Regeneration Energy Minimization For Amine-Based DAC Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DAC Technology Background and Objectives

Direct Air Capture (DAC) technology has emerged as a critical component in the global effort to combat climate change by directly removing carbon dioxide from the atmosphere. The development of DAC systems dates back to the early 2000s, with significant advancements occurring over the past decade as climate mitigation strategies have gained urgency. Amine-based DAC systems, in particular, have shown promising results due to their high CO2 selectivity and capacity.

The evolution of DAC technology has been marked by continuous improvements in sorbent materials, process design, and energy efficiency. Initial DAC systems required prohibitively high energy inputs, often exceeding 10 GJ per ton of CO2 captured. Recent technological innovations have reduced this figure substantially, though regeneration energy requirements remain a significant barrier to widespread commercial deployment.

Current research trends focus on developing novel amine compounds, optimizing sorbent structures, and enhancing process integration to minimize the energy penalty associated with sorbent regeneration. The field is witnessing a convergence of chemical engineering principles, materials science, and process optimization techniques to address these challenges.

The primary objective of regeneration energy minimization for amine-based DAC systems is to reduce the thermal energy required for CO2 desorption while maintaining high capture efficiency. This goal is driven by the need to make DAC economically viable at scale, as energy costs typically represent 50-75% of the total operational expenses in these systems.

Specific technical objectives include: reducing regeneration temperatures from the current 80-120°C range to below 80°C; decreasing the specific energy requirement to less than 4 GJ per ton of CO2; improving the working capacity of amine sorbents to reduce material circulation rates; and developing heat integration strategies that can utilize low-grade waste heat or renewable energy sources.

The achievement of these objectives would represent a significant breakthrough in DAC technology, potentially enabling cost reductions from current levels of $250-600 per ton of CO2 to below $100 per ton—a threshold widely considered necessary for large-scale deployment. Such advancements would position DAC as a viable complement to emissions reduction strategies in hard-to-abate sectors and provide a technological pathway for achieving negative emissions, which climate models increasingly indicate will be necessary to limit global warming to 1.5°C above pre-industrial levels.

As global carbon neutrality targets gain prominence in policy frameworks, the development of energy-efficient DAC systems has become a strategic priority for research institutions, technology companies, and governments worldwide, driving unprecedented investment and innovation in this field.

The evolution of DAC technology has been marked by continuous improvements in sorbent materials, process design, and energy efficiency. Initial DAC systems required prohibitively high energy inputs, often exceeding 10 GJ per ton of CO2 captured. Recent technological innovations have reduced this figure substantially, though regeneration energy requirements remain a significant barrier to widespread commercial deployment.

Current research trends focus on developing novel amine compounds, optimizing sorbent structures, and enhancing process integration to minimize the energy penalty associated with sorbent regeneration. The field is witnessing a convergence of chemical engineering principles, materials science, and process optimization techniques to address these challenges.

The primary objective of regeneration energy minimization for amine-based DAC systems is to reduce the thermal energy required for CO2 desorption while maintaining high capture efficiency. This goal is driven by the need to make DAC economically viable at scale, as energy costs typically represent 50-75% of the total operational expenses in these systems.

Specific technical objectives include: reducing regeneration temperatures from the current 80-120°C range to below 80°C; decreasing the specific energy requirement to less than 4 GJ per ton of CO2; improving the working capacity of amine sorbents to reduce material circulation rates; and developing heat integration strategies that can utilize low-grade waste heat or renewable energy sources.

The achievement of these objectives would represent a significant breakthrough in DAC technology, potentially enabling cost reductions from current levels of $250-600 per ton of CO2 to below $100 per ton—a threshold widely considered necessary for large-scale deployment. Such advancements would position DAC as a viable complement to emissions reduction strategies in hard-to-abate sectors and provide a technological pathway for achieving negative emissions, which climate models increasingly indicate will be necessary to limit global warming to 1.5°C above pre-industrial levels.

As global carbon neutrality targets gain prominence in policy frameworks, the development of energy-efficient DAC systems has become a strategic priority for research institutions, technology companies, and governments worldwide, driving unprecedented investment and innovation in this field.

Market Analysis for Amine-Based Carbon Capture

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The amine-based carbon capture segment represents a substantial portion of this market, valued at approximately $2.1 billion in 2022 and projected to reach $5.8 billion by 2030, growing at a CAGR of 13.5% during the forecast period.

