Design Criteria for Solenoid Valves in Emergency Shutdown Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve ESD System Background and Objectives

Solenoid valves play a crucial role in Emergency Shutdown (ESD) systems, serving as critical components in ensuring the safety and reliability of industrial processes. These systems are designed to rapidly halt operations in the event of a hazardous situation, preventing potential accidents, equipment damage, and environmental harm. The development of solenoid valves for ESD applications has been driven by the increasing complexity of industrial processes and the growing emphasis on safety across various sectors.

The primary objective of incorporating solenoid valves in ESD systems is to provide a fail-safe mechanism that can quickly isolate or depressurize systems when triggered. These valves are engineered to respond swiftly to electrical signals, enabling rapid closure or opening as required by the specific emergency scenario. The design criteria for solenoid valves in ESD systems have evolved significantly over the years, focusing on enhancing reliability, response time, and durability under extreme conditions.

Historically, the use of solenoid valves in safety-critical applications dates back to the mid-20th century, with continuous improvements in materials, design, and control systems. The oil and gas industry, in particular, has been a driving force behind many advancements in ESD solenoid valve technology due to the high-risk nature of its operations. As industrial processes became more automated and complex, the demand for more sophisticated and reliable ESD systems grew, leading to innovations in valve design and integration with digital control systems.

The technological evolution of solenoid valves for ESD applications has been marked by several key trends. These include the development of redundant designs to minimize the risk of failure, the integration of smart diagnostics for predictive maintenance, and the use of advanced materials to withstand harsh operating environments. Additionally, there has been a push towards standardization and certification to ensure consistent performance and compliance with stringent safety regulations across different industries.

Looking forward, the design criteria for solenoid valves in ESD systems are expected to focus on further improving reliability, reducing response times, and enhancing compatibility with Industry 4.0 concepts. This includes the development of valves with built-in sensors for real-time monitoring, improved energy efficiency, and the ability to operate in a wider range of environmental conditions. The integration of these valves with advanced control systems and the Industrial Internet of Things (IIoT) is also anticipated to play a significant role in the next generation of ESD systems.

The primary objective of incorporating solenoid valves in ESD systems is to provide a fail-safe mechanism that can quickly isolate or depressurize systems when triggered. These valves are engineered to respond swiftly to electrical signals, enabling rapid closure or opening as required by the specific emergency scenario. The design criteria for solenoid valves in ESD systems have evolved significantly over the years, focusing on enhancing reliability, response time, and durability under extreme conditions.

Historically, the use of solenoid valves in safety-critical applications dates back to the mid-20th century, with continuous improvements in materials, design, and control systems. The oil and gas industry, in particular, has been a driving force behind many advancements in ESD solenoid valve technology due to the high-risk nature of its operations. As industrial processes became more automated and complex, the demand for more sophisticated and reliable ESD systems grew, leading to innovations in valve design and integration with digital control systems.

The technological evolution of solenoid valves for ESD applications has been marked by several key trends. These include the development of redundant designs to minimize the risk of failure, the integration of smart diagnostics for predictive maintenance, and the use of advanced materials to withstand harsh operating environments. Additionally, there has been a push towards standardization and certification to ensure consistent performance and compliance with stringent safety regulations across different industries.

Looking forward, the design criteria for solenoid valves in ESD systems are expected to focus on further improving reliability, reducing response times, and enhancing compatibility with Industry 4.0 concepts. This includes the development of valves with built-in sensors for real-time monitoring, improved energy efficiency, and the ability to operate in a wider range of environmental conditions. The integration of these valves with advanced control systems and the Industrial Internet of Things (IIoT) is also anticipated to play a significant role in the next generation of ESD systems.

Market Analysis for ESD Solenoid Valves

The market for Emergency Shutdown (ESD) solenoid valves is experiencing significant growth, driven by increasing safety regulations across industries and the growing emphasis on process automation. The global ESD valve market, which includes solenoid valves as a key component, is projected to reach substantial value in the coming years. This growth is primarily attributed to the rising demand for fail-safe mechanisms in critical industrial processes, particularly in oil and gas, chemical, and power generation sectors.

