Design Of Pilot Plants For Solid Amine DAC In Varying Climates

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid Amine DAC Technology Background and Objectives

Direct Air Capture (DAC) technology has emerged as a critical component in the global effort to combat climate change by removing carbon dioxide directly from the atmosphere. Among various DAC approaches, solid amine-based systems have gained significant attention due to their promising efficiency and operational flexibility. The evolution of solid amine DAC technology can be traced back to the early 2000s, with substantial advancements occurring in the past decade as climate mitigation urgency has intensified.

Solid amine sorbents function by chemically binding CO2 molecules to amine groups attached to solid supports, offering advantages over liquid systems including reduced corrosion, lower energy requirements for regeneration, and greater operational stability. The technology has progressed from laboratory-scale demonstrations to small pilot implementations, with current research focusing on optimizing sorbent formulations, improving regeneration efficiency, and enhancing overall system durability.

The primary technical objective for solid amine DAC pilot plants is to demonstrate scalable, cost-effective carbon capture across diverse climatic conditions. This includes achieving consistent capture rates despite variations in temperature, humidity, and atmospheric CO2 concentration. Current targets aim for capture costs below $100 per ton of CO2, representing a significant improvement from earlier systems that operated at several hundred dollars per ton.

Climate variability presents unique challenges and opportunities for solid amine DAC technology. Humidity levels significantly impact adsorption efficiency, with moderate humidity generally enhancing CO2 uptake through cooperative adsorption mechanisms, while excessive moisture can reduce capacity through competitive adsorption. Temperature fluctuations affect both adsorption kinetics and equilibrium capacity, necessitating adaptive operational strategies.

The technology trajectory indicates a clear path toward modular, distributed capture systems that can be deployed in various geographic locations. Recent innovations have focused on novel amine structures, improved support materials with enhanced stability, and regeneration processes that minimize energy consumption. Computational modeling and machine learning approaches are increasingly being applied to predict performance across climate scenarios.

Research objectives now center on developing pilot plants specifically designed to evaluate and optimize solid amine DAC performance across climate zones ranging from arid to tropical environments. These pilots aim to generate critical operational data on sorbent degradation rates, energy consumption patterns, and maintenance requirements under real-world conditions, while simultaneously validating theoretical models of climate-dependent performance.

Solid amine sorbents function by chemically binding CO2 molecules to amine groups attached to solid supports, offering advantages over liquid systems including reduced corrosion, lower energy requirements for regeneration, and greater operational stability. The technology has progressed from laboratory-scale demonstrations to small pilot implementations, with current research focusing on optimizing sorbent formulations, improving regeneration efficiency, and enhancing overall system durability.

The primary technical objective for solid amine DAC pilot plants is to demonstrate scalable, cost-effective carbon capture across diverse climatic conditions. This includes achieving consistent capture rates despite variations in temperature, humidity, and atmospheric CO2 concentration. Current targets aim for capture costs below $100 per ton of CO2, representing a significant improvement from earlier systems that operated at several hundred dollars per ton.

Climate variability presents unique challenges and opportunities for solid amine DAC technology. Humidity levels significantly impact adsorption efficiency, with moderate humidity generally enhancing CO2 uptake through cooperative adsorption mechanisms, while excessive moisture can reduce capacity through competitive adsorption. Temperature fluctuations affect both adsorption kinetics and equilibrium capacity, necessitating adaptive operational strategies.

The technology trajectory indicates a clear path toward modular, distributed capture systems that can be deployed in various geographic locations. Recent innovations have focused on novel amine structures, improved support materials with enhanced stability, and regeneration processes that minimize energy consumption. Computational modeling and machine learning approaches are increasingly being applied to predict performance across climate scenarios.

Research objectives now center on developing pilot plants specifically designed to evaluate and optimize solid amine DAC performance across climate zones ranging from arid to tropical environments. These pilots aim to generate critical operational data on sorbent degradation rates, energy consumption patterns, and maintenance requirements under real-world conditions, while simultaneously validating theoretical models of climate-dependent performance.

