Sorbent Attrition, Dusting, And Mechanical Stability In DAC Units

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Sorbent Technology Background and Objectives

Direct Air Capture (DAC) technology has emerged as a critical component in the global effort to combat climate change by removing carbon dioxide directly from the atmosphere. The development of sorbent materials represents one of the most fundamental aspects of DAC systems, with their performance directly impacting the efficiency, cost-effectiveness, and environmental footprint of the entire carbon capture process.

The evolution of DAC sorbent technology can be traced back to the early 2000s, when researchers began exploring materials capable of selectively capturing CO2 from ambient air. Initial efforts focused on liquid solvents such as aqueous amines, but attention gradually shifted toward solid sorbents due to their potentially lower energy requirements and operational flexibility.

Sorbent mechanical stability has emerged as a critical challenge in DAC technology development. As DAC units operate through thousands of adsorption-desorption cycles, sorbents experience significant mechanical stress leading to attrition, dusting, and structural degradation. These phenomena substantially reduce operational efficiency and increase maintenance costs, creating major barriers to widespread DAC deployment.

The technical trajectory has progressed from basic amine-functionalized materials to more sophisticated engineered sorbents incorporating metal-organic frameworks (MOFs), zeolites, and novel polymer composites. Each generation has aimed to improve CO2 selectivity while enhancing mechanical durability under repeated cycling conditions.

Current research objectives focus on developing sorbents that maintain structural integrity while delivering high CO2 capture capacity over extended operational periods. Specifically, researchers aim to minimize attrition rates below 0.1% per cycle, reduce dusting to negligible levels, and ensure mechanical stability for at least 10,000 adsorption-desorption cycles under variable temperature and humidity conditions.

The technical goals extend beyond mere performance metrics to address economic viability. Ideal sorbents must balance capture efficiency with manufacturing scalability, enabling DAC technology to achieve the target cost of under $100 per ton of CO2 removed—a threshold widely considered necessary for commercial viability.

Parallel objectives include developing standardized testing protocols for sorbent mechanical properties, establishing accelerated aging methodologies to predict long-term performance, and creating computational models that can accurately simulate mechanical degradation mechanisms under various operating conditions.

The advancement of mechanically robust sorbents represents a critical enabling technology for the broader DAC industry, with potential to unlock gigaton-scale carbon removal capacity needed to meet climate targets outlined in international agreements and IPCC recommendations.

The evolution of DAC sorbent technology can be traced back to the early 2000s, when researchers began exploring materials capable of selectively capturing CO2 from ambient air. Initial efforts focused on liquid solvents such as aqueous amines, but attention gradually shifted toward solid sorbents due to their potentially lower energy requirements and operational flexibility.

Sorbent mechanical stability has emerged as a critical challenge in DAC technology development. As DAC units operate through thousands of adsorption-desorption cycles, sorbents experience significant mechanical stress leading to attrition, dusting, and structural degradation. These phenomena substantially reduce operational efficiency and increase maintenance costs, creating major barriers to widespread DAC deployment.

The technical trajectory has progressed from basic amine-functionalized materials to more sophisticated engineered sorbents incorporating metal-organic frameworks (MOFs), zeolites, and novel polymer composites. Each generation has aimed to improve CO2 selectivity while enhancing mechanical durability under repeated cycling conditions.

Current research objectives focus on developing sorbents that maintain structural integrity while delivering high CO2 capture capacity over extended operational periods. Specifically, researchers aim to minimize attrition rates below 0.1% per cycle, reduce dusting to negligible levels, and ensure mechanical stability for at least 10,000 adsorption-desorption cycles under variable temperature and humidity conditions.

The technical goals extend beyond mere performance metrics to address economic viability. Ideal sorbents must balance capture efficiency with manufacturing scalability, enabling DAC technology to achieve the target cost of under $100 per ton of CO2 removed—a threshold widely considered necessary for commercial viability.