In the oil and gas industry, ESD solenoid valves play a crucial role in ensuring safety during emergencies, such as fire, gas leaks, or equipment failures. The increasing number of offshore and onshore oil and gas projects worldwide is boosting the demand for these valves. Similarly, the chemical industry's focus on improving plant safety and reducing the risk of accidents is driving the adoption of advanced ESD systems, including solenoid valves.

The power generation sector, especially nuclear power plants, represents another significant market for ESD solenoid valves. Stringent safety regulations and the need for reliable shutdown mechanisms in case of emergencies are fueling the demand in this sector. Additionally, the growing renewable energy sector, particularly wind and solar power plants, is creating new opportunities for ESD solenoid valve manufacturers.

Geographically, North America and Europe lead the market due to strict safety regulations and the presence of major industrial players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, and increasing investments in process automation.

The market is characterized by intense competition among key players, including Emerson Electric Co., Schlumberger Limited, and IMI plc. These companies are focusing on product innovations, such as the development of smart solenoid valves with enhanced diagnostic capabilities and improved reliability. The trend towards Industry 4.0 and the Internet of Things (IoT) is also influencing the market, with manufacturers integrating advanced sensors and communication technologies into ESD solenoid valves.

Despite the positive outlook, the market faces challenges such as the high initial cost of ESD systems and the complexity of installation and maintenance. However, the long-term benefits of improved safety and reduced downtime are expected to outweigh these challenges, driving continued market growth.

In the oil and gas industry, ESD solenoid valves play a crucial role in ensuring safety during emergencies, such as fire, gas leaks, or equipment failures. The increasing number of offshore and onshore oil and gas projects worldwide is boosting the demand for these valves. Similarly, the chemical industry's focus on improving plant safety and reducing the risk of accidents is driving the adoption of advanced ESD systems, including solenoid valves.

The power generation sector, especially nuclear power plants, represents another significant market for ESD solenoid valves. Stringent safety regulations and the need for reliable shutdown mechanisms in case of emergencies are fueling the demand in this sector. Additionally, the growing renewable energy sector, particularly wind and solar power plants, is creating new opportunities for ESD solenoid valve manufacturers.

Geographically, North America and Europe lead the market due to strict safety regulations and the presence of major industrial players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, and increasing investments in process automation.

The market is characterized by intense competition among key players, including Emerson Electric Co., Schlumberger Limited, and IMI plc. These companies are focusing on product innovations, such as the development of smart solenoid valves with enhanced diagnostic capabilities and improved reliability. The trend towards Industry 4.0 and the Internet of Things (IoT) is also influencing the market, with manufacturers integrating advanced sensors and communication technologies into ESD solenoid valves.

Despite the positive outlook, the market faces challenges such as the high initial cost of ESD systems and the complexity of installation and maintenance. However, the long-term benefits of improved safety and reduced downtime are expected to outweigh these challenges, driving continued market growth.

Technical Challenges in ESD Solenoid Valve Design

The design of solenoid valves for Emergency Shutdown Systems (ESD) presents several significant technical challenges that engineers must overcome to ensure reliable and fail-safe operation in critical industrial applications. One of the primary difficulties lies in achieving rapid response times while maintaining high flow rates. ESD systems require valves to close quickly to prevent potential disasters, but this rapid action can lead to pressure spikes and mechanical stress on valve components.

Material selection poses another substantial challenge. Valve components must withstand harsh environmental conditions, including extreme temperatures, corrosive fluids, and high pressures. Engineers must carefully choose materials that offer both durability and chemical resistance while also considering factors such as thermal expansion and compatibility with process fluids.

Ensuring consistent performance over long periods of inactivity is a critical issue in ESD valve design. These valves may remain dormant for extended periods but must function flawlessly when activated. This requirement necessitates innovative solutions to prevent sticking, corrosion, and degradation of seals and other components during idle periods.

Power management presents a unique set of challenges in ESD solenoid valve design. The valves must operate reliably even in the event of power failure, often requiring fail-safe mechanisms or backup power sources. Additionally, engineers must optimize power consumption to minimize heat generation and extend the life of electrical components.

Diagnostic capabilities and self-monitoring features are increasingly important in modern ESD valve designs. Implementing reliable sensors and monitoring systems without compromising the valve's primary function or introducing potential failure points is a complex task. These diagnostic systems must provide accurate information about valve status and potential issues without increasing the risk of false alarms or unnecessary shutdowns.

