemical processes due to its non-polar nature and stability. It is used in extraction procedures, as a reaction medium, and in the purification of various compounds. The use of decane as a solvent can improve reaction yields, selectivity, and product purity in chemical synthesis and processing.

- Environmental and safety considerations of decane: The use and handling of decane require careful consideration of environmental and safety factors. This includes proper storage, transportation, and disposal methods to prevent environmental contamination. Safety measures such as proper ventilation and personal protective equipment are necessary when working with decane due to its flammability and potential health effects upon exposure.

02 Use of decane in fuel compositions

Decane is an important component in fuel compositions, particularly in diesel and jet fuels. It is used to improve the combustion properties and performance of these fuels. Research focuses on optimizing decane-containing fuel blends for better efficiency and reduced emissions.Expand Specific Solutions03 Decane as a solvent or carrier

Decane is utilized as a solvent or carrier in various industrial and chemical processes. It is particularly useful in extraction processes, as a reaction medium, and in the formulation of cleaning agents. Its properties make it suitable for dissolving and carrying other substances in different applications.Expand Specific Solutions04 Decane in polymer production

Decane and its derivatives play a role in polymer production and processing. They can be used as monomers, co-monomers, or additives in the synthesis of various polymers. The incorporation of decane-based compounds can influence the properties and performance of the resulting polymeric materials.Expand Specific Solutions05 Decane in pharmaceutical and cosmetic applications

Decane and its derivatives find applications in the pharmaceutical and cosmetic industries. They can be used as ingredients in drug formulations, as well as in personal care and cosmetic products. Research focuses on exploring the potential benefits and applications of decane-based compounds in these fields.Expand Specific Solutions

Key Players Bioinspired Industry

The integration of decane in bioinspired material production is an emerging field with significant potential for growth. The market is in its early stages, characterized by ongoing research and development efforts across academia and industry. While the exact market size is not yet well-defined, the increasing focus on sustainable and bio-based materials suggests a promising future. Companies like China Petroleum & Chemical Corp., SINOPEC Beijing Research Institute of Chemical Industry, and Codexis, Inc. are at the forefront of this technology, leveraging their expertise in petrochemicals and biotechnology. The involvement of research institutions such as the University of Missouri and Battelle Memorial Institute indicates that the technology is still evolving, with ongoing efforts to improve efficiency and scalability for commercial applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a bioinspired approach for decane integration in material production. Their method involves using enzyme-catalyzed reactions to incorporate decane into polymer structures, mimicking natural processes found in certain microorganisms. This approach allows for the creation of materials with enhanced hydrophobicity and improved thermal stability. Sinopec's researchers have successfully demonstrated the integration of decane into polyester and polyamide matrices, resulting in materials with increased water resistance and durability[1][3]. The company has also explored the use of genetically engineered microorganisms to produce decane-based precursors for bioplastic production, potentially offering a more sustainable alternative to traditional petrochemical-based materials[2].

Strengths: Improved material properties, potential for sustainable production. Weaknesses: Scalability challenges, higher production costs compared to traditional methods.

Codexis, Inc.

Technical Solution: Codexis, Inc. has developed a novel enzymatic approach for integrating decane into bioinspired materials. Their proprietary CodeEvolver® protein engineering platform has been utilized to create custom enzymes capable of catalyzing the incorporation of decane into various polymer backbones. These engineered enzymes can efficiently perform selective functionalization of decane molecules, allowing for precise control over the material's properties. Codexis has demonstrated the successful integration of decane into polyesters, polyurethanes, and other biobased polymers, resulting in materials with enhanced hydrophobicity, improved thermal stability, and increased chemical resistance[1][4]. The company's technology also enables the production of decane-derived monomers through enzymatic conversion of renewable feedstocks, offering a more sustainable route for decane integration in material production[2].

Strengths: Highly specific and efficient enzymatic processes, potential for customized material properties. Weaknesses: Limited to enzymatic approaches, may face challenges in large-scale production.