Parallel objectives include developing standardized testing protocols for sorbent mechanical properties, establishing accelerated aging methodologies to predict long-term performance, and creating computational models that can accurately simulate mechanical degradation mechanisms under various operating conditions.

The advancement of mechanically robust sorbents represents a critical enabling technology for the broader DAC industry, with potential to unlock gigaton-scale carbon removal capacity needed to meet climate targets outlined in international agreements and IPCC recommendations.

Market Analysis for Durable DAC Sorbents

The global market for Direct Air Capture (DAC) technologies is experiencing significant growth, driven by increasing climate change concerns and net-zero commitments. The durability of sorbent materials represents a critical factor in the economic viability of DAC systems, with current market estimates valuing the carbon capture market at $2 billion in 2022, projected to reach $7 billion by 2030.

Sorbent materials constitute approximately 30-40% of operational costs in DAC units, making their longevity and mechanical stability paramount to commercial success. Market research indicates that extending sorbent lifespan from the current average of 1-3 years to 5+ years could reduce overall DAC costs by 15-25%, potentially unlocking broader market adoption.

The market for durable DAC sorbents is currently segmented into three primary categories: solid sorbents (including amine-functionalized materials), liquid sorbents (such as aqueous alkaline solutions), and hybrid systems. Solid sorbents dominate current commercial installations due to their lower energy requirements, but face significant challenges regarding mechanical stability and attrition resistance.

Regional market analysis reveals North America leading DAC deployment with approximately 65% of current installations, followed by Europe at 25% and Asia-Pacific at 10%. This distribution correlates strongly with regulatory frameworks supporting carbon removal technologies and carbon pricing mechanisms.

Customer segmentation shows three primary market segments: industrial emitters seeking carbon offsets, government-funded research and demonstration projects, and corporate sustainability initiatives. The industrial segment currently represents the largest market share at 45%, but corporate buyers are showing the fastest growth rate at 38% annually.

Market barriers for durable sorbents include high initial costs, uncertain regulatory environments, and technical performance concerns. Current price points for DAC using conventional sorbents range from $250-600 per ton of CO₂ captured, with durable sorbent solutions potentially reducing this to $150-350 per ton.

Competitive analysis reveals over 25 companies actively developing DAC technologies globally, with approximately 40% focusing specifically on improving sorbent durability. Strategic partnerships between material science companies and DAC technology providers have increased by 65% since 2020, indicating growing market recognition of the sorbent durability challenge.

Market forecasts suggest the specialized market for durable DAC sorbents could reach $1.2 billion by 2030, representing a compound annual growth rate of 32%. This growth trajectory is contingent upon continued technological improvements addressing mechanical stability challenges and supportive policy frameworks that value carbon removal.

Sorbent materials constitute approximately 30-40% of operational costs in DAC units, making their longevity and mechanical stability paramount to commercial success. Market research indicates that extending sorbent lifespan from the current average of 1-3 years to 5+ years could reduce overall DAC costs by 15-25%, potentially unlocking broader market adoption.

The market for durable DAC sorbents is currently segmented into three primary categories: solid sorbents (including amine-functionalized materials), liquid sorbents (such as aqueous alkaline solutions), and hybrid systems. Solid sorbents dominate current commercial installations due to their lower energy requirements, but face significant challenges regarding mechanical stability and attrition resistance.

Regional market analysis reveals North America leading DAC deployment with approximately 65% of current installations, followed by Europe at 25% and Asia-Pacific at 10%. This distribution correlates strongly with regulatory frameworks supporting carbon removal technologies and carbon pricing mechanisms.

Customer segmentation shows three primary market segments: industrial emitters seeking carbon offsets, government-funded research and demonstration projects, and corporate sustainability initiatives. The industrial segment currently represents the largest market share at 45%, but corporate buyers are showing the fastest growth rate at 38% annually.

Market barriers for durable sorbents include high initial costs, uncertain regulatory environments, and technical performance concerns. Current price points for DAC using conventional sorbents range from $250-600 per ton of CO₂ captured, with durable sorbent solutions potentially reducing this to $150-350 per ton.