Miniaturization and weight reduction efforts further complicate the design process. As industries push for more compact and efficient systems, engineers must find ways to reduce valve size and weight without sacrificing performance or reliability. This often involves exploring new materials, optimizing internal geometries, and developing innovative actuation mechanisms.

Lastly, meeting stringent regulatory requirements and industry standards poses a significant challenge. ESD valves must comply with various safety standards and certifications, which can vary by industry and region. Designers must navigate these complex regulatory landscapes while still delivering cost-effective and efficient solutions that meet the specific needs of different applications.

Material selection poses another substantial challenge. Valve components must withstand harsh environmental conditions, including extreme temperatures, corrosive fluids, and high pressures. Engineers must carefully choose materials that offer both durability and chemical resistance while also considering factors such as thermal expansion and compatibility with process fluids.

Ensuring consistent performance over long periods of inactivity is a critical issue in ESD valve design. These valves may remain dormant for extended periods but must function flawlessly when activated. This requirement necessitates innovative solutions to prevent sticking, corrosion, and degradation of seals and other components during idle periods.

Power management presents a unique set of challenges in ESD solenoid valve design. The valves must operate reliably even in the event of power failure, often requiring fail-safe mechanisms or backup power sources. Additionally, engineers must optimize power consumption to minimize heat generation and extend the life of electrical components.

Diagnostic capabilities and self-monitoring features are increasingly important in modern ESD valve designs. Implementing reliable sensors and monitoring systems without compromising the valve's primary function or introducing potential failure points is a complex task. These diagnostic systems must provide accurate information about valve status and potential issues without increasing the risk of false alarms or unnecessary shutdowns.

Miniaturization and weight reduction efforts further complicate the design process. As industries push for more compact and efficient systems, engineers must find ways to reduce valve size and weight without sacrificing performance or reliability. This often involves exploring new materials, optimizing internal geometries, and developing innovative actuation mechanisms.

Lastly, meeting stringent regulatory requirements and industry standards poses a significant challenge. ESD valves must comply with various safety standards and certifications, which can vary by industry and region. Designers must navigate these complex regulatory landscapes while still delivering cost-effective and efficient solutions that meet the specific needs of different applications.

Current Design Solutions for ESD Solenoid Valves

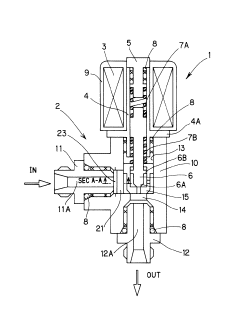

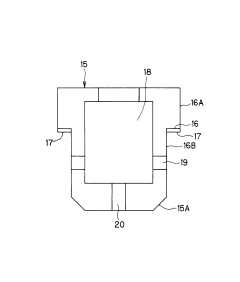

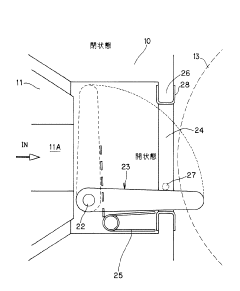

01 Solenoid valve design and structure

Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, efficiency, and reliability for different applications.- Solenoid valve design and structure: Solenoid valves are electromechanical devices that control the flow of fluids. Their design typically includes a coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various structural improvements focus on enhancing efficiency, reliability, and response time.

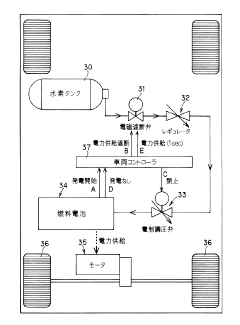

- Application in fuel injection systems: Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They control the precise timing and amount of fuel delivered to the engine, improving fuel efficiency and reducing emissions. Advancements in this area focus on faster response times, durability, and compatibility with various fuel types.

- Pressure control and regulation: Solenoid valves are used for pressure control and regulation in various systems. They can maintain constant pressure, relieve excess pressure, or control pressure differentials. Innovations in this area include improved pressure sensing, faster response to pressure changes, and integration with electronic control systems.