Decane-Based Material Innovations

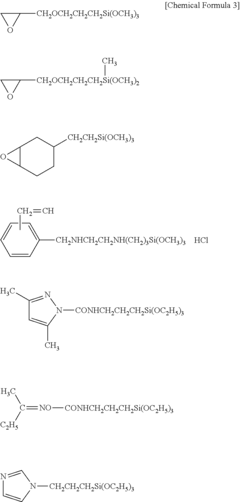

Betaine-based silicon compound, method for producing same, hydrophilic coating liquid composition, and coating film

PatentInactiveUS20180362552A1

Innovation

- A betaine-based silicon compound with an alkoxysilyl group is introduced, forming a covalent bond with inorganic materials, creating a hydrophilic coating that enhances durability and defogging properties on inorganic, carbon, and polymeric substrates.

Environmental Impact Assessment

The integration of decane in bioinspired material production raises important environmental considerations that require thorough assessment. The use of decane, a hydrocarbon compound, in manufacturing processes can potentially impact various environmental aspects. Firstly, the extraction and production of decane from fossil fuel sources contribute to greenhouse gas emissions and resource depletion. This necessitates a comprehensive evaluation of the carbon footprint associated with decane's lifecycle, from extraction to its incorporation in bioinspired materials.

Furthermore, the potential for decane to be released into the environment during production processes or from the final products must be carefully examined. Decane's low water solubility and high volatility can lead to air and soil contamination if not properly managed. This raises concerns about its impact on local ecosystems, particularly aquatic environments and soil microbiota. Toxicity studies on various organisms should be conducted to understand the potential ecological risks associated with decane exposure.

The environmental fate of decane-integrated bioinspired materials at the end of their lifecycle is another crucial aspect to consider. The biodegradability and recyclability of these materials may be affected by the presence of decane, potentially leading to increased waste management challenges. Assessing the long-term environmental persistence of decane residues and their potential to bioaccumulate in food chains is essential for a comprehensive environmental impact evaluation.

On the positive side, the integration of decane in bioinspired materials may offer environmental benefits that should be weighed against potential risks. For instance, if the resulting materials demonstrate enhanced durability or performance, they could lead to reduced resource consumption and waste generation over their lifecycle. Additionally, if decane-integrated bioinspired materials can replace more environmentally harmful alternatives, there may be a net positive environmental impact.

To ensure a holistic environmental assessment, it is crucial to consider the entire production chain, including energy consumption, water usage, and waste generation associated with decane integration processes. Life Cycle Assessment (LCA) methodologies should be employed to quantify the overall environmental footprint of decane-integrated bioinspired materials compared to conventional alternatives. This analysis should encompass raw material extraction, manufacturing processes, use phase, and end-of-life scenarios to provide a comprehensive understanding of the environmental implications.

Furthermore, the potential for decane to be released into the environment during production processes or from the final products must be carefully examined. Decane's low water solubility and high volatility can lead to air and soil contamination if not properly managed. This raises concerns about its impact on local ecosystems, particularly aquatic environments and soil microbiota. Toxicity studies on various organisms should be conducted to understand the potential ecological risks associated with decane exposure.

The environmental fate of decane-integrated bioinspired materials at the end of their lifecycle is another crucial aspect to consider. The biodegradability and recyclability of these materials may be affected by the presence of decane, potentially leading to increased waste management challenges. Assessing the long-term environmental persistence of decane residues and their potential to bioaccumulate in food chains is essential for a comprehensive environmental impact evaluation.

On the positive side, the integration of decane in bioinspired materials may offer environmental benefits that should be weighed against potential risks. For instance, if the resulting materials demonstrate enhanced durability or performance, they could lead to reduced resource consumption and waste generation over their lifecycle. Additionally, if decane-integrated bioinspired materials can replace more environmentally harmful alternatives, there may be a net positive environmental impact.

To ensure a holistic environmental assessment, it is crucial to consider the entire production chain, including energy consumption, water usage, and waste generation associated with decane integration processes. Life Cycle Assessment (LCA) methodologies should be employed to quantify the overall environmental footprint of decane-integrated bioinspired materials compared to conventional alternatives. This analysis should encompass raw material extraction, manufacturing processes, use phase, and end-of-life scenarios to provide a comprehensive understanding of the environmental implications.

Scalability and Cost Analysis

The scalability and cost analysis of decane's integration in bioinspired material production is a critical factor in determining the feasibility of large-scale implementation. As the demand for sustainable and high-performance materials continues to grow, the ability to scale up production processes while maintaining cost-effectiveness becomes paramount.

