Thermal And Oxidative Degradation Pathways In Solid Amine Sorbents

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid Amine Sorbent Degradation Background and Objectives

Solid amine sorbents have emerged as promising materials for carbon dioxide capture applications due to their high CO2 adsorption capacity, selectivity, and relatively low regeneration energy requirements. The development of these materials dates back to the 1990s when researchers began exploring alternatives to liquid amine scrubbing technologies that had dominated industrial CO2 capture processes for decades. The evolution of solid amine sorbents has been marked by significant improvements in material design, synthesis methods, and performance characteristics.

The technological trajectory of solid amine sorbents has progressed from simple impregnated systems to sophisticated chemically tethered structures. Early generations relied primarily on physical impregnation of amines into porous supports, while later developments focused on covalently bonding amine groups to achieve greater stability and cyclability. Recent advances have introduced hybrid materials combining multiple capture mechanisms and hierarchical pore structures to optimize both kinetics and capacity.

Despite these advancements, a critical challenge limiting the widespread implementation of solid amine sorbents is their susceptibility to thermal and oxidative degradation during repeated adsorption-desorption cycles. This degradation manifests as progressive loss of CO2 capture capacity, structural deterioration, and formation of potentially harmful byproducts. Understanding these degradation pathways is essential for developing more robust materials capable of maintaining performance over thousands of cycles in real-world applications.

The primary objective of this technical research is to comprehensively investigate the fundamental mechanisms underlying thermal and oxidative degradation in solid amine sorbents. By elucidating these pathways at the molecular level, we aim to identify the key factors that trigger and accelerate degradation processes under various operating conditions. This knowledge will serve as the foundation for developing mitigation strategies and designing next-generation materials with enhanced stability.

Secondary objectives include establishing standardized protocols for accelerated aging tests that can reliably predict long-term stability, quantifying the relationship between structural characteristics and degradation resistance, and exploring potential regeneration methods for partially degraded materials. Additionally, we seek to develop in-situ monitoring techniques capable of detecting early signs of degradation before significant performance losses occur.

The expected outcomes of this research will directly inform material design principles for creating more durable solid amine sorbents, potentially extending operational lifetimes by an order of magnitude. This advancement would significantly improve the economic viability of these materials for industrial-scale carbon capture applications, supporting global efforts to reduce greenhouse gas emissions through both post-combustion capture and direct air capture technologies.

The technological trajectory of solid amine sorbents has progressed from simple impregnated systems to sophisticated chemically tethered structures. Early generations relied primarily on physical impregnation of amines into porous supports, while later developments focused on covalently bonding amine groups to achieve greater stability and cyclability. Recent advances have introduced hybrid materials combining multiple capture mechanisms and hierarchical pore structures to optimize both kinetics and capacity.

Despite these advancements, a critical challenge limiting the widespread implementation of solid amine sorbents is their susceptibility to thermal and oxidative degradation during repeated adsorption-desorption cycles. This degradation manifests as progressive loss of CO2 capture capacity, structural deterioration, and formation of potentially harmful byproducts. Understanding these degradation pathways is essential for developing more robust materials capable of maintaining performance over thousands of cycles in real-world applications.

The primary objective of this technical research is to comprehensively investigate the fundamental mechanisms underlying thermal and oxidative degradation in solid amine sorbents. By elucidating these pathways at the molecular level, we aim to identify the key factors that trigger and accelerate degradation processes under various operating conditions. This knowledge will serve as the foundation for developing mitigation strategies and designing next-generation materials with enhanced stability.

Secondary objectives include establishing standardized protocols for accelerated aging tests that can reliably predict long-term stability, quantifying the relationship between structural characteristics and degradation resistance, and exploring potential regeneration methods for partially degraded materials. Additionally, we seek to develop in-situ monitoring techniques capable of detecting early signs of degradation before significant performance losses occur.

The expected outcomes of this research will directly inform material design principles for creating more durable solid amine sorbents, potentially extending operational lifetimes by an order of magnitude. This advancement would significantly improve the economic viability of these materials for industrial-scale carbon capture applications, supporting global efforts to reduce greenhouse gas emissions through both post-combustion capture and direct air capture technologies.