- Miniaturization and integration: There is a trend towards miniaturization and integration of solenoid valves in compact systems. This includes the development of micro-solenoid valves for use in medical devices, analytical instruments, and other applications requiring precise fluid control in small spaces. Challenges include maintaining performance while reducing size and power consumption.

- Energy efficiency and power management: Improving the energy efficiency of solenoid valves is a key focus area. This includes developing low-power solenoids, optimizing magnetic circuit designs, and implementing smart power management systems. These advancements aim to reduce power consumption, heat generation, and extend the operational life of the valves.

02 Solenoid valve control systems

Control systems for solenoid valves include electronic circuits and microcontrollers that regulate valve operation. These systems can incorporate sensors, feedback mechanisms, and advanced algorithms to ensure precise timing, pressure control, and flow regulation. Some designs feature adaptive control to optimize performance under varying conditions.Expand Specific Solutions03 Solenoid valve applications in automotive systems

Solenoid valves play crucial roles in various automotive systems, including fuel injection, transmission control, and emission control systems. They are used to regulate fluid flow, control pressure, and manage the timing of different processes within the engine and related components, contributing to improved vehicle performance and efficiency.Expand Specific Solutions04 Energy-efficient solenoid valve designs

Innovations in solenoid valve design focus on improving energy efficiency. This includes the development of low-power solenoids, optimized magnetic circuits, and materials with enhanced magnetic properties. Some designs incorporate energy recovery mechanisms or use alternative actuation methods to reduce power consumption while maintaining performance.Expand Specific Solutions05 Miniaturization and integration of solenoid valves

Advancements in manufacturing techniques and materials have led to the miniaturization of solenoid valves. These compact designs allow for integration into smaller spaces and more complex systems. Some innovations focus on combining multiple valve functions into a single unit or integrating valves with other components to create more efficient and space-saving solutions.Expand Specific Solutions

Key Manufacturers and Suppliers in ESD Valve Industry

The market for solenoid valves in emergency shutdown systems is in a mature growth phase, characterized by established technologies and steady demand. The global market size is estimated to be in the billions of dollars, driven by stringent safety regulations across industries. Technologically, the field is moderately mature, with ongoing innovations focused on improving reliability, response time, and integration with digital control systems. Key players like Robert Bosch GmbH, Honeywell International Technologies Ltd., and Emerson (through its Rosemount division) are leading the market with advanced solutions. Other significant contributors include Fisher Controls International LLC and Festo SE & Co. KG, who are pushing the boundaries of valve design and automation integration for emergency shutdown applications.

Robert Bosch GmbH

Technical Solution: Bosch's design criteria for solenoid valves in emergency shutdown systems focus on reliability and rapid response. They utilize a dual-coil design with redundant electrical circuits to ensure fail-safe operation[1]. The valves incorporate a high-force solenoid actuator capable of overcoming high system pressures, with typical response times under 100 milliseconds[2]. Bosch employs advanced materials such as corrosion-resistant alloys and high-temperature polymers to withstand harsh industrial environments. Their valves feature integrated position sensors and diagnostics for real-time monitoring and predictive maintenance[3].

Strengths: Highly reliable due to redundant design, fast response times, and robust construction. Weaknesses: Potentially higher cost due to advanced features and materials, may require more complex control systems.

Fisher Controls International LLC

Technical Solution: Fisher Controls' approach to solenoid valve design for emergency shutdown systems emphasizes modularity and adaptability. Their valves utilize a patented pilot-operated design that allows for high flow rates with minimal power consumption[4]. The company employs a unique "soft-landing" technology to reduce wear and extend valve life, crucial for emergency systems that may sit idle for long periods[5]. Fisher's valves incorporate self-diagnostic capabilities and can interface with various industrial control protocols for seamless integration into existing systems[6].

Strengths: Energy-efficient design, long service life, and easy integration with control systems. Weaknesses: May have limitations in extremely high-pressure applications, potentially more complex maintenance due to advanced features.

Innovative Technologies in ESD Valve Design

Emergency shutdown valve diagnostics using a pressure transmitter

PatentInactiveEP1711872A1

Innovation

- A pressure transmitter with a semiconductor-based pressure sensor and a high-speed analog-to-digital converter, such as a sigma-delta converter, captures and stores pressure data at a much higher rate, allowing for detailed pressure signatures to be obtained and analyzed, potentially using wavelet analysis or other signal processing techniques.

