Sorbent Screening Protocols And Benchmarking For DAC Developers

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Sorbent Technology Background and Objectives

Direct Air Capture (DAC) technology has emerged as a critical component in the global effort to combat climate change by removing carbon dioxide directly from the atmosphere. The development of efficient sorbent materials represents the cornerstone of effective DAC systems, as these materials determine the energy requirements, operational costs, and overall carbon removal capacity of the technology.

The evolution of DAC sorbent technology can be traced back to early carbon capture methods developed for industrial applications in the 1930s. Initially focused on liquid solvents like monoethanolamine (MEA), the field has progressively expanded to include solid sorbents with enhanced CO2 selectivity and reduced regeneration energy requirements. This technological progression has accelerated significantly over the past decade, driven by increasing climate urgency and substantial public and private investment.

Current DAC sorbent technologies primarily fall into three categories: liquid solvent-based systems utilizing alkaline solutions, solid sorbent approaches employing functionalized materials, and novel hybrid systems combining aspects of both. Each pathway presents distinct advantages and challenges regarding energy consumption, scalability, and operational stability under atmospheric conditions.

The primary objective of sorbent screening protocols and benchmarking is to establish standardized methodologies for evaluating and comparing diverse DAC sorbent materials across multiple performance parameters. These include CO2 uptake capacity, selectivity over other atmospheric gases, kinetics of adsorption and desorption, cycling stability, and energy requirements for regeneration. Such standardization is essential for accelerating technology development and enabling meaningful comparisons between emerging solutions.

Additionally, these protocols aim to identify materials that can function effectively under real-world conditions, including variable humidity levels, temperature fluctuations, and the presence of contaminants. The ultimate goal is to discover and optimize sorbents capable of achieving economically viable atmospheric carbon removal at less than $100 per ton of CO2, a threshold widely considered necessary for commercial viability and meaningful climate impact.

The technological trajectory suggests increasing focus on novel materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and engineered biohybrid systems that leverage biological mechanisms for carbon fixation. These next-generation sorbents promise significantly improved performance metrics but require robust screening methodologies to evaluate their practical potential for large-scale deployment.

As the field advances, comprehensive benchmarking will become increasingly critical for guiding research priorities, informing investment decisions, and supporting policy development around negative emissions technologies. The establishment of industry-standard protocols represents a foundational step toward building a mature DAC industry capable of contributing meaningfully to global climate mitigation efforts.

The evolution of DAC sorbent technology can be traced back to early carbon capture methods developed for industrial applications in the 1930s. Initially focused on liquid solvents like monoethanolamine (MEA), the field has progressively expanded to include solid sorbents with enhanced CO2 selectivity and reduced regeneration energy requirements. This technological progression has accelerated significantly over the past decade, driven by increasing climate urgency and substantial public and private investment.

Current DAC sorbent technologies primarily fall into three categories: liquid solvent-based systems utilizing alkaline solutions, solid sorbent approaches employing functionalized materials, and novel hybrid systems combining aspects of both. Each pathway presents distinct advantages and challenges regarding energy consumption, scalability, and operational stability under atmospheric conditions.

The primary objective of sorbent screening protocols and benchmarking is to establish standardized methodologies for evaluating and comparing diverse DAC sorbent materials across multiple performance parameters. These include CO2 uptake capacity, selectivity over other atmospheric gases, kinetics of adsorption and desorption, cycling stability, and energy requirements for regeneration. Such standardization is essential for accelerating technology development and enabling meaningful comparisons between emerging solutions.

Additionally, these protocols aim to identify materials that can function effectively under real-world conditions, including variable humidity levels, temperature fluctuations, and the presence of contaminants. The ultimate goal is to discover and optimize sorbents capable of achieving economically viable atmospheric carbon removal at less than $100 per ton of CO2, a threshold widely considered necessary for commercial viability and meaningful climate impact.