Market Analysis for Solid Amine Sorbent Applications

The global market for solid amine sorbents has witnessed significant growth in recent years, primarily driven by increasing environmental regulations and the urgent need for carbon capture technologies. The market size for solid amine sorbents was valued at approximately $520 million in 2022 and is projected to reach $1.2 billion by 2030, representing a compound annual growth rate of 11.3% during the forecast period.

Carbon capture and storage (CCS) applications dominate the market, accounting for nearly 65% of the total demand for solid amine sorbents. This segment's growth is fueled by governmental initiatives to reduce carbon emissions across major industrialized nations, particularly in power generation and heavy industrial sectors. The European Union's commitment to achieve carbon neutrality by 2050 has created substantial market opportunities in the region.

The industrial gas purification segment represents the second-largest application area, constituting about 20% of the market share. Solid amine sorbents are increasingly preferred over liquid amines in this sector due to their lower energy requirements and reduced equipment corrosion issues. This transition is particularly evident in natural gas processing facilities where the removal of CO2 and H2S is critical for meeting pipeline specifications.

Emerging applications in direct air capture (DAC) technologies, though currently representing only 5% of the market, are expected to grow at the fastest rate of 18.7% annually through 2030. This growth is supported by substantial venture capital investments and governmental funding for negative emissions technologies.

Regionally, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are experiencing the fastest growth rates due to their expanding industrial base and increasing environmental regulations. The Middle East, traditionally slower to adopt carbon capture technologies, is now showing increased interest driven by diversification strategies away from fossil fuel dependence.

Key challenges affecting market demand include the thermal and oxidative degradation of these sorbents, which significantly impacts their operational lifespan and economic viability. End-users report that degradation-related replacement costs can account for up to 30% of operational expenses in carbon capture facilities. This has created a distinct market segment for degradation-resistant formulations, which command premium pricing of 40-60% above standard products.

Consumer preferences are shifting toward sorbents with demonstrated stability under repeated temperature swing cycles, with particular emphasis on resistance to oxidative degradation in flue gas environments. Market research indicates that extending sorbent lifespan by just 20% could reduce the total cost of carbon capture by approximately 15%, representing a significant value proposition for technology developers addressing degradation pathways.

Carbon capture and storage (CCS) applications dominate the market, accounting for nearly 65% of the total demand for solid amine sorbents. This segment's growth is fueled by governmental initiatives to reduce carbon emissions across major industrialized nations, particularly in power generation and heavy industrial sectors. The European Union's commitment to achieve carbon neutrality by 2050 has created substantial market opportunities in the region.

The industrial gas purification segment represents the second-largest application area, constituting about 20% of the market share. Solid amine sorbents are increasingly preferred over liquid amines in this sector due to their lower energy requirements and reduced equipment corrosion issues. This transition is particularly evident in natural gas processing facilities where the removal of CO2 and H2S is critical for meeting pipeline specifications.

Emerging applications in direct air capture (DAC) technologies, though currently representing only 5% of the market, are expected to grow at the fastest rate of 18.7% annually through 2030. This growth is supported by substantial venture capital investments and governmental funding for negative emissions technologies.

Regionally, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are experiencing the fastest growth rates due to their expanding industrial base and increasing environmental regulations. The Middle East, traditionally slower to adopt carbon capture technologies, is now showing increased interest driven by diversification strategies away from fossil fuel dependence.

Key challenges affecting market demand include the thermal and oxidative degradation of these sorbents, which significantly impacts their operational lifespan and economic viability. End-users report that degradation-related replacement costs can account for up to 30% of operational expenses in carbon capture facilities. This has created a distinct market segment for degradation-resistant formulations, which command premium pricing of 40-60% above standard products.

Consumer preferences are shifting toward sorbents with demonstrated stability under repeated temperature swing cycles, with particular emphasis on resistance to oxidative degradation in flue gas environments. Market research indicates that extending sorbent lifespan by just 20% could reduce the total cost of carbon capture by approximately 15%, representing a significant value proposition for technology developers addressing degradation pathways.

Current Challenges in Thermal-Oxidative Stability

The thermal and oxidative stability of solid amine sorbents represents a critical challenge in carbon capture technologies. These materials, while promising for CO2 adsorption, suffer from significant degradation under operational conditions, limiting their long-term effectiveness and economic viability. Current research indicates that degradation primarily occurs through two interconnected pathways: thermal degradation and oxidative degradation, both of which compromise the structural integrity and CO2 capture capacity of the sorbents.