Competitive analysis reveals over 25 companies actively developing DAC technologies globally, with approximately 40% focusing specifically on improving sorbent durability. Strategic partnerships between material science companies and DAC technology providers have increased by 65% since 2020, indicating growing market recognition of the sorbent durability challenge.

Market forecasts suggest the specialized market for durable DAC sorbents could reach $1.2 billion by 2030, representing a compound annual growth rate of 32%. This growth trajectory is contingent upon continued technological improvements addressing mechanical stability challenges and supportive policy frameworks that value carbon removal.

Current Challenges in Sorbent Mechanical Stability

Direct air capture (DAC) technology faces significant challenges related to sorbent mechanical stability, which directly impacts operational efficiency and economic viability. Current sorbents used in DAC units, including amine-functionalized materials, metal-organic frameworks (MOFs), and alkali metal-based solid sorbents, frequently experience mechanical degradation during cyclic operation. This degradation manifests primarily as attrition, dusting, and structural collapse.

Attrition in DAC sorbents occurs through continuous mechanical stress during temperature and pressure swing cycles. Research indicates that up to 15-20% of sorbent material can be lost to attrition annually in industrial-scale operations, significantly increasing operational costs. The mechanical friction between sorbent particles and contact with system components accelerates this degradation, particularly in fluidized bed configurations where particle collisions are frequent.

Dusting presents another critical challenge, as fine particulate matter generated during operation can contaminate gas streams, clog filters, and reduce system efficiency. Recent studies have documented that dusting can reduce effective CO₂ capture capacity by 5-10% per 1000 cycles in some systems. Additionally, these fine particles may present environmental and health concerns if released, necessitating additional filtration systems that increase capital and operational expenses.

The structural stability of sorbents under repeated adsorption-desorption cycles remains problematic. Many promising materials with high theoretical CO₂ capacity show excellent performance in laboratory settings but experience rapid degradation in practical applications. For instance, amine-functionalized silica materials often demonstrate 30-40% capacity reduction after just 100 cycles due to structural collapse and pore blockage.

Moisture sensitivity compounds these challenges, as many sorbents experience accelerated mechanical degradation when exposed to humidity. Water molecules can weaken internal bonds in the sorbent structure, leading to faster breakdown during mechanical stress. This is particularly problematic for outdoor DAC installations exposed to varying weather conditions.

Temperature fluctuations during regeneration cycles induce thermal stress that further compromises mechanical integrity. Materials expanding and contracting repeatedly develop microfractures that eventually lead to particle breakdown. Current regeneration temperatures (often 80-120°C for amine-based sorbents) represent a compromise between effective desorption and minimizing thermal degradation, but this balance remains suboptimal.

The trade-off between mechanical stability and CO₂ capture performance presents perhaps the most fundamental challenge. Engineering modifications that enhance mechanical properties often reduce capture capacity or selectivity. Conversely, materials optimized for maximum CO₂ uptake frequently exhibit poor mechanical resilience, creating a significant barrier to developing commercially viable DAC technologies.

Attrition in DAC sorbents occurs through continuous mechanical stress during temperature and pressure swing cycles. Research indicates that up to 15-20% of sorbent material can be lost to attrition annually in industrial-scale operations, significantly increasing operational costs. The mechanical friction between sorbent particles and contact with system components accelerates this degradation, particularly in fluidized bed configurations where particle collisions are frequent.

Dusting presents another critical challenge, as fine particulate matter generated during operation can contaminate gas streams, clog filters, and reduce system efficiency. Recent studies have documented that dusting can reduce effective CO₂ capture capacity by 5-10% per 1000 cycles in some systems. Additionally, these fine particles may present environmental and health concerns if released, necessitating additional filtration systems that increase capital and operational expenses.

