Hybrid DAC Systems Combining Solid Amines And Electro-Swing Adsorption

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid DAC Technology Evolution and Objectives

Direct Air Capture (DAC) technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations. The earliest DAC systems emerged in the early 2000s, primarily focusing on single-method approaches using either liquid solvents or solid sorbents. These initial systems demonstrated proof-of-concept but suffered from high energy requirements and operational costs, limiting their commercial viability.

By the mid-2010s, solid amine-based DAC systems gained prominence due to their relatively lower regeneration energy requirements compared to liquid systems. These solid sorbents offered advantages in terms of reduced corrosion issues and operational flexibility. Concurrently, electro-swing adsorption (ESA) technology began developing as an alternative approach, utilizing electrical energy rather than thermal energy for sorbent regeneration, potentially offering significant efficiency improvements.

The concept of hybrid DAC systems combining solid amines with electro-swing adsorption represents the latest evolutionary step in this technological progression. This hybrid approach emerged around 2018-2019, aiming to leverage the complementary strengths of both technologies while mitigating their individual limitations. The fundamental objective is to develop carbon capture systems with substantially improved energy efficiency, reduced operational costs, and enhanced scalability.

Current hybrid DAC technology seeks to integrate the high CO₂ selectivity and capacity of solid amines with the potentially lower energy requirements and faster cycling capabilities of electro-swing processes. This integration aims to overcome the thermal degradation issues associated with conventional temperature swing adsorption (TSA) methods typically used with solid amines, while addressing the capacity limitations often encountered in pure ESA systems.

The primary technical objectives for hybrid DAC systems include achieving energy consumption below 500 kWh per ton of CO₂ captured, developing sorbents with both high CO₂ affinity and electrical responsiveness, and designing systems capable of continuous operation with minimal performance degradation over thousands of cycles. Additional goals include reducing capital costs to under $300 per ton of annual CO₂ capture capacity and developing modular designs that can be deployed across diverse geographical and climatic conditions.

Looking forward, the technology roadmap for hybrid DAC systems envisions progression from current laboratory-scale demonstrations to pilot plants capable of capturing 100-1000 tons of CO₂ annually by 2025, followed by commercial-scale implementations exceeding 10,000 tons annually by 2030. This ambitious trajectory aligns with global carbon neutrality goals and represents a critical pathway for negative emissions technologies essential for addressing climate change.

By the mid-2010s, solid amine-based DAC systems gained prominence due to their relatively lower regeneration energy requirements compared to liquid systems. These solid sorbents offered advantages in terms of reduced corrosion issues and operational flexibility. Concurrently, electro-swing adsorption (ESA) technology began developing as an alternative approach, utilizing electrical energy rather than thermal energy for sorbent regeneration, potentially offering significant efficiency improvements.

The concept of hybrid DAC systems combining solid amines with electro-swing adsorption represents the latest evolutionary step in this technological progression. This hybrid approach emerged around 2018-2019, aiming to leverage the complementary strengths of both technologies while mitigating their individual limitations. The fundamental objective is to develop carbon capture systems with substantially improved energy efficiency, reduced operational costs, and enhanced scalability.

Current hybrid DAC technology seeks to integrate the high CO₂ selectivity and capacity of solid amines with the potentially lower energy requirements and faster cycling capabilities of electro-swing processes. This integration aims to overcome the thermal degradation issues associated with conventional temperature swing adsorption (TSA) methods typically used with solid amines, while addressing the capacity limitations often encountered in pure ESA systems.

The primary technical objectives for hybrid DAC systems include achieving energy consumption below 500 kWh per ton of CO₂ captured, developing sorbents with both high CO₂ affinity and electrical responsiveness, and designing systems capable of continuous operation with minimal performance degradation over thousands of cycles. Additional goals include reducing capital costs to under $300 per ton of annual CO₂ capture capacity and developing modular designs that can be deployed across diverse geographical and climatic conditions.