Direct Air Capture (DAC) technologies, particularly those utilizing amine-based systems, are gaining traction as viable solutions for carbon dioxide removal directly from ambient air. The market for DAC specifically is estimated at $630 million in 2023, with projections indicating potential growth to $3.7 billion by 2032 if technological advancements in regeneration energy efficiency continue at the current pace.

Key market drivers include stringent government regulations on carbon emissions, increasing corporate commitments to carbon neutrality, and growing investment in carbon removal technologies. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for carbon capture implementation, while carbon credit markets provide additional revenue streams for DAC operators.

Energy consumption remains the primary cost factor for amine-based DAC systems, with regeneration energy requirements accounting for 60-70% of operational expenses. This presents a significant market opportunity for technologies that can minimize regeneration energy requirements, potentially reducing overall costs by 30-45% and making DAC economically viable at scale.

Market segmentation shows diverse applications across power generation, industrial processes, and emerging direct air capture installations. Geographically, North America leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 21%, with the latter showing the fastest growth rate due to rapid industrialization and increasing environmental regulations in China and India.

Customer demand is shifting toward integrated solutions that not only capture carbon but also provide pathways for utilization or permanent storage. Industries with hard-to-abate emissions, including cement, steel, and chemical manufacturing, represent high-value market segments willing to pay premium prices for effective carbon capture technologies.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized carbon capture firms such as Carbon Engineering and Climeworks, and emerging startups focused specifically on energy-efficient amine regeneration technologies. Recent market consolidation through mergers and acquisitions indicates growing commercial interest in the sector, with total investment in DAC technologies reaching $1.1 billion in 2022, a 110% increase from the previous year.

Direct Air Capture (DAC) technologies, particularly those utilizing amine-based systems, are gaining traction as viable solutions for carbon dioxide removal directly from ambient air. The market for DAC specifically is estimated at $630 million in 2023, with projections indicating potential growth to $3.7 billion by 2032 if technological advancements in regeneration energy efficiency continue at the current pace.

Key market drivers include stringent government regulations on carbon emissions, increasing corporate commitments to carbon neutrality, and growing investment in carbon removal technologies. The European Union's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for carbon capture implementation, while carbon credit markets provide additional revenue streams for DAC operators.

Energy consumption remains the primary cost factor for amine-based DAC systems, with regeneration energy requirements accounting for 60-70% of operational expenses. This presents a significant market opportunity for technologies that can minimize regeneration energy requirements, potentially reducing overall costs by 30-45% and making DAC economically viable at scale.

Market segmentation shows diverse applications across power generation, industrial processes, and emerging direct air capture installations. Geographically, North America leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 21%, with the latter showing the fastest growth rate due to rapid industrialization and increasing environmental regulations in China and India.

Customer demand is shifting toward integrated solutions that not only capture carbon but also provide pathways for utilization or permanent storage. Industries with hard-to-abate emissions, including cement, steel, and chemical manufacturing, represent high-value market segments willing to pay premium prices for effective carbon capture technologies.

The competitive landscape features established industrial gas companies like Air Liquide and Linde, specialized carbon capture firms such as Carbon Engineering and Climeworks, and emerging startups focused specifically on energy-efficient amine regeneration technologies. Recent market consolidation through mergers and acquisitions indicates growing commercial interest in the sector, with total investment in DAC technologies reaching $1.1 billion in 2022, a 110% increase from the previous year.

Technical Challenges in Regeneration Energy Requirements

The regeneration energy requirement represents the most significant technical challenge in amine-based Direct Air Capture (DAC) systems, accounting for approximately 60-80% of the total operational energy consumption. Current commercial systems require between 7-9 GJ per ton of CO₂ captured, which is substantially higher than the theoretical minimum of approximately 1.8 GJ/ton. This energy gap presents a critical barrier to widespread DAC deployment and economic viability.

The high regeneration energy demand stems primarily from the strong chemical bonds formed between CO₂ and amine sorbents. Breaking these bonds requires substantial thermal energy input, typically in the form of steam at temperatures ranging from 100-150°C. The process is further complicated by the high specific heat capacity of water, which constitutes a significant portion of the liquid amine solutions used in absorption-based systems.