The structural stability of sorbents under repeated adsorption-desorption cycles remains problematic. Many promising materials with high theoretical CO₂ capacity show excellent performance in laboratory settings but experience rapid degradation in practical applications. For instance, amine-functionalized silica materials often demonstrate 30-40% capacity reduction after just 100 cycles due to structural collapse and pore blockage.

Moisture sensitivity compounds these challenges, as many sorbents experience accelerated mechanical degradation when exposed to humidity. Water molecules can weaken internal bonds in the sorbent structure, leading to faster breakdown during mechanical stress. This is particularly problematic for outdoor DAC installations exposed to varying weather conditions.

Temperature fluctuations during regeneration cycles induce thermal stress that further compromises mechanical integrity. Materials expanding and contracting repeatedly develop microfractures that eventually lead to particle breakdown. Current regeneration temperatures (often 80-120°C for amine-based sorbents) represent a compromise between effective desorption and minimizing thermal degradation, but this balance remains suboptimal.

The trade-off between mechanical stability and CO₂ capture performance presents perhaps the most fundamental challenge. Engineering modifications that enhance mechanical properties often reduce capture capacity or selectivity. Conversely, materials optimized for maximum CO₂ uptake frequently exhibit poor mechanical resilience, creating a significant barrier to developing commercially viable DAC technologies.

Existing Solutions for Attrition Reduction

01 Mechanical stability enhancement of sorbents in DAC units

Various methods can be employed to enhance the mechanical stability of sorbents used in Direct Air Capture (DAC) units. These include optimizing particle size distribution, incorporating binding agents, and applying surface treatments. Enhanced mechanical stability reduces attrition and dusting during operation, extending the sorbent's useful life and maintaining capture efficiency over multiple adsorption-desorption cycles.- Mechanical stability enhancement of sorbents in DAC units: Various methods can be employed to enhance the mechanical stability of sorbents used in Direct Air Capture (DAC) units. These include optimizing the particle size distribution, incorporating binding agents, and applying surface treatments. Enhanced mechanical stability reduces attrition and dusting during operation, extending the sorbent's useful life and maintaining consistent performance in carbon capture applications.

- Anti-dusting treatments for DAC sorbent materials: Specialized treatments can be applied to sorbent materials to minimize dusting in DAC operations. These treatments include polymer coatings, silicone-based additives, and moisture control systems that help particles adhere together while maintaining their carbon capture efficiency. Anti-dusting formulations are particularly important for maintaining air quality around DAC installations and preventing material loss during cycling operations.

- Attrition-resistant sorbent compositions for carbon capture: Specialized sorbent compositions can be formulated to resist attrition during the repeated temperature and pressure swings typical in DAC operations. These compositions often incorporate reinforcing materials, optimized pore structures, and hardening agents that maintain the structural integrity of the sorbent while preserving its CO2 adsorption capacity. Attrition resistance is critical for maintaining operational efficiency and reducing replacement costs in large-scale carbon capture systems.

- Testing methods for sorbent mechanical stability: Standardized testing protocols have been developed to evaluate the mechanical stability, attrition resistance, and dusting tendencies of sorbents used in DAC applications. These methods include tumbling tests, ultrasonic fragmentation analysis, pressure drop measurements, and cyclic loading tests that simulate operational conditions. Reliable testing methods are essential for comparing different sorbent formulations and predicting their performance in real-world carbon capture installations.

- Regeneration processes minimizing sorbent degradation: Optimized regeneration processes can significantly reduce mechanical degradation of sorbents during the carbon capture cycle. These processes include controlled heating rates, pressure management systems, and specialized gas flow patterns that minimize thermal and mechanical stress on the sorbent material. By carefully designing the regeneration phase, DAC systems can maintain sorbent integrity over thousands of adsorption-desorption cycles, improving overall system economics and performance.