Looking forward, the technology roadmap for hybrid DAC systems envisions progression from current laboratory-scale demonstrations to pilot plants capable of capturing 100-1000 tons of CO₂ annually by 2025, followed by commercial-scale implementations exceeding 10,000 tons annually by 2030. This ambitious trajectory aligns with global carbon neutrality goals and represents a critical pathway for negative emissions technologies essential for addressing climate change.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing climate change concerns and stringent emission regulations. Currently valued at approximately $2.5 billion, the market is projected to reach $7 billion by 2028, representing a compound annual growth rate of 19.2%. Direct Air Capture (DAC) technologies, while still emerging, are gaining traction with projected market value expected to exceed $3.5 billion by 2030.

Hybrid DAC systems combining solid amines and electro-swing adsorption represent a promising segment within this growing market. These systems address the limitations of traditional carbon capture methods by offering improved energy efficiency and operational flexibility. The demand for such hybrid solutions is particularly strong in regions with ambitious carbon neutrality targets, including the European Union, North America, and parts of Asia.

Industrial sectors represent the primary market for these hybrid DAC systems, with power generation, cement production, and chemical manufacturing showing the highest adoption potential. These industries face mounting pressure to reduce carbon footprints while maintaining operational efficiency. The hybrid approach offers a compelling value proposition by potentially reducing energy penalties by 30-40% compared to conventional amine scrubbing technologies.

Market analysis indicates that early adopters of hybrid DAC systems are primarily large corporations with established sustainability commitments and available capital for infrastructure investments. The technology is particularly attractive to companies operating in jurisdictions with carbon pricing mechanisms, where the economic case for carbon capture becomes more favorable.

Government incentives and carbon pricing mechanisms significantly influence market dynamics. Regions with carbon prices exceeding $50 per ton create favorable economics for DAC deployment. The Inflation Reduction Act in the United States, offering tax credits up to $180 per ton for direct air capture, has substantially improved the business case for these technologies.

Venture capital investment in DAC technologies has surged, with funding reaching $1.1 billion in 2022, a threefold increase from 2020. This investment trend reflects growing confidence in the commercial viability of advanced carbon capture solutions, including hybrid systems combining solid amines and electro-swing adsorption.

Customer segments for hybrid DAC systems extend beyond traditional industrial emitters to include technology companies seeking carbon-neutral operations, municipalities implementing climate action plans, and corporations pursuing carbon-negative product offerings. This diversification of potential customers expands the addressable market significantly.

Market barriers include high capital costs, technological maturity concerns, and uncertain regulatory frameworks in many regions. However, the hybrid approach addresses some key technical barriers by combining the high selectivity of solid amines with the energy efficiency advantages of electro-swing processes, potentially accelerating market penetration compared to single-technology approaches.

Hybrid DAC systems combining solid amines and electro-swing adsorption represent a promising segment within this growing market. These systems address the limitations of traditional carbon capture methods by offering improved energy efficiency and operational flexibility. The demand for such hybrid solutions is particularly strong in regions with ambitious carbon neutrality targets, including the European Union, North America, and parts of Asia.

Industrial sectors represent the primary market for these hybrid DAC systems, with power generation, cement production, and chemical manufacturing showing the highest adoption potential. These industries face mounting pressure to reduce carbon footprints while maintaining operational efficiency. The hybrid approach offers a compelling value proposition by potentially reducing energy penalties by 30-40% compared to conventional amine scrubbing technologies.

Market analysis indicates that early adopters of hybrid DAC systems are primarily large corporations with established sustainability commitments and available capital for infrastructure investments. The technology is particularly attractive to companies operating in jurisdictions with carbon pricing mechanisms, where the economic case for carbon capture becomes more favorable.

Government incentives and carbon pricing mechanisms significantly influence market dynamics. Regions with carbon prices exceeding $50 per ton create favorable economics for DAC deployment. The Inflation Reduction Act in the United States, offering tax credits up to $180 per ton for direct air capture, has substantially improved the business case for these technologies.