Heat management inefficiencies represent another major challenge. Current regeneration processes suffer from substantial heat losses during the temperature cycling between absorption (typically at ambient temperatures) and desorption phases. The large temperature swing necessary for effective regeneration creates significant thermal inefficiencies that have proven difficult to mitigate through conventional heat integration approaches.

Mass transfer limitations during the desorption phase also contribute to energy inefficiency. As CO₂ is released from the sorbent, it must diffuse through the liquid phase before being collected. This diffusion process often becomes rate-limiting, requiring extended heating periods and consequently increasing energy consumption. The formation of bicarbonates and other intermediate species further complicates the desorption kinetics.

Water co-evaporation presents an additional energy penalty. During the thermal regeneration process, significant energy is consumed in evaporating water from amine solutions, which does not contribute directly to CO₂ release but substantially increases the overall energy requirement. This parasitic energy loss can account for 20-30% of the total regeneration energy.

Material degradation under repeated thermal cycling introduces further complications. High-temperature regeneration accelerates amine oxidation and thermal degradation, reducing sorbent capacity over time and necessitating more frequent replacement or regeneration cycles, indirectly increasing the energy footprint of the system.

Scale-up challenges also impact energy efficiency. Laboratory-optimized processes often experience efficiency losses when scaled to industrial levels due to non-uniform heating, increased pressure drops, and suboptimal flow distributions. These factors can increase regeneration energy requirements by 15-25% compared to theoretical or laboratory-scale performance.

The high regeneration energy demand stems primarily from the strong chemical bonds formed between CO₂ and amine sorbents. Breaking these bonds requires substantial thermal energy input, typically in the form of steam at temperatures ranging from 100-150°C. The process is further complicated by the high specific heat capacity of water, which constitutes a significant portion of the liquid amine solutions used in absorption-based systems.

Heat management inefficiencies represent another major challenge. Current regeneration processes suffer from substantial heat losses during the temperature cycling between absorption (typically at ambient temperatures) and desorption phases. The large temperature swing necessary for effective regeneration creates significant thermal inefficiencies that have proven difficult to mitigate through conventional heat integration approaches.

Mass transfer limitations during the desorption phase also contribute to energy inefficiency. As CO₂ is released from the sorbent, it must diffuse through the liquid phase before being collected. This diffusion process often becomes rate-limiting, requiring extended heating periods and consequently increasing energy consumption. The formation of bicarbonates and other intermediate species further complicates the desorption kinetics.

Water co-evaporation presents an additional energy penalty. During the thermal regeneration process, significant energy is consumed in evaporating water from amine solutions, which does not contribute directly to CO₂ release but substantially increases the overall energy requirement. This parasitic energy loss can account for 20-30% of the total regeneration energy.

Material degradation under repeated thermal cycling introduces further complications. High-temperature regeneration accelerates amine oxidation and thermal degradation, reducing sorbent capacity over time and necessitating more frequent replacement or regeneration cycles, indirectly increasing the energy footprint of the system.

Scale-up challenges also impact energy efficiency. Laboratory-optimized processes often experience efficiency losses when scaled to industrial levels due to non-uniform heating, increased pressure drops, and suboptimal flow distributions. These factors can increase regeneration energy requirements by 15-25% compared to theoretical or laboratory-scale performance.

Current Approaches to Regeneration Energy Minimization

01 Amine-based sorbent regeneration techniques

Various techniques are employed to regenerate amine-based sorbents used in Direct Air Capture (DAC) systems. These techniques focus on reducing the energy requirements for the desorption of CO2 from the amine sorbents. Methods include temperature swing adsorption, vacuum pressure swing, and combinations thereof. The regeneration process typically involves heating the CO2-loaded sorbent to release the captured carbon dioxide, with innovations aimed at minimizing the thermal energy needed for this step.- Amine-based sorbent regeneration techniques: Various techniques are employed to regenerate amine-based sorbents in Direct Air Capture (DAC) systems, focusing on reducing energy consumption. These techniques include temperature swing adsorption, vacuum pressure swing processes, and combined approaches that optimize the desorption of CO2 from amine compounds. The regeneration process typically involves heating the sorbent to release captured CO2, with innovations aimed at lowering the temperature requirements and improving overall energy efficiency.

- Heat integration and energy recovery systems: Heat integration and energy recovery systems are crucial for reducing the regeneration energy requirements in amine-based DAC systems. These systems capture and reuse waste heat from the regeneration process, implement heat exchangers to transfer thermal energy between process streams, and utilize multi-stage heating approaches. By optimizing heat management, these innovations significantly decrease the external energy input needed for sorbent regeneration.