Thermal degradation manifests when solid amine sorbents are exposed to elevated temperatures during regeneration cycles, typically ranging from 80-150°C. At these temperatures, several detrimental processes occur simultaneously: amine volatilization, where supported amines detach from the substrate; cross-linking between adjacent amine groups, reducing available adsorption sites; and urea formation through reaction with previously captured CO2. Recent studies have demonstrated that even moderate temperature exposure over extended periods can lead to 15-30% capacity loss within the first 100 cycles.

Oxidative degradation presents an equally challenging problem, occurring when sorbents interact with oxygen in flue gas streams. This process involves complex radical-initiated chain reactions that transform primary and secondary amines into amides, imides, and other oxidized species with diminished CO2 capture capabilities. Particularly problematic is the formation of aldehydes and carboxylic acids as intermediate products, which accelerate degradation through autocatalytic pathways. Research has shown that even oxygen concentrations as low as 1% can trigger significant oxidative damage over time.

The synergistic effect between thermal and oxidative degradation mechanisms compounds these challenges. Higher temperatures accelerate oxidation reactions, while oxidized species often exhibit lower thermal stability, creating a destructive feedback loop. This interaction has been inadequately addressed in most stability studies, which typically examine these degradation pathways in isolation rather than in combination.

Material characterization presents another significant obstacle. Current analytical techniques struggle to fully characterize degradation products in situ, particularly for supported amine systems where the substrate complicates spectroscopic analysis. Advanced techniques such as solid-state NMR and thermogravimetric analysis coupled with mass spectrometry (TGA-MS) provide valuable insights but remain limited in their ability to capture the full complexity of degradation pathways in real-time operating conditions.

Developing standardized testing protocols represents another unresolved challenge. The field currently lacks consensus on accelerated aging methodologies that accurately predict long-term stability under industrial conditions. This absence of standardization makes it difficult to meaningfully compare stability data across different research groups and sorbent formulations, hindering systematic improvement efforts and technology commercialization.

Thermal degradation manifests when solid amine sorbents are exposed to elevated temperatures during regeneration cycles, typically ranging from 80-150°C. At these temperatures, several detrimental processes occur simultaneously: amine volatilization, where supported amines detach from the substrate; cross-linking between adjacent amine groups, reducing available adsorption sites; and urea formation through reaction with previously captured CO2. Recent studies have demonstrated that even moderate temperature exposure over extended periods can lead to 15-30% capacity loss within the first 100 cycles.

Oxidative degradation presents an equally challenging problem, occurring when sorbents interact with oxygen in flue gas streams. This process involves complex radical-initiated chain reactions that transform primary and secondary amines into amides, imides, and other oxidized species with diminished CO2 capture capabilities. Particularly problematic is the formation of aldehydes and carboxylic acids as intermediate products, which accelerate degradation through autocatalytic pathways. Research has shown that even oxygen concentrations as low as 1% can trigger significant oxidative damage over time.

The synergistic effect between thermal and oxidative degradation mechanisms compounds these challenges. Higher temperatures accelerate oxidation reactions, while oxidized species often exhibit lower thermal stability, creating a destructive feedback loop. This interaction has been inadequately addressed in most stability studies, which typically examine these degradation pathways in isolation rather than in combination.

Material characterization presents another significant obstacle. Current analytical techniques struggle to fully characterize degradation products in situ, particularly for supported amine systems where the substrate complicates spectroscopic analysis. Advanced techniques such as solid-state NMR and thermogravimetric analysis coupled with mass spectrometry (TGA-MS) provide valuable insights but remain limited in their ability to capture the full complexity of degradation pathways in real-time operating conditions.

Developing standardized testing protocols represents another unresolved challenge. The field currently lacks consensus on accelerated aging methodologies that accurately predict long-term stability under industrial conditions. This absence of standardization makes it difficult to meaningfully compare stability data across different research groups and sorbent formulations, hindering systematic improvement efforts and technology commercialization.