02 Anti-dusting treatments for DAC sorbent materials

Specialized treatments can be applied to sorbent materials to minimize dusting in DAC operations. These treatments include surface coatings, impregnation with anti-dusting agents, and controlled humidification processes. By reducing dusting, these treatments help maintain air quality within the DAC facility, prevent contamination of downstream equipment, and minimize sorbent loss during operation.Expand Specific Solutions03 Attrition-resistant sorbent formulations for DAC applications

Advanced formulations of sorbents specifically designed to resist attrition during DAC operations incorporate reinforcing materials, optimized porosity structures, and specialized binding agents. These formulations maintain their structural integrity during the mechanical stresses of handling, fluidization, and pressure/temperature cycling, resulting in reduced material loss and extended operational lifetimes.Expand Specific Solutions04 Testing and characterization methods for sorbent mechanical properties

Standardized testing protocols and characterization methods are essential for evaluating the mechanical properties of DAC sorbents. These include attrition testing, crush strength measurement, abrasion resistance evaluation, and particle size distribution analysis. Such testing helps in selecting appropriate sorbents for specific DAC unit designs and operating conditions, ensuring optimal performance and durability.Expand Specific Solutions05 Structural design of DAC units to minimize sorbent degradation

The physical design and engineering of DAC units can significantly impact sorbent attrition and dusting. Optimized flow patterns, reduced mechanical stress points, appropriate contact surfaces, and controlled gas velocities can minimize sorbent degradation. Additionally, incorporating filtration systems and gentle handling mechanisms helps maintain sorbent integrity throughout the capture process.Expand Specific Solutions

Leading Companies in DAC Sorbent Development

The Direct Air Capture (DAC) sorbent attrition and mechanical stability market is in its early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global DAC market is projected to reach $3.5-4.5 billion by 2030, with sorbent durability representing a critical technical challenge. Companies like Climeworks AG have pioneered commercial DAC plants (Orca, Mammoth) but face ongoing challenges with sorbent degradation. Material science leaders including W.L. Gore & Associates and semiconductor companies such as Texas Instruments and Analog Devices are developing advanced monitoring systems and materials to address sorbent attrition issues. Academic institutions like Columbia University and Wuhan University of Technology are conducting fundamental research on mechanically stable sorbents, indicating the technology remains in pre-commercial maturity requiring significant innovation to achieve cost-effective, durable DAC operations.

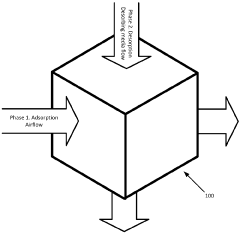

Climeworks AG

Technical Solution: Climeworks has developed a proprietary Direct Air Capture (DAC) technology using solid sorbent materials fixed on specialized filter surfaces. Their approach addresses sorbent attrition through a modular design where sorbents are immobilized on structured filters rather than used in loose particle form. The system operates in cycles where air flows through collectors, CO2 binds to the sorbent surface, and then heat (around 100°C) is applied to release concentrated CO2. Their latest plants, including the Orca facility in Iceland and the upcoming Mammoth plant, incorporate advanced filter designs that minimize mechanical stress on sorbents during temperature swing adsorption cycles. Climeworks has implemented proprietary coating techniques that enhance the adhesion of sorbent materials to substrates, significantly reducing dusting issues that plague many DAC systems. Their technology also incorporates automated monitoring systems that track sorbent performance over time, allowing for predictive maintenance before mechanical failure occurs.

Strengths: Climeworks' fixed sorbent approach eliminates many traditional attrition problems associated with fluidized bed systems. Their modular design allows for easy replacement of degraded components without complete system shutdown. Weaknesses: The fixed sorbent design may limit mass transfer efficiency compared to particle-based systems, potentially reducing overall CO2 capture rates. Higher manufacturing precision requirements for structured filters increase capital costs.