Venture capital investment in DAC technologies has surged, with funding reaching $1.1 billion in 2022, a threefold increase from 2020. This investment trend reflects growing confidence in the commercial viability of advanced carbon capture solutions, including hybrid systems combining solid amines and electro-swing adsorption.

Customer segments for hybrid DAC systems extend beyond traditional industrial emitters to include technology companies seeking carbon-neutral operations, municipalities implementing climate action plans, and corporations pursuing carbon-negative product offerings. This diversification of potential customers expands the addressable market significantly.

Market barriers include high capital costs, technological maturity concerns, and uncertain regulatory frameworks in many regions. However, the hybrid approach addresses some key technical barriers by combining the high selectivity of solid amines with the energy efficiency advantages of electro-swing processes, potentially accelerating market penetration compared to single-technology approaches.

Current Challenges in Hybrid DAC Implementation

Despite the promising potential of hybrid Direct Air Capture (DAC) systems that combine solid amines and electro-swing adsorption, several significant challenges impede their widespread implementation and commercial viability. The integration of these two technologies introduces complex engineering hurdles that must be overcome to achieve efficient carbon capture at scale.

Material stability represents a primary concern in hybrid DAC systems. Solid amine sorbents often suffer from degradation over multiple adsorption-desorption cycles, particularly when exposed to contaminants in ambient air such as SOx, NOx, and water vapor. This degradation reduces the CO2 capture capacity and necessitates frequent material replacement, increasing operational costs significantly. Similarly, electrodes used in electro-swing components face corrosion and fouling issues that compromise long-term performance.

Energy efficiency remains a critical bottleneck for hybrid systems. While the combination aims to reduce the energy penalty compared to traditional thermal-swing processes, the electrical requirements for the electro-swing component still contribute to substantial energy consumption. Current systems typically require 1.5-2.5 GJ per ton of CO2 captured, which exceeds the theoretical minimum by a considerable margin and impacts economic feasibility.

Scale-up challenges present formidable obstacles to commercialization. Laboratory-scale demonstrations have shown promising results, but translating these to industrial-scale operations introduces issues related to flow distribution, pressure drop across adsorption beds, and heat management. The physical integration of solid amine modules with electro-swing components requires careful engineering to maintain optimal performance parameters across varying operational conditions.

Cost effectiveness continues to be problematic, with current hybrid DAC systems estimated to operate at $250-600 per ton of CO2 captured. This range exceeds the carbon price in most markets, limiting economic viability without significant subsidies or carbon pricing mechanisms. Material costs, particularly for specialized electrodes and high-performance amine sorbents, contribute substantially to capital expenditures.

System control and optimization present additional challenges. Hybrid systems require sophisticated control algorithms to manage the interplay between adsorption kinetics, electrochemical processes, and varying environmental conditions. Current control systems lack the predictive capabilities needed to optimize performance across diverse operational scenarios, resulting in sub-optimal carbon capture rates and energy utilization.

Water management issues further complicate implementation, as moisture competes with CO2 for adsorption sites on solid amines while also affecting the conductivity and performance of electro-swing components. Balancing these competing effects requires precise humidity control that is difficult to maintain in real-world conditions.

Material stability represents a primary concern in hybrid DAC systems. Solid amine sorbents often suffer from degradation over multiple adsorption-desorption cycles, particularly when exposed to contaminants in ambient air such as SOx, NOx, and water vapor. This degradation reduces the CO2 capture capacity and necessitates frequent material replacement, increasing operational costs significantly. Similarly, electrodes used in electro-swing components face corrosion and fouling issues that compromise long-term performance.

Energy efficiency remains a critical bottleneck for hybrid systems. While the combination aims to reduce the energy penalty compared to traditional thermal-swing processes, the electrical requirements for the electro-swing component still contribute to substantial energy consumption. Current systems typically require 1.5-2.5 GJ per ton of CO2 captured, which exceeds the theoretical minimum by a considerable margin and impacts economic feasibility.