The technological trajectory suggests increasing focus on novel materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and engineered biohybrid systems that leverage biological mechanisms for carbon fixation. These next-generation sorbents promise significantly improved performance metrics but require robust screening methodologies to evaluate their practical potential for large-scale deployment.

As the field advances, comprehensive benchmarking will become increasingly critical for guiding research priorities, informing investment decisions, and supporting policy development around negative emissions technologies. The establishment of industry-standard protocols represents a foundational step toward building a mature DAC industry capable of contributing meaningfully to global climate mitigation efforts.

Market Analysis for Direct Air Capture Solutions

The Direct Air Capture (DAC) market is experiencing significant growth as global efforts to combat climate change intensify. Current market valuations estimate the DAC industry at approximately $2 billion in 2023, with projections indicating potential growth to $15 billion by 2030, representing a compound annual growth rate of over 33%. This remarkable growth trajectory is driven by increasing corporate commitments to carbon neutrality and governmental policy support worldwide.

Market demand for DAC solutions is primarily segmented into three categories: voluntary carbon markets, enhanced oil recovery applications, and compliance markets. The voluntary market is currently the largest segment, with companies like Microsoft, Stripe, and Shopify making substantial investments in carbon removal technologies to meet their sustainability goals. This segment is expected to maintain strong growth as more corporations adopt net-zero targets.

Geographically, North America leads the market with approximately 65% of current DAC installations, followed by Europe at 25% and Asia-Pacific at 8%. This distribution reflects both technological development centers and favorable policy environments. The United States' Inflation Reduction Act, which includes a $180/ton tax credit for direct air capture, has significantly accelerated market development in North America.

Customer segmentation reveals diverse stakeholders, including energy companies seeking to offset emissions, technology firms with ambitious climate goals, and governments implementing carbon reduction strategies. Each segment presents unique requirements regarding cost thresholds, scalability needs, and integration capabilities with existing infrastructure.

Price sensitivity remains a critical market factor, with current DAC costs ranging from $250-$600 per ton of CO2 removed. Market analysis indicates that widespread adoption would require costs to decrease to below $100 per ton, highlighting the importance of sorbent efficiency improvements in achieving commercial viability.

Competitive dynamics show a market dominated by specialized technology providers like Carbon Engineering, Climeworks, and Global Thermostat, alongside increasing interest from traditional energy companies and industrial conglomerates. Recent market entries from chemical manufacturing companies specifically targeting sorbent development indicate growing recognition of this critical component in the DAC value chain.

Market barriers include high capital requirements, technological uncertainties, and regulatory complexities. However, the increasing standardization of carbon accounting methodologies and growing policy support are gradually reducing these barriers, potentially accelerating market expansion in the coming years.

Market demand for DAC solutions is primarily segmented into three categories: voluntary carbon markets, enhanced oil recovery applications, and compliance markets. The voluntary market is currently the largest segment, with companies like Microsoft, Stripe, and Shopify making substantial investments in carbon removal technologies to meet their sustainability goals. This segment is expected to maintain strong growth as more corporations adopt net-zero targets.

Geographically, North America leads the market with approximately 65% of current DAC installations, followed by Europe at 25% and Asia-Pacific at 8%. This distribution reflects both technological development centers and favorable policy environments. The United States' Inflation Reduction Act, which includes a $180/ton tax credit for direct air capture, has significantly accelerated market development in North America.

Customer segmentation reveals diverse stakeholders, including energy companies seeking to offset emissions, technology firms with ambitious climate goals, and governments implementing carbon reduction strategies. Each segment presents unique requirements regarding cost thresholds, scalability needs, and integration capabilities with existing infrastructure.

Price sensitivity remains a critical market factor, with current DAC costs ranging from $250-$600 per ton of CO2 removed. Market analysis indicates that widespread adoption would require costs to decrease to below $100 per ton, highlighting the importance of sorbent efficiency improvements in achieving commercial viability.