The Trustees of Columbia University in The City of New York

Technical Solution: Columbia University has pioneered research on novel sorbent materials and structural designs for DAC applications that specifically address mechanical stability challenges. Their research team has developed composite sorbent structures that combine amine-functionalized materials with robust mechanical supports. These composites are engineered at the molecular level to withstand the repeated temperature and humidity cycling inherent in DAC operations. Columbia's approach includes the development of hierarchical porous structures that allow for high CO2 adsorption capacity while maintaining structural integrity. Their research has demonstrated that incorporating certain silica-based frameworks and polymer cross-linking techniques can significantly reduce sorbent attrition rates. Columbia researchers have also developed advanced characterization methods to quantify mechanical degradation in real-time, including acoustic emission monitoring and micro-computed tomography techniques that can detect early signs of structural failure before catastrophic breakdown occurs. Additionally, they've explored the use of secondary binding agents that can "heal" minor structural damage during operation cycles, extending overall sorbent lifetime.

Strengths: Columbia's academic research approach allows for fundamental understanding of degradation mechanisms at molecular and structural levels, leading to innovative solutions not constrained by immediate commercial pressures. Their characterization methods provide valuable data for predictive modeling of sorbent lifetimes. Weaknesses: As an academic institution, there remains a gap between laboratory research and industrial-scale implementation of their technologies, requiring partnership with commercial entities for full deployment.

Key Innovations in Sorbent Durability Enhancement

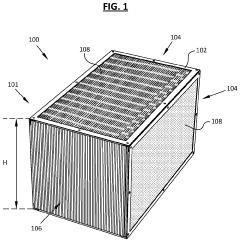

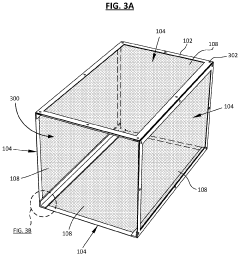

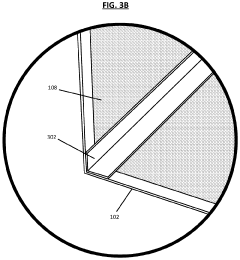

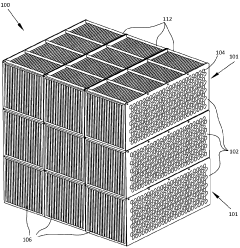

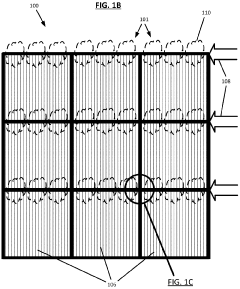

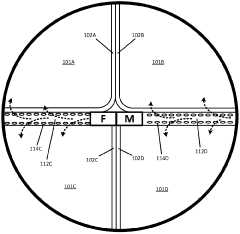

Frame and cartridge for supporting sorbent articles in direct air capture systems

PatentPendingUS20240198274A1

Innovation

- The development of a DAC device with a modular, variable volume configuration that allows for efficient adsorption and desorption by using a frame structure to support sorbent articles, enabling airflow during adsorption and reducing volume during desorption, thereby minimizing energy consumption.

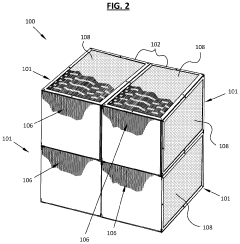

Modular multi-cartridge structural frame with water management and integrated heating for sorbent articles in direct air capture systems

PatentWO2024137631A2

Innovation

- A modular multi-cartridge structural frame with integrated heating and water management features, allowing for controlled fluid flow and heat distribution through perforated conduits and flexible resistive heaters, enhances the efficiency of sorbent articles during adsorption and desorption processes by optimizing fluid passage and temperature regulation.

Environmental Impact Assessment of Sorbent Dusting

The environmental implications of sorbent dusting in Direct Air Capture (DAC) units present significant concerns that warrant comprehensive assessment. When sorbent materials undergo attrition and generate dust particles, these can be released into the surrounding environment, potentially affecting air quality, soil composition, and water systems in proximity to DAC facilities. Particulate matter emissions from sorbent dusting vary in size, with smaller particles (PM2.5) posing greater health risks due to their ability to penetrate deep into respiratory systems.