Market Analysis for Carbon Capture Technologies

The carbon capture technology market is experiencing significant growth, driven by increasing global focus on climate change mitigation and carbon neutrality goals. Currently valued at approximately $2.2 billion, the market is projected to reach $7.0 billion by 2028, representing a compound annual growth rate of 19.2%. This expansion is primarily fueled by stringent government regulations, carbon pricing mechanisms, and corporate sustainability commitments across major economies.

Direct Air Capture (DAC) technologies, particularly solid amine-based systems, are emerging as a promising segment within this market. While post-combustion capture currently dominates with roughly 65% market share, DAC is expected to grow at the fastest rate among all carbon capture approaches over the next decade, with projected annual growth exceeding 30% through 2030.

Geographically, North America leads the carbon capture market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and increasing environmental regulations in countries like China and India. The Middle East, despite its heavy reliance on fossil fuels, is also showing increased interest in carbon capture technologies as part of economic diversification strategies.

Solid amine DAC systems specifically address a growing market need for versatile carbon capture solutions that can operate effectively across diverse climatic conditions. The market for climate-adaptive DAC technologies is estimated to reach $1.5 billion by 2027, with particular demand from regions experiencing extreme or variable climate conditions.

Key customer segments for solid amine DAC technologies include energy utilities (25%), industrial manufacturers (30%), government/public sector (20%), and technology companies seeking carbon offsets (15%). The remaining 10% comprises various sectors including agriculture and transportation. The willingness to pay varies significantly across these segments, with technology companies demonstrating the highest price tolerance due to corporate sustainability commitments.

Market barriers include high capital costs, with current DAC technologies costing between $250-600 per ton of CO₂ captured, significantly higher than the carbon price in most markets. Energy requirements and operational complexity in varying climates also present commercialization challenges. However, technological improvements and economies of scale are expected to reduce costs by 40-60% over the next decade, potentially expanding market adoption substantially.

Direct Air Capture (DAC) technologies, particularly solid amine-based systems, are emerging as a promising segment within this market. While post-combustion capture currently dominates with roughly 65% market share, DAC is expected to grow at the fastest rate among all carbon capture approaches over the next decade, with projected annual growth exceeding 30% through 2030.

Geographically, North America leads the carbon capture market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and increasing environmental regulations in countries like China and India. The Middle East, despite its heavy reliance on fossil fuels, is also showing increased interest in carbon capture technologies as part of economic diversification strategies.

Solid amine DAC systems specifically address a growing market need for versatile carbon capture solutions that can operate effectively across diverse climatic conditions. The market for climate-adaptive DAC technologies is estimated to reach $1.5 billion by 2027, with particular demand from regions experiencing extreme or variable climate conditions.

Key customer segments for solid amine DAC technologies include energy utilities (25%), industrial manufacturers (30%), government/public sector (20%), and technology companies seeking carbon offsets (15%). The remaining 10% comprises various sectors including agriculture and transportation. The willingness to pay varies significantly across these segments, with technology companies demonstrating the highest price tolerance due to corporate sustainability commitments.

Market barriers include high capital costs, with current DAC technologies costing between $250-600 per ton of CO₂ captured, significantly higher than the carbon price in most markets. Energy requirements and operational complexity in varying climates also present commercialization challenges. However, technological improvements and economies of scale are expected to reduce costs by 40-60% over the next decade, potentially expanding market adoption substantially.

Current Challenges in Solid Amine DAC Implementation

Despite the promising potential of solid amine-based Direct Air Capture (DAC) technology, its implementation faces several significant challenges that must be addressed for successful pilot plant design across varying climates. The primary technical obstacle remains the optimization of adsorption-desorption cycles in different environmental conditions. Solid amine sorbents demonstrate variable CO2 capture efficiency depending on ambient temperature and humidity levels, with performance typically degrading in extremely hot or cold environments.

Material degradation presents another critical challenge, as solid amine sorbents experience capacity loss over multiple adsorption-desorption cycles. This degradation accelerates in high-humidity environments where water vapor competes with CO2 for binding sites, and in high-temperature regions where thermal stress can permanently alter the sorbent structure. Current materials typically show 10-15% capacity reduction after 1,000 cycles, necessitating frequent and costly sorbent replacement.