Competitive dynamics show a market dominated by specialized technology providers like Carbon Engineering, Climeworks, and Global Thermostat, alongside increasing interest from traditional energy companies and industrial conglomerates. Recent market entries from chemical manufacturing companies specifically targeting sorbent development indicate growing recognition of this critical component in the DAC value chain.

Market barriers include high capital requirements, technological uncertainties, and regulatory complexities. However, the increasing standardization of carbon accounting methodologies and growing policy support are gradually reducing these barriers, potentially accelerating market expansion in the coming years.

Current Sorbent Technologies and Challenges

Direct Air Capture (DAC) technology relies heavily on effective sorbent materials to selectively capture CO2 from ambient air. Currently, the field employs several categories of sorbent technologies, each with distinct advantages and limitations that impact their commercial viability for large-scale carbon removal.

Solid sorbents represent a major category, including metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials. These materials offer high surface areas and can be engineered for selective CO2 adsorption. MOFs, in particular, have demonstrated exceptional CO2 capacity under laboratory conditions, with some variants achieving uptake exceeding 300 mg CO2/g sorbent. However, they often suffer from stability issues in humid conditions and high production costs that limit industrial deployment.

Liquid sorbents, primarily aqueous solutions of amines or alkali hydroxides, constitute another significant approach. These systems benefit from established industrial processes but face challenges related to energy-intensive regeneration and corrosion of equipment. The hydroxide-based systems (e.g., potassium hydroxide solutions) demonstrate excellent CO2 capture rates but require complex precipitation and calcination steps for regeneration.

Hybrid systems combining aspects of both solid and liquid approaches have emerged as promising alternatives. These systems aim to leverage the high surface area of porous supports with the reactivity of liquid absorbents, though integration challenges persist.

A critical challenge across all sorbent technologies is the energy requirement for regeneration. Current systems typically demand 1.5-3.5 GJ of energy per ton of CO2 captured, significantly impacting operational economics. This regeneration energy represents approximately 70-80% of the total energy consumption in DAC processes.

Sorbent durability presents another major hurdle. Most materials experience performance degradation after multiple adsorption-desorption cycles, with capacity losses of 5-15% observed after just 100 cycles in many systems. This degradation necessitates frequent replacement, increasing operational costs and environmental footprint.

Selectivity challenges also persist, particularly in humid environments where water competes with CO2 for adsorption sites. Most current sorbents demonstrate reduced CO2 capacity by 30-60% under realistic humidity conditions compared to dry laboratory testing.

Manufacturing scalability remains problematic, with many high-performance materials requiring complex synthesis procedures and expensive precursors. Production costs for advanced MOFs and specialized amine-functionalized materials can exceed $100/kg, compared to conventional industrial adsorbents at $5-20/kg.

These technological limitations highlight the need for standardized screening protocols that evaluate sorbents under realistic operating conditions, considering not only initial capacity but also cycle stability, humidity tolerance, and regeneration energy requirements.

Solid sorbents represent a major category, including metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials. These materials offer high surface areas and can be engineered for selective CO2 adsorption. MOFs, in particular, have demonstrated exceptional CO2 capacity under laboratory conditions, with some variants achieving uptake exceeding 300 mg CO2/g sorbent. However, they often suffer from stability issues in humid conditions and high production costs that limit industrial deployment.

Liquid sorbents, primarily aqueous solutions of amines or alkali hydroxides, constitute another significant approach. These systems benefit from established industrial processes but face challenges related to energy-intensive regeneration and corrosion of equipment. The hydroxide-based systems (e.g., potassium hydroxide solutions) demonstrate excellent CO2 capture rates but require complex precipitation and calcination steps for regeneration.

Hybrid systems combining aspects of both solid and liquid approaches have emerged as promising alternatives. These systems aim to leverage the high surface area of porous supports with the reactivity of liquid absorbents, though integration challenges persist.