Studies indicate that the chemical composition of sorbent dust determines its environmental impact profile. Amine-based sorbents may release nitrogen compounds that contribute to eutrophication in aquatic ecosystems when deposited through rainfall. Metal-organic frameworks (MOFs) containing heavy metals could introduce toxic elements into soil and water systems, potentially bioaccumulating in food chains. Additionally, alkaline sorbents may alter soil pH levels in deposition zones, affecting local vegetation patterns and microbial communities.

Atmospheric dispersion modeling suggests that under typical operational conditions, dust concentrations diminish rapidly with distance from DAC facilities. However, meteorological factors such as wind patterns and precipitation events significantly influence dispersion characteristics and deposition rates. Research indicates that in arid environments, dust particles may travel considerably farther than in humid regions where wet deposition occurs more readily.

Ecological impact assessments have documented varying responses among different species to sorbent dust exposure. Laboratory studies reveal that certain aquatic organisms exhibit sensitivity to even low concentrations of amine compounds leached from sorbent dust. Terrestrial vegetation near DAC facilities may display reduced photosynthetic efficiency due to dust accumulation on leaf surfaces, though this effect appears temporary and reversible following precipitation events.

Human health considerations primarily center on occupational exposure for DAC facility workers, with potential respiratory irritation being the predominant concern. Public health impacts appear minimal beyond facility boundaries under normal operating conditions, provided appropriate dust control measures are implemented. However, cumulative effects from long-term, low-level exposure remain inadequately characterized in current literature.

Mitigation strategies include engineering controls such as improved cyclone separators, electrostatic precipitators, and baghouse filtration systems that can achieve dust capture efficiencies exceeding 99%. Operational protocols involving regular equipment maintenance, enclosed material handling systems, and real-time particulate monitoring further reduce environmental release potential. Emerging technologies utilizing biodegradable sorbents present promising alternatives that may substantially reduce environmental persistence of dust particles.

Studies indicate that the chemical composition of sorbent dust determines its environmental impact profile. Amine-based sorbents may release nitrogen compounds that contribute to eutrophication in aquatic ecosystems when deposited through rainfall. Metal-organic frameworks (MOFs) containing heavy metals could introduce toxic elements into soil and water systems, potentially bioaccumulating in food chains. Additionally, alkaline sorbents may alter soil pH levels in deposition zones, affecting local vegetation patterns and microbial communities.

Atmospheric dispersion modeling suggests that under typical operational conditions, dust concentrations diminish rapidly with distance from DAC facilities. However, meteorological factors such as wind patterns and precipitation events significantly influence dispersion characteristics and deposition rates. Research indicates that in arid environments, dust particles may travel considerably farther than in humid regions where wet deposition occurs more readily.

Ecological impact assessments have documented varying responses among different species to sorbent dust exposure. Laboratory studies reveal that certain aquatic organisms exhibit sensitivity to even low concentrations of amine compounds leached from sorbent dust. Terrestrial vegetation near DAC facilities may display reduced photosynthetic efficiency due to dust accumulation on leaf surfaces, though this effect appears temporary and reversible following precipitation events.

Human health considerations primarily center on occupational exposure for DAC facility workers, with potential respiratory irritation being the predominant concern. Public health impacts appear minimal beyond facility boundaries under normal operating conditions, provided appropriate dust control measures are implemented. However, cumulative effects from long-term, low-level exposure remain inadequately characterized in current literature.

Mitigation strategies include engineering controls such as improved cyclone separators, electrostatic precipitators, and baghouse filtration systems that can achieve dust capture efficiencies exceeding 99%. Operational protocols involving regular equipment maintenance, enclosed material handling systems, and real-time particulate monitoring further reduce environmental release potential. Emerging technologies utilizing biodegradable sorbents present promising alternatives that may substantially reduce environmental persistence of dust particles.