Energy consumption requirements pose substantial implementation barriers, particularly in regions with limited renewable energy access. The desorption phase demands significant thermal energy input, typically requiring temperatures between 80-120°C. This energy demand varies considerably across climate zones, with colder regions requiring additional heating for both process operation and preventing moisture freezing within the system.

Water management represents a complex challenge in solid amine DAC systems. In humid environments, excess moisture can reduce CO2 adsorption efficiency and accelerate sorbent degradation, while in arid regions, water scarcity limits the cooling capacity necessary for optimal operation. Current designs lack robust moisture management systems adaptable to these varying conditions.

Scale-up limitations further complicate pilot plant implementation. Laboratory-scale successes often fail to translate directly to industrial-scale operations due to uneven airflow distribution, heat transfer inefficiencies, and pressure drop issues across larger sorbent beds. These engineering challenges are magnified when designing systems that must function across diverse climate conditions.

Monitoring and control systems for solid amine DAC plants remain underdeveloped, particularly for climate-adaptive operations. Real-time sensors for measuring CO2 capture efficiency, sorbent degradation, and system performance under varying environmental conditions are still in early development stages, limiting the ability to optimize operations dynamically.

Cost-effectiveness continues to be a significant barrier, with current solid amine DAC systems averaging $250-600 per ton of CO2 captured. This cost varies substantially across different climates due to varying energy requirements, operational challenges, and maintenance needs, making economic viability highly location-dependent.

Material degradation presents another critical challenge, as solid amine sorbents experience capacity loss over multiple adsorption-desorption cycles. This degradation accelerates in high-humidity environments where water vapor competes with CO2 for binding sites, and in high-temperature regions where thermal stress can permanently alter the sorbent structure. Current materials typically show 10-15% capacity reduction after 1,000 cycles, necessitating frequent and costly sorbent replacement.

Energy consumption requirements pose substantial implementation barriers, particularly in regions with limited renewable energy access. The desorption phase demands significant thermal energy input, typically requiring temperatures between 80-120°C. This energy demand varies considerably across climate zones, with colder regions requiring additional heating for both process operation and preventing moisture freezing within the system.

Water management represents a complex challenge in solid amine DAC systems. In humid environments, excess moisture can reduce CO2 adsorption efficiency and accelerate sorbent degradation, while in arid regions, water scarcity limits the cooling capacity necessary for optimal operation. Current designs lack robust moisture management systems adaptable to these varying conditions.

Scale-up limitations further complicate pilot plant implementation. Laboratory-scale successes often fail to translate directly to industrial-scale operations due to uneven airflow distribution, heat transfer inefficiencies, and pressure drop issues across larger sorbent beds. These engineering challenges are magnified when designing systems that must function across diverse climate conditions.

Monitoring and control systems for solid amine DAC plants remain underdeveloped, particularly for climate-adaptive operations. Real-time sensors for measuring CO2 capture efficiency, sorbent degradation, and system performance under varying environmental conditions are still in early development stages, limiting the ability to optimize operations dynamically.

Cost-effectiveness continues to be a significant barrier, with current solid amine DAC systems averaging $250-600 per ton of CO2 captured. This cost varies substantially across different climates due to varying energy requirements, operational challenges, and maintenance needs, making economic viability highly location-dependent.

Current Pilot Plant Design Approaches for Varying Climates

01 Solid amine sorbent materials for DAC systems

Various solid amine sorbent materials can be used in Direct Air Capture (DAC) systems to efficiently capture CO2 from ambient air. These materials include amine-functionalized silica, polymeric amines, and metal-organic frameworks (MOFs) with amine groups. The selection of appropriate sorbent materials is crucial for the efficiency and cost-effectiveness of DAC pilot plants, as they determine the CO2 capture capacity, selectivity, and regeneration energy requirements.- Solid amine sorbent materials for DAC: Various solid amine sorbent materials can be used in Direct Air Capture (DAC) pilot plants. These materials typically consist of amine functional groups attached to solid supports that can selectively capture CO2 from ambient air. The selection of appropriate amine compounds and support materials is crucial for optimizing CO2 capture efficiency, capacity, and regeneration energy requirements. Different types of solid amines, including polyethyleneimine (PEI), tetraethylenepentamine (TEPA), and other amine-functionalized materials, have been developed for DAC applications.