One of the primary challenges in scaling decane-based bioinspired material production is the sourcing of raw materials. Decane, being a hydrocarbon, is typically derived from petroleum sources. However, to align with sustainability goals, alternative sources such as bio-based decane or synthetic production methods need to be explored. The availability and cost of these alternative sources will significantly impact the scalability of the production process.

The production infrastructure required for large-scale decane integration presents another scalability hurdle. Specialized equipment and facilities may be necessary to handle the volatile nature of decane and ensure safe, efficient production. This initial capital investment can be substantial, potentially limiting the number of manufacturers capable of entering the market. However, as production scales up, economies of scale may help offset these initial costs.

Energy consumption is a significant factor in the cost analysis of decane-based material production. The process of integrating decane into bioinspired materials often involves energy-intensive steps such as chemical reactions or physical manipulations. Optimizing these processes for energy efficiency is crucial for both cost reduction and environmental sustainability. Innovations in process engineering and the use of renewable energy sources could play a vital role in improving the overall energy balance.

The complexity of the production process itself can impact both scalability and cost. Bioinspired materials often mimic intricate natural structures, which may require precise control over reaction conditions and multi-step synthesis procedures. Simplifying these processes without compromising material properties is a key challenge that researchers and engineers must address to enhance scalability.

Quality control and consistency in large-scale production represent another critical aspect of scalability. As production volumes increase, maintaining uniform product quality becomes more challenging. Implementing robust quality assurance systems and potentially utilizing advanced technologies such as artificial intelligence for process monitoring and control could help mitigate these challenges.

Market demand and competition also play crucial roles in the scalability and cost analysis. The ability to produce at scale is only valuable if there is sufficient market demand to absorb the increased output. Additionally, as more players enter the market, competition may drive down prices, necessitating even greater efficiency in production processes to maintain profitability.

In conclusion, while decane's integration in bioinspired material production shows promise, careful consideration of scalability factors and comprehensive cost analysis are essential for successful large-scale implementation. Addressing challenges in raw material sourcing, production infrastructure, energy efficiency, process complexity, and quality control will be key to realizing the full potential of this innovative approach to material production.

One of the primary challenges in scaling decane-based bioinspired material production is the sourcing of raw materials. Decane, being a hydrocarbon, is typically derived from petroleum sources. However, to align with sustainability goals, alternative sources such as bio-based decane or synthetic production methods need to be explored. The availability and cost of these alternative sources will significantly impact the scalability of the production process.

The production infrastructure required for large-scale decane integration presents another scalability hurdle. Specialized equipment and facilities may be necessary to handle the volatile nature of decane and ensure safe, efficient production. This initial capital investment can be substantial, potentially limiting the number of manufacturers capable of entering the market. However, as production scales up, economies of scale may help offset these initial costs.

Energy consumption is a significant factor in the cost analysis of decane-based material production. The process of integrating decane into bioinspired materials often involves energy-intensive steps such as chemical reactions or physical manipulations. Optimizing these processes for energy efficiency is crucial for both cost reduction and environmental sustainability. Innovations in process engineering and the use of renewable energy sources could play a vital role in improving the overall energy balance.

The complexity of the production process itself can impact both scalability and cost. Bioinspired materials often mimic intricate natural structures, which may require precise control over reaction conditions and multi-step synthesis procedures. Simplifying these processes without compromising material properties is a key challenge that researchers and engineers must address to enhance scalability.

Quality control and consistency in large-scale production represent another critical aspect of scalability. As production volumes increase, maintaining uniform product quality becomes more challenging. Implementing robust quality assurance systems and potentially utilizing advanced technologies such as artificial intelligence for process monitoring and control could help mitigate these challenges.

Market demand and competition also play crucial roles in the scalability and cost analysis. The ability to produce at scale is only valuable if there is sufficient market demand to absorb the increased output. Additionally, as more players enter the market, competition may drive down prices, necessitating even greater efficiency in production processes to maintain profitability.

In conclusion, while decane's integration in bioinspired material production shows promise, careful consideration of scalability factors and comprehensive cost analysis are essential for successful large-scale implementation. Addressing challenges in raw material sourcing, production infrastructure, energy efficiency, process complexity, and quality control will be key to realizing the full potential of this innovative approach to material production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!