Scale-up challenges present formidable obstacles to commercialization. Laboratory-scale demonstrations have shown promising results, but translating these to industrial-scale operations introduces issues related to flow distribution, pressure drop across adsorption beds, and heat management. The physical integration of solid amine modules with electro-swing components requires careful engineering to maintain optimal performance parameters across varying operational conditions.

Cost effectiveness continues to be problematic, with current hybrid DAC systems estimated to operate at $250-600 per ton of CO2 captured. This range exceeds the carbon price in most markets, limiting economic viability without significant subsidies or carbon pricing mechanisms. Material costs, particularly for specialized electrodes and high-performance amine sorbents, contribute substantially to capital expenditures.

System control and optimization present additional challenges. Hybrid systems require sophisticated control algorithms to manage the interplay between adsorption kinetics, electrochemical processes, and varying environmental conditions. Current control systems lack the predictive capabilities needed to optimize performance across diverse operational scenarios, resulting in sub-optimal carbon capture rates and energy utilization.

Water management issues further complicate implementation, as moisture competes with CO2 for adsorption sites on solid amines while also affecting the conductivity and performance of electro-swing components. Balancing these competing effects requires precise humidity control that is difficult to maintain in real-world conditions.

Existing Hybrid DAC System Architectures

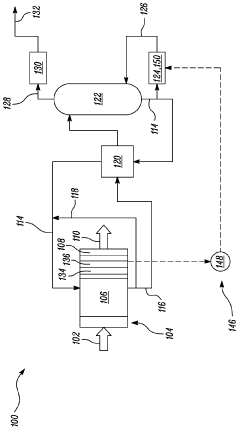

01 Hybrid DAC system design for enhanced adsorption

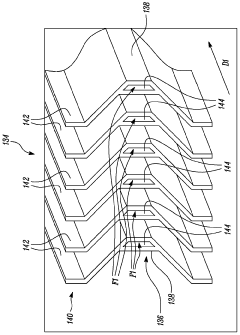

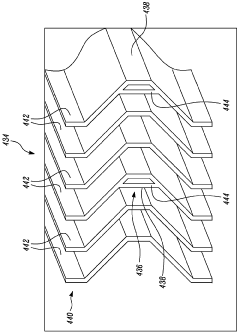

Hybrid Direct Air Capture (DAC) systems combine multiple adsorption technologies to enhance CO2 capture efficiency. These systems integrate traditional adsorption materials with novel components to optimize the adsorption-desorption cycle. The hybrid approach allows for better energy utilization and increased adsorption capacity compared to conventional single-technology systems, resulting in improved overall system performance and reduced operational costs.- Hybrid DAC system design for improved adsorption: Hybrid Direct Air Capture (DAC) systems combine multiple adsorption technologies to enhance CO2 capture efficiency. These systems integrate traditional adsorption materials with novel components to optimize the adsorption process. The hybrid approach allows for better temperature control, reduced energy consumption, and increased adsorption capacity compared to conventional single-technology systems.

- Advanced materials for enhanced adsorption efficiency: Novel materials with specialized surface properties are developed to increase the adsorption efficiency in DAC systems. These materials include modified zeolites, metal-organic frameworks (MOFs), and composite adsorbents with tailored pore structures. The advanced materials demonstrate higher selectivity for CO2, faster adsorption kinetics, and improved regeneration capabilities, leading to overall system efficiency improvements.

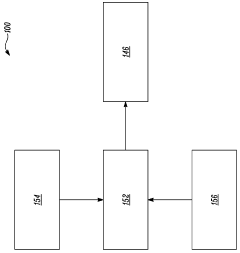

- Digital control systems for optimizing adsorption cycles: Digital control systems incorporating advanced algorithms are implemented to optimize the adsorption-desorption cycles in hybrid DAC systems. These systems utilize real-time monitoring and adaptive control strategies to adjust operational parameters based on environmental conditions and system performance. The digital control approach enables precise timing of cycle phases, resulting in maximized adsorption efficiency and reduced energy consumption.