A critical challenge across all sorbent technologies is the energy requirement for regeneration. Current systems typically demand 1.5-3.5 GJ of energy per ton of CO2 captured, significantly impacting operational economics. This regeneration energy represents approximately 70-80% of the total energy consumption in DAC processes.

Sorbent durability presents another major hurdle. Most materials experience performance degradation after multiple adsorption-desorption cycles, with capacity losses of 5-15% observed after just 100 cycles in many systems. This degradation necessitates frequent replacement, increasing operational costs and environmental footprint.

Selectivity challenges also persist, particularly in humid environments where water competes with CO2 for adsorption sites. Most current sorbents demonstrate reduced CO2 capacity by 30-60% under realistic humidity conditions compared to dry laboratory testing.

Manufacturing scalability remains problematic, with many high-performance materials requiring complex synthesis procedures and expensive precursors. Production costs for advanced MOFs and specialized amine-functionalized materials can exceed $100/kg, compared to conventional industrial adsorbents at $5-20/kg.

These technological limitations highlight the need for standardized screening protocols that evaluate sorbents under realistic operating conditions, considering not only initial capacity but also cycle stability, humidity tolerance, and regeneration energy requirements.

Established Screening Protocols for DAC Sorbents

01 High-throughput sorbent screening methodologies

Advanced methodologies for high-throughput screening of sorbent materials involve systematic protocols to evaluate multiple candidates simultaneously. These approaches typically include automated sample preparation, rapid analysis techniques, and standardized testing conditions to ensure reproducibility. The screening process often incorporates parallel testing platforms that can assess various performance parameters such as adsorption capacity, selectivity, and kinetics under controlled conditions, significantly reducing the time and resources required for material discovery and optimization.- High-throughput sorbent screening methodologies: Advanced methodologies for high-throughput screening of sorbent materials involve automated systems that can rapidly evaluate multiple sorbent candidates simultaneously. These protocols typically include preparation of sorbent libraries, automated dispensing systems, parallel testing under controlled conditions, and data acquisition systems that capture key performance metrics such as adsorption capacity, selectivity, and kinetics. The high-throughput approach significantly reduces the time and resources required for identifying optimal sorbent materials for specific applications.

- Performance benchmarking and standardized evaluation protocols: Standardized protocols for benchmarking sorbent performance ensure consistent and comparable evaluation across different materials and laboratories. These protocols define specific testing conditions, reference materials, and performance metrics that enable objective comparison of sorbent efficiency. Key parameters typically include adsorption capacity under standard conditions, regeneration efficiency, mechanical stability, and cost-effectiveness. Standardized benchmarking facilitates the selection of optimal sorbents for specific applications and accelerates the development of improved materials.

- Computational screening and predictive modeling: Computational approaches for sorbent screening utilize molecular simulations, machine learning algorithms, and predictive models to evaluate potential sorbent materials before physical testing. These methods can predict adsorption properties, selectivity, and stability based on molecular structure and physical properties. By integrating computational screening with experimental validation, researchers can significantly reduce the experimental space that needs to be explored, accelerating the discovery of high-performance sorbent materials while minimizing resource expenditure.

- Real-time monitoring and dynamic performance evaluation: Advanced sorbent screening protocols incorporate real-time monitoring systems that track performance metrics during operation. These systems utilize sensors, spectroscopic techniques, and data analytics to continuously evaluate sorbent efficiency under dynamic conditions. Real-time monitoring enables the assessment of sorbent performance under varying conditions, including fluctuations in temperature, pressure, and contaminant concentrations, providing insights into long-term stability and performance degradation that static testing methods cannot capture.

- Efficiency metrics and performance optimization frameworks: Comprehensive frameworks for evaluating sorbent efficiency incorporate multiple performance metrics and economic considerations. These frameworks typically include technical parameters such as adsorption capacity, selectivity, and kinetics, as well as practical considerations like regeneration energy requirements, operational lifetime, and manufacturing costs. By integrating these diverse metrics into a unified evaluation framework, researchers and engineers can identify optimal sorbent materials that balance technical performance with economic viability for specific applications.