- Novel amine compound formulations: Specialized amine compound formulations are developed to reduce regeneration energy requirements in DAC systems. These formulations include modified molecular structures, supported amine materials, and composite sorbents that combine amines with other materials to enhance CO2 binding selectivity while requiring less energy for release. The novel compounds are designed to achieve optimal balance between CO2 capture capacity and regeneration energy demand.

- Renewable energy integration for regeneration: Integration of renewable energy sources with DAC systems significantly reduces the carbon footprint of the regeneration process. Solar thermal energy, wind power, and geothermal heat are harnessed to provide the energy needed for sorbent regeneration. These systems include specialized heat transfer mechanisms, energy storage solutions, and control systems that optimize the use of intermittent renewable resources for the continuous operation of DAC facilities.

- Advanced process control and optimization: Advanced control systems and optimization algorithms are implemented to minimize energy consumption during the regeneration phase of amine-based DAC operations. These systems utilize real-time monitoring, predictive modeling, and adaptive control strategies to adjust operating parameters based on changing conditions. Machine learning approaches optimize regeneration cycles, timing, and energy input levels to achieve maximum efficiency while maintaining capture performance.

02 Heat integration and energy recovery systems

Heat integration and energy recovery systems are crucial for reducing the overall energy consumption in amine-based DAC systems. These systems capture and reuse waste heat from the regeneration process, implement heat exchangers between the absorption and desorption units, and utilize low-grade heat sources. By optimizing heat transfer and recovery, these approaches significantly decrease the external energy input required for sorbent regeneration.Expand Specific Solutions03 Novel amine formulations for reduced regeneration energy

Research has led to the development of novel amine formulations specifically designed to reduce regeneration energy requirements. These formulations include modified amine structures, amine blends, and supported amine materials that exhibit lower binding energies with CO2 while maintaining high capture capacity. The chemical modifications aim to decrease the enthalpy of CO2 desorption, thereby lowering the energy needed for the regeneration phase of the DAC process.Expand Specific Solutions04 Renewable energy integration for DAC regeneration

Integration of renewable energy sources with DAC systems offers a pathway to reduce both the carbon footprint and operational costs of the regeneration process. Solar thermal energy, geothermal heat, and waste heat from industrial processes can be harnessed to provide the thermal energy required for amine regeneration. These approaches enable more sustainable operation of DAC systems by reducing reliance on fossil fuel-derived energy for the energy-intensive regeneration step.Expand Specific Solutions05 Advanced process control and optimization strategies

Advanced process control and optimization strategies are implemented to minimize energy consumption during the regeneration of amine-based DAC systems. These include real-time monitoring of CO2 loading, adaptive control algorithms that adjust regeneration parameters based on operating conditions, and model predictive control systems. By optimizing the regeneration cycle timing, temperature profiles, and flow rates, these strategies can significantly reduce the energy requirements while maintaining efficient CO2 capture performance.Expand Specific Solutions

Leading Companies in Amine-Based DAC Technology

The direct air capture (DAC) technology for amine-based regeneration energy minimization is in an early growth phase, with market size expanding as carbon capture becomes critical for climate goals. The technology is advancing from lab-scale to commercial demonstration, showing moderate maturity. Key players include Chinese institutions like Southeast University, Huaneng Clean Energy Research Institute, and China Petroleum & Chemical Corp., which are developing energy-efficient solvent regeneration processes. Western organizations such as Shell Internationale Research and National University of Singapore are focusing on novel materials and process optimization. The competitive landscape shows strong collaboration between academic institutions and energy companies, with Chinese entities particularly active in scaling up pilot projects for industrial applications.