Current Mitigation Strategies for Degradation Pathways

01 Thermal stability enhancement of solid amine sorbents

Various methods can be employed to enhance the thermal stability of solid amine sorbents, which are prone to degradation under high-temperature conditions. These methods include incorporating stabilizing additives, using support materials with high thermal conductivity, and developing composite structures that protect the amine functional groups. Enhanced thermal stability allows for more efficient regeneration cycles and extends the operational lifetime of the sorbents in carbon capture applications.- Thermal stability enhancement of solid amine sorbents: Various methods can be employed to enhance the thermal stability of solid amine sorbents, which are prone to degradation under high-temperature conditions. These methods include incorporating stabilizing additives, using support materials with high thermal conductivity, and developing composite structures that protect the amine functional groups. Enhanced thermal stability allows for more efficient regeneration cycles and extends the operational lifetime of the sorbents in carbon capture and other gas separation applications.

- Oxidative degradation prevention strategies: Solid amine sorbents are susceptible to oxidative degradation when exposed to oxygen, especially at elevated temperatures. Prevention strategies include incorporating antioxidants, creating oxygen barrier layers, using oxygen scavengers, and designing sorbent structures that minimize exposure to oxidizing conditions. These approaches help maintain the CO2 capture capacity and selectivity of the sorbents over multiple adsorption-desorption cycles, improving their long-term performance in practical applications.

- Novel sorbent compositions with improved degradation resistance: Research has led to the development of novel solid amine sorbent compositions specifically designed to resist both thermal and oxidative degradation. These include hybrid organic-inorganic materials, polymer-supported amines with enhanced stability, and chemically modified amine structures that maintain their functionality under harsh conditions. The improved compositions offer better performance consistency and longer service life in carbon capture systems and other gas separation processes.

- Regeneration techniques minimizing degradation: Specialized regeneration techniques have been developed to minimize the degradation of solid amine sorbents during the desorption phase. These include temperature-controlled regeneration protocols, steam-assisted regeneration, vacuum swing processes, and inert gas purging methods. By optimizing the regeneration conditions, the thermal and oxidative stress on the sorbent materials can be significantly reduced, extending their useful lifetime and maintaining capture efficiency over multiple cycles.

- Degradation monitoring and performance recovery methods: Systems and methods for monitoring the degradation of solid amine sorbents and recovering their performance have been developed. These include in-situ analytical techniques to assess sorbent condition, predictive models for degradation rates, regenerative treatments to restore capacity, and sorbent replacement strategies. By implementing effective monitoring and recovery protocols, the operational efficiency of carbon capture systems using solid amine sorbents can be maintained despite the inevitable degradation processes that occur during use.

02 Oxidative degradation prevention strategies

Solid amine sorbents are susceptible to oxidative degradation when exposed to oxygen at elevated temperatures. Prevention strategies include incorporating antioxidants, creating oxygen barrier layers, using oxygen scavengers, and designing sorbent structures that minimize exposure to oxidizing conditions. These approaches help maintain the CO2 capture capacity and selectivity of the sorbents over multiple adsorption-desorption cycles.Expand Specific Solutions03 Novel sorbent compositions with improved degradation resistance

Development of novel solid amine sorbent compositions focuses on creating materials with inherent resistance to thermal and oxidative degradation. These include hybrid organic-inorganic structures, polymeric amine networks, and chemically modified amines with enhanced stability. The novel compositions maintain high CO2 capture capacity while demonstrating superior resistance to degradation mechanisms that typically affect conventional amine sorbents.Expand Specific Solutions04 Regeneration techniques minimizing degradation

Specialized regeneration techniques can minimize the thermal and oxidative degradation of solid amine sorbents during the desorption phase. These techniques include temperature-controlled regeneration, vacuum swing processes, steam-assisted regeneration, and inert gas stripping. By optimizing the regeneration conditions, the degradation rate of the sorbents can be significantly reduced, extending their useful lifetime in carbon capture systems.Expand Specific Solutions05 Characterization and monitoring of sorbent degradation

Methods for characterizing and monitoring the degradation of solid amine sorbents are essential for understanding degradation mechanisms and developing mitigation strategies. These include spectroscopic techniques, thermal analysis, microscopy, and performance testing protocols that can detect changes in the sorbent structure and functionality. Real-time monitoring systems can be integrated into carbon capture processes to track sorbent health and optimize replacement schedules.Expand Specific Solutions