02 Performance metrics and benchmarking standards for sorbent evaluation

Standardized performance metrics are essential for objective comparison of different sorbent materials. These metrics typically include adsorption capacity, selectivity coefficients, regeneration efficiency, and operational stability. Benchmarking protocols establish reference materials and testing conditions that allow for consistent evaluation across different laboratories and research groups. The development of these standards enables researchers to reliably compare novel sorbents against established materials and identify promising candidates for specific applications based on quantifiable performance criteria.Expand Specific Solutions03 Computational screening and predictive modeling for sorbent development

Computational approaches have revolutionized sorbent screening by enabling the prediction of material properties before synthesis. These methods include molecular simulations, machine learning algorithms, and quantum mechanical calculations that can predict adsorption behavior, selectivity, and stability. By integrating computational screening with experimental validation, researchers can significantly narrow the field of candidate materials, focusing laboratory efforts on the most promising structures. This approach accelerates the discovery process and provides insights into structure-property relationships that guide rational sorbent design.Expand Specific Solutions04 Automated workflow systems for sorbent testing and data analysis

Automated workflow systems integrate sample handling, testing procedures, and data analysis to streamline the sorbent evaluation process. These systems typically incorporate robotic sample preparation, automated testing equipment, and software for data collection and analysis. By reducing human intervention, these workflows minimize experimental variability and enhance reproducibility. Additionally, integrated data management systems facilitate the comparison of results across multiple experiments and enable more sophisticated analysis of structure-performance relationships, accelerating the identification of optimal sorbent materials.Expand Specific Solutions05 Economic and efficiency metrics for industrial sorbent implementation

Beyond technical performance, the industrial implementation of sorbents requires comprehensive economic and efficiency evaluations. These assessments consider factors such as production costs, operational expenses, energy requirements, and environmental impact. Performance metrics include cost per unit of target substance removed, energy consumption during regeneration, and lifecycle analysis of the sorbent material. By integrating these economic considerations with technical performance data, researchers and engineers can identify sorbents that not only perform well in laboratory settings but also offer practical advantages in real-world industrial applications.Expand Specific Solutions

Leading Organizations in DAC Sorbent Development

The Direct Air Capture (DAC) technology market is currently in an early growth phase, characterized by rapid innovation in sorbent technologies and screening protocols. The global DAC market is projected to expand significantly, with estimates suggesting a multi-billion dollar industry by 2030 as carbon removal becomes critical for climate goals. Technologically, the field shows varying maturity levels among key players. Established companies like Climeworks AG and Carboncapture, Inc. lead with commercial deployments, while research institutions such as Xi'an Jiaotong University and Shanghai Jiao Tong University contribute fundamental advancements in sorbent materials. Industrial players including Shell Internationale Research and W.L. Gore & Associates bring materials expertise and scaling capabilities. The competitive landscape reflects a blend of specialized DAC startups, academic research centers, and diversifying energy corporations collaborating to overcome technical and economic barriers.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed sophisticated sorbent screening protocols for DAC applications as part of their broader carbon management portfolio. Their approach leverages extensive experience in materials science and chemical engineering to evaluate both solid and liquid sorbents. Shell's methodology incorporates high-throughput automated testing platforms that can simultaneously evaluate multiple sorbent candidates under precisely controlled conditions. Their protocols emphasize practical deployment considerations including sorbent manufacturing scalability, raw material availability, and environmental impact assessments. Shell's benchmarking framework evaluates materials against a comprehensive set of performance indicators including CO2 working capacity, selectivity over other atmospheric gases, regeneration energy requirements, and mechanical/chemical stability during cycling. The company has established accelerated aging protocols that simulate years of operational cycles in compressed timeframes to predict long-term performance degradation[4]. Shell's screening approach also incorporates techno-economic analysis to identify materials that not only perform well technically but also offer pathways to cost-effective DAC implementation at scale.