Solenoid shutoff valve and method of controlling same

PatentInactiveJP2007247743A

Innovation

- A simplified design using a fixed iron core and plunger biased by an elastic member, with a locking mechanism that maintains the valve in open or closed states without continuous excitation, utilizing a cylindrical coil and inlet/outlet ports for valve operation.

Safety Standards and Regulations for ESD Systems

Safety standards and regulations play a crucial role in the design and implementation of Emergency Shutdown (ESD) systems, particularly concerning solenoid valves. These standards ensure that ESD systems operate reliably and effectively in critical situations, minimizing risks to personnel, equipment, and the environment.

The International Electrotechnical Commission (IEC) has established several key standards relevant to ESD systems. IEC 61508, "Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems," provides a comprehensive framework for developing safety-critical systems. This standard introduces the concept of Safety Integrity Levels (SIL), which define the level of risk reduction required for a safety function.

For solenoid valves in ESD systems, IEC 61511, "Functional safety - Safety instrumented systems for the process industry sector," is particularly relevant. This standard applies the principles of IEC 61508 specifically to the process industry, providing guidelines for the specification, design, installation, operation, and maintenance of safety instrumented systems.

The American Petroleum Institute (API) has also developed standards applicable to ESD systems in the oil and gas industry. API Standard 14C, "Analysis, Design, Installation, and Testing of Safety Systems for Offshore Production Facilities," outlines requirements for safety systems, including ESD systems, in offshore oil and gas production facilities.

In addition to these international standards, regional and national regulations must be considered. In the United States, the Occupational Safety and Health Administration (OSHA) provides regulations for process safety management in 29 CFR 1910.119. These regulations require employers to develop and implement safety management systems for processes involving highly hazardous chemicals.

When designing solenoid valves for ESD systems, manufacturers must ensure compliance with these standards and regulations. This includes considerations such as fail-safe design, redundancy, diagnostic capabilities, and environmental resistance. The valves must be capable of achieving the required Safety Integrity Level (SIL) as determined by a risk assessment of the specific application.

Testing and certification are essential aspects of compliance. Third-party certification bodies, such as TÜV or Exida, can provide independent verification that solenoid valves meet the required safety standards. This certification process typically involves rigorous testing of the valve's performance under various conditions, including extreme temperatures, pressures, and vibration.

Ongoing maintenance and testing requirements are also specified in these standards. Regular proof testing of solenoid valves in ESD systems is crucial to ensure their continued reliability and performance. The frequency and nature of these tests are often dictated by the applicable standards and the specific SIL requirements of the system.

The International Electrotechnical Commission (IEC) has established several key standards relevant to ESD systems. IEC 61508, "Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems," provides a comprehensive framework for developing safety-critical systems. This standard introduces the concept of Safety Integrity Levels (SIL), which define the level of risk reduction required for a safety function.

For solenoid valves in ESD systems, IEC 61511, "Functional safety - Safety instrumented systems for the process industry sector," is particularly relevant. This standard applies the principles of IEC 61508 specifically to the process industry, providing guidelines for the specification, design, installation, operation, and maintenance of safety instrumented systems.

The American Petroleum Institute (API) has also developed standards applicable to ESD systems in the oil and gas industry. API Standard 14C, "Analysis, Design, Installation, and Testing of Safety Systems for Offshore Production Facilities," outlines requirements for safety systems, including ESD systems, in offshore oil and gas production facilities.

In addition to these international standards, regional and national regulations must be considered. In the United States, the Occupational Safety and Health Administration (OSHA) provides regulations for process safety management in 29 CFR 1910.119. These regulations require employers to develop and implement safety management systems for processes involving highly hazardous chemicals.

When designing solenoid valves for ESD systems, manufacturers must ensure compliance with these standards and regulations. This includes considerations such as fail-safe design, redundancy, diagnostic capabilities, and environmental resistance. The valves must be capable of achieving the required Safety Integrity Level (SIL) as determined by a risk assessment of the specific application.

Testing and certification are essential aspects of compliance. Third-party certification bodies, such as TÜV or Exida, can provide independent verification that solenoid valves meet the required safety standards. This certification process typically involves rigorous testing of the valve's performance under various conditions, including extreme temperatures, pressures, and vibration.