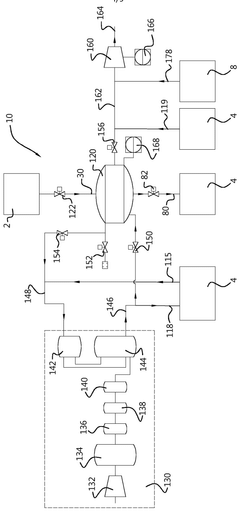

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed a comprehensive Thermal Cascade Utilization System for minimizing regeneration energy in amine-based DAC systems. Their approach features a multi-stage regeneration process that strategically releases CO2 at different temperature thresholds, optimizing energy input based on the binding strength distribution within the loaded amine solution. The institute has engineered specialized heat integration networks that recover thermal energy across the entire temperature spectrum of the process, achieving heat recovery rates exceeding 80%. Their technology incorporates advanced lean/rich solution heat exchangers with enhanced surface geometries that minimize approach temperatures to as low as 5°C, significantly improving thermal transfer efficiency. Additionally, Huaneng has developed proprietary amine formulations with modified molecular structures that reduce regeneration enthalpy requirements while maintaining high CO2 absorption capacity and selectivity. The system also features intelligent control algorithms that continuously optimize operational parameters based on real-time monitoring of solution properties and environmental conditions.

Strengths: Their technology demonstrates excellent energy performance metrics with regeneration requirements reduced by approximately 30-35% compared to conventional MEA systems. The solution offers good scalability across different capacity ranges. Weaknesses: The system's complexity requires sophisticated monitoring and control systems, potentially increasing maintenance requirements and operational expertise needed.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive regeneration energy minimization strategy for amine-based DAC systems centered around their Dual-Phase Optimization Technology. This approach tackles energy consumption from both thermodynamic and kinetic perspectives. Their system employs proprietary blended amine formulations with modified molecular structures that reduce the enthalpy of CO2 desorption while maintaining high capture efficiency. Sinopec's process incorporates a staged pressure reduction mechanism during regeneration, allowing for partial CO2 release at lower temperatures before final stripping at elevated temperatures. Their technology includes an advanced heat recovery network with specialized plate heat exchangers achieving thermal transfer efficiencies exceeding 90%. Additionally, they've implemented a variable-frequency control system that dynamically adjusts pumping and compression parameters based on real-time monitoring of CO2 loading and solution properties, further reducing parasitic energy losses throughout the capture-regeneration cycle.

Strengths: Sinopec's extensive industrial infrastructure enables rapid scaling and deployment of their technology across multiple sites. Their integrated approach addresses both chemical and mechanical aspects of energy optimization. Weaknesses: The system's complexity requires sophisticated control systems and may face challenges in smaller-scale applications with limited technical support capabilities.

Key Innovations in Sorbent Regeneration Processes

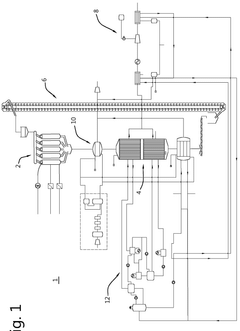

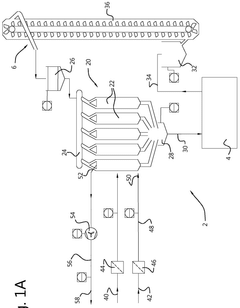

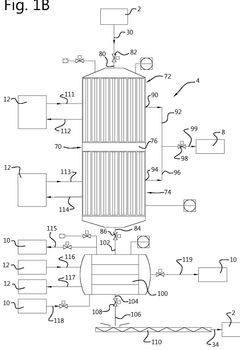

Direct air capture of co2 using leaf-like layered contactor coupled with electro dialysis bipolar membrane regeneration

PatentPendingUS20240157299A1

Innovation

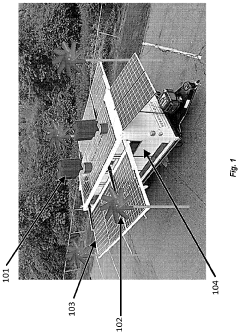

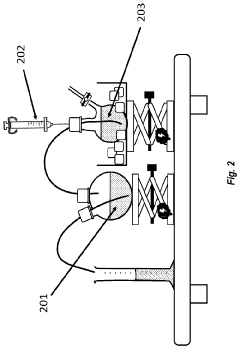

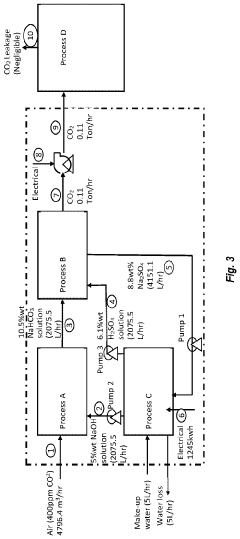

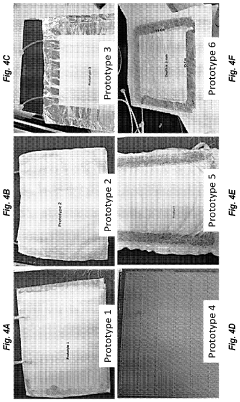

- A self-powered portable DAC system utilizing a liquid air contactor with a hydrophobic membrane and an electrodialysis bipolar membrane (EDBM) for electrochemical regeneration, which allows for efficient CO2 capture and conversion to an aqueous carbonate compound, powered by wind or solar energy, and integrated with a CO2 sequestration pump for geological storage.