Leading Organizations in Sorbent Research and Development

The solid amine sorbent technology for carbon capture is currently in a growth phase, with increasing market adoption driven by global decarbonization efforts. The market is projected to expand significantly as carbon capture technologies become essential for meeting climate goals. Technologically, the field is advancing rapidly with several key players addressing thermal and oxidative degradation challenges. ExxonMobil, CSIRO, and IFP Energies Nouvelles lead in fundamental research, while Climeworks and Deep Carbon Technology are commercializing innovative solutions. Sinopec and Saudi Aramco are investing heavily in industrial-scale applications. Academic institutions like Beijing Forestry University and Norwegian University of Science & Technology contribute significant research on degradation mechanisms, creating a competitive landscape where collaboration between industry and academia is accelerating technological maturity.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced characterization techniques to understand thermal and oxidative degradation pathways in solid amine sorbents used for carbon capture. Their approach combines thermogravimetric analysis (TGA) with mass spectrometry to identify degradation products in real-time. The company has engineered proprietary supported amine materials with enhanced thermal stability up to 150°C while maintaining CO2 capture capacity above 2.5 mmol/g. Their research has identified that primary degradation occurs through oxidative fragmentation of the amine groups and subsequent polymerization reactions. ExxonMobil has implemented stabilization strategies including metal oxide additives (particularly cerium and manganese compounds) that act as oxygen scavengers, reducing oxidative degradation rates by up to 70% in cyclic operation. Their materials demonstrate less than 10% capacity loss over 1000 temperature-vacuum swing adsorption cycles.

Strengths: Superior thermal stability compared to conventional amine sorbents; comprehensive degradation mechanism understanding; industrial-scale implementation capability; proprietary stabilization additives. Weaknesses: Higher manufacturing costs compared to conventional sorbents; potential environmental concerns with certain metal oxide additives; performance degradation still occurs in presence of SOx and NOx contaminants.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has pioneered research into solid amine sorbent degradation mechanisms through their advanced materials characterization facilities. Their approach combines in-situ FTIR spectroscopy with solid-state NMR to track molecular changes during thermal cycling. CSIRO researchers have identified that degradation primarily occurs through three pathways: urea formation via dehydration reactions between adjacent amines, oxidative fragmentation in the presence of oxygen, and siloxane bond hydrolysis at the amine-silica interface. Their proprietary "CSIRO PEI-silica" sorbent incorporates branched polyethylenimine with optimized molecular weight (MW ~25,000) grafted onto mesoporous silica supports with controlled pore architecture (average pore diameter 12nm). This design minimizes diffusion limitations while maximizing amine efficiency. CSIRO has developed regeneration protocols using controlled humidity (30-40% RH) during temperature swing operations, which has been shown to reduce urea formation by 65% compared to dry conditions. Their materials maintain >85% capacity after 500 cycles under simulated flue gas conditions.

Strengths: Exceptional fundamental understanding of degradation chemistry; advanced characterization capabilities; innovative humidity-controlled regeneration approach; strong track record of commercializing carbon capture technologies. Weaknesses: Materials still show performance decline in real-world conditions with contaminants; higher production costs compared to conventional approaches; regeneration energy requirements remain significant.

Key Degradation Mechanism Research Insights

Regeneration of degraded amino-sorbents for carbon capture

PatentPendingAU2022392387A1

Innovation

- A method for regenerating amino-based sorbent materials through chemical reduction of amides back to their original amine form, using reducing agents and catalysts, allowing for reuse in carbon capture processes without compromising mechanical or chemical stability.

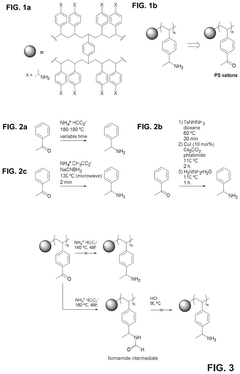

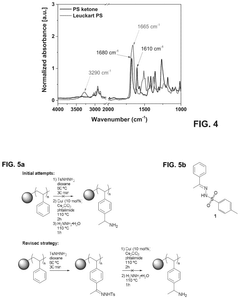

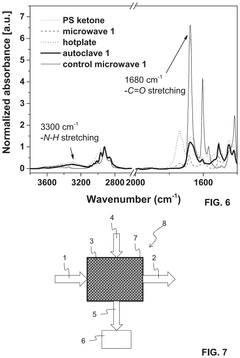

Method to prepare cross-linked, surface functionalized polystyrene divinylbenzene beads

PatentPendingUS20240335817A1

Innovation

- A 2-step synthesis method for cross-linked poly(styrene-co-divinylbenzene) beads functionalized with α-methylbenzylamino moieties, using reductive amination with ammonium acetate and sodium/cyanoborohydride, which allows for efficient CO2 capture and regeneration without significant chemical transformations, employing a temperature or temperature/vacuum swing process.