- Energy-efficient regeneration techniques: Innovative regeneration techniques are developed to reduce the energy requirements for adsorbent regeneration in DAC systems. These techniques include low-temperature desorption methods, pressure-swing processes, and hybrid thermal-electrical approaches. By optimizing the regeneration phase, these systems achieve higher overall efficiency and lower operational costs while maintaining high adsorption capacity over multiple cycles.

- Signal processing and data conversion for adsorption monitoring: Advanced signal processing and data conversion technologies are implemented to accurately monitor and analyze adsorption performance in real-time. These systems utilize high-precision digital-to-analog converters (DACs) and specialized sensors to track adsorption parameters with high fidelity. The improved monitoring capabilities enable better system control, early detection of efficiency drops, and data-driven optimization of the adsorption process.

02 Advanced adsorbent materials for DAC systems

Novel adsorbent materials significantly improve the efficiency of Direct Air Capture systems. These materials include engineered porous structures, functionalized surfaces, and composite materials that demonstrate higher CO2 selectivity and capacity. The advanced adsorbents feature optimized pore size distribution and surface chemistry that enhance adsorption kinetics while maintaining structural integrity through multiple adsorption-desorption cycles.Expand Specific Solutions03 Energy-efficient regeneration techniques in hybrid DAC

Energy-efficient regeneration techniques are crucial for improving the overall efficiency of hybrid DAC systems. These techniques include low-temperature desorption processes, pressure swing mechanisms, and integrated heat recovery systems that minimize energy consumption during the adsorbent regeneration phase. By optimizing the regeneration cycle, these systems achieve higher net carbon capture while reducing the energy penalty associated with traditional regeneration methods.Expand Specific Solutions04 Control systems for optimizing DAC adsorption efficiency

Advanced control systems play a vital role in maximizing the adsorption efficiency of hybrid DAC systems. These control systems utilize real-time monitoring, predictive algorithms, and adaptive control strategies to optimize operating parameters such as flow rates, temperature, and pressure. By continuously adjusting system conditions based on environmental factors and adsorbent performance, these control systems ensure optimal adsorption efficiency throughout varying operational conditions.Expand Specific Solutions05 Integration of DAC systems with renewable energy sources

Integration of hybrid DAC systems with renewable energy sources significantly enhances overall system sustainability and efficiency. These integrated systems utilize intermittent renewable energy for powering the energy-intensive adsorption and regeneration processes. Smart energy management systems coordinate the DAC operation with renewable energy availability, enabling more efficient utilization of resources and reducing the carbon footprint of the capture process itself.Expand Specific Solutions

Leading Organizations in Hybrid DAC Research

The hybrid DAC systems combining solid amines and electro-swing adsorption technology is in an early growth phase, with an estimated market size of $1-2 billion that's projected to expand significantly as carbon capture becomes critical for climate goals. The technology maturity varies across key players, with Climeworks AG leading commercial deployment of DAC systems, while Mitsubishi Heavy Industries and Global Thermostat are advancing hybrid approaches. Academic institutions like MIT and Georgia Tech are driving fundamental research, while industrial players including ExxonMobil and IBM are developing proprietary solutions integrating both solid amine sorbents and electro-swing mechanisms. The competitive landscape features collaboration between research institutions and corporations to overcome efficiency and cost challenges in this emerging carbon capture technology.

Climeworks AG

Technical Solution: Climeworks has developed a hybrid Direct Air Capture (DAC) system that combines solid amine sorbents with electro-swing adsorption technology. Their approach uses specially designed adsorption collectors containing a proprietary solid amine-based sorbent material that selectively captures CO2 from ambient air. The electro-swing component enables energy-efficient regeneration of the sorbent by applying electrical current rather than relying solely on thermal energy. This system operates in a modular fashion with stackable "collectors" that can be scaled according to capture requirements. The process works by drawing air through the collectors where CO2 binds to the amine-functionalized surface. Once saturated, the material is regenerated using a combination of moderate heat (around 100°C) and electrical stimulation that weakens the chemical bonds between the CO2 and the sorbent, releasing concentrated CO2 for subsequent utilization or storage. Climeworks' commercial plants demonstrate this technology at scale, with their Orca plant in Iceland capturing approximately 4,000 tons of CO2 annually.