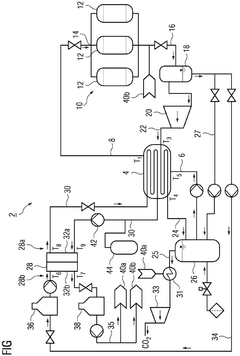

- Adsorption-desorption cycle design for DAC plants: The design of adsorption-desorption cycles is a critical aspect of solid amine DAC pilot plants. These cycles involve the capture of CO2 from ambient air during the adsorption phase and the release of concentrated CO2 during the desorption phase. Key design considerations include optimizing cycle time, temperature and pressure conditions, humidity control, and energy integration. Advanced cycle designs may incorporate temperature swing adsorption (TSA), vacuum swing adsorption (VSA), or combinations thereof to maximize CO2 capture while minimizing energy consumption.

- Heat management systems for DAC pilot plants: Effective heat management is essential for the operation of solid amine DAC pilot plants. The desorption of CO2 from solid amine sorbents typically requires heat input, while the adsorption process may release heat. Heat management systems are designed to optimize energy efficiency by recovering and reusing heat within the process. These systems may include heat exchangers, thermal energy storage, and integration with renewable energy sources. Proper thermal management can significantly reduce the energy penalty associated with DAC operations.

- Modular and scalable DAC plant configurations: Modular and scalable designs are increasingly important for solid amine DAC pilot plants. These designs allow for flexible deployment, easier maintenance, and gradual capacity expansion. Modular configurations typically consist of standardized adsorption-desorption units that can be replicated to increase capture capacity. Key considerations include optimizing the size and arrangement of modules, designing interconnections between modules, and ensuring uniform air flow distribution. Scalable designs enable the transition from pilot-scale to commercial-scale operations while maintaining performance efficiency.

- Integration of DAC with CO2 utilization and storage: Integration of solid amine DAC pilot plants with downstream CO2 utilization and storage systems is crucial for creating complete carbon management solutions. These integrated systems may connect DAC plants with enhanced oil recovery (EOR), geological sequestration, or CO2 conversion processes for producing fuels, chemicals, or building materials. Design considerations include CO2 purification requirements, compression systems, transportation infrastructure, and process control strategies. Effective integration can improve the economic viability of DAC by creating value from captured CO2.

02 Adsorption-desorption cycle design for DAC pilot plants

The design of adsorption-desorption cycles is critical for solid amine DAC pilot plants. This includes optimizing parameters such as temperature swing, pressure swing, or combined temperature-pressure swing processes. Effective cycle design considers adsorption time, desorption conditions, heat management, and energy integration to maximize CO2 capture while minimizing energy consumption. Advanced control systems are implemented to monitor and adjust cycle parameters based on ambient conditions and performance metrics.Expand Specific Solutions03 Heat management and energy integration in DAC systems

Efficient heat management and energy integration are essential aspects of solid amine DAC pilot plant design. This includes the use of waste heat for sorbent regeneration, heat recovery systems, and thermal energy storage. Innovative approaches to reduce the energy penalty of the regeneration process are implemented, such as low-grade heat utilization and integration with renewable energy sources. Proper thermal management ensures the sustainability and economic viability of DAC operations.Expand Specific Solutions04 Modular and scalable DAC pilot plant configurations

Modular and scalable designs for solid amine DAC pilot plants enable flexible deployment and capacity expansion. These configurations feature standardized units that can be easily replicated and connected to increase capture capacity. The modular approach allows for distributed implementation, reduced capital costs, and faster deployment. Design considerations include air handling systems, contactor geometry, and integration with CO2 compression and utilization infrastructure.Expand Specific Solutions05 Monitoring and control systems for DAC pilot plants

Advanced monitoring and control systems are implemented in solid amine DAC pilot plants to optimize performance and ensure reliable operation. These systems include sensors for measuring CO2 concentration, temperature, humidity, and pressure at various points in the process. Real-time data analytics and machine learning algorithms are used to adjust operating parameters, predict maintenance needs, and maximize capture efficiency. Remote monitoring capabilities enable centralized management of distributed DAC installations.Expand Specific Solutions