System and method for direct air capture

PatentWO2025141054A1

Innovation

- A system utilizing an adsorber section, regeneration section with multiple desorption stages at distinct temperature levels under vacuum, a transport section, and a heat recovery system with a two-stage heat pump assembly to optimize energy use, incorporating granular sorbent material and high-purity nitrogen purge to enhance adsorption efficiency.

Carbon Pricing and Policy Incentives for DAC Implementation

Carbon pricing mechanisms and policy incentives are critical enablers for the widespread implementation of Direct Air Capture (DAC) technologies, particularly those focused on regeneration energy minimization for amine-based systems. Currently, the global carbon pricing landscape remains fragmented, with prices ranging from less than $1 to over $130 per ton of CO2 across different jurisdictions. This significant variation creates an uneven playing field for DAC deployment.

For amine-based DAC systems, where regeneration energy represents approximately 70-80% of operational costs, policy frameworks that recognize and reward energy efficiency innovations are particularly valuable. The European Union's Emissions Trading System (ETS) and carbon border adjustment mechanisms are creating price signals that increasingly favor energy-efficient carbon removal technologies, with prices reaching €80-90 per ton in recent trading periods.

In the United States, the Inflation Reduction Act of 2022 has dramatically altered the economic landscape for DAC through the enhanced 45Q tax credit, which now offers up to $180 per ton for direct air capture with geological sequestration. This substantial incentive specifically benefits technologies that can minimize regeneration energy requirements, as lower operational costs combined with the tax credit can potentially make certain DAC operations economically viable.

Several countries have implemented complementary policies that further enhance the business case for energy-efficient DAC systems. These include innovation grants targeting regeneration energy breakthroughs, accelerated depreciation allowances for energy-efficient equipment, and renewable energy subsidies that can be paired with DAC operations to reduce the carbon intensity of the regeneration process itself.

The voluntary carbon market also plays an increasingly important role, with premium prices being paid for high-quality carbon removal credits. Projects demonstrating lower energy intensity in their regeneration processes can command prices of $200-600 per ton, reflecting buyer preference for more sustainable removal approaches.

Looking forward, policy innovations such as carbon take-back obligations, guaranteed purchase agreements for negative emissions, and technology-specific procurement targets are emerging as promising mechanisms to drive investment in regeneration energy minimization research. These approaches provide the long-term certainty needed for capital-intensive DAC projects while specifically rewarding improvements in energy efficiency metrics.

For amine-based DAC systems, where regeneration energy represents approximately 70-80% of operational costs, policy frameworks that recognize and reward energy efficiency innovations are particularly valuable. The European Union's Emissions Trading System (ETS) and carbon border adjustment mechanisms are creating price signals that increasingly favor energy-efficient carbon removal technologies, with prices reaching €80-90 per ton in recent trading periods.

In the United States, the Inflation Reduction Act of 2022 has dramatically altered the economic landscape for DAC through the enhanced 45Q tax credit, which now offers up to $180 per ton for direct air capture with geological sequestration. This substantial incentive specifically benefits technologies that can minimize regeneration energy requirements, as lower operational costs combined with the tax credit can potentially make certain DAC operations economically viable.

Several countries have implemented complementary policies that further enhance the business case for energy-efficient DAC systems. These include innovation grants targeting regeneration energy breakthroughs, accelerated depreciation allowances for energy-efficient equipment, and renewable energy subsidies that can be paired with DAC operations to reduce the carbon intensity of the regeneration process itself.

The voluntary carbon market also plays an increasingly important role, with premium prices being paid for high-quality carbon removal credits. Projects demonstrating lower energy intensity in their regeneration processes can command prices of $200-600 per ton, reflecting buyer preference for more sustainable removal approaches.