Strengths: Modular design allows for flexible deployment and scaling; lower regeneration temperatures compared to purely thermal systems; integration with renewable energy sources; proven commercial implementation. Weaknesses: Still relatively high energy consumption per ton of CO2 captured; higher capital costs compared to some competing technologies; requires significant electricity infrastructure.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed a sophisticated hybrid DAC system that combines their expertise in solid amine sorbents with electro-swing adsorption technology. Their approach utilizes proprietary KS-21 solid sorbents, which are amine-functionalized materials specifically engineered for efficient CO2 capture. The system incorporates an innovative electro-swing mechanism that applies controlled electrical current to assist in the regeneration phase, significantly reducing the thermal energy requirements compared to conventional temperature-swing processes. MHI's technology operates in a continuous cycle where ambient air contacts the solid amine sorbents in specialized adsorption chambers, followed by a regeneration phase using the electro-swing principle. This hybrid approach allows for operation at lower temperatures (around 80-90°C) while maintaining high CO2 desorption efficiency. MHI has demonstrated this technology at pilot scale, achieving capture rates of several tons per day with energy consumption in the range of 2-3 GJ per ton of CO2 captured, representing a substantial improvement over first-generation DAC systems.

Strengths: Leverages MHI's extensive experience in carbon capture technologies; highly efficient proprietary sorbent materials; reduced energy consumption through electro-swing assistance; potential for integration with existing industrial infrastructure. Weaknesses: Technology still scaling to full commercial deployment; requires specialized manufacturing of advanced sorbent materials; optimal performance depends on specific operating conditions and electrical infrastructure.

Key Patents in Solid Amine and Electro-Swing Integration

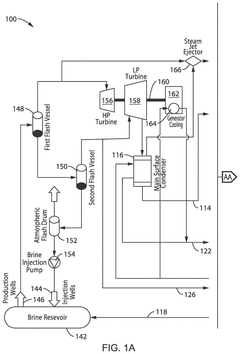

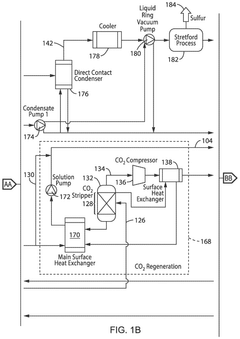

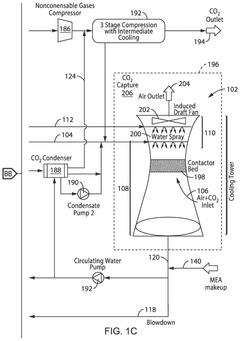

Direct air capture of carbon dioxide

PatentPendingUS20240325965A1

Innovation

- Integration of a liquid CO2-absorbent solvent, such as monoethanolamine, into cooling water in cooling towers allows concurrent CO2 capture and water evaporation, with a solvent retention system and regeneration process to recover and reuse the solvent, reducing costs and environmental impact.

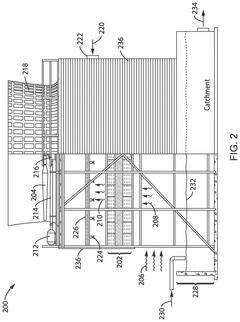

Direct air capture system and method

PatentPendingGB2624212A

Innovation

- Incorporating a mist eliminator and a cooling device in a heat exchange relationship to capture drift/droplets and reduce the temperature of the airflow, thereby reducing evaporation rates and water loss, with optional integration of a refrigeration circuit and heat exchangers to optimize energy use and capture waste heat for further processing.