Strengths: Extensive R&D infrastructure and resources allowing for comprehensive testing; integration of sorbent evaluation with broader system design and economic modeling; ability to leverage expertise across multiple scientific disciplines. Weaknesses: Primary focus on supporting technologies rather than developing standalone commercial DAC systems; potential conflicts with core fossil fuel business; less public disclosure of specific technical approaches compared to pure-play DAC companies.

Climeworks AG

Technical Solution: Climeworks has developed a proprietary Direct Air Capture (DAC) technology using solid sorbent materials. Their approach employs a two-step temperature/vacuum swing adsorption process with specialized amine-functionalized filters. The company has established comprehensive sorbent screening protocols that evaluate materials based on CO2 capacity, selectivity, kinetics, and cyclic stability. Their methodology includes rapid throughput testing using automated systems that can evaluate hundreds of sorbent formulations under varying conditions (temperature, humidity, CO2 concentration). Climeworks' benchmarking framework incorporates both laboratory-scale testing and field validation at their commercial plants, allowing for real-world performance assessment. Their protocols specifically address degradation mechanisms under repeated cycling and contaminant exposure, which is critical for long-term DAC operations[1][3]. The company has successfully scaled their technology from laboratory to commercial deployment with plants in Switzerland and Iceland (Orca and Mammoth facilities).

Strengths: Industry-leading commercial deployment experience providing real-world validation data; proprietary amine-functionalized filter technology with proven durability; established testing infrastructure for rapid material evaluation. Weaknesses: Higher energy requirements for temperature swing regeneration compared to some emerging technologies; relatively high cost per ton of CO2 captured compared to theoretical limits; limited public disclosure of specific sorbent compositions due to IP protection.

Key Benchmarking Methodologies and Standards

Sorbent membranes with conductive layer for efficient sorbent regeneration

PatentWO2025072864A9

Innovation

- Integration of a conductive film made of carbon nanotubes (CNTs) and polymeric binder directly onto sorbent membranes for DAC systems, enabling direct heating for CO2 desorption and membrane regeneration.

- Novel membrane assembly design that combines CO2 capture functionality with integrated regeneration capability in a single component, eliminating the need for separate heating systems.

- Development of a direct heating approach for sorbent regeneration that potentially reduces energy requirements and simplifies the overall DAC system design.

Direct air capture and liquid environment desorption process

PatentPendingUS20250153103A1

Innovation

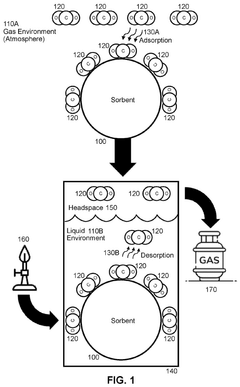

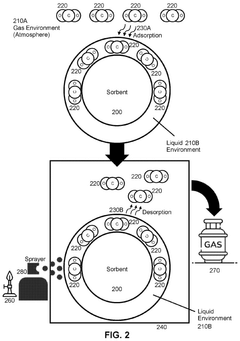

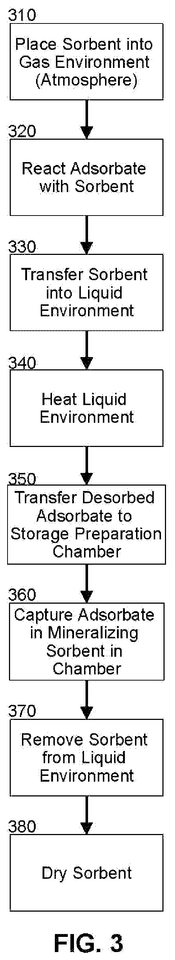

- A hybrid approach combining gas phase adsorption and liquid phase desorption, where a sorbent material is used to capture gas molecules in a gas phase and then transferred to a liquid phase for desorption, allowing for efficient gas release and regeneration of the sorbent.