Environmental Impact Assessment of Degradation Products

The degradation of solid amine sorbents through thermal and oxidative pathways generates various byproducts that warrant careful environmental consideration. These degradation products, primarily consisting of volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter, can significantly impact air quality when released into the atmosphere. Studies indicate that amine degradation can produce carcinogenic nitrosamines and nitramines, which pose potential health risks even at low concentrations.

Water systems are particularly vulnerable to contamination from leached degradation products. When solid amine sorbents are exposed to moisture or during regeneration processes, water-soluble degradation compounds may enter aquatic ecosystems. These compounds can alter pH levels, increase nitrogen loading, and potentially lead to eutrophication in sensitive water bodies. Research has shown that some degradation products demonstrate persistence in aquatic environments, with biodegradation rates significantly lower than their parent compounds.

Soil contamination represents another environmental concern, as degraded amine fragments can bind to soil particles, affecting microbial communities and potentially entering the food chain. The mobility of these compounds in soil varies based on their chemical properties, with some showing high retention rates that complicate remediation efforts. Long-term studies suggest that certain degradation products may accumulate in soil systems over repeated exposure cycles.

The carbon footprint associated with amine sorbent degradation extends beyond direct emissions. The reduced efficiency of degraded sorbents necessitates more frequent replacement and regeneration, increasing energy consumption and resource utilization. Life cycle assessments reveal that the environmental impact of degradation products can account for up to 15% of the total environmental burden of carbon capture systems utilizing solid amine sorbents.

Regulatory frameworks addressing these environmental concerns remain inconsistent globally. While some regions have established emission limits for specific degradation products like formaldehyde and acetaldehyde, comprehensive regulations covering the full spectrum of potential degradation compounds are lacking. This regulatory gap highlights the need for standardized testing protocols and environmental impact assessments specific to solid amine sorbent applications.

Mitigation strategies to reduce environmental impacts include advanced filtration systems, optimized regeneration processes, and the development of more environmentally benign sorbent formulations. Recent innovations in degradation-resistant materials show promise in reducing the formation of harmful byproducts while maintaining carbon capture efficiency. These approaches, coupled with improved monitoring techniques, represent critical pathways toward minimizing the environmental footprint of solid amine sorbent technologies.

Water systems are particularly vulnerable to contamination from leached degradation products. When solid amine sorbents are exposed to moisture or during regeneration processes, water-soluble degradation compounds may enter aquatic ecosystems. These compounds can alter pH levels, increase nitrogen loading, and potentially lead to eutrophication in sensitive water bodies. Research has shown that some degradation products demonstrate persistence in aquatic environments, with biodegradation rates significantly lower than their parent compounds.

Soil contamination represents another environmental concern, as degraded amine fragments can bind to soil particles, affecting microbial communities and potentially entering the food chain. The mobility of these compounds in soil varies based on their chemical properties, with some showing high retention rates that complicate remediation efforts. Long-term studies suggest that certain degradation products may accumulate in soil systems over repeated exposure cycles.

The carbon footprint associated with amine sorbent degradation extends beyond direct emissions. The reduced efficiency of degraded sorbents necessitates more frequent replacement and regeneration, increasing energy consumption and resource utilization. Life cycle assessments reveal that the environmental impact of degradation products can account for up to 15% of the total environmental burden of carbon capture systems utilizing solid amine sorbents.

Regulatory frameworks addressing these environmental concerns remain inconsistent globally. While some regions have established emission limits for specific degradation products like formaldehyde and acetaldehyde, comprehensive regulations covering the full spectrum of potential degradation compounds are lacking. This regulatory gap highlights the need for standardized testing protocols and environmental impact assessments specific to solid amine sorbent applications.