Energy Efficiency Considerations for Hybrid DAC

Energy efficiency represents a critical factor in the development and deployment of hybrid Direct Air Capture (DAC) systems that combine solid amines and electro-swing adsorption technologies. These hybrid systems must overcome significant energy challenges to achieve commercial viability and environmental sustainability.

The energy consumption profile of hybrid DAC systems reveals a complex interplay between thermal and electrical energy requirements. Solid amine components typically demand thermal energy for regeneration, while electro-swing adsorption relies primarily on electrical energy. Initial assessments indicate that hybrid systems can achieve energy consumption rates of 4-7 GJ per ton of CO2 captured, representing a substantial improvement over first-generation DAC technologies that required 7-12 GJ per ton.

Heat management strategies play a pivotal role in optimizing energy efficiency. The integration of waste heat recovery systems can significantly reduce the net energy consumption of hybrid DAC operations. Research indicates that approximately 30-40% of thermal energy can be recovered through advanced heat exchanger designs specifically tailored for the unique temperature profiles of hybrid regeneration processes.

Electrical efficiency improvements focus on reducing the energy requirements for electro-swing components. Recent innovations in electrode materials and system architecture have demonstrated potential reductions in electrical consumption by 25-35% compared to conventional electro-swing systems. Carbon-based nanomaterials with enhanced conductivity properties show particular promise for improving electrical efficiency while maintaining adsorption performance.

System integration approaches that optimize the synergy between solid amine and electro-swing components represent a significant opportunity for efficiency gains. Cascading energy systems, where the waste heat from one process powers another, can reduce overall energy requirements by 15-20%. Additionally, intelligent control systems that dynamically adjust operational parameters based on environmental conditions and carbon capture targets have demonstrated efficiency improvements of 10-15% in pilot installations.

Renewable energy integration presents both opportunities and challenges for hybrid DAC systems. While renewable sources can significantly reduce the carbon footprint of DAC operations, their intermittent nature necessitates sophisticated energy storage and management systems. Hybrid systems designed with flexible operation capabilities can leverage renewable energy availability, potentially reducing operational costs by 20-30% compared to systems reliant on continuous grid power.

Future efficiency pathways include the development of novel materials that reduce regeneration temperatures for solid amines while enhancing the electrical conductivity for electro-swing components. Computational modeling suggests that next-generation hybrid systems could potentially operate at energy consumption levels below 3 GJ per ton of CO2, representing a transformative improvement in DAC technology efficiency.

The energy consumption profile of hybrid DAC systems reveals a complex interplay between thermal and electrical energy requirements. Solid amine components typically demand thermal energy for regeneration, while electro-swing adsorption relies primarily on electrical energy. Initial assessments indicate that hybrid systems can achieve energy consumption rates of 4-7 GJ per ton of CO2 captured, representing a substantial improvement over first-generation DAC technologies that required 7-12 GJ per ton.

Heat management strategies play a pivotal role in optimizing energy efficiency. The integration of waste heat recovery systems can significantly reduce the net energy consumption of hybrid DAC operations. Research indicates that approximately 30-40% of thermal energy can be recovered through advanced heat exchanger designs specifically tailored for the unique temperature profiles of hybrid regeneration processes.

Electrical efficiency improvements focus on reducing the energy requirements for electro-swing components. Recent innovations in electrode materials and system architecture have demonstrated potential reductions in electrical consumption by 25-35% compared to conventional electro-swing systems. Carbon-based nanomaterials with enhanced conductivity properties show particular promise for improving electrical efficiency while maintaining adsorption performance.

System integration approaches that optimize the synergy between solid amine and electro-swing components represent a significant opportunity for efficiency gains. Cascading energy systems, where the waste heat from one process powers another, can reduce overall energy requirements by 15-20%. Additionally, intelligent control systems that dynamically adjust operational parameters based on environmental conditions and carbon capture targets have demonstrated efficiency improvements of 10-15% in pilot installations.