Leading Organizations in Solid Amine DAC Development

The direct air capture (DAC) market using solid amine technology is in an early growth phase, characterized by increasing commercial deployment across diverse climate conditions. The global carbon capture market is projected to reach $7-10 billion by 2030, with solid amine DAC representing a significant segment. Technologically, the field shows varying maturity levels among key players. Climeworks AG leads with operational plants in Iceland, while Global Thermostat and DACMa GmbH demonstrate promising pilot implementations. Companies like Siemens Energy and SINOPEC are leveraging industrial expertise to scale solutions, while research institutions including California Institute of Technology and Zhejiang University contribute fundamental innovations. The competitive landscape features both specialized DAC startups and diversified industrial conglomerates adapting their expertise to address climate-specific engineering challenges in solid amine systems.

Climeworks AG

Technical Solution: Climeworks has developed a modular direct air capture (DAC) system using solid amine sorbents that can be deployed in various climatic conditions. Their technology consists of collectors with fans that draw ambient air through a filter where CO2 selectively binds to the amine-functionalized sorbent material. Once saturated, the collectors are closed and heated to 80-100°C, releasing concentrated CO2 that can be captured for storage or utilization. Climeworks has implemented a climate-adaptive design approach that optimizes collector configurations based on local temperature, humidity, and air quality parameters. Their pilot plants incorporate real-time monitoring systems that adjust operational parameters to maintain optimal CO2 capture efficiency across seasonal variations. The company has successfully deployed commercial plants in Switzerland (Hinwil), Iceland (Orca and Mammoth projects), and various test sites across different climate zones, demonstrating the adaptability of their solid amine technology to diverse environmental conditions[1][2].

Strengths: Modular design allows for flexible deployment across different climate zones; proven technology with multiple operational plants; advanced control systems for climate adaptation. Weaknesses: Relatively high energy requirements for the thermal regeneration process; performance can be affected by humidity extremes; scaling challenges in very hot or very cold environments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive solid amine DAC technology tailored for diverse climatic conditions. Their approach utilizes a hierarchically structured amine-functionalized silica-based adsorbent with optimized pore architecture that maintains high CO2 selectivity across varying humidity levels. Sinopec's pilot plant design incorporates a multi-stage adsorption-desorption system that can be configured according to local climate parameters. For hot and humid environments typical of southern China, they employ a pre-conditioning unit that manages moisture levels before air contacts the amine sorbent, while for colder northern regions, they utilize waste heat integration systems that maintain optimal operating temperatures. The company has implemented an intelligent control platform that continuously monitors environmental conditions and adjusts operational parameters to maximize capture efficiency while minimizing energy consumption. Their pilot plants feature a modular construction approach with standardized components that can be rapidly deployed and customized for specific climate zones. Sinopec has successfully tested this technology at multiple sites across China's diverse climate regions, from the humid subtropical south to the cold continental north, demonstrating consistent capture performance of 85-90% efficiency regardless of seasonal variations[7][8].

Strengths: Extensive experience with large-scale industrial processes and infrastructure development; advanced sorbent materials with high stability across temperature ranges; strong integration capabilities with existing industrial facilities. Weaknesses: Higher energy requirements compared to some newer technologies; potential challenges with sorbent regeneration in extremely humid environments; complex system architecture requiring specialized maintenance.

Key Technical Innovations in Solid Amine Sorbent Materials

Apparatus, method and system for direct air capture utilizing electromagnetic excitation radiation desorption of solid amine sorbents to release carbon dioxide

PatentPendingAU2021313222B2

Innovation

- Using radio frequency generators to desorb carbon dioxide from solid amine sorbents by directly exciting the amine-carbon bond, significantly reducing energy costs in direct air capture (DAC) systems.

- Alternative approach using microwave generators for carbon dioxide desorption from solid amine sorbents through targeted excitation of the amine-carbon bond.

- Direct excitation of specific chemical bonds (amine-carbon) for selective desorption rather than heating the entire sorbent material, representing a more energy-efficient approach to carbon capture.