Looking forward, policy innovations such as carbon take-back obligations, guaranteed purchase agreements for negative emissions, and technology-specific procurement targets are emerging as promising mechanisms to drive investment in regeneration energy minimization research. These approaches provide the long-term certainty needed for capital-intensive DAC projects while specifically rewarding improvements in energy efficiency metrics.

Life Cycle Assessment of Amine-Based DAC Systems

Life Cycle Assessment (LCA) of amine-based Direct Air Capture (DAC) systems provides critical insights into the environmental impacts across the entire technology lifecycle. These assessments typically evaluate impacts from raw material extraction through manufacturing, operation, and end-of-life disposal, offering a comprehensive environmental footprint analysis.

The energy requirements for regeneration represent a significant portion of the overall environmental impact of amine-based DAC systems. LCA studies consistently identify the regeneration phase as the most energy-intensive component, accounting for approximately 60-80% of the total energy consumption. This high energy demand directly translates to increased greenhouse gas emissions when fossil fuel sources power the regeneration process.

Material production and manufacturing phases contribute additional environmental burdens, particularly through the synthesis of specialized amine sorbents. The production of these chemical compounds involves energy-intensive processes and potentially hazardous precursors, resulting in embedded carbon and toxicity concerns that must be quantified through proper LCA methodologies.

Water consumption emerges as another critical factor in comprehensive assessments. Amine-based DAC systems require significant water inputs for various processes, including cooling during regeneration and solvent makeup. In water-stressed regions, this consumption pattern may create sustainability challenges that offset carbon removal benefits.

Recent LCA studies have highlighted the importance of system boundaries and functional units in assessment outcomes. When comparing different DAC technologies, variations in system boundary definitions can lead to dramatically different conclusions regarding environmental performance. Standardization efforts are underway to establish consistent LCA frameworks specifically for carbon removal technologies.

The environmental payback period—the time required for a DAC system to offset its embodied emissions through carbon removal—varies significantly based on energy source. Systems powered by renewable energy sources demonstrate payback periods of 1-3 years, while those relying on grid electricity may require 5-10 years to achieve net carbon benefits, depending on regional electricity carbon intensity.

Land use impacts and potential chemical emissions from amine degradation represent additional environmental considerations that comprehensive LCAs must address. These factors, though often secondary to energy concerns, can become significant when scaling DAC deployment to climate-relevant levels.

Future LCA research directions include developing dynamic assessment models that account for technological improvements over time and integration with energy system transitions, providing more accurate projections of life-cycle impacts as DAC technologies mature and deploy at scale.

The energy requirements for regeneration represent a significant portion of the overall environmental impact of amine-based DAC systems. LCA studies consistently identify the regeneration phase as the most energy-intensive component, accounting for approximately 60-80% of the total energy consumption. This high energy demand directly translates to increased greenhouse gas emissions when fossil fuel sources power the regeneration process.

Material production and manufacturing phases contribute additional environmental burdens, particularly through the synthesis of specialized amine sorbents. The production of these chemical compounds involves energy-intensive processes and potentially hazardous precursors, resulting in embedded carbon and toxicity concerns that must be quantified through proper LCA methodologies.

Water consumption emerges as another critical factor in comprehensive assessments. Amine-based DAC systems require significant water inputs for various processes, including cooling during regeneration and solvent makeup. In water-stressed regions, this consumption pattern may create sustainability challenges that offset carbon removal benefits.

Recent LCA studies have highlighted the importance of system boundaries and functional units in assessment outcomes. When comparing different DAC technologies, variations in system boundary definitions can lead to dramatically different conclusions regarding environmental performance. Standardization efforts are underway to establish consistent LCA frameworks specifically for carbon removal technologies.

The environmental payback period—the time required for a DAC system to offset its embodied emissions through carbon removal—varies significantly based on energy source. Systems powered by renewable energy sources demonstrate payback periods of 1-3 years, while those relying on grid electricity may require 5-10 years to achieve net carbon benefits, depending on regional electricity carbon intensity.

Land use impacts and potential chemical emissions from amine degradation represent additional environmental considerations that comprehensive LCAs must address. These factors, though often secondary to energy concerns, can become significant when scaling DAC deployment to climate-relevant levels.

Future LCA research directions include developing dynamic assessment models that account for technological improvements over time and integration with energy system transitions, providing more accurate projections of life-cycle impacts as DAC technologies mature and deploy at scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!