Ongoing maintenance and testing requirements are also specified in these standards. Regular proof testing of solenoid valves in ESD systems is crucial to ensure their continued reliability and performance. The frequency and nature of these tests are often dictated by the applicable standards and the specific SIL requirements of the system.

Reliability and Failure Mode Analysis of ESD Valves

Reliability and failure mode analysis are critical aspects of designing solenoid valves for emergency shutdown (ESD) systems. These valves play a crucial role in ensuring the safety and integrity of industrial processes, making their reliability paramount. A comprehensive analysis of potential failure modes helps identify vulnerabilities and implement appropriate mitigation strategies.

One of the primary considerations in reliability analysis is the valve's ability to maintain its intended function under various operating conditions. This includes assessing the valve's performance in extreme temperatures, pressures, and corrosive environments. Failure modes such as sticking, leakage, or incomplete closure must be thoroughly evaluated to determine their likelihood and potential consequences.

The analysis typically employs techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to systematically identify and prioritize potential failure modes. These methods help quantify the risk associated with each failure mode and guide the allocation of resources for improvement.

Material selection plays a significant role in valve reliability. The choice of materials for valve components must consider factors such as chemical compatibility, wear resistance, and thermal stability. Proper material selection can mitigate issues like corrosion, erosion, and fatigue, which are common causes of valve failure in harsh industrial environments.

Actuator reliability is another critical aspect of ESD valve performance. The actuator must consistently provide sufficient force to operate the valve under all anticipated conditions. Failure modes related to actuator malfunction, such as loss of power supply or mechanical breakage, require careful consideration and redundancy measures where appropriate.

Testing and validation procedures form an integral part of the reliability analysis. Accelerated life testing, cycle testing, and environmental stress screening can provide valuable data on valve performance and potential failure modes. These tests help validate design assumptions and identify areas for improvement before field deployment.

Maintenance strategies also factor into the overall reliability of ESD valves. Predictive maintenance techniques, such as condition monitoring and diagnostic systems, can help detect early signs of degradation and prevent unexpected failures. Regular inspection and maintenance schedules should be developed based on the identified failure modes and their criticality.

Human factors and operational procedures must not be overlooked in the reliability analysis. Proper training for operators and maintenance personnel can significantly reduce the risk of failures due to human error. Clear and concise operating procedures, along with fail-safe designs, contribute to the overall reliability of the ESD system.

One of the primary considerations in reliability analysis is the valve's ability to maintain its intended function under various operating conditions. This includes assessing the valve's performance in extreme temperatures, pressures, and corrosive environments. Failure modes such as sticking, leakage, or incomplete closure must be thoroughly evaluated to determine their likelihood and potential consequences.

The analysis typically employs techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to systematically identify and prioritize potential failure modes. These methods help quantify the risk associated with each failure mode and guide the allocation of resources for improvement.

Material selection plays a significant role in valve reliability. The choice of materials for valve components must consider factors such as chemical compatibility, wear resistance, and thermal stability. Proper material selection can mitigate issues like corrosion, erosion, and fatigue, which are common causes of valve failure in harsh industrial environments.

Actuator reliability is another critical aspect of ESD valve performance. The actuator must consistently provide sufficient force to operate the valve under all anticipated conditions. Failure modes related to actuator malfunction, such as loss of power supply or mechanical breakage, require careful consideration and redundancy measures where appropriate.

Testing and validation procedures form an integral part of the reliability analysis. Accelerated life testing, cycle testing, and environmental stress screening can provide valuable data on valve performance and potential failure modes. These tests help validate design assumptions and identify areas for improvement before field deployment.

Maintenance strategies also factor into the overall reliability of ESD valves. Predictive maintenance techniques, such as condition monitoring and diagnostic systems, can help detect early signs of degradation and prevent unexpected failures. Regular inspection and maintenance schedules should be developed based on the identified failure modes and their criticality.

Human factors and operational procedures must not be overlooked in the reliability analysis. Proper training for operators and maintenance personnel can significantly reduce the risk of failures due to human error. Clear and concise operating procedures, along with fail-safe designs, contribute to the overall reliability of the ESD system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!