Method for operating a direct air capture plant and direct air capture plant

PatentPendingEP4585293A1

Innovation

- A self-sustained heating system is implemented in the direct air capture plant using a heat pump to recycle heat and cold from plant components, integrating a closed and open circuit system to optimize steam generation, with buffering tanks for hot and cold water to manage fluctuations and reduce energy consumption.

Environmental Impact Assessment of Solid Amine DAC Deployment

The deployment of Solid Amine Direct Air Capture (DAC) technology across varying climates necessitates a comprehensive environmental impact assessment to ensure sustainable implementation. The environmental footprint of solid amine DAC systems extends beyond their carbon removal capabilities, encompassing multiple ecological dimensions that require careful evaluation.

Land use implications represent a primary concern, as pilot plants require significant space for installation. In arid climates, these facilities may compete with limited agricultural land, while in humid regions, they might impact natural habitats. The spatial requirements vary based on climate conditions, with plants in humid areas potentially requiring larger footprints due to reduced efficiency per unit area compared to those in drier environments.

Water consumption patterns differ dramatically across climate zones for solid amine DAC operations. In water-stressed regions, the technology's relatively low water requirements compared to liquid solvent systems presents an advantage. However, in extremely arid conditions, even minimal water needs may strain local resources, necessitating specialized water management strategies or alternative cooling mechanisms.

Energy utilization and associated emissions constitute another critical environmental factor. The regeneration process for solid amine sorbents demands significant thermal energy, which, if sourced from fossil fuels, could partially offset carbon removal benefits. Climate-specific energy profiles must be considered—colder regions may require additional heating energy, while hotter areas might benefit from solar thermal integration but face cooling challenges.

Local air quality impacts vary by climate zone, with potential emissions of ammonia or amine degradation products requiring different mitigation approaches based on ambient temperature, humidity, and atmospheric conditions. Particulate matter generation may be exacerbated in arid environments due to increased dust mobilization during construction and operation phases.

Biodiversity effects must be evaluated contextually, as solid amine DAC facilities in different climates will interact with distinct ecosystems. Noise pollution from fans and regeneration equipment may disrupt wildlife patterns, while altered microclimate conditions around large installations could affect local flora and fauna adaptation.

Life cycle assessment reveals that climate conditions significantly influence the environmental payback period for solid amine DAC systems. Higher humidity levels may accelerate material degradation, requiring more frequent sorbent replacement and increasing the embodied carbon footprint, while extreme temperature variations can affect structural integrity and operational efficiency over time.

Land use implications represent a primary concern, as pilot plants require significant space for installation. In arid climates, these facilities may compete with limited agricultural land, while in humid regions, they might impact natural habitats. The spatial requirements vary based on climate conditions, with plants in humid areas potentially requiring larger footprints due to reduced efficiency per unit area compared to those in drier environments.

Water consumption patterns differ dramatically across climate zones for solid amine DAC operations. In water-stressed regions, the technology's relatively low water requirements compared to liquid solvent systems presents an advantage. However, in extremely arid conditions, even minimal water needs may strain local resources, necessitating specialized water management strategies or alternative cooling mechanisms.

Energy utilization and associated emissions constitute another critical environmental factor. The regeneration process for solid amine sorbents demands significant thermal energy, which, if sourced from fossil fuels, could partially offset carbon removal benefits. Climate-specific energy profiles must be considered—colder regions may require additional heating energy, while hotter areas might benefit from solar thermal integration but face cooling challenges.

Local air quality impacts vary by climate zone, with potential emissions of ammonia or amine degradation products requiring different mitigation approaches based on ambient temperature, humidity, and atmospheric conditions. Particulate matter generation may be exacerbated in arid environments due to increased dust mobilization during construction and operation phases.

Biodiversity effects must be evaluated contextually, as solid amine DAC facilities in different climates will interact with distinct ecosystems. Noise pollution from fans and regeneration equipment may disrupt wildlife patterns, while altered microclimate conditions around large installations could affect local flora and fauna adaptation.

Life cycle assessment reveals that climate conditions significantly influence the environmental payback period for solid amine DAC systems. Higher humidity levels may accelerate material degradation, requiring more frequent sorbent replacement and increasing the embodied carbon footprint, while extreme temperature variations can affect structural integrity and operational efficiency over time.