Environmental Impact Assessment of DAC Technologies

Direct Air Capture (DAC) technologies, while promising for carbon dioxide removal, carry significant environmental implications that must be thoroughly assessed. The deployment of DAC systems involves substantial land use requirements, with estimates suggesting that large-scale facilities may occupy several hectares per megaton of CO2 captured annually. This spatial footprint varies considerably depending on the specific technology employed, with solid sorbent systems generally requiring less land area than liquid solvent approaches.

Water consumption represents another critical environmental consideration. Certain DAC technologies, particularly those utilizing aqueous hydroxide solutions, can consume between 1-7 tons of water per ton of CO2 captured. In water-stressed regions, this requirement could exacerbate existing resource pressures and potentially create competition with agricultural or municipal water needs.

Energy demands constitute perhaps the most significant environmental factor in DAC operations. Current technologies require approximately 1.5-2.5 GJ of thermal energy and 0.3-0.5 GJ of electricity per ton of CO2 captured. The source of this energy fundamentally determines the net environmental benefit of DAC deployment. Systems powered by fossil fuels without carbon capture may ultimately release more CO2 than they remove, while renewable energy integration maximizes climate benefits but requires substantial additional renewable capacity.

Material production and lifecycle impacts must also be considered. The manufacturing of sorbents involves energy-intensive processes and potentially hazardous chemicals. Solid sorbents typically require replacement every 3-5 years, generating waste streams that require proper management. Life cycle assessments indicate that sorbent production can contribute 5-15% of the total carbon footprint of DAC operations.

Local ecosystem effects vary by location and technology type. Air movement through DAC facilities may alter local microclimate conditions, while chemical emissions, though typically minimal, require monitoring. Noise pollution from fans and pumps presents another consideration for facilities near populated areas.

The environmental impact assessment must also consider the end-use of captured carbon. Permanent geological sequestration offers the most definitive climate benefit, while utilization pathways such as synthetic fuel production present more complex environmental trade-offs that require careful evaluation through comprehensive life cycle assessment methodologies.

Water consumption represents another critical environmental consideration. Certain DAC technologies, particularly those utilizing aqueous hydroxide solutions, can consume between 1-7 tons of water per ton of CO2 captured. In water-stressed regions, this requirement could exacerbate existing resource pressures and potentially create competition with agricultural or municipal water needs.

Energy demands constitute perhaps the most significant environmental factor in DAC operations. Current technologies require approximately 1.5-2.5 GJ of thermal energy and 0.3-0.5 GJ of electricity per ton of CO2 captured. The source of this energy fundamentally determines the net environmental benefit of DAC deployment. Systems powered by fossil fuels without carbon capture may ultimately release more CO2 than they remove, while renewable energy integration maximizes climate benefits but requires substantial additional renewable capacity.

Material production and lifecycle impacts must also be considered. The manufacturing of sorbents involves energy-intensive processes and potentially hazardous chemicals. Solid sorbents typically require replacement every 3-5 years, generating waste streams that require proper management. Life cycle assessments indicate that sorbent production can contribute 5-15% of the total carbon footprint of DAC operations.

Local ecosystem effects vary by location and technology type. Air movement through DAC facilities may alter local microclimate conditions, while chemical emissions, though typically minimal, require monitoring. Noise pollution from fans and pumps presents another consideration for facilities near populated areas.

The environmental impact assessment must also consider the end-use of captured carbon. Permanent geological sequestration offers the most definitive climate benefit, while utilization pathways such as synthetic fuel production present more complex environmental trade-offs that require careful evaluation through comprehensive life cycle assessment methodologies.