Renewable energy integration presents both opportunities and challenges for hybrid DAC systems. While renewable sources can significantly reduce the carbon footprint of DAC operations, their intermittent nature necessitates sophisticated energy storage and management systems. Hybrid systems designed with flexible operation capabilities can leverage renewable energy availability, potentially reducing operational costs by 20-30% compared to systems reliant on continuous grid power.

Future efficiency pathways include the development of novel materials that reduce regeneration temperatures for solid amines while enhancing the electrical conductivity for electro-swing components. Computational modeling suggests that next-generation hybrid systems could potentially operate at energy consumption levels below 3 GJ per ton of CO2, representing a transformative improvement in DAC technology efficiency.

Scalability and Deployment Strategies

Scaling hybrid DAC systems that combine solid amines and electro-swing adsorption presents unique challenges and opportunities. The modular nature of these systems offers significant advantages for incremental deployment, allowing facilities to start with smaller installations and expand capacity as needed. This approach reduces initial capital expenditure while enabling operational experience to inform subsequent scaling decisions.

For large-scale implementation, a distributed network model has emerged as particularly promising. This strategy involves deploying multiple medium-sized DAC units across strategic locations rather than concentrating capacity in massive centralized facilities. The distributed approach optimizes for local conditions, including renewable energy availability, CO2 utilization opportunities, and storage potential.

Critical to successful scaling is the standardization of key components. Industry leaders are developing standardized modules for both solid amine sorbent beds and electro-swing components, enabling manufacturing economies of scale while simplifying maintenance and replacement protocols. These standardized units typically capture between 1,000-10,000 tons of CO2 annually, providing flexibility in deployment configurations.

Integration with existing infrastructure represents another vital scaling consideration. Hybrid DAC systems show particular promise when co-located with renewable energy sources that can provide the electrical input for the electro-swing component. Additionally, proximity to industrial CO2 users or sequestration sites significantly impacts economic viability by reducing transportation costs.

Supply chain development remains a challenge for widespread deployment. The specialized materials required for high-performance solid amine sorbents and electro-swing components currently face production bottlenecks. Industry consortia are actively working to expand manufacturing capacity for critical components, particularly advanced electrode materials and engineered porous substrates for amine functionalization.

Deployment timelines typically follow a three-phase approach: pilot installations (1-5 years), commercial demonstration (5-10 years), and widespread deployment (10+ years). This phased strategy allows for technological refinement while building the necessary manufacturing and operational expertise. Current projections suggest that hybrid DAC systems could reach gigaton-scale capture capacity by the 2040s, assuming continued policy support and technological advancement.

For large-scale implementation, a distributed network model has emerged as particularly promising. This strategy involves deploying multiple medium-sized DAC units across strategic locations rather than concentrating capacity in massive centralized facilities. The distributed approach optimizes for local conditions, including renewable energy availability, CO2 utilization opportunities, and storage potential.

Critical to successful scaling is the standardization of key components. Industry leaders are developing standardized modules for both solid amine sorbent beds and electro-swing components, enabling manufacturing economies of scale while simplifying maintenance and replacement protocols. These standardized units typically capture between 1,000-10,000 tons of CO2 annually, providing flexibility in deployment configurations.

Integration with existing infrastructure represents another vital scaling consideration. Hybrid DAC systems show particular promise when co-located with renewable energy sources that can provide the electrical input for the electro-swing component. Additionally, proximity to industrial CO2 users or sequestration sites significantly impacts economic viability by reducing transportation costs.

Supply chain development remains a challenge for widespread deployment. The specialized materials required for high-performance solid amine sorbents and electro-swing components currently face production bottlenecks. Industry consortia are actively working to expand manufacturing capacity for critical components, particularly advanced electrode materials and engineered porous substrates for amine functionalization.

Deployment timelines typically follow a three-phase approach: pilot installations (1-5 years), commercial demonstration (5-10 years), and widespread deployment (10+ years). This phased strategy allows for technological refinement while building the necessary manufacturing and operational expertise. Current projections suggest that hybrid DAC systems could reach gigaton-scale capture capacity by the 2040s, assuming continued policy support and technological advancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!