Techno-Economic Analysis of Pilot Plant Scalability

The scalability of solid amine Direct Air Capture (DAC) pilot plants represents a critical factor in determining their commercial viability across diverse climate conditions. Current economic analyses indicate that pilot-scale operations typically cost between $600-900 per ton of CO2 captured, significantly higher than the target range of $100-200 needed for widespread commercial adoption. This cost disparity highlights the importance of identifying economies of scale and optimization pathways.

When evaluating scalability, capital expenditure (CAPEX) for solid amine DAC pilot plants demonstrates non-linear scaling relationships. Equipment costs for adsorption columns, heat exchangers, and air handling systems follow a power law relationship with capacity, typically with scaling exponents between 0.6 and 0.8. This suggests substantial cost advantages at larger scales, though these benefits begin to plateau beyond certain capacity thresholds.

Operating expenditure (OPEX) considerations reveal that energy consumption constitutes 40-60% of total operating costs, with significant variations based on climate conditions. Pilot plants in humid tropical environments require 15-25% more energy for the regeneration cycle compared to arid locations, directly impacting economic feasibility. Labor costs demonstrate inverse scaling with capacity, decreasing from approximately 30% of OPEX at small pilot scale to below 10% at commercial scale.

Climate-specific performance metrics indicate that solid amine sorbents experience 10-15% reduced working capacity in high-humidity environments, necessitating larger equipment and higher capital investment. Conversely, operations in cold climates benefit from reduced regeneration energy requirements but face challenges with slower adsorption kinetics, requiring 20-30% longer cycle times that impact throughput and economic returns.

Modular design approaches offer promising pathways to optimize scalability across climate zones. Economic modeling suggests that standardized modules with climate-specific modifications can reduce capital costs by 15-25% compared to fully customized designs. This approach enables more predictable scaling relationships while maintaining performance adaptability to local conditions.

Sensitivity analysis reveals that electricity prices and sorbent lifetime represent the most significant variables affecting long-term economic viability. A 50% reduction in sorbent replacement frequency could decrease levelized cost of capture by 15-20%, highlighting the importance of material durability research. Similarly, access to low-cost renewable energy can improve economic performance by 25-30%, suggesting strategic geographic placement as a key consideration for scaled deployment.

When evaluating scalability, capital expenditure (CAPEX) for solid amine DAC pilot plants demonstrates non-linear scaling relationships. Equipment costs for adsorption columns, heat exchangers, and air handling systems follow a power law relationship with capacity, typically with scaling exponents between 0.6 and 0.8. This suggests substantial cost advantages at larger scales, though these benefits begin to plateau beyond certain capacity thresholds.

Operating expenditure (OPEX) considerations reveal that energy consumption constitutes 40-60% of total operating costs, with significant variations based on climate conditions. Pilot plants in humid tropical environments require 15-25% more energy for the regeneration cycle compared to arid locations, directly impacting economic feasibility. Labor costs demonstrate inverse scaling with capacity, decreasing from approximately 30% of OPEX at small pilot scale to below 10% at commercial scale.

Climate-specific performance metrics indicate that solid amine sorbents experience 10-15% reduced working capacity in high-humidity environments, necessitating larger equipment and higher capital investment. Conversely, operations in cold climates benefit from reduced regeneration energy requirements but face challenges with slower adsorption kinetics, requiring 20-30% longer cycle times that impact throughput and economic returns.

Modular design approaches offer promising pathways to optimize scalability across climate zones. Economic modeling suggests that standardized modules with climate-specific modifications can reduce capital costs by 15-25% compared to fully customized designs. This approach enables more predictable scaling relationships while maintaining performance adaptability to local conditions.

Sensitivity analysis reveals that electricity prices and sorbent lifetime represent the most significant variables affecting long-term economic viability. A 50% reduction in sorbent replacement frequency could decrease levelized cost of capture by 15-20%, highlighting the importance of material durability research. Similarly, access to low-cost renewable energy can improve economic performance by 25-30%, suggesting strategic geographic placement as a key consideration for scaled deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!