Scalability and Cost Analysis of Promising Sorbents

The economic viability of Direct Air Capture (DAC) technologies hinges significantly on the scalability and cost-effectiveness of sorbent materials. Current analysis indicates that leading sorbent candidates face substantial challenges when transitioning from laboratory-scale demonstrations to industrial deployment. Solid sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials demonstrate promising CO2 capture capacities in controlled environments but often suffer from degradation issues and reduced performance under real-world conditions.

Cost modeling reveals that sorbent materials typically represent 15-30% of total DAC system capital expenditure, with regeneration energy requirements constituting a major operational expense. For instance, temperature swing adsorption (TSA) systems utilizing solid sorbents require significant thermal energy inputs, while moisture swing systems may offer lower energy penalties but face throughput limitations. The economic threshold for commercially viable DAC operations is estimated at $100-150 per ton of CO2 captured, a target that remains challenging with current sorbent technologies.

Scaling considerations must account for material production capacity, which presents a bottleneck for specialized sorbents like engineered MOFs. Current global production capabilities for advanced sorbent materials fall significantly short of the volumes required for gigaton-scale carbon removal. Manufacturing processes for high-performance sorbents often involve complex synthesis routes with expensive precursors, further complicating large-scale implementation.

Lifecycle analysis of promising sorbents indicates varying environmental footprints. While some materials offer excellent carbon capture performance, their production may involve energy-intensive processes or environmentally problematic chemicals. The embodied carbon in sorbent manufacturing must be factored into net carbon removal calculations, with ideal candidates achieving carbon payback periods of less than six months of operational use.

Recent techno-economic assessments suggest that hybrid systems combining different sorbent types may offer optimal cost-performance ratios. For example, utilizing robust, lower-cost materials for initial capture followed by more selective sorbents for concentration could balance performance with economic constraints. Additionally, integration with renewable energy sources for regeneration processes shows potential to significantly reduce operational costs, though such systems require careful engineering to manage intermittency challenges.

The development of standardized cost metrics for sorbent evaluation remains crucial for meaningful comparison across different DAC approaches. These metrics should incorporate not only material costs but also regeneration energy requirements, replacement frequency due to degradation, and manufacturing scalability factors to provide a comprehensive economic assessment of promising sorbent candidates.

Cost modeling reveals that sorbent materials typically represent 15-30% of total DAC system capital expenditure, with regeneration energy requirements constituting a major operational expense. For instance, temperature swing adsorption (TSA) systems utilizing solid sorbents require significant thermal energy inputs, while moisture swing systems may offer lower energy penalties but face throughput limitations. The economic threshold for commercially viable DAC operations is estimated at $100-150 per ton of CO2 captured, a target that remains challenging with current sorbent technologies.

Scaling considerations must account for material production capacity, which presents a bottleneck for specialized sorbents like engineered MOFs. Current global production capabilities for advanced sorbent materials fall significantly short of the volumes required for gigaton-scale carbon removal. Manufacturing processes for high-performance sorbents often involve complex synthesis routes with expensive precursors, further complicating large-scale implementation.

Lifecycle analysis of promising sorbents indicates varying environmental footprints. While some materials offer excellent carbon capture performance, their production may involve energy-intensive processes or environmentally problematic chemicals. The embodied carbon in sorbent manufacturing must be factored into net carbon removal calculations, with ideal candidates achieving carbon payback periods of less than six months of operational use.

Recent techno-economic assessments suggest that hybrid systems combining different sorbent types may offer optimal cost-performance ratios. For example, utilizing robust, lower-cost materials for initial capture followed by more selective sorbents for concentration could balance performance with economic constraints. Additionally, integration with renewable energy sources for regeneration processes shows potential to significantly reduce operational costs, though such systems require careful engineering to manage intermittency challenges.

The development of standardized cost metrics for sorbent evaluation remains crucial for meaningful comparison across different DAC approaches. These metrics should incorporate not only material costs but also regeneration energy requirements, replacement frequency due to degradation, and manufacturing scalability factors to provide a comprehensive economic assessment of promising sorbent candidates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!