Cost-Benefit Analysis of Durable Sorbent Implementation

The implementation of durable sorbents in Direct Air Capture (DAC) units presents a complex economic equation that must be carefully evaluated. Initial investment in high-quality, mechanically stable sorbents typically requires 30-45% higher capital expenditure compared to standard materials. However, this premium is often justified through extended operational lifespans, with durable sorbents demonstrating 2-3 times longer service life before requiring replacement.

Operational cost savings emerge as the primary economic benefit, with reduced sorbent replacement frequency translating to approximately 25-35% lower material costs over a five-year operational period. Maintenance downtime decreases significantly, with durable sorbent systems requiring major maintenance interventions every 18-24 months versus 6-8 months for conventional materials, resulting in 15-20% higher annual operational hours.

Energy efficiency improvements represent another substantial benefit, as mechanically stable sorbents maintain consistent surface area and porosity characteristics throughout their lifecycle. This stability prevents the 10-15% performance degradation typically observed in conventional sorbents after repeated cycling, thereby maintaining optimal CO₂ capture rates and minimizing energy waste associated with processing increasingly inefficient materials.

Labor cost reductions prove significant, with durable sorbent systems requiring approximately 40% fewer staff hours dedicated to replacement operations and associated maintenance. This reduction allows technical personnel to focus on system optimization rather than reactive maintenance, further enhancing operational efficiency.

Waste management costs decrease proportionally with reduced sorbent replacement frequency. Spent sorbent disposal or regeneration expenses typically account for 8-12% of operational costs in conventional DAC units, making this a meaningful economic consideration when evaluating durable alternatives.

Risk mitigation value must also be quantified, as sorbent attrition and dusting create operational hazards including equipment damage, filtration system overloading, and potential environmental contamination. Insurance premiums for DAC facilities utilizing durable sorbents are typically 10-15% lower, reflecting reduced operational risk profiles.

The economic breakeven point for durable sorbent implementation generally occurs between 14-22 months of operation, depending on facility scale and operational parameters. This relatively short payback period, combined with the compounding benefits of improved system reliability and reduced environmental impact, presents a compelling economic case for prioritizing mechanical stability in sorbent selection and development for DAC applications.

Operational cost savings emerge as the primary economic benefit, with reduced sorbent replacement frequency translating to approximately 25-35% lower material costs over a five-year operational period. Maintenance downtime decreases significantly, with durable sorbent systems requiring major maintenance interventions every 18-24 months versus 6-8 months for conventional materials, resulting in 15-20% higher annual operational hours.

Energy efficiency improvements represent another substantial benefit, as mechanically stable sorbents maintain consistent surface area and porosity characteristics throughout their lifecycle. This stability prevents the 10-15% performance degradation typically observed in conventional sorbents after repeated cycling, thereby maintaining optimal CO₂ capture rates and minimizing energy waste associated with processing increasingly inefficient materials.

Labor cost reductions prove significant, with durable sorbent systems requiring approximately 40% fewer staff hours dedicated to replacement operations and associated maintenance. This reduction allows technical personnel to focus on system optimization rather than reactive maintenance, further enhancing operational efficiency.

Waste management costs decrease proportionally with reduced sorbent replacement frequency. Spent sorbent disposal or regeneration expenses typically account for 8-12% of operational costs in conventional DAC units, making this a meaningful economic consideration when evaluating durable alternatives.

Risk mitigation value must also be quantified, as sorbent attrition and dusting create operational hazards including equipment damage, filtration system overloading, and potential environmental contamination. Insurance premiums for DAC facilities utilizing durable sorbents are typically 10-15% lower, reflecting reduced operational risk profiles.

The economic breakeven point for durable sorbent implementation generally occurs between 14-22 months of operation, depending on facility scale and operational parameters. This relatively short payback period, combined with the compounding benefits of improved system reliability and reduced environmental impact, presents a compelling economic case for prioritizing mechanical stability in sorbent selection and development for DAC applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!