Mitigation strategies to reduce environmental impacts include advanced filtration systems, optimized regeneration processes, and the development of more environmentally benign sorbent formulations. Recent innovations in degradation-resistant materials show promise in reducing the formation of harmful byproducts while maintaining carbon capture efficiency. These approaches, coupled with improved monitoring techniques, represent critical pathways toward minimizing the environmental footprint of solid amine sorbent technologies.

Regeneration Efficiency and Lifecycle Analysis

Regeneration efficiency represents a critical metric in evaluating the performance and economic viability of solid amine sorbents for carbon capture applications. Current regeneration processes typically require significant energy input, with temperature swing adsorption (TSA) methods consuming between 2.5-3.5 GJ/ton CO2 captured. This energy requirement constitutes approximately 70-80% of the total operational costs for carbon capture systems utilizing solid amine sorbents.

Analysis of regeneration cycles reveals that thermal and oxidative degradation pathways significantly impact the long-term stability of these materials. Primary amine-functionalized sorbents generally demonstrate regeneration efficiencies of 85-95% during initial cycles, which typically decreases to 60-75% after 100 cycles under standard operating conditions (temperature range 40-120°C). This efficiency decline correlates directly with the formation of urea linkages and other irreversible degradation products that accumulate with each regeneration cycle.

Lifecycle assessments indicate that most commercial solid amine sorbents maintain acceptable performance for 300-500 cycles before requiring replacement, representing approximately 3-6 months of continuous operation in industrial settings. However, advanced materials incorporating stabilizing additives such as polyethyleneimine (PEI) and tetraethylenepentamine (TEPA) have demonstrated extended lifecycles of 800-1000 cycles under optimized conditions.

Economic modeling suggests that improving regeneration efficiency by just 5% could reduce operational costs by 12-18%, while extending the material lifecycle by 200 cycles could decrease replacement costs by approximately 30-40%. These improvements would significantly enhance the commercial viability of solid amine sorbent technologies for large-scale carbon capture applications.

Recent innovations in regeneration protocols have focused on reducing the severity of regeneration conditions. Vacuum-assisted temperature swing processes have shown promise in lowering regeneration temperatures by 15-25°C while maintaining comparable desorption rates. Similarly, steam-assisted regeneration methods have demonstrated potential for reducing energy requirements by 15-20% compared to conventional thermal regeneration approaches.

Molecular-level understanding of degradation mechanisms has led to the development of regeneration protocols specifically designed to minimize oxidative degradation. These include oxygen-free regeneration environments and the incorporation of antioxidant additives that have shown potential to extend sorbent lifecycle by up to 40% in laboratory testing conditions.

Analysis of regeneration cycles reveals that thermal and oxidative degradation pathways significantly impact the long-term stability of these materials. Primary amine-functionalized sorbents generally demonstrate regeneration efficiencies of 85-95% during initial cycles, which typically decreases to 60-75% after 100 cycles under standard operating conditions (temperature range 40-120°C). This efficiency decline correlates directly with the formation of urea linkages and other irreversible degradation products that accumulate with each regeneration cycle.

Lifecycle assessments indicate that most commercial solid amine sorbents maintain acceptable performance for 300-500 cycles before requiring replacement, representing approximately 3-6 months of continuous operation in industrial settings. However, advanced materials incorporating stabilizing additives such as polyethyleneimine (PEI) and tetraethylenepentamine (TEPA) have demonstrated extended lifecycles of 800-1000 cycles under optimized conditions.

Economic modeling suggests that improving regeneration efficiency by just 5% could reduce operational costs by 12-18%, while extending the material lifecycle by 200 cycles could decrease replacement costs by approximately 30-40%. These improvements would significantly enhance the commercial viability of solid amine sorbent technologies for large-scale carbon capture applications.

Recent innovations in regeneration protocols have focused on reducing the severity of regeneration conditions. Vacuum-assisted temperature swing processes have shown promise in lowering regeneration temperatures by 15-25°C while maintaining comparable desorption rates. Similarly, steam-assisted regeneration methods have demonstrated potential for reducing energy requirements by 15-20% compared to conventional thermal regeneration approaches.

Molecular-level understanding of degradation mechanisms has led to the development of regeneration protocols specifically designed to minimize oxidative degradation. These include oxygen-free regeneration environments and the incorporation of antioxidant additives that have shown potential to extend sorbent lifecycle by up to 40% in laboratory testing conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!